Butt vuamyog siv ntau thiab ntau dua nyob rau hauv niaj hnub hlau ua, los ntawm lub pob tw vuam tshuab, tib cov hlau los yog cov hlau tsis sib xws xws li tooj liab thiab txhuas tuaj yeem khov kho pob tw ua ke. Nrog rau txoj kev loj hlob ntawm kev lag luam, pob tw vuam tshuab tau siv ntau dua rau cov khoom siv hluav taws xob thiab hluav taws xob, lub zog tshiab tsheb thiab lwm yam kev lag luam. Cov kab lus hauv qab no yuav teb cov kev paub ntawm pob tw vuam rau koj kom meej.

BasicCxav ofBua uttWelding

Lub npe hu ua pob tw welding yog muab ob lub workpiece xaus rau ib leeg, siv lub siab tib lub sijhawm, siv vuam tam sim no kom sov, thiab tom qab ntawd tsim cov vuam sib koom ua ke nyob rau hauv qhov kev txiav txim siab, ua haujlwm tau zoo thiab yooj yim rau kev ua tiav automation. welding txheej txheem.

The Hom of Bua uttWelding

Butt welding feem ntau yog muab faib uatsis kam taub qab vuamthiabflash taub qab vuam

Resistance taub qab vuam

Resistance butt welding yog ib hom khoom theem vuam nyob rau hauv high kub yas lub xeev, thiab kev sib koom ua ke yuav ua tau recrystallization thiab kev sib nrig sib diffusion nyob rau hauv essence, tab sis tag nrho cov yog cov khoom theem kev twb kev txuas.

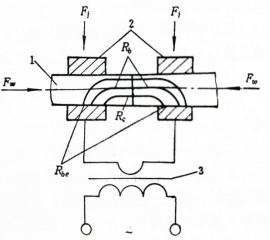

Lub hauv paus ntsiab lus ntawm kev tiv thaiv pob tw vuam thiab kev sib koom ua ke yog qhia hauv daim duab 1.

Daim duab 1. Resistance taub qab vuam schematic daim duab

1- Weldment

2- electrode

3- Solder resistance transformer

4-Ff- clamping quab yuam

Fw- forging quab yuam

Rb-welding kuj

RC-Kev tiv thaiv tiv thaiv

Rbe- tiv thaiv kev sib cuag ntawm cov vuam thiab cov khoom ua haujlwm

Flash Butt Vuam

Cov ntsiab lus ntawm kev sib txuas ntawm lub taub qab vuam sib txuas yog tib yam li qhov sib txuas ntawm lub pob tw vuam sib txuas, uas kuj yog ib qho khoom sib txuas, tab sis cov txheej txheem tsim muaj nws tus yam ntxwv. Thaum kawg ntawm lub flash, ib txheej kua hlau tau tsim rau ntawm lub ntsej muag kawg. Thaum lub sij hawm sab saum toj forging, qhov kawg lub ntsej muag hlau yog thawj zaug nyob rau hauv cov kua theem. Tom qab ntawd cov kua theem txheej yuav raug nyem tawm ntawm qhov sib koom ua ke kawg lub ntsej muag nyob rau hauv qhov kev txiav txim ntawm sab saum toj forging siab.Tom qab lubflash taub qab vuam tshuabwelded qhov chaw, qhov sib koom ua ke yog muaj zog heev, xws li ib tug hlau raj los ntawm lub flash welding, ces los ntawm lubtubing dabtsi yog khoov tshuabkhoov ntawm qhov sib koom ua ke, qhov sib koom ua ke yuav tsis tawg.

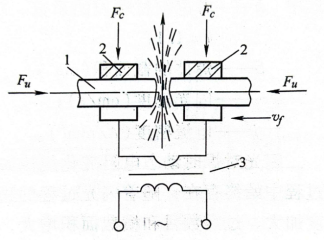

Lub hauv paus ntsiab lus ntawm flash taub qab vuam thiab kev sib koom ua ke yog qhia hauv daim duab 2:

