Mastering Aluminium Spot Welding: Tips and Techniques for Seamless Bonds

Aluminium Spot Welding Machine: Precision Welding for Aluminium and Aluminium Alloys

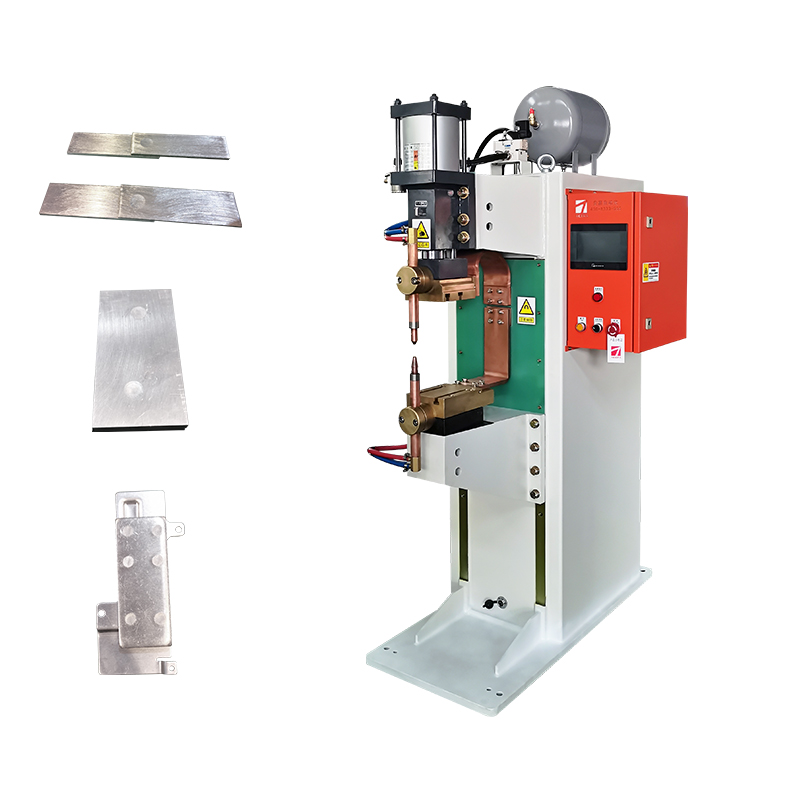

The Aluminium Spot Welding Machine is a high-performance welding solution designed specifically for welding aluminium and its alloys. Aluminium presents unique challenges in the welding process due to its higher thermal conductivity and lower melting point compared to other metals, but with our advanced spot welding machine, these challenges are effectively managed. Built with cutting-edge technology, this machine delivers precise, strong welds while minimizing defects like warping or overheating. Whether you are working in the automotive industry, aerospace, electronics, or other manufacturing sectors, our Aluminium Spot Welding Machine provides reliable and efficient welding results. Designed for precision, durability, and ease of use, this machine is perfect for a range of aluminium spot welding applications.

Key Features

Optimized for Aluminium and Alloys: Aluminium and its alloys are harder to weld due to their conductivity and melting point. Our machine is specially designed to handle these materials with ease, ensuring minimal thermal deformation and high-strength welds. Advanced Control System: Equipped with an intuitive control panel, this machine allows operators to adjust welding parameters such as current, pressure, and time with precision, ensuring consistent and reliable welds for every project. High-Efficiency Power Output: This welding machine is engineered to deliver the appropriate energy required for welding aluminium without causing burn-through or insufficient weld penetration. This ensures the welds are strong and aesthetically clean. Durable Electrodes: The machine uses high-grade copper-based electrodes that are optimized for aluminium welding. These electrodes ensure consistent performance, longer life, and are easy to replace when necessary. Compact and Portable Design: Despite its robust power, the machine is compact and easy to move, making it a perfect fit for busy production lines or smaller workshops.Benefits

Consistent Weld Quality: The advanced control system allows for repeatable and consistent weld quality, ensuring strong joints and reducing the risk of defects such as cracks or weak spots. Reduced Thermal Damage: Aluminium’s low melting point makes it prone to warping or burning during welding. Our machine ensures precise heat application, reducing the risk of thermal damage and preserving the integrity of the material. Increased Productivity: With its high-speed operation and user-friendly interface, this machine significantly reduces welding time, allowing for increased productivity without compromising on quality. Low Maintenance: Designed with durable components and built for long-term use, the machine requires minimal maintenance. The easy-to-access parts, including electrodes, make servicing quick and simple.Applications

Automotive Industry: Ideal for welding aluminium body panels, frames, and other components, the machine helps automotive manufacturers meet the growing demand for lightweight, fuel-efficient vehicles. Aerospace Industry: With aluminium’s widespread use in aircraft components due to its light weight and strength, this machine ensures high-precision welds for critical parts such as fuselage sections and structural components. Electronics and Appliances: Aluminium spot welding is common in the manufacturing of electronic enclosures, heat sinks, and other components requiring clean and strong welds. Fabrication and Manufacturing: For custom fabrication jobs or large-scale manufacturing, this machine can handle various aluminium welding tasks efficiently, from small parts to large structures.Contact Us

Looking to enhance your aluminium welding capabilities? Contact us today for more details on our Aluminium Spot Welding Machine. Our experts are available to discuss your specific needs, provide pricing information, or arrange a product demonstration. Trust us to deliver the right welding solution for your business!Related Products