Muaj ntau txoj hauv kev los koom nrog cov hlau, thiab vuam yog cov txheej txheem tsim nyog rau kev sib txuas ntau yam hlau. Yog tias koj tshiab rau kev lag luam vuam, tej zaum koj yuav tsis paub tias muaj pes tsawg qhov sib txawv ntawm cov txheej txheem vuam los txuas cov hlau. Kab lus no yuav piav qhia txog 8 qhov tseem ceeb ntawm cov txheej txheem vuam, muab rau koj nkag siab tob txog kev lag luam vuam.

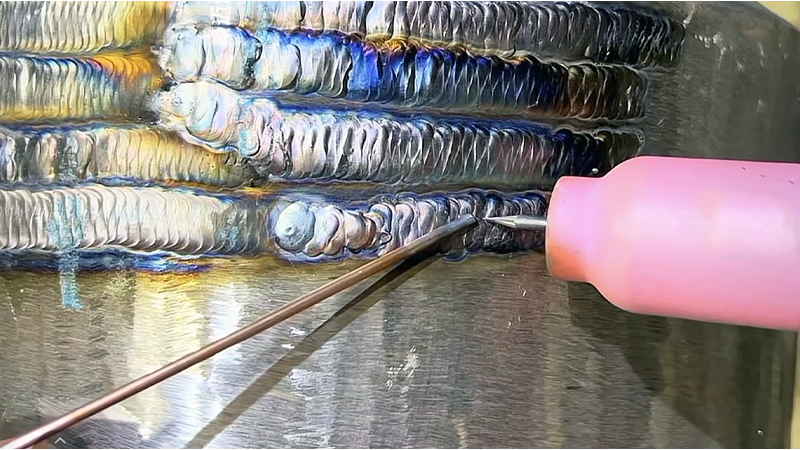

Arc Vuam

Arc vuamsiv hluav taws xob arc los ua kom sov, melting thiab fuses hlau ua ke. Qhov no yog cov txheej txheem vuam ntau tshaj plaws thiab suav nrog cov txheej txheem xws li phau ntawv arc vuam thiab roj-shielded vuam.

Kev tuav arc vuam yog qhov zoo tagnrho rau cov qauv hlau.

Gas-shielded vuam ua haujlwm zoo rau cov ntaub ntawv xws li stainless hlau thiab txhuas.

Tswv yim: Tiv thaiv qhov chaw vuam los ntawm oxidation thiab sparks, thiab tswj qhov tam sim no thiab voltage chaw kom ua tiav qhov zoo tshaj plaws.

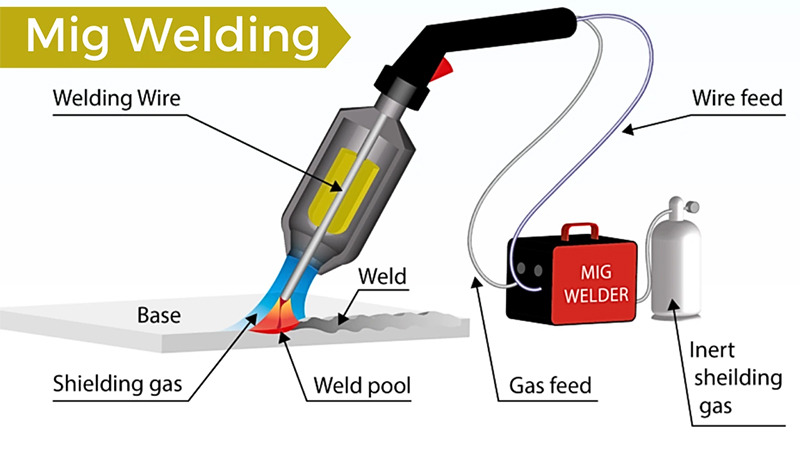

MIG/MAG Welding

MIG/MAG welding koom nrog kev noj cov hlau txuas txuas ntxiv los ntawm lub vuam teeb thaum lub arc melts cov hlau thiab cov hlau nto los tsim cov vuam. Shielding gas ntws los ntawm lub teeb los tiv thaiv cov vuam los ntawm kev sib kis.

MIG vuamyog nrov nyob rau hauv kev lag luam xws li shipbuilding, pipeline tsim, thiab steel lug.

Zoo heev rau cov haujlwm loj, txav tsis tau thiab kho cov haujlwm.

