Yog tias koj tshiab rau kev tiv thaiv vuam lossis nrhiav kev nkag siab zoo dua ntawm nws, ces koj yuav tsum tau nyeem cov lus no kom zoo. Qhov tsab xov xwm no yuav coj koj mus tob rau hauv lub ntiaj teb no ntawm kuj welding. Txawm hais tias koj yog tus pib los yog tab tom nrhiav kom nthuav koj txoj kev paub, kab lus no yuav muab cov kev nkag siab zoo rau koj.

Resistance Welding yog dab tsi?

Resistance vuam yog ib qho kev kub ceev, kev lag luam hlau koom nrog txoj kev. Cov txheej txheem vuam no yog tsim rau cov pob qij txha, pob qij txha, lossis cov pob qij txha uas tsis tas yuav tsum muaj huab cua nruj, nrog cov thicknesses tsawg dua 6 hli rau cov ntawv nyias nyias. Tau kawg, nws tseem tuaj yeem txuas cov hlau ua haujlwm hnyav dua thiab loj dua, tab sis nws qhov kev ua tau zoo tag nrho yuav tsis zoo li qee yam kev siv vuam.

Txhais thiab Cov Ntsiab Cai

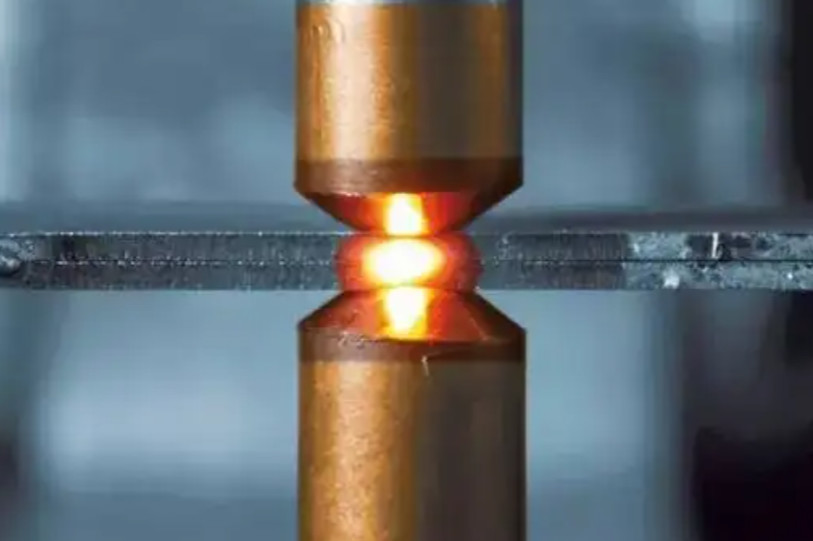

Kuj weldingyog ib txoj kev uas cov workpieces yuav tsum tau muab tso rau ntawm ob electrodes. Los ntawm kev hla tam sim no los ntawm cov khoom ua haujlwm thiab cov ntsiab lus sib cuag, cov cua sov ua haujlwm tshwm sim, ua kom muaj cua sov ntawm qhov sib txuas ntawm cov khoom ua haujlwm. Cov cua sov hauv cheeb tsam no ua rau thaj chaw yaj lossis ua kom muaj zog, thaum lub zog los ntawm ob lub electrodes bonds cov hlau ua ke.

Thaum tam sim no ntws los ntawm ib tug conductor, nws generates tshav kub vim tsis kam. Qhov siab dua qhov kev tiv thaiv thaum qhov tam sim no tsis tu ncua, qhov kub ntau yog tsim. Ntawm qhov chaw uas cov hlau nyob rau hauv kev sib cuag, qhov kev tiv thaiv yog ntau dua nyob rau hauv cov hlau nws tus kheej. Yog li ntawd, thaum ib tug loj tam sim no dhau los ntawm kev sib cuag ntawm cov hlau thiab cov electrode, cov hlau sai sai heats li vim lub loj heev tshav kub. Nyob rau lub sijhawm no, cov hlau ua tau zoo heev, thiab nrog kev siv siab, ob daim hlau ruaj khov ua ke.

