Sheet Hlau welding yog siv nyob rau hauv ntau lub lag luam. Thaum twg koj xav tau los koom nrog cov khoom hlau, koj yuav xav txog yuav ua li cas vuam lawv. Vuam thev naus laus zis tau dhau los ua qhov siab heev, thiab xaiv txoj kev vuam zoo tuaj yeem ua rau koj txoj haujlwm yooj yim dua thiab ua haujlwm zoo dua. Kab lus no yuav qhia koj txog kev nkag siab txog cov ntawv hlau vuam thiab pab koj nrhiav txoj hauv kev vuam txoj cai.

Sheet Hlau Vuam yog dab tsi?

Daim ntawv metal vuamyog cov khoom siv technology, uas yog hais txog kev sib txuas ntawmoblos yog ntau qhov sib cais hlau rau hauv ib qho los ntawm qee txoj kev. Nrog rau txoj kev loj hlob ntawm kev lag luam thev naus laus zis, vuam thev naus laus zis yog siv ntau thiab ntau dua, uas yog cov txheej txheem tseem ceeb hauv kev ua hlau ntawm kev tsim khoom.

Cov txheej txheem ntawm hlau vuam yog dab tsi?

Muaj ntau ntau hom hlau vuam txoj kev, raws li lub xeev thiab txheej txheem cov yam ntxwv ntawm cov hlau nyob rau hauv lub vuam txheej txheem, hlau vuam txoj kev mas muab faib ua peb pawg: fusion vuam, siab vuam thiab brazing.

Fusion Vuam

Fusion welding yog ib txoj hauv kev koom nrog cov khoom hlau los ntawm cua sov thiab melting lawv ua ke. Txoj kev no tsis tas yuav tsum muaj siab. Lub interfaces ntawm ob lub workpieces yog rhuab, ua rau cov hlau los tsim ib tug tseem ceeb atomic quab yuam, tsim ib tug kua xeev nyob rau hauv lub rhuab cheeb tsam. Cov hlau atoms ntawm ob lub workpieces diffuse tag nrho thiab ua ke. Thaum cov hlau molten txias, nws tsim muaj zog welded sib koom ua ke.

Cov txheej txheem fusion welding feem ntau suav nrog arc vuam, roj vuam, thiab laser vuam.

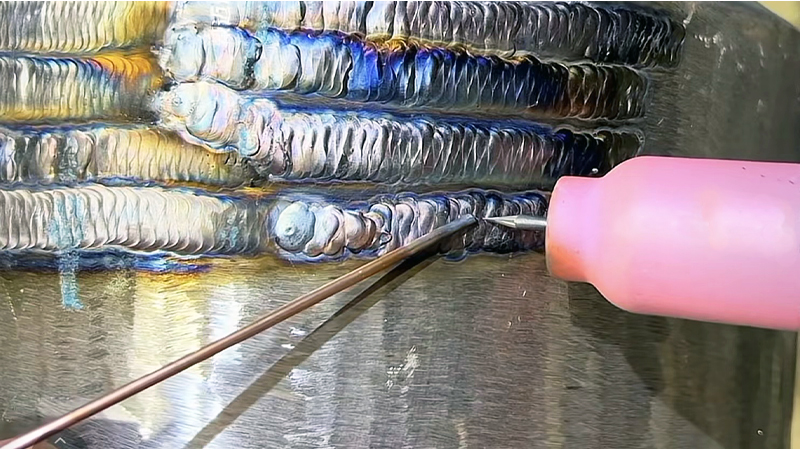

Arc Vuam

Arc vuamyog powered los ntawm ib tug hluav taws xob qhov chaw uas tawm ntawm lub electrode thiab ob workpieces los ua ib tug arc. Qhov no arc hloov mus rau cua sov, yaj cov electrode thiab cov workpieces, koom nrog cov hlau ua ke. Thaum lub sij hawm vuam txheej txheem, tsis tshua muaj hluav taws xob thiab siab tam sim no tsim kom muaj qhov kub thiab txias thiab lub teeb ci, hlawv cov electrode thiab workpieces los tsim ib lub pas dej molten uas txias los ua ib qho vuam.

