Spot vuamyog ib hom kev tiv thaiv vuam, raws li cov txheej txheem tsim tau zoo siv los koom nrog ntau yam hlau, ua rau nws yog ib qho tseem ceeb hauv kev lag luam hlau niaj hnub. Kab lus no muab qee cov lus qhia kom ua tiav qhov muaj zog, txaus nyiam, thiab ruaj khov welds:

Xaiv Txoj CaiChawVuamTshuab

Xaiv qhov kev tiv thaiv qhov chaw vuam yog qhov tseem ceeb heev. Tsis txhob siv cov tshuab uas loj dhau nrog ntau yam nta, vim qhov no tuaj yeem ua rau kev nqis peev. Ib yam li ntawd, tsis txhob xaiv lub tshuab uas tsim nyog, vim nws yuav tsis tso cai rau kev nthuav dav yav tom ntej lossis muaj kev qaug zog zoo.

Qhov kev xaiv zoo tshaj plaws yog lub tshuab muaj peev xwm ntawm qhov tshwj xeeb vuam, nrog txog 25% muaj peev xwm ntxiv hauv vuam tam sim no thiab siab tshaj qhov tam sim no.sheet hlau welding.

Kev siv lub tshuab loj tuaj yeem ua rau muaj teeb meem ntau npaum li lub tshuab me me dhau. Piv txwv li, yog hais tias lub tog raj kheej txoj kab uas hla yog loj heev, nws yuav tsum ua hauj lwm ntawm ib tug huab cua siab hauv qab no 0.2 MPa kom ua tau raws li qhov yuav tsum tau welding siab. Qhov no tuaj yeem ua rau cov lus teb tsis zoo los ntawm kev siv tshuab siab. Yog tias lub tog raj kheej tsis ua sai sai thaum cov hlau mus txog lub xeev yas thiab xav tau kev sib tsoo sai, qhov vuam lub zog thiab kev ruaj ntseg tuaj yeem raug kev txom nyem.

Ntau lub tuam txhab, kom yooj yim ntawm kev tswj cov cuab yeej thiab cov khoom siv vuam tsis sib xws, xaiv cov khoom siv raws li cov qauv qauv es tsis yog cov txheej txheem vuam yuav tsum tau ua. Qhov no tuaj yeem ua rau tsis zoo sib xws thaum vuam qhov loj thiab qhov tsawg tshaj plaws. Qhov no yog ib qho yuam kev los ntawm inexperienced engineers. Txoj hauv kev kom raug yog kom phim cov khoom siv loj rau cov khoom ua haujlwm welded.

Tau Kev cob qhia hauvChawVuam

Ua ntej, nws yog ib qho tseem ceeb heev kom tau txais kev cob qhia hauv vuam cov ntsiab lus thiab cov txheej txheem. Kev nkag siab txog cov ntsiab lus ntawm qhov chaw vuam yog qhov tseem ceeb rau kev kho cov txheej txheem vuam kom raug thiab siv cov khoom siv kom raug.

Spot vuam tej zaum yuav zoo li ncaj nraim, raws li nws zoo nkaus li leej twg tuaj yeem ua haujlwm thiab kho qhovqhov chaw vuam tshuab: Muab qhov chaw nruab nrab ntawm cov electrodes, nias lub pob pib, thiab cov khoom yog welded ua ke. Txawm li cas los xij, qhov no yog kev dag ntxias. Nws yog ib qho tseem ceeb kom nkag siab txog qhov tseem ceeb ntawm vuam cov ntsiab lus thiab cov tsis muaj thiab kho txhua tus rau nws cov txiaj ntsig zoo.

Xav txog nws zoo li kev ua noj: tib cov khoom xyaw, tab sis cov seasonings sib txawv, qib cua sov, thiab lub sijhawm ua noj tuaj yeem tsim cov khoom sib txawv!

Peb lub ntsiab tseem ceeb ntawm qhov chaw vuam yog vuam tam sim no, vuam lub sij hawm, thiab vuam siab. Tsis tas li ntawd muaj xws li lub sij hawm ua ntej lub siab, vuam lub sij hawm luv luv, thiab tom qab vuam tuav.

Los ntawm kev sib txuas cov kev txwv no, koj tuaj yeem ua tiav qhov nyuaj, nruab nrab, lossis muag vuam specifications, uas ua rau muaj qhov sib txawv vuam, xws li:

Hard specifications:Qhov tsawg kawg nkaus deformation, tsis tshua muaj hluav taws xob cuam tshuam, vuam ceev, tab sis yuav tsum muaj lub zog siab, muaj zog, thiab cov khoom siv siab.

Soft specifications:Qhov tseem ceeb ntawm deformation, sib sib zog nqus weld indentation, discoloration, qeeb vuam ceev, tab sis qis zog thiab rigidity yuav tsum tau rau cov khoom.