Resistance Welding Txoj Cai Ua Haujlwm

Lub hauv paus ntsiab lus ntawm kev tiv thaiv qhov chaw vuam thiab tsim cov pob qij txha yog qhia hauv daim duab 1-1. Hlau A thiab hlau B yog muab tso rau ntawm ob lub electrodes, thiab lub siab yog siv rau electrodes. Lub zog tam sim no dhau ntawm ob lub electrodes los ntawm kev hloov pauv ntawm cov welder tsis kam. Qhov chaw sib cuag ntawm lub workpieces tsim ib qho kev sib cuag ntawm lub cev, uas maj mam nthuav tawm raws li qhov tam sim no heats nws. Yas deformation thiab kub tsis tu ncua ua kom cov atoms ntawm qhov chaw sib cuag, ua rau tsim cov molten core. Lub molten core hlob nyob rau hauv daim ntawv ntawm columnar crystals, thawb tawm lub siab dua alloy concentration Cheebtsam ntawm ib leeg. Thaum cov electrodes ntawm lub welder txav deb ntawm cov hlau nto, thiab cov hlau txias, cov workpieces yog welded ua ke, tsim kom muaj ib tug muaj zog hlau daim ntawv cog lus. Qhov sib koom ua ke ploj mus, tawm hauv qab lub weld nugget.

1-1

Cov yam ntxwv cuam tshuam rau kev tiv thaiv vuam

Kuj weldingyog ib txoj kev vuam uas siv hluav taws xob tam sim no los ua kom muaj cua sov los koom nrog cov khoom siv hlau. Raws li tau hais ua ntej, lub hauv paus ntsiab lus ntawm kev siv vuam vuam feem ntau yog los ntawm Joule txoj cai ntawm kev siv cua sov, qhov chaw ntawm vuam cov cua sov yog feem ntau txiav txim siab los ntawm cov tsis xws li tam sim no, tsis kam, thiab vuam lub sij hawm. Nws tuaj yeem hais tau los ntawm cov qauv hauv qab no:

Q = I² Rt

Lub ntsiab lus ntawm txhua qhov welding parameter:

Q — Thaum tshav kub kub (J)

I - Vuam tam sim no (A)

R - Kuj (Ω)

t - Vuam lub sij hawm (s)

Vuam tam sim no

Cov tam sim no muaj kev cuam tshuam tseem ceeb rau cov cua sov uas tsim thaum lub sij hawm vuam, raws li qhia hauv cov qauv. Tus nqi square ntawm tam sim no cuam tshuam cov cua sov, txhais tau hais tias qhov siab dua tam sim no, qhov kub yuav nce sai dua. Yog li ntawd, thaum kho vuam tsis ua ntej welding, nws yog ib qho tseem ceeb kom teem lub tam sim no tsim nyog. Yog tias qhov vuam tam sim no me dhau, qhov vuam yuav tsis yaj, thiab tsis muaj fusion core yuav tsim. Yog tias qhov tam sim no loj dhau lawm, fusion core yuav loj hlob sai, ua rau muaj kev sib tsoo ntau dhau thaum vuam thiab ua rau cov electrodes puas.

