Spot walda inji wata na'ura ce da ake amfani da ita don haɗin ƙarfe, wanda ya zama ruwan dare wajen sarrafa ƙarfe. Tare da ci gaban fasahar walda da haɓaka buƙatun walda, kayan aikin walda suna ƙara bambanta, injin walda na tabo wani nau'in kayan walda ne mai dogon tarihi, ya zuwa yanzu a cikin masana'antar kuma yana taka muhimmiyar rawa. Wannan labarin zai bayyana tabo waldi inji daki-daki, kai ku fahimtar da manufa, iri, abũbuwan amfãni, da dai sauransu.

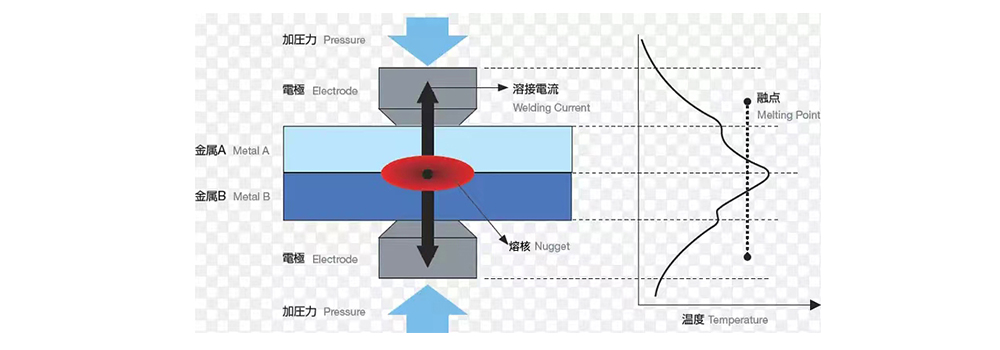

Ka'idar na'urar waldawa tabo

Spot walda inji wani irin nejuriya waldi inji, Wannan walda kayan aiki ne da yin amfani da halin yanzu ta hanyar lantarki da karfe workpiece don samar da juriya zafi don samar da zafi Madogararsa, ta hanyar dumama da kuma pressurizing da biyu karfe lamba an haɗa tare. Electrode clamps biyu zoba karfe workpieces, wannan mataki da ake samu ta hanyar da ake ji matsa lamba ta iska matsa lamba, girman da matsa lamba na clamping workpiece yafi dogara da kauri daga cikin kayan da taurin na kayan, da girma da kauri, mafi girma da kauri. ƙimar matsa lamba da ake buƙata, mafi girman ƙarfin kayan aiki, mafi girman matsa lamba da ake buƙata. Lokacin da kuke walda sabon samfur tare da mai walƙiya tabo, zaku iya daidaita matsa lamba daga ƙarami zuwa babba, yayin da samfurin waldadden ake gwadawa. Har sai kun walda samfurin haɗin gwiwa mai santsi, da tsayin daka don biyan buƙatun, wannan lokacin ƙimar matsa lamba ita ce mafi dacewa.

Bugu da kari zuwa waldi matsa lamba, waldi halin yanzu, waldi lokaci, lamba juriya ma wani muhimmin siga na tabo waldi inji aikin, duk shafi waldi zafi, da sigogi complement juna, saita dace waldi sigogi domin a karshe weld m kayayyakin.

Nau'in walda tabo

Saboda nau'ikan aiki daban-daban, mun raba injin walda ta tabo zuwa ciki2Categories,Standard tabo waldi inji da musamman tabo waldi inji.