Medium specifications:Cov teebmeem thiab cov khoom siv yuav tsum tau poob ntawm ob qhov siab saum toj no.

Cov phau ntawv tshaj lij xws li "Welding Handbook" muab cov lus pom zoo, thiab Agera cov kws tshaj lij kev pabcuam muab kev cob qhia thiab kev taw qhia rau cov neeg siv.

Xaiv Txoj CaiSpot VuamCov hluav taws xob

Kev sib piv cov khoom siv electrode rau cov khoom siv yog qhov tseem ceeb rau kev pom cov txiaj ntsig zoo thiab lub zog ua haujlwm.

Rau qhov chaw vuamaluminiumthiabgalvanized ntawv, siv alumina-dispersed tooj liab electrodes, uas tiv thaiv sticking.

Raustainless hlauthiab cov pa roj carbon tsawg, siv chromium zirconium tooj liab electrodes, uas muaj cov nqi-zoo.

Rautooj liab, tungsten thiab molybdenum electrodes yog xav tau los pab nrog vuam vim lawv cov khoom cua sov.

Kev tsim thiab tsim cov duab electrode kuj tseem ceeb heev, vim tias lawv txiav txim siab qhov loj thiab qhov pom ntawm cov weld nugget thiab nws lub zog.

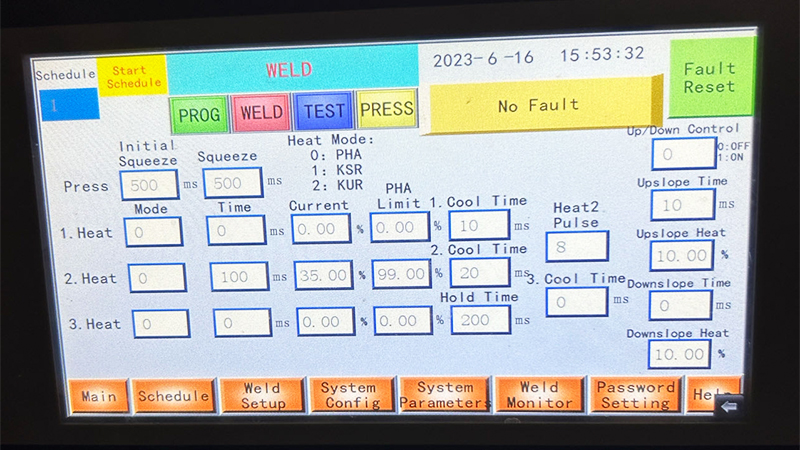

Teem Welding Parameters

Vuam tsis tuaj yeem tsim raws li kev paub dhau los lossis cov ntaub ntawv los ntawm pej xeem qhov chaw. Yog tias tsis muaj cov ntaub ntawv pov thawj, koj tuaj yeem pom qhov zoo tshaj plaws vuam tsis tau los ntawm ntau qhov kev sim welds nrog ntau qhov chaw. Thaum kuaj, ua raws li cov hauv qab no:

Pib Me: Pib nrog kev saib xyuas, me me qhov tseem ceeb rau qhov tsis xws li vuam tam sim no, lub sijhawm, thiab siab, thiab maj mam nce lawv. Txoj kev no yuav pab kom tsis txhob muaj kev puas tsuaj rau cov khoom siv, electrodes, thiab qhov chaw.

Kho Ib Lub Sijhawm Ib Lub Sijhawm: Kho ntau qhov ntsuas ib txhij tuaj yeem ua rau muaj kev txiav txim tsis raug, tshwj xeeb tshaj yog rau cov neeg ua haujlwm tsis muaj kev paub. Yog tias ib qho kev hloov pauv tsis ua haujlwm, sim ua lwm qhov thaum ua tib zoo saib cov kev hloov pauv hauv vuam zoo.

Tso cai rau Parameter Margins: Xyuas kom meej tias muaj cov npoo rau qhov ntsuas kom haum rau qhov sib txawv ntawm qhov chaw.

Thaum qhov zoo tshaj plaws vuam tsis tau lees paub, solidify cov ntaub ntawv thiab siv lawv ua lub hauv paus rau ntau lawm.

Khaws Electrodes

Tsis tu ncua reshape deformed electrodes kom lawv ntawm lawv qhov loj me me thiab ntxuav tawm cov av thiab tooj liab alloy residue ntawm lawv qhov chaw. Qhov kev saib xyuas no yog qhov tseem ceeb rau kev ruaj ntseg vuam.

Electrodes ua hauj lwm nyob rau hauv kev kub siab thiab kub tuaj yeem deform, ua rau lawv qhov chaw sib cuag nrog cov khoom thiab txo cov vuam tam sim no ceev. Tsis tas li ntawd, cov txheej txheej saum npoo av, roj, thiab xeb los ntawm cov khoom tuaj yeem ua raws li cov electrodes, ua rau muaj kev tiv thaiv kev tiv thaiv thiab txo cov vuam tam sim no. Cov teeb meem no ncaj qha cuam tshuam rau vuam zoo.