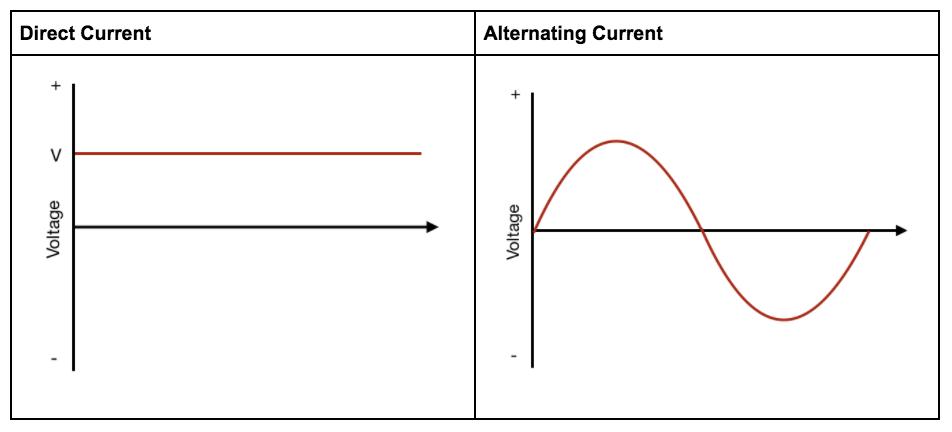

Vuam tam sim no feem ntau muab faib ua alternating tam sim no (AC) thiab ncaj qha tam sim no (DC), raws li qhia hauv daim duab hauv qab no. Covchaw vuam tshuabpeb siv kuj tau muab faib mus rau hauv ncaj qha tam sim no qhov chaw vuam tshuab thiab alternating tam sim no qhov chaw vuam tshuab. Lub tshuab vuam ncaj nraim tam sim no siv peb-theem fais fab mov, ua kom muaj zog sib npaug, thiab tuaj yeem ua tiav vuam zaus ntau dua 1000 Hz, ua rau muaj qhov raug vuam siab. Lawv kuj muaj qhov zoo ntawm qhov xav tau ntawm cov hluav taws xob tsawg los ntawm daim phiaj hluav taws xob, ua rau cov khoom siv hluav taws xob txuag hluav taws xob tau nrov ntawm cov tuam txhab tsim khoom lag luam. Alternating tam sim no qhov chaw vuam tshuab muaj ib theem 50Hz tso zis, siab nruam load peev xwm, thiab siab xav tau rau daim phiaj fais fab. Tsis tas li ntawd, lawv muaj lub zog vuam qis, xav tau lub sijhawm vuam ntev.

Tiv tauj Resistance

Los ntawm cov mis, nws yog ib qho yooj yim kom pom tias tsis kam yog ncaj qha proportional rau lub tshav kub generated. Qhov siab dua qhov tsis kam, qhov ntau dua cov cua sov tsim thaum lub sij hawm vuam. Tsis kam yog muab faib thoob plaws ntau qhov chaw ntawm electrode thiab workpiece. Thaum lub sij hawm vuam, qhov siab tshaj plaws kuj tshwm sim ntawm qhov chaw sib cuag ntawm lub workpiece, uas ua rau lub siab tshaj plaws kub tiam. Tom ntej no yog qhov tsis kam ntawm qhov chaw sib cuag ntawm lub workpiece thiab electrode. Txawm li cas los xij, txij li cov electrode yog dej-txias thiab txias sai sai, qhov kub thiab txias yuav txo qis. Ntawm qhov tod tes, kev sib cuag ntawm cov khoom ua haujlwm, txawm tias nws ploj mus, muaj cov cua sov tsis zoo, ua rau muaj qhov kub thiab txias. Yog li ntawd, tsuas yog ib cheeb tsam me me ntawm cov workpieces tuaj yeem ncav cuag qhov kub thiab txias tsim nyog los tsim cov fusion core thiab weld ua ke.

Tsis tas li ntawd, kub thiab electrode siab cuam tshuam rau qhov tsis kam. Raws li qhov kub thiab txias, cov hlau yield zog txo qis, ua rau thaj chaw sib cuag ntawm cov khoom ua haujlwm thiab nruab nrab ntawm cov khoom ua haujlwm thiab cov electrode, uas ua rau tsis muaj zog. Ua kom cov electrode siab ua rau lub workpiece nto smoother, ua kom cov cheeb tsam sib cuag thiab txo qhov tsis kam. Raws li qhov tshwm sim, muaj qhov tshwm sim uas, thaum lub sij hawm vuam ntawm cov ntaub ntawv raug, qhov kev tiv thaiv nce sai tom qab lub hwj chim, thiab thaum lub hwj chim raug kaw thiab cov ntaub ntawv fusion core, qhov kev tiv thaiv pib txo.

