Aluminium tau siv rau hauv ntau yam kev lag luam vim nws lub teeb yuag, kev tiv thaiv corrosion, zoo hluav taws xob conductivity thiab lwm yam ntxwv, nrog lub zog tshiab, daim ntawv thov ntawm txhuas tau ntxiv dag zog, thiab kev sib txuas ntawm txhuas ntxiv rau riveting, kev sib txuas yog vuam, rau kev sib txuas ntawm aluminium phajtsis kam vuamyog ib qho tseem ceeb ntawm cov txheej txheem, daim ntawv thov scenarios ntxiv rau cov pa kev lag luam daim ntaub ntawv, Nws yog dav siv nyob rau hauv tshiab zog tsheb, aerospace thiab lwm yam teb.

Cov ntsiab lus ntawmAluminiumWelding

Qhov zoo ntawm aluminium phaj kujqhov chaw vuamyog pom tseeb, tsis ntxiv cov ntaub ntawv pab, tsuas yog los ntawm lub hauv paus hlau melting tuaj yeem tsim ib qho kev sib koom ua ke muaj zog.AluminiumNyob rau hauv cov huab cua feem ntau muaj ib txheej ntawm oxide zaj duab xis, aluminium melting point yog 660 degrees Celsius, thiab oxide zaj duab xis yog txhuas oxide, nws melting point yog hais txog 2000 degrees, thiab yaj lub hauv paus cov ntaub ntawv los tsim cov tub ntxhais ua ntej kom tawg oxide txheej. , uas tseem yog cov txheej txheem txhuas qhov chaw vuam yog suav tias yog vim li cas nyuaj dua.

VuamEkhoom sivSkev xaiv tsa

Kev xaiv ntawm aluminium phajqhov chaw vuam tshuab, intermediate zaus inverter DC fais fab mov vim nws cov zis tam sim no yog DC, nrog thermal efficiency ntau dua, yog li nws yog thawj qhov kev xaiv rau txhuas phaj qhov chaw vuam. Cov tsoos peb-theem theem nrab rectifier fais fab mov yog ib nrab-yoj rectifier, capacitive zog cia fais fab mov txawm hais tias cov zis yog DC tab sis lub sij hawm luv luv, yog li nws cov kev ua tau zoo tsis zoo li qhov nruab nrab zaus inverter DC chaw vuam, cov no cov khoom siv hluav taws xob muaj cov ntawv thov nyob rau theem pib, qhov kev thov yav tom ntej yuav muaj tsawg dua.

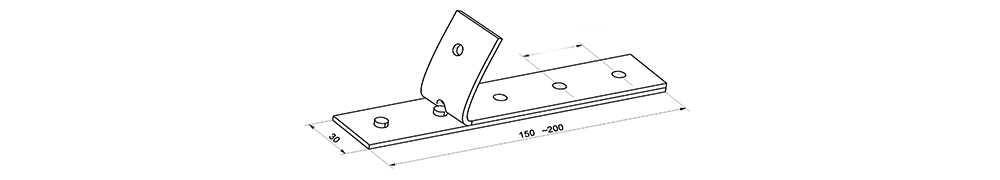

Cov ntsiab lusTo Nua oteWtus qaibAluminiumSlauj kaubWelding

Aluminium phaj qhov chaw vuam txheej txheem, txhuas phaj conductivity thiab thermal conductivity piv yog siab, yog li xav tau ntau dua tam sim no thiab tsim nyog vuam lub sij hawm, uas yuav tsum tau saib xyuas rau cov ntsiab lus hauv qab no:

1. Lub zog ntawm cov khoom siv yuav tsum loj txaus los xyuas kom meej tias cov zis tam sim no tuaj yeem siab tshaj plaws hauv lub sijhawm luv luv, feem ntau 2-3 npaug ntawm cov pa roj carbon steel qhov chaw vuam tam sim no;