Siv cov khoom siv hluav taws xob tshwj xeeb tuaj yeem kho cov khoom electrode sai sai thiab tshem tawm cov av. Tsis txhob siv cov ntaub ntawv rau kev ntxuav tes, vim nws tsis tuaj yeem ua kom cov duab zoo thiab qhov kawg ntawm cov electrodes.

Siv cov cuab yeej siv vuam vuam

Spot welding pob qij txha feem ntau tsis dhau qhov kev sim uas tsis muaj kev puas tsuaj. Cov kev tshuaj ntsuam xyuas feem ntau suav nrog kev tshuaj xyuas qhov muag, torque wrenches (rau vuam ceev), lub tshuab ntsuas tensile, thiab cov ntsuas metallographic.

Tensile thiab Compression Testing: Ua cov kev ntsuam xyuas no ua ntej pib ib hnub tag nrho ntawm kev tsim khoom kom paub meej tias qhov kev ntseeg tau ntawm cov vuam tsis zoo nrog cov ntaub ntawv xeem. Thaum kawg ntawm txhua qhov kev hloov pauv, sim cov khoom siv welded nrog cov ntsuas tam sim no dua kom ntseeg tau tias muaj kev sib xws. Rau qhov tseem ceeb uas yuav tsum tau ua kom zoo dua, ua kom muaj qhov kev sim ua kom puas tsuaj.

Kev Saib Xyuas Txheej Txheem: Siv vuam zoo saib yog lwm qhov kev xaiv, uas tau dhau los ua tus nqi thiab siv dav. Los ntawm kev saib xyuas qhov ntsuas vuam hauv lub sijhawm tiag tiag thiab teeb tsa cov kev txwv sab saud thiab qis, txhua qhov sib txawv tuaj yeem ua rau lub tswb nrov, txo cov vuam tsis xws luag. Cov ntaub ntawv vuam no tseem tuaj yeem muab khaws cia kom zoo traceability.

Tsis tu ncua thiab tshuaj xyuas

Tom qab siv mus ntev, Spot vuam cov cuab yeej xav tau kev kuaj xyuas tsis tu ncua hauv cov cheeb tsam no:

- Conductive Circuit Court:Vuam spatter tuaj yeem cuam tshuam cov khoom seem thiab qhov khoob, ua rau shunting, txo thiab destabilizing cov vuam tam sim no. Tshem tawm weld slag. Kev hloov hluav taws xob ntau zaus tuaj yeem hnav thiab oxidize conductive kev sib txuas, yuav tsum tau rov ua dua. Tighten bolts ntawm cov hlua tooj liab mos thiab tawv tooj liab tuav kom tsis txhob xoob los ntawm kev siv ntev.

- Vuam Cylinder Guide:Tshawb xyuas qhov kev txav mus los thiab qhov khoob. Cov zawv zawg tsis zoo cuam tshuam rau kev ua raws li kev sib txuas; ntau qhov sib txawv cuam tshuam rau weld zoo thiab ib feem ntawm kev sib tw.

- Dej Circuit Court:Xyuas kom cov dej ntws zoo. Ntxuav cov ntsuas ntsuas kom pom tseeb, xyuas txhua txoj hauv kev ntws, thiab tshem cov blockages los yog hloov cov kav dej. Cov dej txias tsis txaus tuaj yeem overheat transformers thiab electrodes, txo cov lifespan los yog ua rau burnout. Tshawb xyuas thiab kho cov dej xau.

- Vuam tam sim no:Tshawb xyuas qhov vuam tam sim no nrog tus neeg thib peb tester kom paub tseeb tias nws ua tau raws li cov qauv. Kev siv ntev ntev tuaj yeem txo cov zis tam sim no, yog li kev ntsuas tsis tu ncua thiab hloov kho lossis kho yuav tsum tau ua.

- Cua Circuit Court:Tshawb xyuas thiab kho cov pa xau, vim tias cov dej xau ua rau lub siab tsis ruaj khov thiab lub zog poob.

- Kev huv huv:Khaws cov khoom siv kom huv si. Cov cim ntshiab thiab cov cuab yeej huv si txo cov neeg ua yuam kev.

Lub caij ntuj sov

Cov no yog qee cov lus pom zoo rau cov neeg siv khoom siv vuam vuam. Nrog ntau tshaj 20 xyoo ntawm kev lag luam vuam kev lag luam, peb muaj ntau yam kev pabcuam, suav nrog kev npaj cov qauv vuam, kev xaiv tshuab, kev cai tsis siv cov khoom siv vuam tshuab, kev teeb tsa thiab commissioning, kev saib xyuas, kev txhawb nqa khoom, thiab qhov chaw. Xav tias dawb hu rau peb!

Lub sij hawm xa tuaj: Plaub Hlis-09-2024