Lub sijhawm vuam

Lub sijhawm vuam ntev dua, qhov siab dua qhov kub tsim. Hauv cov qauv no, tam sim no thiab lub sijhawm tuaj yeem ua tiav ib leeg. Thaum koj xav tau ib qho kev sib txuas uas muaj zog, koj tuaj yeem teeb lub siab tam sim no rau lub sijhawm luv luv los tsim kom muaj cua sov sai thiab tsim cov fusion core kom tiav qhov vuam. Xwb, koj tuaj yeem teem caij qis rau lub sijhawm ntev, tab sis muaj qhov txwv rau txoj hauv kev no. Yog tias lub sijhawm teem sijhawm ntev dhau lawm, nws tuaj yeem ua rau tawg ntau dhau thiab yuav ua rau cov electrode lo. Txawm nws yog tam sim no lossis lub sijhawm, muaj kev txwv. Thaum teeb tsa qhov ntsuas, koj yuav tsum xav txog cov khoom siv thiab thickness ntawm lub workpiece, nrog rau lub zog ntawm lub vuam tshuab.

Khoom Khoom

Cov khoom siv ntawm lub workpiece feem ntau cuam tshuam rau nws qhov kev tiv thaiv, uas ua lub luag haujlwm tseem ceeb hauv kev tsim cov cua sov. Thaum welding stainless hlau, uas muaj kev tiv thaiv siab thiab tsis zoo thermal conductivity, nws yooj yim dua los tsim kom sov tab sis nyuaj rau dissipate nws, yog li me me tam sim no xav tau. Thaum vuam aluminium alloys uas tsis tshua muaj kev tiv thaiv thiab zoo thermal conductivity, nws yog ib qho nyuaj rau tsim kom sov tab sis yooj yim rau dissipate nws, yog li yuav tsum tau loj tam sim no. Cov hlau zoo li cov nyiaj thiab tooj liab muaj cov thermal conductivity thiab tsis tshua muaj zog, yog li txawm tias muaj cov dej ntws siab, lawv tsis tsim kom muaj cua sov ntau tab sis tuaj yeem ua rau nws tawm mus. Yog li ntawd, cov hlau no tsis haum rau kev siv vuam, tab sis tuaj yeem siv los ua cov khoom siv electrode.

Electrode Tsim thiab Geometry

Cov duab thiab cov khoom siv ntawm electrode kuj cuam tshuam rau kev tsim hluav taws xob. Qhov chaw sib cuag ntawm lub electrode thiab lub workpiece cuam tshuam rau qhov ceev tam sim no. Kev siv cov electrodes nquag tuaj yeem ua rau hnav thiab deformation, ua rau thaj chaw sib cuag thiab txo qhov vuam lub zog. Yog li ntawd, peb yuav tsum tau kho thiab hloov cov lus qhia electrode tam sim ntawd. Lub thermal conductivity thiab tsis kam ntawm electrode cuam tshuam rau kev hloov hluav taws xob. Yog li ntawd, peb yuav tsum xaiv cov ntaub ntawv uas muaj thermal conductivity zoo thiab tsis muaj zog.

Kev npaj nto

Cov duab thiab cov khoom siv ntawm cov electrodes kuj cuam tshuam rau kev tsim hluav taws xob. Qhov chaw sib cuag ntawm lub electrode thiab lub workpiece cuam tshuam rau qhov ceev tam sim no. Thaum peb cov electrodes tau siv ntau zaus thiab hnav tawm, nws ua rau thaj chaw sib cuag, ua rau txo qis zog vuam. Yog li ntawd, peb yuav tsum tau kho thiab hloov cov lus qhia electrode tam sim ntawd. Lub thermal conductivity thiab resistivity ntawm cov electrodes cuam tshuam rau kev hloov hluav taws xob. Yog li ntawd, peb yuav tsum xaiv cov khoom uas muaj thermal conductivity thiab tsis tshua muaj resistivity.

Hom Ntawm Resistance Vuam

Vim yog cov khoom sib txawv thiab cov kev xav tau rau vuam, cov txheej txheem vuam sib txawv yog siv los ua kom tiav cov haujlwm. Resistance welding tuaj yeem muab faib ua qhov chaw vuam, qhov projection welding, seam vuam, thiab taub qab vuam raws li txheej txheem vuam.