2. Cov electrode xav tau cov dej txias txias, thiab cov cua sov tuaj yeem raug tshem tawm sai sai tom qab vuam;

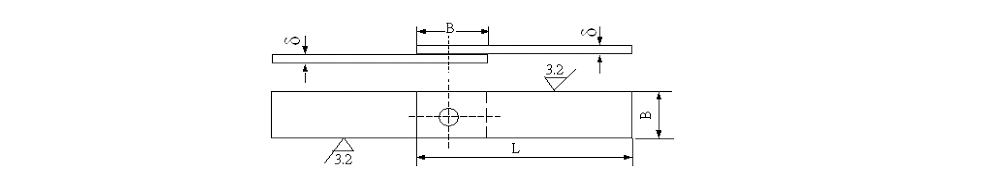

3. Txoj kab uas hla ntawm lub hauv ntej kawg ntawm lub electrode yuav tsum sib npaug, thiab cov phaj sib txawv yuav tsum muaj cov spheres sib txawv, thiab lub hauv paus ntsiab lus yuav tsum tsis txhob qis dua SR25;

4. Lub electrode txoj kab uas hla yuav tsum phim lub thickness ntawm lub phaj, thiab lub electrode txoj kab uas hla hauv qab 1.0MM ntawm lub phaj yog ¢ 13; Daim ntawv thickness 1.0-1.5 Electrode txoj kab uas hla yog ¢ 16; Daim ntawv thickness 1.5-2.0 Electrode txoj kab uas hla yog ¢ 20; Phaj tuab saum 2.0 electrode txoj kab uas hla tsis tsawg dua ¢ 25;

5. Cov khoom siv electrode yog ua los ntawmtooj liab alloynrog siab conductivity lossis hardened tooj liab, thiab cov conductivity tsis tsawg tshaj li 80% IACS;

6. Yuav kom ua tau raws li qhov zoo ntawm cov pob qij txha zoo, qhov saum npoo ntawm cov phaj txhuas yuav tsum tau deoxidized, pickling lossis polishing, thiab cov nplaim tsis kam ntawm A-theem sib koom ua ke ntawm aviation / tub rog cov khoom yuav tsum tau tswj ntawm 50 microohm-100 microohm;

VuamQualityIkev soj ntsuam

Aluminium phaj qhov chaw vuam tom qab qhov kev ntsuam xyuas feem ntau tsis muaj kev puas tsuaj thiab kev puas tsuaj rau ob pawg, tsis muaj kev puas tsuaj feem ntau los ntawm kev pom, X-ray thiab ultrasonic nrhiav kom pom, kev puas tsuaj feem ntau ncab, lub sij hawm tsawg thiab lwm yam kev tshawb nrhiav, cov kev tshawb pom tshwj xeeb yog raws li hauv qab no. :

1. Kev tshuaj xyuas qhov tshwm sim, suav nrog cov duab ntawm kev sib koom ua ke, cov xim sib koom ua ke, indentation qhov tob, thiab lwm yam;

2. X-ray nrhiav kom pom, zaj duab xis nrhiav kom pom ntawm txoj kab uas hla ntawm lub vuam core, seb lub vuam core tawg, shrinkage thiab lwm yam tsis xws luag;

3. Tsis tshua muaj zog nrhiav pom, 15-25 zaug tom qab hlais corrosion ntawm cov pob qij txha, txhawm rau txheeb xyuas cov vuam permeability, vuam tsis xws luag, thiab lwm yam;

4. Tensile xeem, lub ntsiab xeem solder sib koom ua ke lub zog;

5. Stripping test, stripping los yog tearing test ntawm cov pob qij txha, feem ntau yog siv rau ntawm qhov chaw muaj zog nrhiav kom tau thiab kev pom zoo ntawm cov tub ntxhais txoj kab uas hla.

6. Ultrasonic nrhiav kom tau, nrog rau kev txawj tej yam ntxiv ntawm ultrasonic nrhiav kom tau technology, daim ntawv thov ntawm qhov chaw vuam nrhiav kom tau ntxiv dag zog, los ntawm kev sib piv ntawm reflected waveform, raws li zoo raws li kev loj hlob ntawm cov imaging technology, polycrystalline taub hau ultrasonic nrhiav kom tau ib tug zoo xaiv rau. non-destructive kuaj ntawm txhuas qhov chaw vuam.

Cov ntsiab lus

Nrog rau mature daim ntawv thov ntawmMFDC vuam tshuab, nrog rau kev txhim kho ntawm cov txheej txheem vuam thiab kev tshawb pom txhais tau tias, qhov pib ntawm aluminium phaj qhov chaw vuam yuav qis dua thiab qis dua, thiab nws tseem yuav txhawb nqa cov txhuas phaj qhov chaw vuam hauv kev lag luam, nrog rau lub zog tshiab, aerospace thiab ntau dua. siv.

Post lub sij hawm: Aug-07-2024