Seam welding yog cov txheej txheem vuam nyuaj.Cov kab lus no tshawb txog qhov tsis sib xws ntawm seam welding, los ntawm nws cov qauv kev ua haujlwm rau nws cov kev siv, qhov zoo, thiab cov nyom. Txawm hais tias koj yog tus tshiab rau vuam los yog tab tom nrhiav kom nkag siab koj txoj kev nkag siab ntawm cov txheej txheem kev lag luam tseem ceeb no, cov lus qhia no yuav muab kev nkag siab zoo rau kev siv vuam seam ua haujlwm li cas thiab nws feem ntau siv qhov twg.

Taw qhia rau Seam Vuam

Seam welding yog ib hom tshwj xeeb ntawmkuj welding txheej txheemqhov twg ob los yog ntau tshaj ntawm cov hlau tau koom ua ke nrog ib tug nruam seam los yog series ntawm overlapping chaw welds. Nws yog dav siv nyob rau hauv kev lag luam uas yuav tsum tau airtight los yog watertight pob qij txha, xws li automotive, aerospace, thiab manufacturing sectors. Tsis zoo li cov khoom siv vuam ib txwm siv, uas tsim cov ntsiab lus ntawm tus kheej, cov vuam vuam ua rau muaj kev sib txuas, muaj zog vuam los ntawm kev siv cov electrodes uas txav mus raws qhov sib koom ua ke, fusing cov ntaub ntawv ua ke.

Seam Vuam ua haujlwm li cas

Seam welding ua haujlwm ntawm tib lub hauv paus ntsiab lus raws li kev tiv thaiv vuam:hluav taws xob tsis kam yog siv los ua kom sov, uas melts cov ntaub ntawv raug welded ua ke. Txawm li cas los xij, seam welding distinguishes nws tus kheej los ntawm yuav ua li cas lub vuam siv txuas ntxiv raws qhov ntev ntawm lub workpiece. Hauv qab no yog ib qho kev tawg ntawm cov ntsiab lus tseem ceeb thiab cov txheej txheem ua haujlwm li cas.

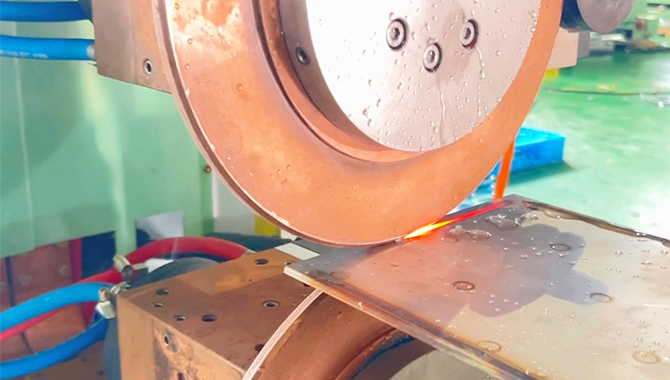

Rotating electrodes:Lub plawv ntawm cov txheej txheem vuam seam yog siv ob lub cylindrical, tig electrodes, feem ntau yog ua los ntawm tooj liab lossis lwm yam khoom siv hluav taws xob. Cov electrodes no nias tawm tsam cov hlau daim, muab ob qho tib si hluav taws xob tam sim no thiab txhua yam quab yuam yuav tsum tau los tsim cov vuam. Raws li cov electrodes tig, lawv txav mus raws qhov ntev ntawm qhov sib koom ua ke, siv lub siab thiab tam sim no tsis tu ncua.

Daim ntawv thov tam sim no:Ib qho hluav taws xob tam sim no dhau los ntawm cov electrodes, tsim kev tawm tsam ntawm qhov chaw uas ob daim hlau kov. Cov tsis kam ua kom sov, ua rau cov hlau yaj thiab fuse ua ke. Nyob rau hauv seam welding, qhov tam sim no yog siv nyob rau hauv ib tug pulsed los yog nruam yam, nyob ntawm seb hom vuam tshwj xeeb (sib tham ntxiv hauv qab no).

Siab thiab txias:Raws li qhov tam sim no ntws, cov rotating electrodes siv tas li mus rau lub workpiece, xyuas kom meej tias cov khoom molten solidifies mus rau hauv ib tug muaj zog, nruam weld. Cov electrodes kuj tseem ua lub tshuab ua kom txias, pab tswj qhov kub thiab txias thiab tiv thaiv kom tsis txhob muaj cua sov, uas tuaj yeem ua rau cov vuam lossis cov ntaub ntawv ib puag ncig puas.

