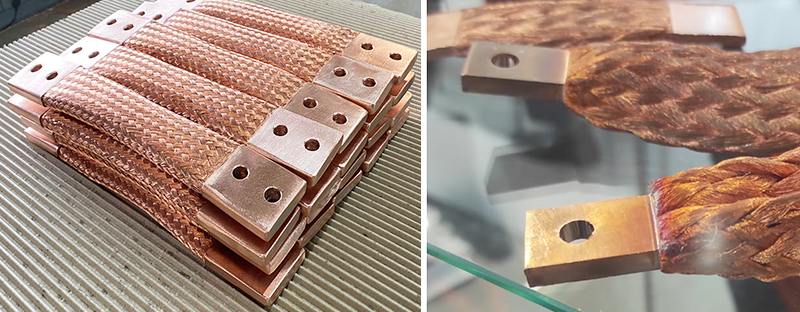

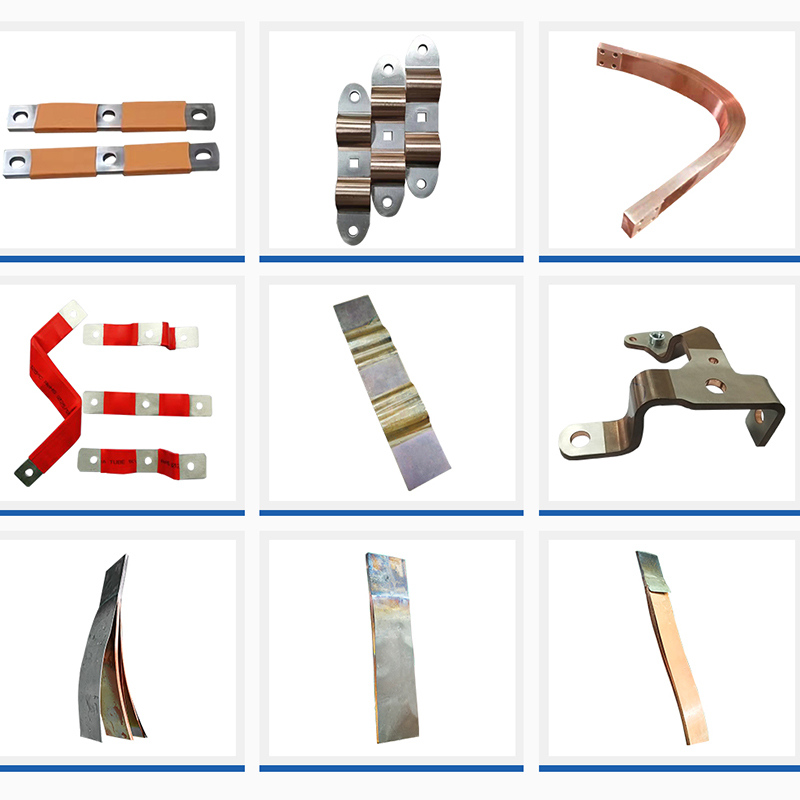

Busbarsana ƙara amfani da su a cikin sabon ɓangaren makamashi na yanzu, gami da masana'antu kamar motocin lantarki, ajiyar makamashi, da tsarin wutar lantarki. Kamar yadda fasaha ta ci gaba, kayan Busbar sun samo asali daga jan ƙarfe zuwa jan ƙarfe-nickel, jan ƙarfe-aluminum, aluminum, da graphene composites. Waɗannan Motocin Bus sun dogara sosai akan ƙira da walda, saboda suna buƙatar haɗawa da batura, tsarin sarrafa wutar lantarki, da sauran abubuwan haɗin gwiwa. Welding a ƙarshen da sassan tsakiya yana da mahimmanci ga waɗannan haɗin gwiwa, tare dayaduwa waldikasancewa hanyar farko don ƙirƙirar Busbar.

Nau'in BusbarYadawa Weld kayan aiki

Akwai manyan nau'ikan kayan walda na Busbar iri biyu. Daya shine juriya yaduwa waldi, wanda kai tsaye heats tushe abu ta wani babban halin yanzu. Sauran shine walƙiya mai girma-mita watsawa, inda graphite ke zafi kuma yana canja wurin zafi zuwa kayan tushe. Duk hanyoyin biyu suna ɗora kayan tushe zuwa wani zafin jiki kuma, ƙarƙashin matsin lamba, suna samar da haɗin kai mai ƙarfi, suna samun tasirin walda. Hanyar dumama da ake amfani da ita ya dogara da kayan Busbar.

