Walda na gindiana amfani da shi sosai wajen sarrafa ƙarfe na zamani, ta hanyar fasahar walda, ƙarfe ɗaya ko makamancinsa irin su tagulla da aluminium ana iya haɗa su tare. Tare da ci gaban masana'antu, fasahar waldawar gindi ta fi amfani da lantarki da lantarki, sabbin motocin makamashi da sauran masana'antu. Labari mai zuwa zai amsa muku dalla-dalla game da ilimin walda.

Na asaliCsai daiButtWelding

The abin da ake kira butt waldi ne don sanya biyu workpiece ƙare dangi da juna, shafi matsa lamba a lokaci guda, amfani da waldi halin yanzu zuwa zafi, sa'an nan samar da wani waldi hadin gwiwa a karkashin mataki na matsa lamba, wani ingantaccen da kuma sauki cimma aiki da kai. hanyar waldawa.

The Nau'ukan of ButtWelding

Butt walda ya kasu kashijuriya butt waldikumawalƙiya gindi waldi

Juriya butt waldi

Juriya butt waldi ne wani irin m lokaci waldi a high zafin jiki na filastik jihar, da kuma hadin gwiwa dangane iya zama recrystallization da juna yaduwa a cikin jigon, amma duk ne m lokaci dangane.

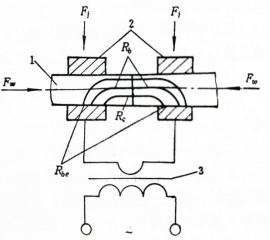

An nuna ƙa'idar juriya waldawar butt da haɗin haɗin gwiwa a cikin hoto 1.

Hoto 1. Tsare-tsare na walda mai juriya

1- Weldment

2- Electrode

3- Solder Juriya Transformer

4-Ff- matse karfi

Fw- ƙirƙira ƙarfi

Rb- juriya na walda

RC-Juriya na lamba

Rbe- Tuntuɓi juriya tsakanin walda da workpiece

walƙiya Butt walda

Haɗin haɗin haɗin haɗin walda na walƙiya mai walƙiya iri ɗaya ne da na haɗin haɗin gwiwar butt ɗin juriya, wanda kuma haɗin gwiwa ne mai ƙarfi, amma tsarin samuwar yana da nasa halaye. A ƙarshen walƙiya, an kafa wani Layer na ƙarfe na ruwa akan ƙarshen fuska. A lokacin ƙirƙira saman, ƙarfen fuskar ƙarshen an fara haɗa shi ƙarƙashin lokacin ruwa. Sa'an nan kuma za a matse Layer na ruwa daga fuskar ƙarshen haɗin gwiwa a ƙarƙashin aikin matsi na ƙirƙira na sama.Bayan dana'ura mai walƙiya walƙiyasassa na walda, haɗin gwiwa yana da ƙarfi sosai, kamar bututun ƙarfe ta walƙiya mai walƙiya, sannan ta hanyarinjin lankwasa tubelankwasawa a haɗin gwiwa, haɗin gwiwa ba zai karya ba.

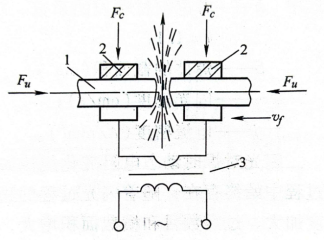

An nuna ƙa'idar waldawar walƙiya mai walƙiya da samuwar haɗin gwiwa a hoto na 2:

Hoto 2. Tsararren walda mai walƙiya mai walƙiya

1- Weldment

2- Electrode

3- Solder Juriya Transformer

4- Fc- clamping ƙarfi Fu- ƙirƙira ƙarfi Vf saurin walƙiya

AmfaninButtWelding

a) Resistance butt walda kayan aiki ne mai sauki, m waldi sigogi, sauki master, sauki cimma atomatik iko;

b) Ƙananan raguwa na juriya na juriya na waldawa, kayan ceto, ƙananan burrs, wanda ya dace don sauƙaƙe tsarin ƙarshe;

c) walƙiya walƙiya na walƙiya yana da ingantaccen yanayin zafi, yana iya walda manyan sassa, kuma an yi amfani dashi don walda bututun iskar gas tare da yanki mai faɗin 100000mm2;

d) walƙiya walƙiya saboda lintel ɗin yana wanzuwa na ɗan gajeren lokaci, ƴan millise seconds kawai, matsayinsa yana canzawa ba da gangan ba, kuma jimlar lokacin dumama a ƙarshen fuskar walda ya fi uniform, don haka ci gaba da walƙiya walƙiya ba zai iya walƙiya kawai ba. m sashe, amma kuma waldi waldi tare da fadada sassa (kamar bakin ciki zanen gado, da dai sauransu);

e) A ƙarshen walƙiya, za a samar da ƙaramin ƙarfe na ƙarfe na bakin ciki a saman walda, don haka ƙazantattun oxide a saman yana da sauƙin fitarwa tare da ƙarfen ruwa a saman ɓangaren mahaɗin, don haka cewa haɗin walda na walƙiya na walƙiya yana da inganci, kuma nau'ikan walda na iya zama ƙari, kuma ana iya walda abubuwa iri-iri iri-iri.

f) Ba a buƙatar filler a cikin tsarin walda, kuma ƙimar amfani da kayan yana da girma;

