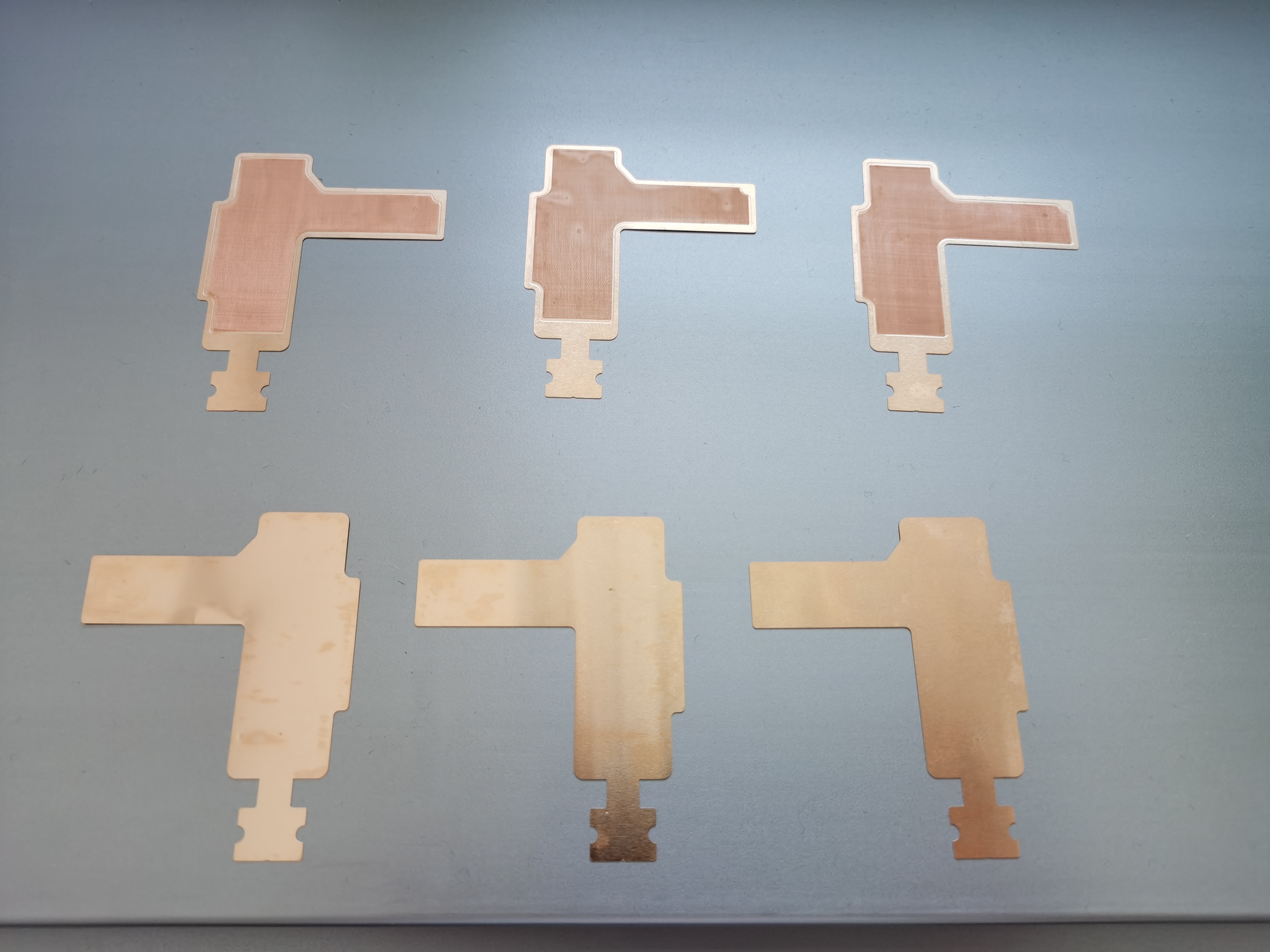

————- Spot welded (kafaffen) daidaita farantin raga

5G yana gudana da sauri, kuma ƙirar ƙetare zafi yana da mahimmanci musamman. Haɓaka daga bututun jan ƙarfe mai sanyaya zuwa farantin zazzabi iri ɗaya. Yadda za a kasance mai inganci da haɓaka yawan amfanin ƙasa shine mahimmancin samarwa. Kafin farantin zazzabi iri ɗaya, akwai saurin yaduwa na cika ruwa a ciki, kamar gyarawa da injin walda tabo, wanda zai iya rage saka hannun jarin kayan aiki na tanderun brazing masu tsada.

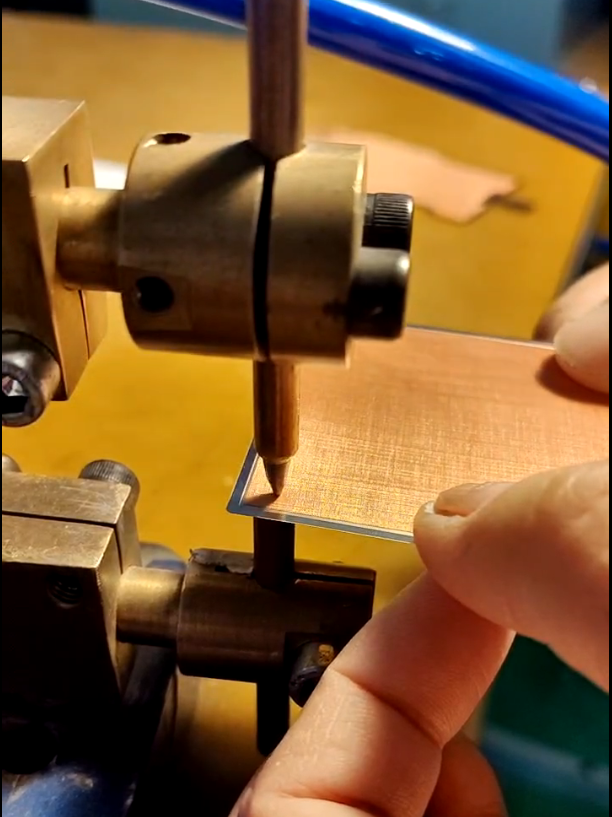

Daidaitawatabo waldiiya gane uniform zafin jiki farantin jan karfe gami 0.14mm-0.22mm kauri +0.38mm jan ragamar walda (fusion gyarawa), kuma babu alama. Ƙunƙarar wutar lantarki da zafi na tagulla suna da kyau sosai, kuma zafin da ake buƙata don walda yana da wuyar samuwa, musamman madaidaicin zafin jiki mai tsananin zafi yana buƙatar ƙananan matsa lamba don inganta zafi mai juriya da kuma rage zafi a cikin ɗan gajeren lokaci. Sabili da haka, daidaiton kulawa na yanzu ya kamata ya zama babba kuma matsa lamba ya kamata ya zama ƙarami. Madaidaicin na'ura mai walƙiya tabo, saurin tashi na yanzu, daidaiton iko mai girma, daidaitaccen daidaito na 0.01A na yanzu, lokacin walda 0.01ms saitin.

Welding electrode, babba lantarki da aka yi da jan karfe-tipped tungsten abu don inganta zafi hanzari, da ƙananan lantarki da ake amfani da farko, da kuma lebur kai jan karfe oxide electrode da ake amfani da su sa jan farantin karfe ba tare da alamomi da kuma rage yiwuwar m.

Daidaitaccen tabo waldi kafaffen takardar jan karfe da raga don aikin waldawa, ba ɓangaren aikin buƙatun ba. Duk da haka, yana sauƙaƙe tsarin samar da kayan aiki, inganta ingantaccen aiki kuma yana rage zuba jari na kayan aiki.

Lokacin aikawa: Satumba-13-2024