Kev txav mus tas li:Qhov kev sib hloov ntawm cov electrodes yog dab tsi teev seam welding sib nrug los ntawm lwm yam kev siv vuam vuam. Cov electrodes txav mus raws txoj kab sib txuas ntawm qhov kev tswj ceev, kom ntseeg tau tias cov cua sov yog siv sib npaug ntawm tag nrho qhov ntev ntawm cov seam. Qhov tshwm sim weld yog muaj zog, zoo ib yam, thiab feem ntau cua-los yog kua-tight.

Hom Seam Vuam

Seam welding tuaj yeem muab faib ua ob hom tseem ceeb raws li kev siv tam sim no:

Nruam Seam Vuam

Nyob rau hauv txoj kev no, ib qho hluav taws xob tsis tu ncua yog siv thaum cov electrodes txav raws qhov sib koom ua ke. Qhov no ua rau muaj kev sib txuas txuas ntxiv uas zoo li cov hlaws dai. Nruam seam vuam feem ntau yog siv thaum yuav tsum tau airtight los yog watertight foob, xws li nyob rau hauv tso tsheb hlau luam los yog roj kav.

Intermittent Seam Vuam

Kuj hu ua yob qhov chaw vuam, txoj kev no siv hluav taws xob tam sim no hauv pulses thaum lub electrodes txav. Qhov tshwm sim yog ib qho kev sib tshooj ntawm qhov chaw welds uas tsim ib lub seam. Hom kev sib khi no feem ntau siv thaum kev ua haujlwm ruaj khov yog qhov tseem ceeb tshaj li qhov airtightness, xws li hauv qee yam kev siv tsheb.

Cov ntaub ntawv tsim nyog rau Seam Vuam

Seam vuam tshuabtshwj xeeb tshaj yog zoo rau cov hlau uas ua hluav taws xob zoo thiab muaj qhov qis melting. Cov ntaub ntawv uas muaj xws li:

Hlau:Ob qho tib si qis-carbon thiab stainless hlau feem ntau yog seam welded hauv tsheb thiab kev siv tshuab.

Aluminium:Thaum nyuaj dua vim nws cov conductivity ntau dua, aluminium feem ntau seam welded hauv aerospace thiab manufacturing.

Copper Alloys:Tooj's zoo heev conductivity ua rau nws zoo tagnrho rau siv nyob rau hauv cov khoom uas yuav tsum tau high thermal thiab hluav taws xob efficiency, xws li radiators thiab hluav taws xob enclosures.

Daim ntawv thov ntawm Seam Vuam

Seam welding yog dav siv hauv kev lag luam uas xav tau lub zog siab, airtight, los yog kua-tight pob qij txha. Hauv qab no yog qee qhov kev siv ntau tshaj plaws:

Automotive Kev Lag Luam:Seam welding feem ntau yog siv los tsim cov khoom siv tsheb xws li roj tso tsheb hlau luam, mufflers, thiab lub log rims. Qhov txuas txuas txuas ntxiv ua kom ntseeg tau tias cov khoom no yog airtight thiab ruaj khov, muaj peev xwm tiv taus ib puag ncig hnyav thiab kev kub ntxhov.

Aerospace:Kev lag luam aerospace feem ntau xav tau cov khoom hnyav tsis tau muaj zog, thiab vuam seam yog ua haujlwm los koom nrog cov ntawv nyias nyias ntawm txhuas thiab hlau. Nyob rau hauv daim teb no, qhov xav tau kev txhim khu kev qha, airtight, thiab watertight pob qij txha yog ib qho tseem ceeb rau cov roj systems thiab cov khoom siv.

Manufacturing ntawm Tanks thiab Thawv:Seam welding feem ntau yog siv los tsim cov roj tso tsheb hlau luam, cov tank dej, thiab cov ntim tshuaj uas yuav tsum tau muab kaw kom tsis txhob muaj dej. Cov kab txuas txuas txuas ntxiv ua kom muaj kev ncaj ncees ntawm lub tank, ua kom nws haum rau tuav cov kua lossis roj hauv qab lub siab.

Hlau thiab Tubes:Seam welding yog siv los tsim cov kav hlau thiab cov raj rau ntau yam kev lag luam, suav nrog roj thiab roj, kav dej, thiab kev tsim kho. Cov txheej txheem ua kom muaj qhov nruam, xau-pov thawj seam uas tuaj yeem tiv taus sab hauv.