Aikace-aikace naButtWelding

Kera Motoci

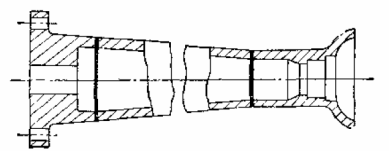

Hoto 3. Mota cardan shaft harsashi filashin butt waldi

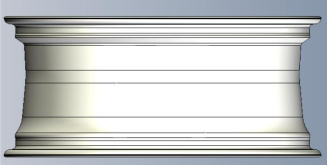

Hoto 4. Mota, babur filashin butt waldi

Masana'antar sararin samaniya

Hoto 5. Jirgin saman sandar butt walda

Masana'antar Petrochemical

Hoto 6. Metal bututu butt waldi

Filin injiniyan gini

Hoto 7. Ƙarshen farantin flange butt waldi

Masana'antar kera jiragen ruwa

Hoto 8. Anga sarkar butt walda

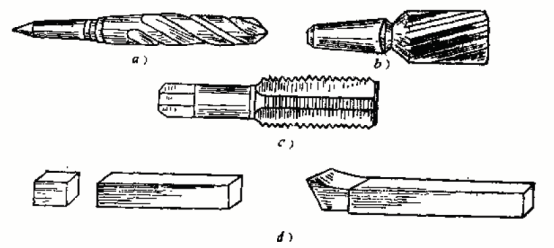

kayan aikin hardware

Hoto 9. Tool butt waldi

SpecificationParameters inButtWeldingProce

Lokacin da aka zaɓi sigogi masu dacewa na ƙayyadaddun walda na butt, ana iya samun manyan haɗin gwiwa tare da kusan kaddarorin iri ɗaya kamar kayan tushe.

a) Babban ƙayyadaddun sigogi na juriya na waldawar butt sune:

tsayin mikewa, yawan walda na yanzu (kowalda halin yanzu), lokacin walda, walda matsa lamba da kuma saman ƙirƙira matsa lamba.

b) Babban ma'auni na waldawar butt ɗin walƙiya sune:

Matsayin walƙiya: daidaita tsayin tsayi, riƙewar walƙiya, saurin walƙiya, ƙarancin walƙiya na yanzu;

Babban matakin ƙirƙira: babban izinin ƙirƙira, babban saurin ƙirƙira, saman ƙirƙira matsa lamba, ƙulla ƙarfi;

Mataki na farko: preheating zafin jiki, lokacin preheating.

Aiki na mikewa tsawon shi ne tabbatar da zama dole izni (welding part shortening) da kuma daidaita yanayin zafin jiki a lokacin dumama muhimmancin da kuma aiki za a iya zaba bisa ga waldi part da kayan Properties, yi nuna cewa mikewa tsawon kada ya zama ƙasa. fiye da rabin diamita na ɓangaren walda, wato, l = 0.6 ~ 1.0d (d shine diamita na katako ko tsawon gefen murabba'in) ya dace. A lokaci guda, lokacin walda abubuwa masu ban sha'awa, don samun daidaitaccen rarraba zafin jiki (wani lokaci la'akari da rigidity na ƙera ƙarfe mara ƙarfe), welding biyu yakamata suyi amfani da tsayin tsayi daban-daban.

A waldi halin yanzu ne sau da yawa bayyana da halin yanzu yawa, da kuma halin yanzu yawa da waldi lokaci su ne biyu main sigogi cewa kayyade walda dumama, kuma za a iya daidai daidaita da juna. A aikace, ana ba da shawarar kiyaye ƙayyadaddun dangantaka tsakanin matsakaicin girman halin yanzu da mafi ƙarancin lokacin walda, kuma a yi amfani da ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙayyadaddun ƙetaren giciye. Girman halin yanzu na ci gaba da walƙiya walƙiya mai walƙiya, kayan ƙarfe tare da ingantaccen wutar lantarki da haɓakar thermal, da sassan welded tare da ɓangaren faɗaɗa ya kamata su zama babba. Don preheating filashin butt waldi da babban sashe welds, da yawa na yanzu ya kamata ya zama ƙasa.

Dukansu matsa lamba na walda da matsa lamba na ƙirƙira na sama suna da tasiri akan yanayin zafi na yanayin lamba da nakasar filastik na kishiyar da wuraren da ke kusa. Za a iya daidaita saurin ƙirƙira na sama da matsi na ƙarfin ƙirƙira, kuma ana iya rage saurin ƙirƙira yadda ya kamata lokacin da babban saurin ƙirƙira ya isa.

TheDhaɓakawaPkima naButtWelding

Tare da zurfin nazarin dangantakar dake tsakanin juriya ingancin walda da walda tsarin sigogi da kuma on-line gano fasahar, mafi barga waldi quality za a iya samu. Bugu da ƙari, an ƙara fadada kayan walda, kuma aikace-aikacen kewayon juriyar walda ya fi girma kuma ya fi girma. Tare da ci gaba da ci gaba najuriya waldi fasaha, juriya waldi zai shagaltar da mafi muhimmanci matsayi a nan gaba masana'antu samar. Musamman a fagen walda na manyan sassan giciye da karafa masu kama da juna, waldawar walƙiya mai walƙiya tana da kyakkyawan ci gaba.

Takaitawa

Tare da haɓaka sabbin masana'antar makamashi, ƙarin aikace-aikacen walda na jan ƙarfe da haɗin aluminum, fasahar waldawar juriya kawai ta dace da buƙatun kasuwa, haɗe tare da sabon tsarin waldawar juriya da fasaha mai daidaitawa, juriya waldi a cikin ci gaba na gaba zai kasance. shigar da mafi girma girma.

Lokacin aikawa: Agusta-30-2024