Spot Vuam

Spot vuamyog ib txoj kev vuam uas hlau yog nias ua ke los ntawm sab sauv thiab qis electrodes thiab welded los ntawm kev hla tam sim no los ntawm nws. Nws yog ib hom kev siv vuam vuam, yooj yim rau kev khiav lag luam, thiab yuav tsum tau muaj kev txawj ntse los ntawm cov neeg ua haujlwm. Vim nws cov txheej txheem vuam tshwj xeeb, qhov chaw vuam yog qhov kev xaiv tseem ceeb rau vuam hlau cov khoom hauv aerospace engineering thiab yog siv dav hauv vuam tsheb lub cev thiab lwm yam khoom. Nws feem ntau yog siv rau vuam cov ntawv nyias ntawm cov pa roj carbon tsawg, txhuas, stainless hlau, galvanized steel, thiab lwm yam nyias daim hlau, feem ntau nyob ib ncig ntawm 3 millimeters tuab.

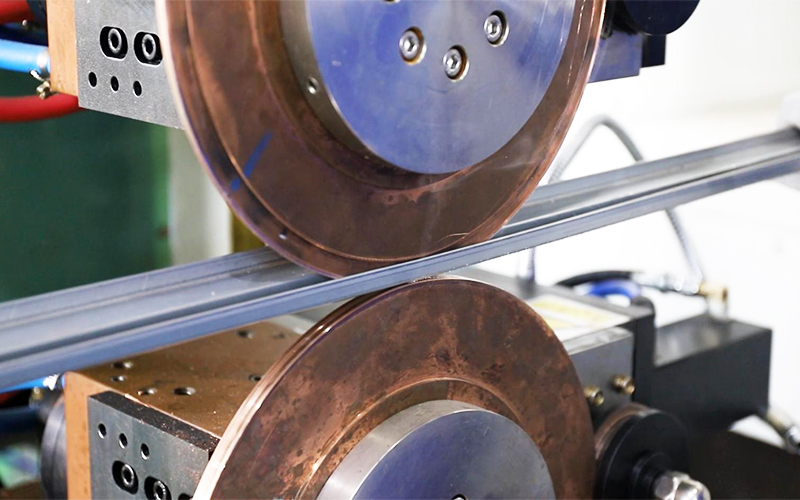

Seam Vuam

Seam vuamfeem ntau yog koom nrog cov npoo ntawm ob lub ntsiab lus hlau. Ob lub hlau ua haujlwm tau muab tso rau ntawm ob lub tshuab electrodes. Thaum ib qho electrode dov thiab siv lub siab, txuas ntxiv lossis cuam tshuam cuam tshuam tshwm sim. Thaum tshav kub kub generated ntawm lub electrode dov point melts lub workpieces thiab koom ua ke, tsim ib tug nruam weld seam. Txoj kev no yog dav siv rau vuam hlau qhov uas yuav tsum tau kaw cov pob qij txha. Txij li qhov chaw vuam yog qhov ntev, txhawm rau tiv thaiv qhov tsis zoo, peb feem ntau siv qhov chaw vuam rau qhov chaw ua ntej seam welding.