Txoj kev vuam no muaj ntau yam kev siv thiab tuaj yeem siv rau vuam ntau yam hlau xws li stainless hlau, txhuas, tooj liab, thiab cov pa roj carbon siab. Vim tias cov khoom siv arc vuam yog txav tau yooj yim thiab yooj yim rau kev khiav lag luam, nws yog dav siv hauv kev lag luam xws li kev tsim khoom, kev tsim kho, thiab nkoj tsim khoom. Piv txwv li, nws yog siv rau rebar sib txuas hauv kev tsim kho. Tsis tas li ntawd, arc vuam yog nquag ua haujlwm hauv kev kho cov khoom siv thiab kev kho tsheb ciav hlau.

Arc welding feem ntau xav tau lub tshuab arc vuam, vuam rods, thiab daim npog ntsej muag. Nws yog tus nqi qis thiab siv dav siv vuam txoj kev. Txawm li cas los xij, vim nws txoj kev nyuaj, qhov zoo ntawm qhov vuam feem ntau nyob ntawm qib kev txawj ntawm tus welder.

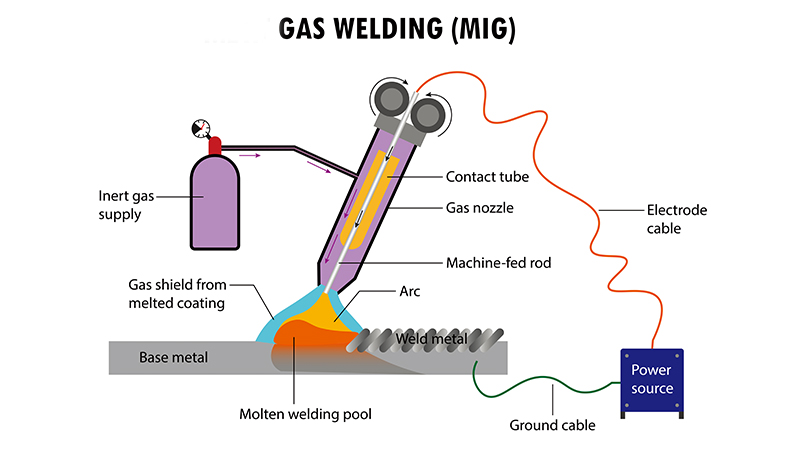

Gas Vuam

Gas vuamsiv ob hom roj: roj roj thiab roj oxidizing. Lub combustion ntawm cov roj no tsim cov cua sov, uas yog siv los yaj cov ntaub ntawv hlau thiab vuam pas nrig uas txuas ntxiv noj ntawm ob lub workpieces, ua kom tiav cov hlau txuas.

Gas vuam feem ntau yog siv rau vuam hlau xws li hlau, txhuas, thiab tooj liab. Nws muaj qhov zoo xws li kev hloov pauv hauv daim ntawv thov, tsis muaj kev txwv ntawm qhov chaw ua haujlwm, thiab kev ua haujlwm yooj yim. Tsis tas li ntawd, nws tsis tas yuav muaj hluav taws xob, ua rau nws siv dav rau kev ua haujlwm sab nraum zoov thiab ntawm cov chaw tsim kho rau kev sib txuas hlau. Yog tias koj xav kho cov yeeb nkab hlau, kev siv roj av yog qhov kev xaiv zoo heev.

Txawm li cas los xij, roj vuam muaj nws cov kev txwv. Qhov zoo ntawm cov vuam yog cuam tshuam los ntawm qhov zoo ntawm vuam pas nrig, thiab cov pob qij txha welded yog feem ntau deformation. Tsis tas li ntawd, qhov ntau lawm efficiency yog tsawg.