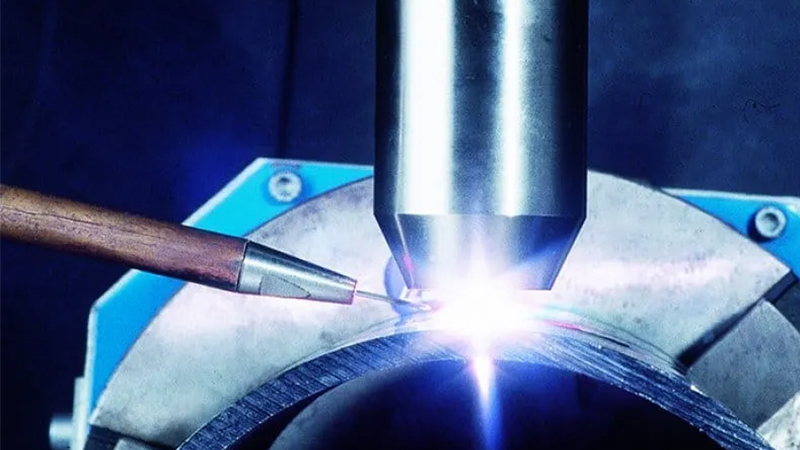

TIG Welding

TIG welding, los yog Tungsten Inert Gas welding, siv cov tungsten electrode uas tsis yog siv los tsim cov welds siab. Cov roj tiv thaiv, zoo li argon, tiv thaiv qhov chaw vuam los ntawm kev sib kis.

High precision ua rau nws zoo tagnrho rau cov ntaub ntawv mos zoo li aluminium thiab stainless hlau.

Feem ntau siv hauv automotive, aerospace, thiab precision manufacturing industries.

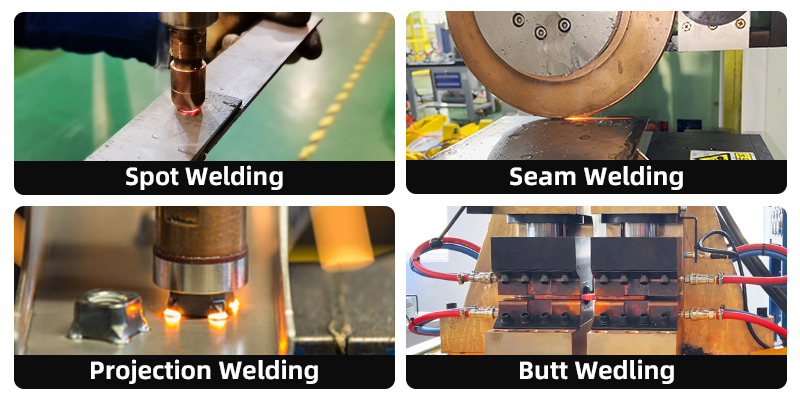

Kuj Vuam

In tsis kam vuam, ob daim hlau yog nias ntawm electrodes, thiab ib qho hluav taws xob tam sim no tsim kom sov los koom nrog lawv. Cov hom tseem ceeb muaj xws li qhov chaw, qhov projection, taub qab, thiab seam vuam.

Resistance welding yog ceev ceev, tsis xav tau cov khoom muab tub lim, thiab yooj yim rau automate.

Nws yog dav siv hauv tsheb, khoom siv hluav taws xob, thiab khoom siv hauv tsev. Piv txwv li, nws zoo meej rau vuam tsheb ceev.

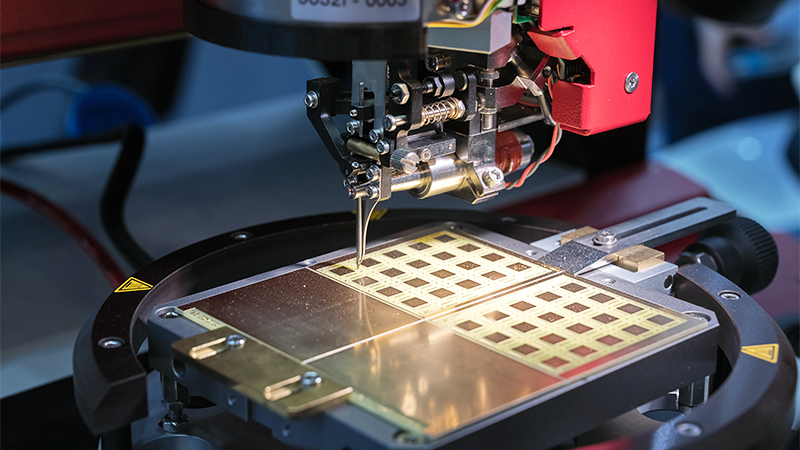

Laser Vuam

Laser vuamyog ib txoj hauv kev uas siv lub teeb ci laser ua lub zog los ua kom sov thiab koom nrog cov hlau lossis yas. Piv nrog rau arc vuam tsoos, laser vuam yog sai dua thiab ua haujlwm zoo dua. Nws tuaj yeem yooj yim ua ke nrogneeg hlau welderthiab yog cov txheej txheem tseem ceeb hauv kev ua cov khoom siv laser. Laser vuam tsis xav tau electrodes thiab tsis tas yuav hu rau cov khoom siv ua haujlwm. Thaum vuam cov ntaub ntawv nyias lossis cov xov hlau zoo, nws tsis ua rau rov qab yaj zoo li arc vuam.

