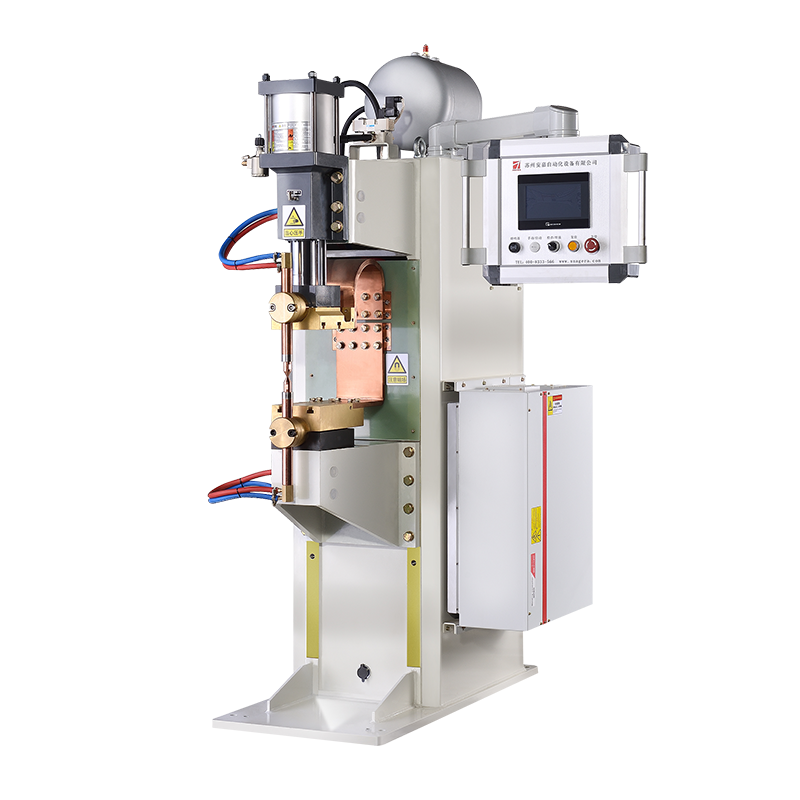

ADB-460 Resistance spot welding machine

Product Introduction

Product Introduction

-

effectively suppress welding spatter

The continuous heat supply generated by the flat output current of the IF spot welder makes the temperature of the nugget rise continuously. At the same time, the precise control of the current rising slope and time will not cause spatter due to heat jumps and uncontrollable current rising time.

-

Short power-on time, high thermal efficiency

The IF spot welder has a flat output welding current, which ensures the high-efficiency and continuous supply of welding heat. And the power-on time is short, reaching the ms level, which makes the welding heat-affected zone small, and the solder joints are formed beautifully.

-

High control precision

Due to the high working frequency (usually 1-4KHz) of the intermediate frequency Inverter spot welder, the feedback control accuracy is 20-80 times that of the general AC spot welding machine and the secondary rectification spot welding machine, and the corresponding output control accuracy is also very high.

-

Energy saving 30%

Save energy, save welding energy at each point, and shorten the welding cycle, especially suitable for welding thick workpieces and highly conductive metals

-

Load balancing of equipment

It is used for spot welding and nut projection welding of high-strength steel and hot formed steel in automobile manufacturing industry, spot welding and multi-point projection welding of ordinary low-carbon steel plate, stainless steel plate,aluminum plate and wire, resistance brazing and spot welding of copper wire in high and low voltage electrical industry, copper plate brazing, composite silver spot welding, etc.

Welder Details

Welder Details

Welding Parameters

Welding Parameters

|

Model |

ADB-5 |

ADB-10 |

ADB-75T |

ADB100T

|

ADB-100 |

ADB-130 |

ADB-130Z |

ADB-180 |

ADB-260 |

ADB-360 |

ADB-460 |

ADB-690 |

ADB-920 |

|

|

Rated Capacity |

KVA |

5 |

10 |

75 |

100 |

100 |

130 |

130 |

180 |

260 |

360 |

460 |

690 |

920 |

|

Power Supply |

ø/V/HZ |

1/220V/50Hz |

3/380V/50Hz |

|||||||||||

|

Primary Cable |

mm2 |

2×10 |

2×10 |

3×16 |

3×16 |

3×16 |

3×16 |

3×16 |

3×25 |

3×25 |

3×35 |

3×50 |

3×75 |

3×90 |

|

Max Primary Current |

KA |

2 |

4 |

18 |

28 |

28 |

37 |

37 |

48 |

60 |

70 |

80 |

100 |

120 |

|

Rated Duty Cycle |

% |

5 |

5 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

20 |

|

Welding Cylinder Size |

Ø*L |

Ø25*30 |

Ø32*30 |

Ø50*40 |

Ø80*50 |

Ø100*60 |

Ø125*100 |

Ø160*100 |

Ø160*100 |

Ø160*100 |

Ø200*100 |

Ø250*150 |

Ø250*150*2 |

Ø250*150*2 |

|

Max Working Pressure(0.5MP) |

N |

240 |

400 |

980 |

2500 |

3900 |

6000 |

10000 |

10000 |

10000 |

15000 |

24000 |

47000 |

47000 |

|

Compressed Air Consumption |

Mpa |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

0.6-0.7 |

|

Cooling Water Consumption |

L/Min |

- |

- |

6 |

6 |

8 |

12 |

12 |

12 |

12 |

15 |

20 |

24 |

30 |

|

Compressed Air Consumption |

L/Min |

1.23 |

1.43 |

1.43 |

2.0

|

2.28 |

5.84 |

5.84 |

5.84 |

5.84 |

9.24 |

9.24 |

26 |

26 |

Custom Process

Custom Process

Welder FAQ

Welder FAQ

-

Q: Do the electrodes of the spot welding machine need to be preheated?

A: The electrode does not require preheating, but in some cases, preheating can improve welding results.

-

Q: What kind of noise will be produced during the welding process of the spot welder?

A: The welding process of the spot welding machine will produce noise, and protective measures such as earplugs are required.

-

Q: Can the maintenance of the spot welding machine be carried out by yourself?

A: Some maintenance tasks can be performed on your own, but more complex tasks will need to be performed by a professional technician.

-

Q: Where does the spot welder need to be installed?

A: The spot welder needs to be installed in a well-ventilated, dry place and connected to the power line.

-

Q: How long does it take to repair a spot welder?

A: Repair time depends on the complexity of the repair task and the severity of the equipment failure, and typically takes hours to days.

-

Q: How do spot welders need to be cleaned?

A: Spot welders should be cleaned with compressed air or detergent, and should not be cleaned with water or other liquids.

Send email to us

Send email to us