Vuam stainless hlau yuav tsum tau tshwj xeeb cov txheej txheem thiab ua tib zoo npaj vim nws cov khoom tshwj xeeb.Stainless hlauyog siv dav hauv kev lag luam xws li kev ua zaub mov, tshuaj, aerospace, thiab kev tsim kho vim nws cov corrosion tsis kam, lub zog, thiab kev zoo nkauj. Txawm li cas los xij, cov khoom zoo tib yam no kuj ua rau nws nyuaj rau kev sib tsoo piv rau cov hlau me me.

Hauv phau ntawv qhia no, peb'yuav npog cov hauv paus ntsiab lus ntawm welding stainless hlau, cov kev cov nyom uas nws nthuav, thiab cov kev coj ua zoo tshaj plaws rau kev ua tau zoo welds. Txawm hais tias koj yog tus pib lossis ib tus kws paub txog kev siv vuam, kev nkag siab cov ntsiab lus no yuav pab koj kom tau txais txiaj ntsig zoo ib yam thaum ua haujlwm nrog stainless hlau.

Properties ntawm Stainless hlau

Stainless hlau muaj tsawg kawg yog 10.5% chromium, uas tsim ib tug passive oxide txheej ntawm qhov chaw, muab nws corrosion kuj. Ntau hom stainless hlau, xws li austenitic, ferritic, martensitic, thiab duplex, muaj kev sib txawv ntawm lub zog, weldability, thiab tsis kam mus corrosion.

Cov yam ntxwv ntawm stainless hlau uas cuam tshuam welding muaj xws li:

High Thermal Expansion: Stainless hlau nthuav dav ntau dua li cov pa roj carbon steel thaum rhuab, ua rau muaj kev pheej hmoo ntawm warping thiab distortion thaum vuam.

Tsawg Thermal Conductivity: Thaum tshav kub kub tsis yooj yim dissipated, ua rau kom muaj cua sov ntawm qhov sib txuas, uas tuaj yeem ua rau kub hnyiab.

rhiab heev rau Thaum tshav kub kub: Cov cua kub ntau dhau tuaj yeem ua rau tsis muaj xim lossis txo qhov corrosion.

Tsim cov Carbides: Chromium carbide tsim tuaj yeem tshwm sim ntawm qhov kub thiab txias, txo kev tiv thaiv corrosion (ib qho tshwm sim hu ua rhiab heev).

Hom Stainless Hlau rau Vuam

1. Austenitic Stainless hlau (300 Series)

Cov yam ntxwv: Tsis muaj hlau nplaum, muaj zog corrosion-resistant, thiab yooj yim rau kev ua haujlwm nrog.

Qib Qib: 304 thiab 316.

Weldability: Zoo, tab sis nws yooj yim rau distortion vim siab thermal expansion.

2. Ferritic Stainless hlau (400 Series)

Yam ntxwv: Sib nqus, qis corrosion kuj dua li hom austenitic tab sis siab dua thermal conductivity.

Qib Siab: 430.

Weldability: Nruab nrab; xav tau kev kho cua sov ua ntej thiab tom qab vuam kom tsis txhob tawg.

3. Martensitic Stainless hlau

Cov yam ntxwv: siab zog, hnav tsis kam, thiab tsis muaj corrosion kuj.

Cov Qib Siab: 410 thiab 420.

Weldability: Nyuaj; yuav tsum tau ceev faj tswj cov cua sov kom tsis txhob tawg.

4. Duplex Stainless Hlau

Cov yam ntxwv: Kev sib xyaw ntawm austenitic thiab ferritic zog, muab lub zog siab thiab corrosion kuj.

Qib Qib: 2205.

Weldability: Yuav tsum muaj cov cua kub tsawg los tiv thaiv embrittlement.

Vuam txoj kev rau Stainless hlau

Qhov zoo tshaj plaws rau: Nyias stainless hlau nplooj ntawv thiab daim ntawv thov yuav tsum tau siab precision.

Qhov zoo: huv si, meej welds nrog tsawg spatter.

Kev txiav txim siab: Yuav tsum muaj tus neeg ua haujlwm txawj thiab kev sib txuas qeeb qeeb.

Qhov zoo tshaj plaws rau: Cov haujlwm loj dua qhov kev ceev yog qhov tseem ceeb.

Qhov zoo: nrawm dua TIG vuam thiab yooj yim kawm.

Kev txiav txim siab: tuaj yeem tsim spatter thiab yuav tsum tau tiv thaiv roj (feem ntau argon lossis sib xyaw nrog CO₂).

Qhov zoo tshaj plaws rau: Sab nraum zoov tej yaam num thiab thicker stainless hlau qhov chaw.

Qhov zoo: Tsis't yuav tsum tau shielding gas, ua rau nws haum rau kev ua hauj lwm sab nraum zoov.

Kev txiav txim siab: tuaj yeem nyuaj rau kev tswj ntawm nyias stainless hlau.

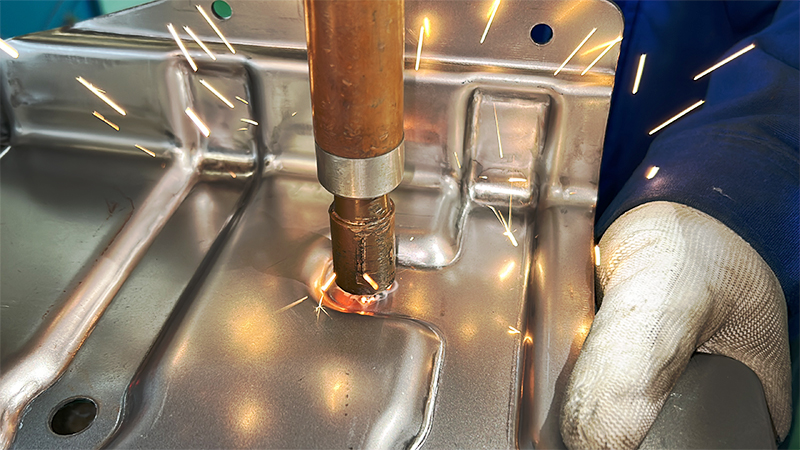

Qhov zoo tshaj plaws rau: Cov ntawv nyias nyias hauv kev siv tsheb thiab kev lag luam.