Plasma Vuam

Plasma vuam tsim cov ntshav los ntawm lub zog siab arc, uas ua rau cov khoom tawg. Cov khoom siv muab tub lim yog ntxiv rau cov hlau ua ke.

Ua haujlwm nrog hlau, yas, thiab ceramics.

Feem ntau siv hauv aerospace, automotive, thiab electronics manufacturing.

Ultrasonic Vuam

Ultrasonic welding siv high-frequency vibrations rau ob qhov chaw nyob rau hauv siab, ua rau lawv mus fuse yam tsis muaj melting. Cov txheej txheem no ua haujlwm rau cov hlau, yas, thiab cov ntaub ntawv sib txawv.

Ua tau meej, ntxuav cov pob qij txha thiab yooj yim rau automate.

Feem ntau nyob rau hauv kev lag luam yuav tsum tau zoo, solid-state welding.

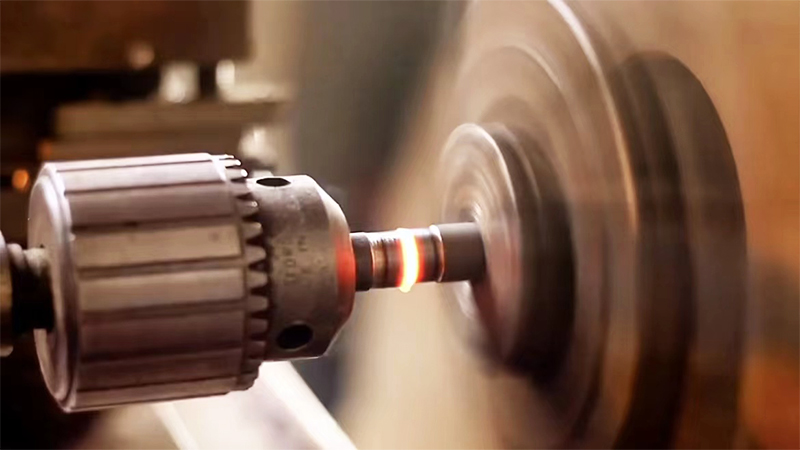

Kev sib txhuam vuam

Kev sib txhuam vuam tsim hluav taws xob los ntawm kev sib txhuam ceev ntawm ob qhov chaw, softening lawv los tsim kom muaj kev sib raug zoo. Cov txheej txheem solid-state no tshem tawm qhov xav tau rau qhov chaw sov sab nraud.

Tiv thaiv qhov tsis xws luag xws li deformation thiab tawg.

Dav siv nyob rau hauv industrial ntau lawm, xws li aircraft log thiab railway qag.

Yuav ua li cas xaiv txoj kev vuam zoo

Thaum xaiv cov txheej txheem vuam, xav txog:

Cov khoom siv (piv txwv li, aluminium, stainless hlau)

Workpiece loj thiab thickness

Precision xav tau

Seb puas xav tau automation

Kev sim ntau txoj hauv kev tuaj yeem pab koj nrhiav qhov kev daws teeb meem zoo tshaj plaws rau koj qhov project tshwj xeeb.

Los ntawm kev nkag siab txog 8 lub ntsiab vuam txheej txheem, koj tuaj yeem xaiv txoj hauv kev rau koj qhov project thiab tshawb nrhiav cov hauv kev tshiab hauv kev lag luam vuam.

Cov lus nug nquag

1. Cov txheej txheem vuam twg yog qhov zoo tshaj plaws rau cov khoom siv tsheb?

Resistance vuam yog qhov kev xaiv zoo tshaj plaws rau cov khoom siv tsheb vim nws qhov ceev ceev, zoo nkauj tiav, thiab yooj yim automation.

2. Cov ntaub ntawv dab tsi tuaj yeem welded?

Koj tuaj yeem welding ntau yam hlau, xws li stainless hlau, tooj liab, txhuas, thiab galvanized hlau.

3. Puas yog tag nrho cov txheej txheem vuam siv cov pas nrig?

Tsis yog. Piv txwv li, kev siv vuam tsis tas yuav tsum tau muab tub lim.

4. Kuv tuaj yeem kawm ntxiv txog kev siv vuam qhov twg?

Koj tuaj yeem mus kawm cov tsev kawm ua haujlwm tshwj xeeb lossis tau txais kev paub ua haujlwm hauv cov chaw tsim khoom.

Post lub sij hawm: Oct-21-2024