Akwai hanyoyi da yawa don haɗa karafa, kuma walda wata dabara ce da ta dace don haɗa sassan ƙarfe da yawa. Idan kun kasance sababbi ga masana'antar walda, ƙila ba za ku iya gane nau'ikan hanyoyin walda daban-daban da ke akwai don haɗa ƙarfe ba. Wannan labarin zai bayyana mahimman hanyoyin walda 8, yana ba ku zurfin fahimtar masana'antar walda.

Arc Welding

Arc waldiyana amfani da baka na lantarki don samar da zafi, narkewa da haɗa karafa tare. Wannan shine tsarin walda da aka fi sani kuma ya haɗa da dabaru kamar walda ta hannu da walda mai garkuwar gas.

Waldawar baka na hannu shine manufa don tsarin karfe.

Weld ɗin garkuwar gas yana aiki da kyau don kayan kamar bakin karfe da aluminum.

Tukwici: Kare yankin walda daga oxidation da tartsatsin wuta, da sarrafa saitunan halin yanzu da ƙarfin lantarki don cimma sakamako mafi kyau.

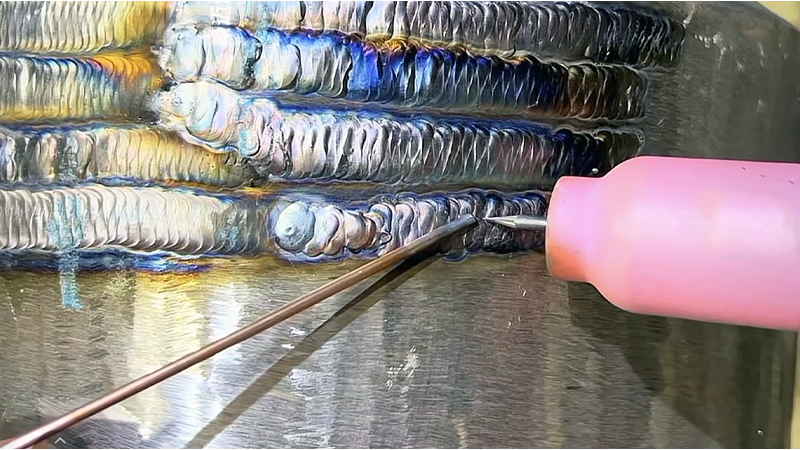

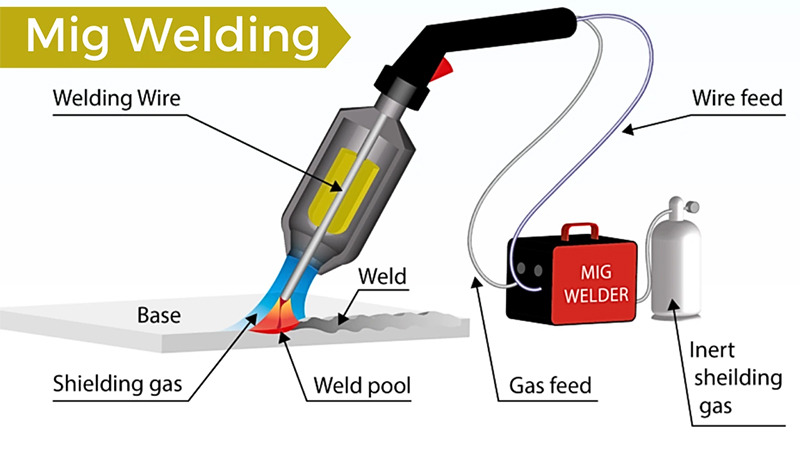

MIG/MAG waldi

MIG/MAG waldi ya ƙunshi ciyar da wutar lantarki mai ci gaba da waya ta wutar walda yayin da baka ke narkewar waya da saman ƙarfe don ƙirƙirar walda. Gas ɗin garkuwa yana bi ta cikin tocila don kare walda daga gurɓata.

Farashin MIGya shahara a masana'antu kamar ginin jirgin ruwa, aikin bututun mai, da tsarin karfe.

Mai girma ga manyan, kayan aiki marasa motsi da ayyukan gyarawa.

TIG Welding

TIG waldi, ko Tungsten Inert Gas walda, yana amfani da na'urar tungsten mara amfani don ƙirƙirar madaidaicin walda. Gas mai kariya, kamar argon, yana kare yankin walda daga gurɓata.

Babban madaidaici yana sa ya dace don kayan laushi kamar aluminum da bakin karfe.