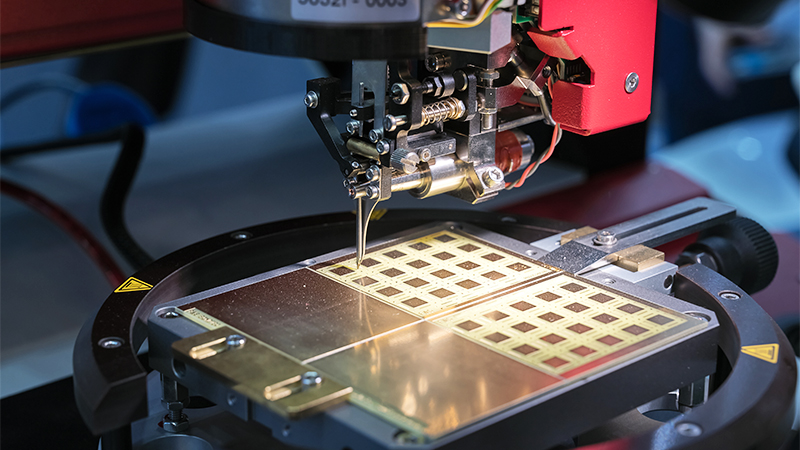

Laser Vuam

Laser vuamsiv lub laser beam ua nws qhov chaw tshav kub. Lub laser beam hits cov npoo ntawm cov hlau workpieces, ua kom sov thiab tsim ib tug weld pas dej ua ke. Thaum lub laser txav mus, cov hlau molten txias thiab sib txuas ua ke. Txoj kev no tuaj yeem siv rau kev sib tshooj welds, pob tw welds, thiab kaw welds hauv ntau daim ntawv thov kev lag luam.

Laser vuam muaj qhov ceev vuam ceev thiab kev ua haujlwm siab, thiab nws tuaj yeem siv rau vuam tsis yog hlau. Nws yog ib qho cuab yeej siv vuam tshuab siv dav siv hauv kev lag luam xws li kev tsim tsheb, khoom siv hluav taws xob, thiab cov hniav nyiaj hniav kub. Txawm li cas los xij, nws tsis tuaj yeem nkag mus rau cov ntaub ntawv tuab, yog li nws yog qhov zoo tshaj plaws rau cov ntaub ntawv nyias nyias. Piv rau lwm txoj kev vuam, cov khoom siv laser vuam zoo li kim dua.

Xovxwm Vuam

Tsis zoo li fusion welding, lub siab vuam yuav tsum tau siv qee qhov siab ntawm cov hlau thaum lub sij hawm vuam txheej txheem. Cov ntaub ntawv hlau tsis yaj mus rau hauv lub xeev ua kua tab sis nyob twj ywm. Kev kub siab welding muaj cua sov cov hlau pob qij txha kom lawv cov plasticity, thiab tom qab ntawd siv lub siab rau cov hlau yas, uas ua rau muaj kev sib koom ua ke zoo dua. Yog li ntawd, kev nyuaj siab plays lub luag haujlwm tseem ceeb hauv cov txheej txheem.

Nrog rau txoj kev loj hlob ntawm kev lag luam kev lag luam, ntau cov ntaub ntawv tshiab thiab cov khoom lag luam tau tshwm sim, ua rau muaj kev nruam ntej hauv kev siv tshuab siab vuam. Cov txheej txheem tseem ceeb ntawm kev siv vuam tam sim no suav nrog kev vuam vuam, diffusion vuam, sib txhuam vuam, thiab ultrasonic vuam.