Qhov zoo: ceev thiab ua haujlwm zoo rau kev sib tshooj sib tshooj.

Kev txiav txim siab: txwv rau qee hom kev sib koom ua ke.

Cov kev coj ua zoo tshaj plaws rau Vuam Stainless Hlau

Kev npaj

Ntxuav qhov chaw kom huv si kom tshem tawm cov av, roj, thiab oxidation. Cov kab mob tuaj yeem ua rau muaj qhov tsis xws luag thiab txo qhov kev tiv thaiv corrosion.

Siv cov cuab yeej tshwj xeeb (txhuam, grinders) rau stainless hlau los tiv thaiv kev sib kis los ntawm lwm yam hlau.

Shielding Gas Xaiv

Rau TIG vuam, siv 100% argon los yog argon-helium mix.

Rau MIG vuam, kev sib xyaw ntawm argon thiab CO₂los yog oxygen txhim kho weld nkag mus thiab stability.

Tswj cua kub nkag

Siv cov hluav taws xob qis tshaj plaws kom tsis txhob muaj kev sib tsoo, tawg, thiab carbide tsim.

Yog tias ua tau, siv pulse welding los tswj cov cua sov kom zoo dua.

Tsawg Distortion

Clamp lub workpieces nruj nreem kom txo qis zog thaum vuam.

Siv backstepping (welding me me nyob rau hauv alternating cov lus qhia) kom faib cov cua sov kom sib npaug.

Tom qab Weld Cleaning thiab Finishing

Tshem tawm cov xim tsis muaj xim nrog cov hlau tsis muaj hlau txhuam los yog cov tshuaj ntxuav kom rov qab ua kom muaj zog corrosion.

Siv cov txheej txheem passivation kom tshem tawm cov kab mob ntawm qhov chaw thiab txhim kho oxide txheej.

Tsis txhob Cracks thiab Sensitization

Rau cov seem tuab, preheating cov hlau tuaj yeem pab txo qhov kev pheej hmoo ntawm kev tawg.

Siv cov qib qis-carbon (xws li 304L lossis 316L) kom tsis txhob muaj chromium carbide tsim.

Feem ntau tsis xws luag hauv Stainless Hlau Vuam

Warping thiab Distortion: Ua los ntawm cov cua kub ntau dhau thiab thermal expansion.

Hlawv-Ntawm: tshwm sim thaum tshav kub melts los ntawm cov khoom, feem ntau pom nrog nyias hlau.

Cracking: Feem ntau yog vim muaj kev tswj xyuas tsis zoo los yog kev sib kis.

Porosity: Ua los ntawm cov khoom siv hauv lub pas dej ua ke, feem ntau yog vim muaj cov roj thaiv tsis txaus.

Discoloration: Overheating tuaj yeem ua rau oxidation, ua rau cov xim zaj sawv.

Kev siv ntawm Stainless Hlau Vuam

Cov Khoom Siv Ua Khoom Noj: Cov hlau tsis muaj steel feem ntau yog siv rau cov tso tsheb hlau luam, cov kav dej, thiab cov chaw hauv cov khoom noj vim nws cov corrosion kuj thiab yooj yim ntawm kev tu.

Pharmaceutical thiab Medical Devices: Cov cuab yeej phais, kev cog qoob loo, thiab cov thawv tsis muaj menyuam yuav tsum tau ua kom huv thiab huv.

Aerospace Kev Lag Luam: Stainless hlau yog siv rau hauv cov khoom siv dav hlau rau nws lub zog thiab ua haujlwm rau qhov kub thiab txias.

Kev tsim vaj tsev thiab kev tsim kho: Handrails, facades, thiab lwm yam qauv siv cov hlau tsis muaj steel rau durability thiab zoo nkauj.

Automotive Kev Lag Luam: Cov pa hluav taws xob, roj tso tsheb hlau luam, thiab cov khoom siv kho kom zoo nkauj feem ntau yog ua los ntawm cov hlau tsis muaj steel.

Xaus

Vuam stainless hlau yog ob qho tib si kev tshawb fawb thiab kev kos duab, yuav tsum muaj kev nkag siab ntawm cov khoom siv tshwj xeeb thiab cov nyom. Nrog rau cov txheej txheem zoo, kev npaj, thiab khoom siv, koj tuaj yeem ua tiav cov khoom zoo, ruaj khov welds uas tswj cov khoom siv's lub zog thiab corrosion kuj.

Txawm hais tias koj tab tom tsim cov khoom lag luam rau cov khoom noj khoom haus, tsim cov khoom tsim vaj tsev, lossis tsim cov khoom siv tsheb ua haujlwm siab, stainless hlau vuam muaj kev sib xyaw ua ke ntawm kev zoo nkauj, durability, thiab functionality. Ua raws li cov kev coj ua zoo tshaj plaws thiab xaiv txoj kev vuam tsim nyog yuav ua kom muaj txiaj ntsig zoo rau koj cov haujlwm vuam stainless hlau.

Post lub sij hawm: Oct-15-2024