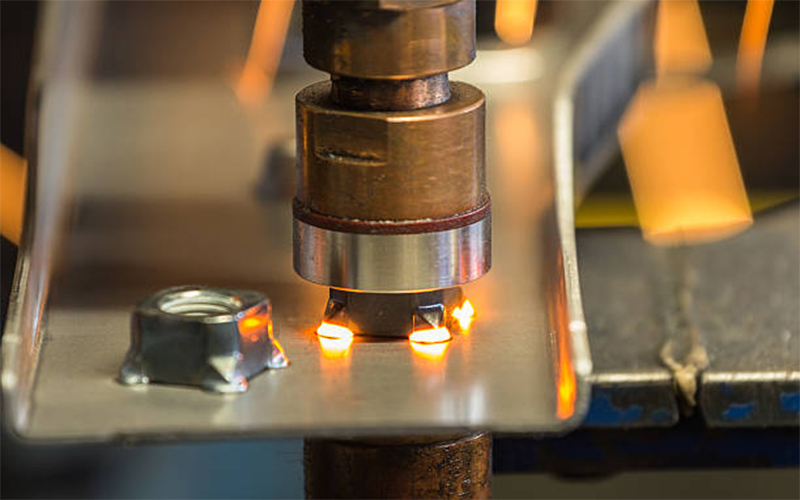

Projection Vuam

Projection vuamyog qhov sib txawv ntawm qhov chaw vuam, qhov tsim ntawm qhov chaw vuam zoo ib yam li qhov chaw vuam, tab sis qhov projection vuam feem ntau yog siv rau cov khoom ua haujlwm nrog cov ntsiab lus tsa. Lub xub ntiag ntawm cov ntsiab lus tsa no txwv cov cheeb tsam uas tam sim no dhau mus, ua kom qhov ceev tam sim no nyob rau hauv qhov chaw vuam. Qhov cua sov no ua kom yooj yim rau kev sib txuas ntawm qhov sib koom ua ke. Txoj kev vuam no yog hu ua projection welding. Projection welding tuaj yeem tsim ib lossis ntau lub fusion cores ntawm qhov sib koom ua ke ib zaug. Thaum lub sij hawm welding, qhov tam sim no yuav tsum tau rau qhov projection vuam ntawm tib qhov chaw vuam yog tsawg dua qhov chaw vuam. Txawm li cas los xij, ua ntej txhua qhov projection yog crushed, tam sim no yuav tsum tau yaj lub projection; txwv tsis pub, tej zaum yuav muaj ib tug loj npaum li cas ntawm spatter. Qhov projection welding tuaj yeem siv los txuas cov txiv ntseej, bolts, lossis daim hlau nrog cov ntsiab lus tsa thiab yog siv dav hauv kev tsim cov khoom siv hluav taws xob thiab tsheb.

Butt Vuam

Butt vuamNws suav nrog kev ua kom lub ntsej muag kawg ntawm ob lub hlau ua haujlwm, muab tso rau ntawm cov electrodes, ruaj ntseg fastening ob lub workpieces, thiab siv cov tam sim no siab los ua kom sov, melting qhov chaw ntawm lub workpieces thiab koom ua ke. Butt welding ntxiv muab faib ua flash butt welding thiab kuj pob tw vuam.

Flash pob tw welding yog txheej txheem vuam ceev uas siv tam sim no kom yaj cov workpieces sai sai, siv lub zog los tsim cov khoom sib txuas. Nws yog feem ntau siv rau vuam loj hla ntu ntawm cov hlau rods, nplooj ntawv, thiab cov kav dej, nrog rau qhov siab tshaj plaws mus txog 20,000mm² thiab siab dua. Thaum lub sij hawm tawm welding txheej txheem, sparks yog tsim nyob rau ntawm qhov chaw sib cuag, li no lub npe flash taub qab vuam. Nws tuaj yeem welding siab carbon steel, stainless hlau, aluminium alloys, thiab tseem tuaj yeem vuam cov hlau sib txawv xws li tooj liab thiab txhuas.

Resistance butt welding siv cov cua sov ua haujlwm kom coj cov pob qij txha ua haujlwm rau lub xeev yas ntawm qhov kub thiab txias, ua tiav cov txheej txheem vuam nrog forging quab yuam. Nws yog qhov tsim nyog rau kev sib koom tes sib txuas nrog cov chaw hla ntu hauv 250mm², feem ntau siv rau vuam me me hla ntu hlau xaim, rods, thiab strips.

Qhov tseem ceeb hauv Kev Tsim Khoom

- Kev tiv thaiv vuam tsis tas yuav tsum tau sib ntxiv ntawm cov hlau thaum lub sij hawm vuam, uas ua rau vuam efficiency thiab tsawg kawg nkaus.

- Vim nws qhov sib xws thiab kev ruaj ntseg, kev siv vuam vuam yog ib qho yooj yim rau automate, seamlessly integrating nrog automation los txhim kho ntau lawm efficiency thiab txuag zog.

- Piv nrog rau lwm txoj kev vuam, kev siv vuam tsis zoo yog tus nqi zoo. Ua ntej, cov cuab yeej siv rau kev ua haujlwm vuam yog qhov tsawg, thiab qhov thib ob, muaj cov khoom siv tsawg tsawg thaum lub sij hawm vuam txheej txheem. Qhov no txo qis cov nqi tsim khoom rau cov tuam txhab hauv kev tsim khoom.