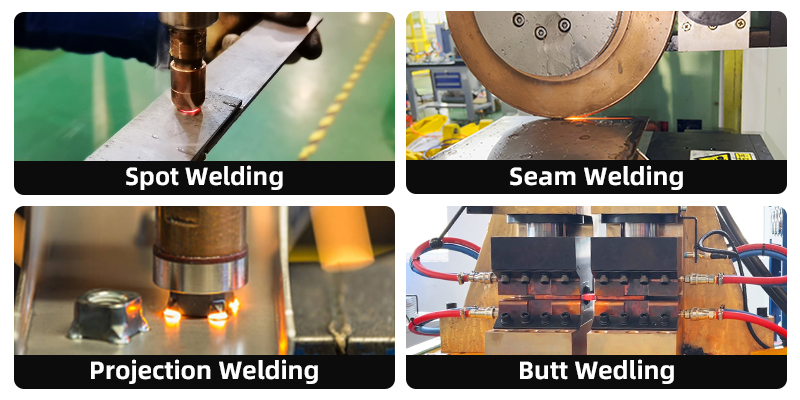

Kuj Vuam

Kuj weldingsiv hluav taws xob tam sim no los ua kom sov qhov sib txuas ntawm cov hlau workpieces thaum siv lub zog los ntawm electrodes kom tiav cov vuam. Nws yog feem ntau siv rau vuam stainless hlau, tooj liab, txhuas, thiab carbon hlau. Vim nws cov vuam zoo thiab zoo ib yam, cov vuam vuam ua lub luag haujlwm tseem ceeb hauv kev lag luam automotive, electronics, thiab aerospace industries. Nrog rau kev nce qib hauv thev naus laus zis, kev siv vuam vuam tau nce ntxiv automation, ntxiv dag zog rau kev tsim khoom.

Resistance vuam tuaj yeem muab faib ua plaub txoj hauv kev:qhov chaw vuam, projection vuam,seam vuam, thiabqab welding. Piv txwv li, yog tias koj xav tau weld ib feem ntawm lub tsheb, xws li txuas cov txiv ntoo rau lub phaj hlau, koj tuaj yeem siv qhov projection vuam. Txawm li cas los xij, cov khoom siv vuam tsis kam yog feem ntau loj thiab tsis yooj yim txav tau, txwv nws siv rau cov chaw tshwj xeeb. Txhua zaus koj welding cov ntaub ntawv sib txawv ntawm cov hlau los yog cov thicknesses, cov kev txwv yuav tsum tau hloov kho, ua rau nws tsim nyog rau cov khoom siv hlau loj.

Diffusion Vuam

Diffusion vuam, tseem hu ua diffusion bonding, muaj cua sov thiab siv lub siab rau cov hlau nto thaum vuam. Cov txheej txheem no tso cai rau cov atoms thiab molecules ntawm cov ntaub ntawv hlau kom diffuse thiab khi nyob rau hauv qhov kub thiab txias. Diffusion vuam siv tau rau ob qho tib si zoo sib xws thiab cov khoom sib txawv, feem ntau txuas tooj liab, txhuas, thiab cov ntaub ntawv sib xyaw.

Txoj kev no tuaj yeem sib txuas ntau cov pob qij txha hauv ib qho kev sib dhos, xws li vuam 20 txheej ntawm 0.1 hli tooj liab ntawv ci. Diffusion vuam tsim cov pob qij txha muaj zog uas tiv taus deformation, feem ntau tshem tawm qhov xav tau rau kev ua haujlwm ntxiv. Txawm li cas los xij, nws kuj muaj qhov tsis zoo, suav nrog kev tsim khoom qis thiab cov khoom siv siab.