Yawanci ana amfani da shi a cikin motoci, sararin samaniya, da madaidaicin masana'antun masana'antu.

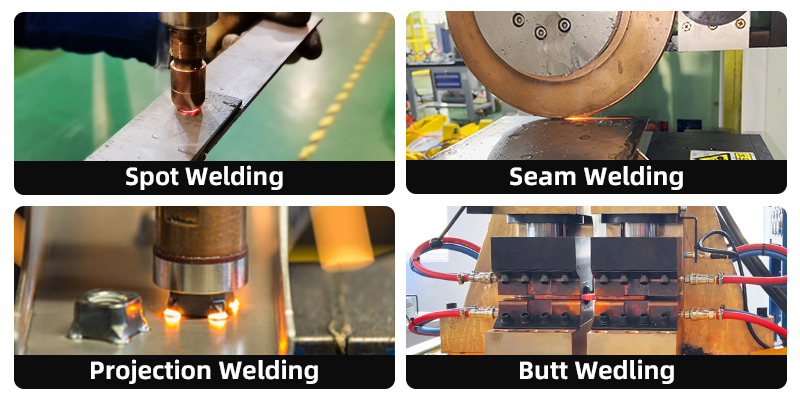

Juriya Welding

In juriya waldi, Ƙarfe guda biyu ana danna tsakanin masu lantarki, kuma wutar lantarki yana haifar da zafi don haɗa su. Manyan nau'ikan sun haɗa da tabo, tsinkaya, gindi, da walƙiya.

Juriya walda yana da sauri, baya buƙatar kayan filler, kuma yana da sauƙin sarrafa kansa.

Ana amfani da shi sosai a sassa na mota, lantarki, da na'urorin gida. Misali, ya dace don walda goro na mota.

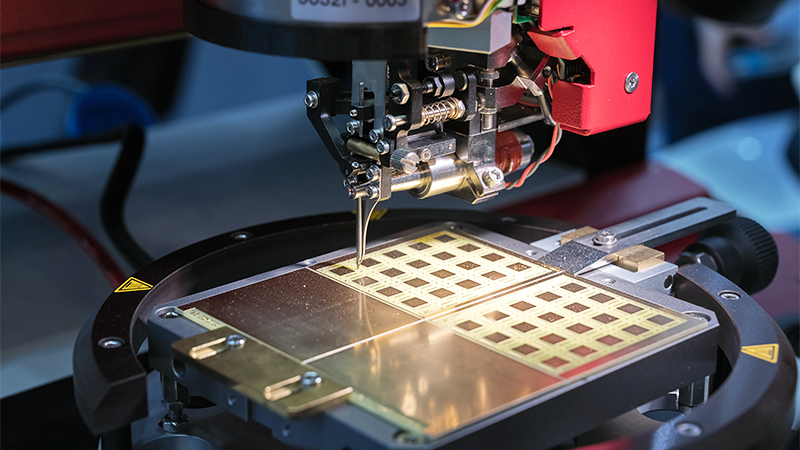

Laser Welding

Laser waldahanya ce da ke amfani da katako na Laser a matsayin tushen makamashi don yin zafi daidai da haɗuwa da karafa ko robobi. Idan aka kwatanta da walƙiyar baka na gargajiya, waldar laser tana da sauri da inganci. Ana iya haɗa shi cikin sauƙi tare darobot waldakuma shine mabuɗin fasaha a cikin sarrafa kayan aikin Laser. Waldawar Laser baya buƙatar na'urorin lantarki kuma baya buƙatar tuntuɓar kayan aikin. Lokacin walda kayan bakin ciki ko wayoyi masu kyau, baya haifar da narkewa kamar waldar baka.

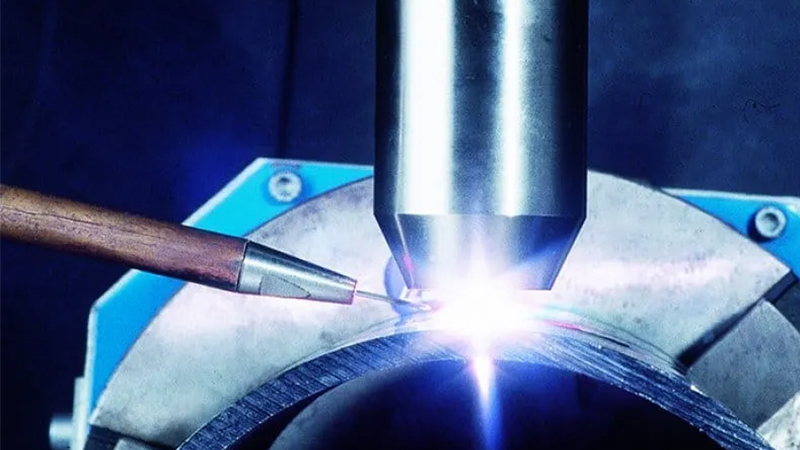

Plasma Welding

Waldawar Plasma tana haifar da plasma ta hanyar baka mai ƙarfi, wanda ke narkar da aikin. Ana ƙara kayan cikawa don haɗa karafa tare.