Resistance Yadawa Welding

Juriya yada walda ana amfani da yafi ga jan karfe Busbars, kamar yadda jan karfe yana da babban narkewa batu da kuma conductivity. Don tabbatar da dumama iri ɗaya da haɓaka aikin, ana amfani da na'urorin lantarki na graphite. Na'urorin lantarki na sama da na ƙasa suna gudanar da babban halin yanzu zuwa Busbar tagulla, suna dumama shi ta hanyar juriya tsakanin yadudduka na tagulla. Na'urar graphite da kansu suma suna haifar da zafi saboda tsayin daka. Wannan dumama da aka haɗe na iya ɗaga zafin Busbar tagulla zuwa sama da 600°C, ya kai har zuwa 1300°C, yana ba da damar samun nasarar rarraba walda a ƙarƙashin matsin lamba.

Welding High-Freequency Diffusion Welding

Weld ɗin yaduwa mai tsayi ya dace da Busbars na aluminum, Busbars na jan karfe-nickel, Busbars na jan karfe-aluminum, da kuma hadaddiyar Busbars kamar tagulla da haɗin gwiwar da ba ƙarfe ba. Wannan hanyar tana amfani da dumama kai tsaye, yana mai da ita manufa don walda hadaddun kayan. A cikin waldi mai girma-girma, graphite yana mai zafi sannan kuma yana canja wurin zafi zuwa kayan tushe, tare da yanayin zafi har zuwa 1200 ° C. A ƙarƙashin matsin lamba, kayan suna samar da haɗin gwiwa mai ƙarfi.

Yadawa Welding Na Kayayyakin Busbar Daban-daban

Kayan jan karfe suna da sauƙin walƙiya saboda kwanciyar hankali na oxides. Manyan Busbars na jan karfe, kamar waɗanda ake amfani da su a cikin tsarin wutar lantarki, suna buƙatar juriya na walda saboda ƙarfin dumamasa. Waɗannan na iya zama lokacin farin ciki kamar 50mm tare da yankin walda na 200x200mm. Ƙananan Busbars, kamar waɗanda ake amfani da su a cikin motocin lantarki, yawanci kauri 3mm tare da yanki na walda na 25x50mm, na iya amfani da ko dai juriya ko babban walƙiya mai girma.

Aluminum Busbars sun fi ƙalubale saboda ma'aunin narkewar aluminium (670°C) da mafi girman wurin narkewar aluminum oxide (2000°C). Don aluminium, ana amfani da walda mai girma mai girma, tare da tsabtace kayan a gaba don cire oxides. Yawan zafin jiki na watsawa yana saita ƙasa da 600 ° C.

Copper-nickel Busbars sun ƙunshi yadudduka da yawa na foil na jan karfe tare da murfin nickel don lalacewa da juriya na lalata. Ana amfani da walda mai saurin yaduwa don ɗaukar babban bambanci a juriyar wutar lantarki tsakanin jan karfe da nickel. Rukunin Busbars, kamar jan karfe hade da graphene, suna buƙatar walƙiya mai saurin yaduwa don daidaita tsarin dumama da kuma guje wa lalata kayan tushe yayin samun yaduwa.

Hanyoyin Matsi a cikin Busbar Diffusion WeldingInji

Waldawar watsawa yana buƙatar matsa lamba mai ƙarfi, wanda za'a iya amfani dashi ta amfani da masu haɓaka ruwan iska, tsarin injin ruwa, ko tsarin servo. Hanyoyi na al'ada galibi suna amfani da tsarin na'ura mai aiki da karfin ruwa don ingantaccen fitarwa da ƙarfinsu. A zamanin yau, matsi na servo yana ƙara shahara saboda madaidaicin sarrafa matsinsa da daidaitacce matsuguni, yana tabbatar da daidaito mai girma a cikin girman samfurin welded.

Kammalawa

Wannan taƙaitaccen bayyani ne na waldawar watsawar Busbar. Idan kuna neman madaidaiciyar hanyar walda don Busbars, wannan labarin yakamata ya ba da wasu amsoshi. Tare da ci gaba da haɓaka fasahar walda, ana ɗaukar ƙarin sabbin dabaru don biyan bukatun al'ummar zamani.

Lokacin aikawa: Satumba-20-2024