Daidaitaccen wuriwalda

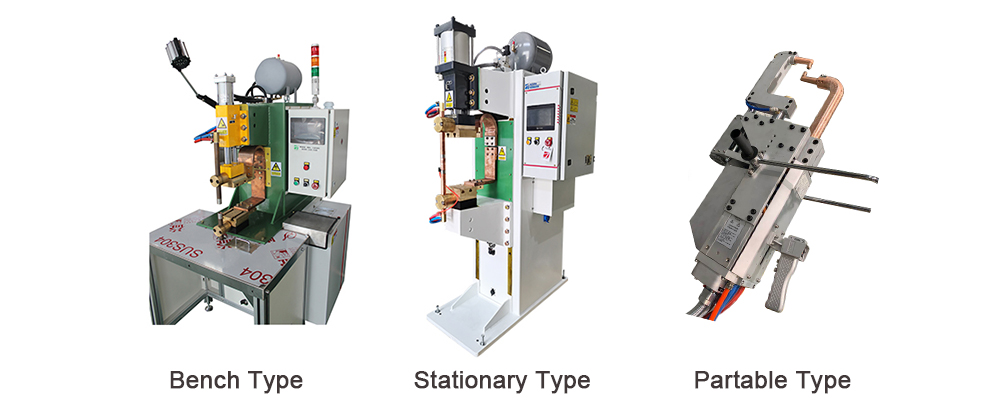

Bench irin tabo walda

Benchtop spot waldi inji gabaɗaya ƙaramin ƙarfi ne, mafi dacewa da walda ƙananan samfuran ƙarfe, kamar sassan lantarki. Wannan jikin injin waldawa ta wurin ƙarami ne, mai sauƙin motsawa, gabaɗaya ana sanya shi akan benci ko tebur don amfani, mai aiki na iya zama don kammala aikin walda.

A tsayetabo walda

Fislage yana da girma kuma yana da nauyi, injin ɗin ba shi da sauƙi don motsawa, kuma gabaɗaya ana gyara shi a wani wuri a cikin masana'anta, don haka ana kiran shi dana tsayetabo walda. Idan aka kwatanta da na'urar waldawa ta wurin tebur, dana tsayeinji waldi gabaɗaya shine babban ƙarfi, ƙarfin walda mai ƙarfi, kuma gabaɗaya sassan ƙarfe na walda tare da kauri mafi girma. Don dalilai na tsaro, ana shigar da maɓallan ƙafa, kuma ma'aikacin kuma zai iya ɗauka da sakin aikin da hannu.

Mai ɗaukar nauyitabo waldigun gun

Hakanan ana kiranta dakatarwar tabo walda, saboda gabaɗaya an dakatar da shi don aiki.Jikin mai ɗaukar hotoNa'urar walda ta tabo ba ta da girma, ana iya motsa ta zuwa digiri 360, galibi ana amfani da ita don walda ba ta da sauƙi don motsawa ko wuce iyakokin manyan kayan walda na na'ura, irin su waldawar jiki galibi suna amfani da wannan kayan aikin. Kuna iya daidaita tsayin daka zuwa wurin da ya dace, daidaita sashin da ake buƙatar waldawa, riƙe maɓallin hannu, kuma zaku iya kammala aikin walda.

Na'urar waldawa ta musamman ta atomatik

Multi-kai tabo walda

Baya ga daidaitattun kayan aikin walda na tabo na sama, zaku iya keɓance injin walda musamman don samfurin ku gwargwadon samfuran ku da buƙatun walda. Misali, idan kuna son walda karfen takarda mai girman girman girman, amfani da daidaitaccen injin waldawa tabo bai dace da aiki ba kuma saurin walda yana jinkirin. Kuna iya tambayar masana'anta don tsara muku wani nau'in walda mai sarrafa kansa da yawa, wanda zai iya walda maki da yawa lokaci guda, ta haka yana haɓaka ingancin walda. Ana amfani da wannan na'urar walda ta tabo don walda akwatunan ƙarfe, kuma farashin kayan aiki ya fi na'ura mai ƙima saboda yana buƙatar daidaita shi gwargwadon buƙata.

Farashin XY inji waldi

A cikin walda ta atomatik ta atomatik, fasahar da ake amfani da ita ita ce ciyarwar axis ta XY. A cikin sauki sharuddan, wannan inji ne daidaitaccen tabo waldi inji tare da Xy axis motsi tebur, da tebur da aka tsara bisa ga girman da workpiece. A cikin aikin walda, ma'aikacin kawai yana buƙatar sanya kayan aikin akan madaidaicin bench ɗin, maɓallin canzawa na pneumatic, injin zai aika ta atomatik sassan zuwa matsayin waldi, daidaitaccen matsayi, sannan fara waldawa. Ana amfani da wannan na'ura sau da yawa don walda firam ɗin ƙarfe, ƙarfe na takarda da ragar waya.

Idan kun ji cewa daidaitaccen na'ura ba zai iya biyan buƙatun walda ɗin ku ba, kuma kuna son haɓaka haɓakawa da haɓakawa, zaku iya yin la'akari da na'urar walƙiya ta musamman na musamman. Kawai aika sassa na karfe don tabo masana'antun walda kamar Agera, za mu tattauna da walda tsari da bukatun tare da ku, da kuma siffanta walda makirci bisa ga bukatun, da kuma tsara wani tabo weld.er injiwannan keɓantacce gare ku.

