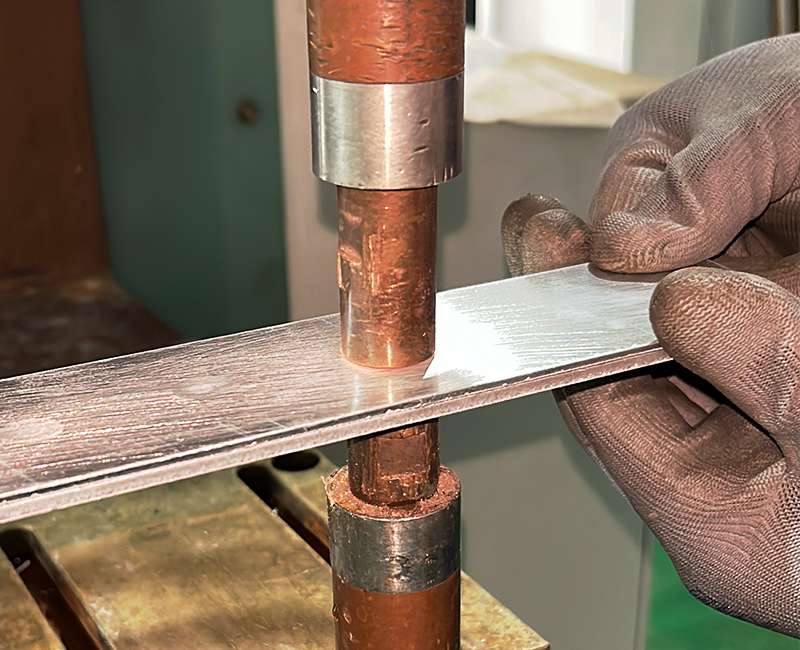

Haɗin da bai cika ba, wanda aka fi sani da "ƙarancin sanyi" ko "rashin haɗuwa," lamari ne mai mahimmanci wanda zai iya faruwa a lokacin tafiyar matakai na walda ta tabo ta amfani da shi.injunan waldawa tabo. Yana nufin yanayin da narkakkar ƙarfen ya kasa cika haɗawa da kayan tushe, yana haifar da haɗin gwiwa mai rauni da rashin dogaro. Wannan labarin yana nufin bincika abubuwa daban-daban waɗanda zasu iya haifar da rashin cika fuska a cikitabo waldi.

Welding Yanzu

Welding halin yanzu yana daya daga cikin mahimman sigogi a cikintsarin walda, kuma yana da tasiri mai yawa akan zafin da ake samu yayin walda. Rashin isasshen walda na halin yanzu yana daya daga cikin manyan dalilan rashin Fusion. Lokacin walda halin yanzu yayi ƙasa da ƙasa, maiyuwa bazai haifar da isasshen zafi don narkar da ƙasa gabaɗaya ba. A sakamakon haka, narkakkarfan ba zai iya shiga da kuma haɗawa da kyau ba, wanda ke haifar da rashin cikar fuska a wurin haɗin walda.

Rashin isassun matsi na Electrode

Rashin isassun ƙarfin lantarki kuma na iya haifar da rashin cika fuska. Ana amfani da matsa lamba na lantarki akan kayan aikin don tabbatar da daidaitaccen lamba da shigar azzakari cikin farji yayin walda. Idan ƙarfin lantarki ya yi ƙasa da ƙasa, wurin tuntuɓar da ke tsakanin kayan aikin da kayan aikin ƙarami ne, lokacin waldawa, motsin atomic na haɗin gwiwa na solder ɗin ba zai wadatar ba, ta yadda za'a iya haɗa haɗin haɗin siyar guda biyu.

Daidaita Electrode Ba daidai bane

Daidaitaccen daidaitawar na'urorin lantarki na iya haifar da rarrabawar zafi mara daidaituwa, yana haifar da rashin cika fuska. Lokacin da na'urorin ba a daidaita su ba, zafi da aka haifar yayin aikin walda bazai iya rarraba daidai da wuri a cikin yankin walda ba. Wannan rarrabawar zafi mara daidaituwa zai iya haifar da rashin cika fuska a yankunan gida. Sabili da haka, kafin aikin waldawa ya fara, tabbatar da duba ko na'urorin lantarki na sama da na ƙasa daidai ne, idan ba a daidaita su ba, dole ne a daidaita su ta hanyar kayan aiki.

Gurɓatar Saman Aiki ko Oxidation

Lalacewa ko hadawan abu da iskar shaka na workpiece surface iya tsoma baki tare da al'ada Fusion yayin tabo waldi. Abubuwan gurɓatawa, kamar mai, datti, ko sutura, suna aiki azaman shamaki tsakanin narkakkar ƙarfe da narkakken, yana hana narkewa. Hakazalika, iskar shakawar iska na iya samar da wani Layer na oxide wanda ke hana haɗin gwiwa da haɗin gwiwa daidai. Misali, lokacin da kake son walda fin injin da aka yifintubeinjia kan bututu, idan saman bututun ya yi tsatsa, dole ne waldi ya kasance ba fusion ba, don haka haɗin gwiwar da aka haɗa zai zama mara ƙarfi kuma yana shafar ingancin samfurin.

Short lokacin walda

Rashin isasshen lokacin walda yana hana narkakkar karfe yin kwarara da kyau da hadawa da kayan tushe. Idan lokacin walda ya yi ƙanƙanta, tuntuɓar ƙarfe ba ta cika haɗawa ba kafin ƙarshen fitarwa, kuma wannan rashin isasshen haɗin zai haifar da walƙiya mara ƙarfi da aminci.

Fahimtar abubuwan da ke haifar da rashin cikar haɗin walda na wuri yana da mahimmanci don tabbatar da ingancin walda. Ta hanyar magance matsalolin rashin isasshen walda na yanzu, ƙarancin ƙarfin lantarki, daidaitawar lantarki mara kyau, gurɓataccen yanayi ko iskar shaka, da ƙarancin lokacin walda, zaku iya rage abin da ya faru na haɗuwa da bai cika lokacin aikin walda ba, ta yadda za a iya inganta ingancin walda gabaɗaya.

Lokacin aikawa: Satumba-24-2024