Yana aiki da karafa, robobi, da yumbu.

Yawancin lokaci ana amfani da su a sararin samaniya, motoci, da masana'antar lantarki.

Ultrasonic Welding

waldi na Ultrasonic yana amfani da girgizar mitoci mai girma zuwa saman biyu a ƙarƙashin matsin lamba, yana haifar da haɗarsu ba tare da narkewa ba. Wannan dabara tana aiki don karafa, robobi, har ma da kayan da ba su da kama.

Yana samar da daidaitattun haɗin gwiwa, mai tsabta kuma yana da sauƙin sarrafa kansa.

Na kowa a cikin masana'antu masu buƙatar lafiya, walƙiya mai ƙarfi.

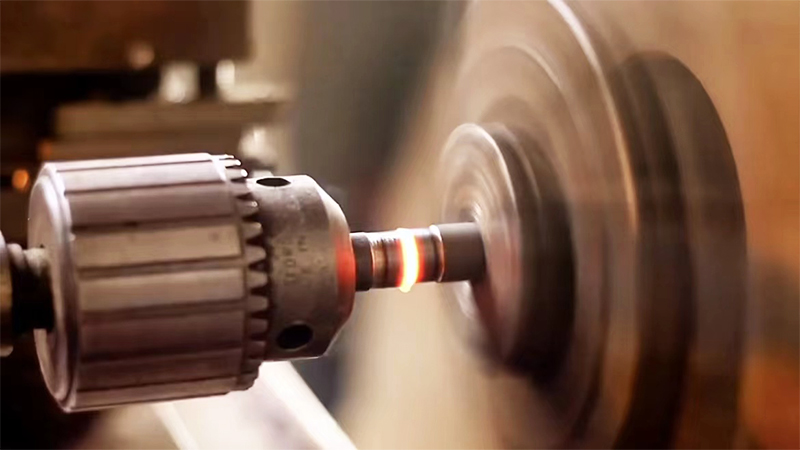

Welding

Waldawar juzu'i yana haifar da zafi ta hanyar saurin shafa saman biyu, yana sassauta su don ƙirƙirar haɗin gwiwa mai ƙarfi. Wannan tsari mai ƙarfi yana kawar da buƙatar tushen zafi na waje.

Yana hana lahani kamar nakasa da fasa.

Ana amfani da shi sosai wajen samar da masana'antu, kamar ƙafafun jirgin sama da axles na layin dogo.

Yadda Ake Zaban Tsarin Welding Dama

Lokacin zabar tsarin walda, la'akari:

Nau'in kayan (misali, aluminum, bakin karfe)

Girman kayan aiki da kauri

Madaidaicin buƙatun

Ko ana buƙatar aiki da kai

Gwajin hanyoyin da yawa na iya taimaka muku nemo mafi kyawun mafita don takamaiman aikin ku.

Ta hanyar fahimtar waɗannan manyan hanyoyin walda 8, zaku iya zaɓar hanyar da ta dace don aikin ku kuma bincika sabbin damammaki a cikin masana'antar walda.

Tambayoyin da ake yawan yi

1. Wanne tsarin walda ne mafi kyau ga kayan aikin mota?

Weld ɗin juriya shine babban zaɓi don sassa na kera saboda saurin saurin sa, ƙarewar kyawun sa, da sauƙin sarrafa kansa.

2. Wadanne kayan za a iya waldawa?

Kuna iya walda karafa iri-iri, gami da bakin karfe, jan karfe, aluminum, da galvanized karfe.

3. Shin duk matakan walda suna amfani da sandunan filler?

A'a. Misali, juriya walda baya buƙatar sandunan filler.

4. A ina zan iya ƙarin koyan fasahar walda?

Kuna iya halartar makarantun koyar da sana'o'i na musamman ko samun gogewa ta hannu a wuraren masana'antu.

Lokacin aikawa: Oktoba-21-2024