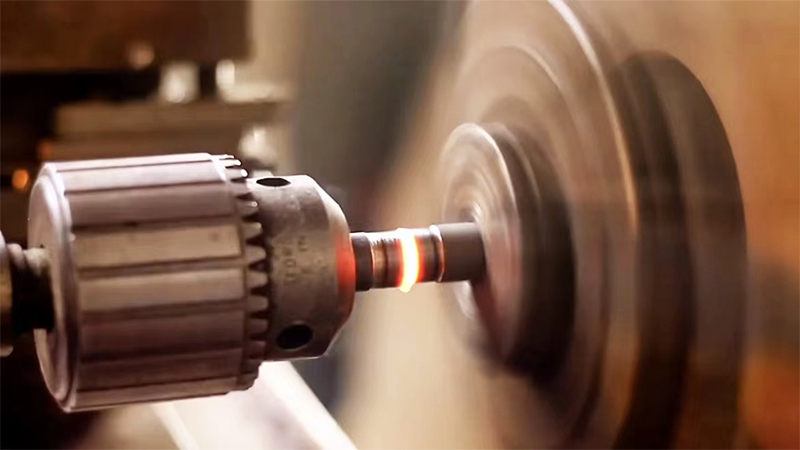

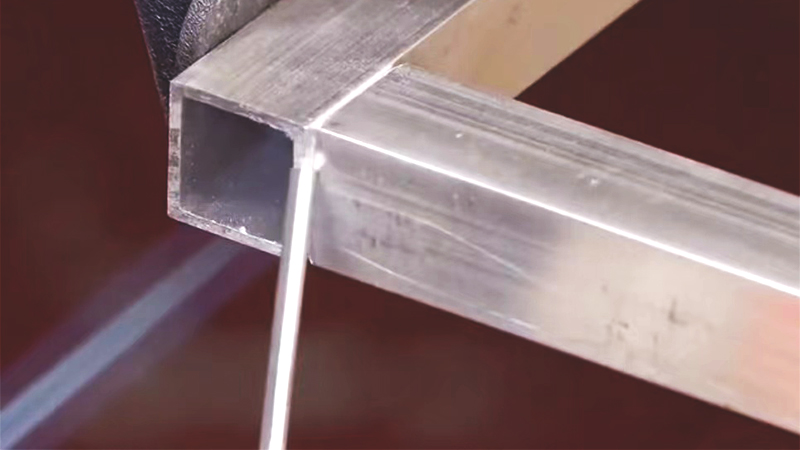

Kev sib txhuam vuam

Kev sib txhuam vuamyog cov txheej txheem vuam uas siv cov cua sov tsim los ntawm kev sib txhuam kev sib txhuam ntawm cov khoom ua haujlwm hauv siab. Nws yog ib txoj hauv kev zoo, txuag hluav taws xob uas tsim cov welds zoo. Piv nrog rau lub pob tw vuam, kev sib txhuam vuam muaj qhov chaw me me uas cuam tshuam rau cov cua sov thiab zoo dua rau kev koom nrog cov hlau sib txawv.

Kev sib txhuam vuam yog qhov tshwj xeeb thiab muaj qhov zoo xws li kev siv hluav taws xob tsawg thiab ib puag ncig tus phooj ywg, ua rau nws nrov hauv kev lag luam xws li kev tsim khoom siv tshuab, aerospace, thiab lub zog. Txawm li cas los xij, nws feem ntau tsuas yog tsim nyog rau kev sib txuas cov hlau rods thiab cov kav dej ntawm tib txoj kab uas hla. Thaum cov duab thiab sib dhos txoj hauj lwm ntawm lub workpieces yog tsau, nws yuav nyuaj rau weld.

Ultrasonic Vuam

Ultrasonic welding siv high-frequency vibrations generated los ntawm ultrasonic tsis los tsim kev sib txhuam, deformation, thiab tshav kub ntawm cov hlau hu. Lub siab yog siv los ntawm lub suab nrov thiab qis dua kom ua tiav cov txheej txheem vuam. Qhov no yog ib txoj kev vuam tshwj xeeb uas tsis cuam tshuam cov hluav taws xob tam sim no dhau los ntawm cov khoom siv hluav taws xob lossis cov khoom siv hluav taws xob sab nraud, thiab nws qhia qee tus yam ntxwv nrog kev sib txhuam vuam thiab diffusion vuam.

Ultrasonic vuamtuaj yeem siv rau ntau yam ntaub ntawv, suav nrog cov hlau zoo sib xws thiab sib txawv xws li tooj liab, txhuas, kub, thiab nyiaj. Txawm li cas los xij, nws feem ntau siv rau vuam cov ntaub ntawv tsis yog xim hlau xws li ABS, PP, thiab PC, qhov uas nws ua tau zoo dua.