Yadda za a zabi madaidaicin walda

Wani nau'in waldar tabo da za a zaɓa ya dogara da samfurin da kuke son waldawa, sannan kuma buƙatun walda ɗin ku.

Da farko, kana bukatar ka ƙayyade ko samfurin za a iya welded ta tabo waldi fasahar, m siffar ko manyan sassa ba dace da tabo waldi kayan aiki, za ka iya tuntubar tabo waldi inji manufacturer ko za ka iya walda, za ka iya kuma dauki sassa zuwa tabo waldi inji manufacturer ga samfurin.

Idan ka ƙayyade cewa samfurinka na iya yin walda tare da tabo mai walƙiya, mataki na gaba shine ƙayyade ƙirar walda. A wannan lokacin, ya zama dole don duba kayan, kauri da girman samfurin, sassan masu kauri suna buƙatar yin amfani da walƙiya mai ƙarfi mai ƙarfi, da kuma sassan da manyan firam ɗin da ba su da kyau don matsawa zaɓi walƙiya tabo ta hannu. Hakanan zaka iya ba da shawarar wasu ra'ayoyi don keɓance na'urar walda ta tabo tare da sarrafa kansa.

Amfanin tabo walda

Gudun walda yana da sauri.Idan aka kwatanta da sauran na'urorin walda kamar na'urar waldawa ta Laser, na'urar waldawar tabo tana da sauri sosai, ana iya kammala lokacin waldawa a cikin daƙiƙa ɗaya, har ma da maki da yawa ana iya walda su a lokaci guda, wanda ke haɓaka ingancin walda.

Ƙananan alamomin walda.Muddin kun daidaita ma'auni masu dacewa, samfurin welded yana da kyau, ƙananan nakasawa, babu burrs, gabaɗaya baya buƙatar yin aiki bayan waldawa, adana tsarin sarrafawa.

Babu buƙatar cika solder.Mai walda tabo yana buƙatar jera sassa biyu na ƙarfe ne kawai don yin walda, kuma ana iya haɗa shi ba tare da ƙara komai ba. Sauran hanyoyin walda sun yi kama da walda na baka, wajibi ne a ƙara solder a cikin tsarin walda don waldawa, ta wannan hanyar waldawar tana jinkirin, kuma buƙatun fasaha na walda suna da girma.

Sauƙaƙe aiki.Aiki na na'ura waldi na tabo abu ne mai sauqi qwarai, kawai buƙatar daidaita sigogin walda kafin waldawa, zaku iya fara walda mai girma, wannan aikin walda za a iya kammala ta ma'aikata na yau da kullun.

Aikace-aikacen injin walda tabo

Kayan walda

Spot walda inji ana amfani da waldi karfe kayan, sau da yawa amfani da waldi bakin karfe, low carbon karfe, galvanized karfe, jan karfe, aluminum da sauran kayan, ban da walda na wannan abu, kuma iya haɗa dissimilar karafa. Baya gasheet karfe waldi, da haɗin gwiwa tsinkaya walda na goro, kusoshi da zanen gado kuma iya amfani da tabo walda.

Aikace-aikacen masana'antu

Ana amfani da na'urar walda ta Spot a cikin masana'antar, kuma sarrafa ƙarfe na iya ganin adadi sau da yawa. Spot walda inji ana amfani da yafi a mota masana'antu, lantarki da lantarki, iyali kayan, sheet karfe kabad, inji masana'antu da sauran masana'antu. A duk lokacin da kuke buƙatar haɗin ƙarfe, ƙila za ku yi amfani da walda tabo.

Sumfarin ciki

Abin da ke sama shine taƙaitaccen gabatarwar na'urar walda ta tabo, idan kuna neman ingantacciyar na'ura ta walda, wannan labarin yakamata ku sami amsar. Zaɓin na'ura mai dacewa da tabo mai dacewa yana da mahimmanci, injin walƙiya mai kyau na iya haifar da samfurin da ya fi dacewa a gare ku, na'ura mara kyau zai rage aikin ku. Hakanan zaka iya tuntuɓarAgeratabo waldi inji masana'antun, Za mu ba da shawarar samfurin da ya dace a gare ku.

Lokacin aikawa: Yuli-26-2024