Daim duab 2. Flash taub qab vuam schematic daim duab

1- Weldment

2- electrode

3- Solder resistance transformer

4- Fc- clamping force Fu- forging force Vf flash ceev

Qhov zoo ntawmBua uttWelding

a) Cov cuab yeej siv vuam pob tw yog qhov yooj yim, tsawg dua vuam tsis, yooj yim rau tus tswv, yooj yim rau kev tswj tsis siv neeg;

b) Kev txo qis me me ntawm cov pob tw vuam qhov chaw, txuag cov ntaub ntawv, tsawg burrs, uas yog qhov tsim nyog rau kev ua kom yooj yim rau cov txheej txheem tom kawg;

c) nyem pob tw vuam muaj qhov ua haujlwm siab thermal, tuaj yeem vuam qhov chaw loj, thiab tau siv rau vuam cov kav dej nrog thaj tsam ntawm 100000mm2;

d) nyem pob tw vuam vim tias lub lintel muaj nyob rau lub sijhawm luv luv, tsuas yog ob peb milliseconds, nws txoj haujlwm hloov pauv, thiab tag nrho lub sijhawm cua sov thoob plaws lub ntsej muag kawg ntawm lub vuam yog sib xws, yog li txuas txuas flash vuam tsis tuaj yeem tsuas yog vuam ib compact seem, tab sis kuj weld welds nrog nthuav seem (xws li cov ntawv nyias, thiab lwm yam);

e) Thaum kawg ntawm lub teeb, ib txheej nyias ntawm cov kua hlau yuav raug tsim rau ntawm qhov chaw ntawm lub vuam, kom cov oxide impurities ntawm qhov chaw yooj yim tawm nrog cov kua hlau nyob rau sab saum toj ntawm lub interface, yog li tias lub pob nyem vuam pob qij txha yog qhov zoo, thiab cov vuam ntau yam tuaj yeem ua tau ntau dua, thiab ntau yam khoom sib txawv tuaj yeem welded.

f) Tsis muaj qhov yuav tsum tau muab tso rau hauv cov txheej txheem vuam, thiab cov khoom siv siv yog siab;

Daim ntawv thov ntawmBua uttWelding

Automotive Manufacturing

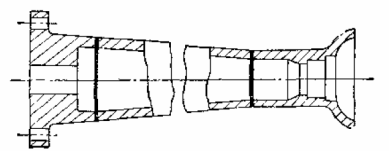

Daim duab 3. Tsheb cardan ncej plhaub flash taub qab vuam

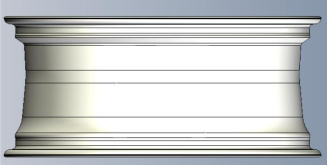

Daim duab 4. Tsheb, maus taus log flash taub qab vuam

Aerospace kev lag luam

Daim duab 5. Aircraft pas nrig taub qab vuam

Petrochemical kev lag luam

Daim duab 6. Hlau kav taub qab vuam

Kev tsim kho engineering field

Daim duab 7. Xaus phaj flange taub qab vuam

Shipbuilding kev lag luam

Daim duab 8. Anchor chain butt welding

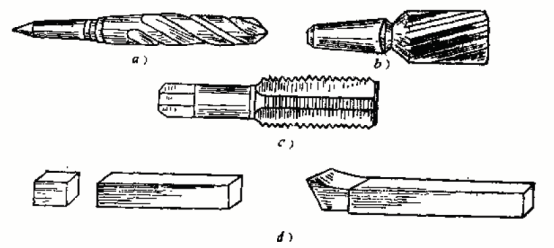

cov cuab yeej kho vajtse

Daim duab 9. Cov cuab yeej taub qab vuam

SpecificationParameters hauvBua uttWeldingProcess

Thaum xaiv qhov tsis zoo ntawm pob tw vuam specifications, cov pob qij txha zoo nrog yuav luag tib yam li cov ntaub ntawv hauv paus tuaj yeem tau txais.

a) Cov ntsiab lus tseem ceeb ntawm kev tiv thaiv pob tw vuam yog:

stretching ntev, vuam tam sim no ceev (los yogvuam tam sim no), vuam lub sij hawm, vuam siab thiab sab saum toj forging siab.

b) Lub ntsiab tsis tseem ceeb ntawm flash taub qab vuam yog:

Flash theem: kho stretch ntev, flash retention, flash ceev, flash tam sim no ceev;

Sab saum toj forging theem: sab saum toj forging nyiaj, sab saum toj forging ceev, sab saum toj forging siab, clamping quab yuam;

Preheating theem: preheating kub, preheating lub sij hawm.