Brazing Vuam

Brazingyog ib txoj kev vuam qhov twg cov hlau muab tub lim nrog lub melting point hauv qab ntawm lub workpieces yog rhuab thiab melted los sau cov khoob ntawm ob hlau workpieces, ua kom tiav cov hlau koom txheej txheem. Tsis zoo li fusion welding thiab siab vuam, txoj kev no tsis tas yuav melting lub workpieces los yog siv lub siab. Brazing feem ntau yog siv los koom nrog cov khoom sib tshooj, nrog qhov sib txawv ntawm qhov ntau thiab tsawg ntawm 0.01 txog 0.1 millimeters.

Niaj hnub no, brazing yog nce siv nyob rau hauv kev lag luam xws li machinery, electronics, instruments, thiab teeb pom kev zoo. Qhov zoo ntawm brazing feem ntau yog nyob ntawm cov khoom siv hlau siv. Yog li ntawd, thaum brazing hlau workpieces, nws yog ib qho tseem ceeb rau xaiv ib tug muab tub lim hlau nrog zoo wetting zog uas yuav ua tau zoo sau cov pob qij txha. Brazing yog categorized rau hauv mos brazing thiab nyuaj brazing raws li lub melting point ntawm cov muab tub lim hlau.

Soft Soldering

Mos soldering siv cov hlau muab tub lim nrog cov ntsiab lus melting hauv qab 450 degrees Celsius. Cov pob qij txha tsim los ntawm cov muag muag muag muaj lub zog qis dua thiab tsis muaj cua sov ua haujlwm. Nws yog feem ntau siv rau kev sib txuas hluav taws xob hauv cov khoom siv hluav taws xob precision thiab soldering nrog soldering hlau. Yog tias qhov kev xav tau ntawm lub zog tsis tseem ceeb thiab qhov chaw melting ntawm cov hlau muab tub lim yog siab dua li cov hlau uas tau raug soldered, muag muag muag tuaj yeem ua haujlwm.

Hard Yog lildering

Brazing nrog high-melting-point muab tub lim hlau, hu ua nyuaj soldering, siv cov hlau muab tub lim nrog cov ntsiab lus melting saum 450 degrees Celsius. Cov pob qij txha tsim los ntawm cov tawv soldering muaj zog dua piv rau cov los ntawm cov muag muag muag. Hard soldering feem ntau siv cov khoom xws li nyiaj, txhuas, tooj liab, thiab npib tsib xee. Kev xaiv ntawm cov hlau muab tub lim yog nyob ntawm cov yam ntxwv ntawm cov khoom siv ua haujlwm thiab cov kev xav tau ntawm kev sib koom ua ke. Hard soldering feem ntau haum rau stainless hlau, aluminium alloys, tooj liab, thiab lwm yam ntaub ntawv uas muaj zog yuav tsum tau. Nws yog siv rau cov pob qij txha uas ua haujlwm nyob rau hauv qhov kub thiab txias thiab nrhiav kev siv dav hauv aerospace, electronics, thiab hluav taws xob kev lag luam.

Xaus

Muaj ntau hom hlau vuam, thiab cov uas tau hais los saum toj no yog cov txheej txheem ntau dua. Raws li kev siv thev naus laus zis txuas ntxiv mus, ntau thiab ntau txoj kev vuam tau tshwm sim. Thaum xav txog yuav ua li cas welding koj cov hlau workpieces, nws yog ib qho tseem ceeb uas yuav tau xav txog yam xws li cov khoom ntawm lub workpiece, nws cov duab, qhov chaw ua hauj lwm, thiab lwm yam. Xaiv txoj kev vuam tsim nyog raws li cov xwm txheej no yog qhov tseem ceeb heev.

Post lub sij hawm: Jun-19-2024