- Resistance vuam yog dav siv nyob rau hauv ntau yam lag luam thiab yog tshwj xeeb yog indispensable nyob rau hauv cov sectors xws li aerospace, automotive manufacturing, thiab ntau dua.

- Resistance vuam yog tsim rau vuam ntau hom hlau hauv kev lag luam tsim, xws li stainless hlau, carbon hlau, txhuas, tooj liab, thiab lwm yam, ua rau nws muaj ntau yam hauv nws daim ntawv thov.

Daim ntawv thov

Resistance vuam yog siv dav, feem ntau hauv kev lag luam xws li cov khoom siv tsheb, aerospace, electronics, thiab kev lag luam hnyav. Raws li qhov kev thov rau welded hlau Cheebtsam nyob rau hauv ntau yam industries tseem loj hlob, cov txheej txheem siab dua rau vuam tshuab tau teem, tsav txoj kev vam meej thiab kev loj hlob ntawm kuj welding.

Automotive Industry Applications

Hauv kev tsim tsheb, qhov kev nyab xeeb thiab kev ruaj ntseg yog qhov tseem ceeb, kev siv vuam vuam yog ib txoj kev siv vuam ntau. Nws nquag ua haujlwm rau kev koom nrog ntau yam hlau hauv lub cev tsheb, xws li lub ru tsev, qhov rooj, cov ntawv hlau, thiab cov txiv ntoo hlau. Resistance welding muaj kev ua haujlwm siab, ruaj khov vuam zoo, thiab yooj yim automated, ua rau nws yog ib qho tseem ceeb hauv kev lag luam tsheb tsim.

Aerospace Kev Lag Luam Kev Lag Luam

Resistance welding feem ntau yog siv los txuas cov khoom siv hlau hauv cov dav hlau thiab foob pob hluav taws, xws li koom nrog cov dav hlau tis thiab fuselages, nrog rau ntau yam hlau me me. Cov khoom no yuav tsum muaj lub zog siab thiab ua haujlwm ntev, nrog rau cov kev xav tau nruj heev rau qhov zoo ntawm cov pob qij txha, uas yog qhov zoo ntawm cov vuam zoo. Kev tiv thaiv vuam ua lub luag haujlwm tseem ceeb hauv kev lag luam aerospace, thiab kev nce qib hauv daim teb no kuj tau txhawb nqa los ntawm aerospace sector.

Kev Siv Hluav Taws Xob Kev Lag Luam

Resistor vuam feem ntau yog siv rau cov khoom siv hluav taws xob thiab qee yam hlau hauv cov khoom siv hluav taws xob. Nws muaj cov vuam precision siab thiab tsim nyog rau kev sib txuas cov khoom me me xws li cov khoom siv hluav taws xob thiab cov xov hlau. Nyob rau hauv niaj hnub evolving era ntawm cov khoom siv hluav taws xob, resistor welding accelerates kev sib dhos ntawm cov khoom siv hluav taws xob, tsav tsheb kev lag luam nce qib.

Kev lag luam hnyav

Resistance welding feem ntau yog siv rau vuam cov hlau loj hauv cov txuas hniav thiab cov tsev, xws li choj hauv qab flanges thiab steel reinforcement. Nws kuj tseem siv rau hauv kev tsim cov tshuab loj los txuas cov khoom hlau. Nrog nws cov cuab yeej siv tau zoo thiab ruaj khov, vuam vuam tau dhau los ua ib txoj hauv kev tseem ceeb hauv kev lag luam hnyav. Nws ua kom muaj kev nyab xeeb ntawm cov cuab yeej hnyav thiab cov qauv.

Cov khoom siv thiab cov khoom siv

Vuam Tshuab

Kuj welding tshuabtau muab faib ua plaub pawg loj: qhov chaw vuam tshuab, qhov projection vuam tshuab, seam vuam tshuab, thiab pob tw vuam tshuab, raws li cov txheej txheem sib txawv. Xaiv cov khoom siv vuam tsim nyog raws li cov yam ntxwv ntawm cov ntaub ntawv thiab cov duab.