Lub luag haujlwm ntawm kev ncab ntev yog los xyuas kom meej qhov tsim nyog pub (vuam qhov luv luv) thiab kho qhov kub thiab txias thaum cua sov qhov tseem ceeb thiab kev ua haujlwm tuaj yeem xaiv raws li qhov vuam ntu thiab cov khoom siv, kev xyaum qhia tau hais tias qhov ntev stretching yuav tsum tsis txhob tsawg dua. tshaj li ib nrab ntawm txoj kab uas hla ntawm qhov vuam, uas yog, l = 0.6 ~ 1.0d (d yog txoj kab uas hla ntawm cov ntoo lossis sab ntev ntawm lub square) yog qhov tsim nyog. Nyob rau tib lub sijhawm, thaum vuam cov ntaub ntawv sib txawv, txhawm rau kom tau txais qhov sib npaug ntawm qhov kub thiab txias (qee zaum xav txog qhov rigidity ntawm non-ferrous hlau weldments), ob qhov vuam yuav tsum siv qhov ntev sib txawv.

Lub vuam tam sim no feem ntau qhia los ntawm qhov ceev tam sim no, thiab qhov ceev tam sim no thiab vuam lub sij hawm yog ob qho tseem ceeb uas txiav txim siab vuam cua sov, thiab tuaj yeem hloov kho kom haum rau ib leeg. Hauv kev xyaum, nws raug nquahu kom tswj hwm qee qhov kev sib raug zoo ntawm qhov siab tshaj plaws tam sim no thiab lub sijhawm vuam yam tsawg kawg nkaus, thiab siv cov lus qhia nyuaj dua li qhov ntu ntu txo qis. Qhov ceev ceev ntawm nruam flash taub qab vuam, cov ntaub ntawv hlau nrog zoo hluav taws xob thiab cov cua sov thiab welded seem nrog cov ntu txuas yuav tsum yog. Rau preheating flash taub qab vuam thiab ntu loj welds, qhov ceev tam sim no yuav tsum tsawg.

Ob lub vuam siab thiab lub siab forging saum toj kawg nkaus muaj kev cuam tshuam rau cov cua sov dissolution ntawm qhov chaw sib cuag thiab cov yas deformation ntawm qhov opposite thiab nyob ib sab. Sab saum toj forging ceev thiab sab saum toj forging quab yuam siab tuaj yeem sib tw, thiab sab saum toj forging ceev yuav raug txo kom tsim nyog thaum sab saum toj forging ceev loj txaus.

CovDkev loj hlobProspect ntawmBua uttWelding

Nrog rau qhov kev kawm tob ntawm kev sib raug zoo ntawm kev ua haujlwm vuam zoo thiab cov txheej txheem vuam tsis zoo thiab kev tshawb nrhiav hauv online, kev ruaj khov vuam zoo tuaj yeem tau txais. Tsis tas li ntawd, cov khoom siv vuam tau raug nthuav dav ntxiv, thiab daim ntawv thov ntau yam ntawm kev siv vuam vuam yog ntau dua thiab dav. Nrog rau kev vam meej tsis tu ncua ntawmtiv thaiv vuam tshuab, kuj welding yuav nyob rau hauv ib tug tseem ceeb txoj hauj lwm nyob rau hauv lub neej yav tom ntej industrial ntau lawm. Tshwj xeeb tshaj yog nyob rau hauv lub welding teb ntawm loj cross-section thiab dissimilar hlau, flash taub qab vuam muaj ib tug zoo txoj kev vam meej.

Cov ntsiab lus

Nrog rau txoj kev loj hlob ntawm lub zog tshiab kev lag luam, ntau thiab ntau welding daim ntawv thov ntawm tooj liab thiab txhuas kev twb kev txuas, kuj welding tshuab cia li ua raws li cov kev xav tau ntawm kev ua lag luam, ua ke nrog cov tshiab kuj welding txheej txheem thiab adaptive tswj technology, kuj welding nyob rau hauv lub neej yav tom ntej txoj kev loj hlob yuav. usher nyob rau hauv ib tug loj boom.

Post lub sij hawm: Aug-30-2024