Cov hluav taws xob

Covelectrodeyog ib qho tseem ceeb tivthaiv kom ntseeg tau tias vuam zoo. Cov ntaub ntawv tseem ceeb rau vuam electrodes yog: chromium zirconium tooj liab, txhuas oxide tooj liab, beryllium cobalt tooj liab, tungsten, molybdenum, graphite, thiab lwm yam. Nyob ntawm qhov sib txawv workpieces raug welded, electrodes tau muab faib ua cov electrodes, spherical electrodes, txiv ntseej electrodes, ntsia liaj qhov rooj. electrodes, thiab lwm yam. Feem ntau, electrode fixation yuav tapered haum, nrog taper ratios feem ntau nyob rau hauv 1:10 thiab 1:5.

Txias Systems

Thaum lub sijhawm ua haujlwm, cov tshuab vuam tsis zoo yuav tsum tau siv cov dej kom txias xws li electrodes thiab transformers. Yog li ntawd, peb nruab ib lub tshuab cua txias rau kev siv vuam tshuab. Cov dej txias txias yuav tsum qis dua 30 ° C. Yog tias qhov kub thiab txias dhau lawm, nws yuav ua rau muaj kev tiv thaiv ntawm lub tshuab vuam. Nws yog qhov zoo tshaj plaws los siv cov dej txias uas tsis muaj impurity-dawb rau kev ncig los tiv thaiv cov dej stains thiab cov yeeb nkab thaiv.

Yuav Ua Li Cas Xaiv Txoj Kev Vuam Zoo?

Kev xaiv ntawm txoj kev vuam yog nyob ntawm ntau yam.

Workpiece Thickness thiab Zoo: txawvwelding txoj kevyog tsim rau workpieces ntawm txawv thicknesses thiab duab. Piv txwv li, kev siv vuam tsis kam yog feem ntau tsuas yog tsim rau vuam nyias cov nplooj ntawv, thaum cov oddly zoo li tus thiab tuab workpieces feem ntau welded siv arc vuam.

Welding Quality Requirements: Qhov xav tau vuam zoo kuj tseem hais txog kev xaiv vuam txoj kev. Rau cov khoom ua haujlwm uas xav tau kev sib khi siab thiab sib koom ua ke, cov txheej txheem vuam uas ua tau raws li cov cai no yuav tsum tau xaiv.

Kev Ua Tau Zoo thiab Tus Nqi: Yog tias yuav tsum muaj qhov ntim ntau lawm txhua xyoo, xaiv txoj kev vuam nrog kev ua haujlwm siab yog tsim nyog. Cov nqi txiav txim siab kuj yuav tsum tau muab rau hauv tus account.

Environmental Factors: Qee txoj kev vuam tsim cov khoom pov tseg thiab emissions, ua rau muaj kuab paug ib puag ncig. Yog li ntawd, kev txiav txim siab ib puag ncig yuav tsum tau coj mus rau hauv tus account thaum xaiv txoj kev vuam.

FAQ:

Dab tsi yog qhov txwv ntawm kev siv vuam vuam?

Kev tiv thaiv vuam tsis haum rau vuam cov hlau loj.

Koj ua li cas kom muaj kev nyab xeeb hauv kev siv vuam vuam?

Thaum ua haujlwm tsis kam vuam, hnav lub kaus mom kev nyab xeeb thiab looj tsom iav.

Kuv tuaj yeem tau txais kev cob qhia hauv kev siv vuam vuam li cas?

Koj tuaj yeem tau txais kev cob qhia ntawm akuj welding chaw tsim tshuaj paus.

Dab tsi yog qhov teeb meem tseem ceeb ntawm kev tiv thaiv vuam pob qij txha?

Cold solder joint, tsis muaj zog, vuam deformation, oxidation.

Kev tshuaj xyuas txoj kev tiv thaiv vuam pob qij txha

Kev ntsuam xyuas kev puas tsuaj, kev kuaj xyuas microscopic, kuaj pom, kuaj metallographic, kuaj ultrasonic.

Post lub sij hawm: Apr-02-2024