Khoom noj khoom haus thiab dej haus ntim:Hauv kev lag luam ntim khoom, seam welding yog ua haujlwm los tsim cov kaus poom hlau, ntim, thiab hau. Qhov precision thiab ceev ntawm seam welding ua rau nws yog ib qho kev xaiv zoo tshaj plaws rau kev tsim khoom loj, kom ntseeg tau tias cov khoom raug kaw ruaj ntseg thiab nyob twj ywm tsis muaj menyuam.

Hluav taws xob Cheebtsam:Seam welding kuj tseem siv los tsim cov khoom xws li radiators, cua sov cov ntsiab lus, thiab cov khoom siv hluav taws xob. Lub nruam seam ua kom muaj hluav taws xob txuas ntxiv thiab kev ua haujlwm ruaj khov.

Qhov zoo ntawm Seam Vuam

Seam welding muaj ntau yam txiaj ntsig dua lwm cov txheej txheem vuam, ua rau nws yog qhov kev xaiv nrov hauv kev lag luam uas yuav tsum tau ua kom ruaj khov, cov pob qij txha zoo. Nov yog qee qhov txiaj ntsig tseem ceeb:

Ceev thiab Efficiency: Seam welding yog heev npaum, tshwj xeeb tshaj yog nyob rau hauv tas li lawm ntau lawm chaw. Cov txheej txheem automated tso cai rau kev vuam ceev raws li tag nrho qhov ntev ntawm cov seam, txo lub sijhawm ntau lawm.

Strong, Consistent Welds: Cov xwm txheej tas mus li ntawm seam welding kom ntseeg tau tias cov vuam zoo sib xws thoob plaws qhov sib koom ua ke, ua rau muaj kev sib txuas zoo dua, txhim khu kev qha. Qhov kev sib xws no txo cov kev pheej hmoo ntawm cov teeb meem xws li cov kab nrib pleb lossis qhov chaw tsis muaj zog.

Airtight thiab Watertight Seals: Seam welding yog qhov zoo tagnrho rau cov ntawv thov uas qhov sib koom ua ke yuav tsum raug kaw tag nrho, xws li hauv cov tso tsheb hlau luam, cov kav dej, thiab cov thawv ntim khoom. Qhov txuas txuas txuas ntxiv kom ntseeg tau tias tsis muaj qhov khoob uas cov cua lossis cov kua tuaj yeem dhau mus.

Tsawg Distortion: Vim tias cov vuam cua sov yog nyob hauv cheeb tsam thiab cov electrodes muab cov cua txias tas mus li, cov vuam vuam ua rau muaj kev cuam tshuam tsawg heev rau cov khoom nyob ib puag ncig. Qhov no yog ib qho tseem ceeb tshwj xeeb tshaj yog thaum ua hauj lwm nrog cov hlau nyias uas ua rau warping.

Automation-Friendly: Seam vuam txheej txheem yog sib xws nrog automation, ua rau lawv zoo tagnrho rau cov chaw tsim khoom loj. Automated seam vuam tshuab tuaj yeem tsim cov txiaj ntsig zoo ib yam nrog kev cuam tshuam rau tib neeg tsawg, txo cov nqi zog thiab nce cov khoom tsim tawm.

Kev sib tw thiab kev txwv ntawm Seam Vuam

Txawm hais tias seam welding muaj ntau qhov zoo, nws kuj muaj qee qhov kev sib tw thiab kev txwv:

Cov khoom siv siab:Cov cuab yeej tshwj xeeb uas xav tau rau kev sib khi vuam, tshwj xeeb tshaj yog rau kev sib txuas txuas txuas ntxiv, tuaj yeem kim. Qhov no ua rau nws tsis yooj yim rau kev cob qhia me me lossis cov tuam txhab uas muaj peev nyiaj tsawg.

Cov khoom txwv:Seam welding ua haujlwm zoo tshaj plaws ntawm cov hlau conductive xws li hlau thiab txhuas. Cov ntaub ntawv uas tsis zoo conductivity los yog kub-rhiab, xws li tej yam yas los yog ceramics, tsis tuaj yeem welded siv txoj kev no.

Thickness txwv:Seam welding yog qhov zoo tshaj plaws ntawm cov ntaub ntawv nyias, feem ntau hauv qab 3 hli hauv thickness. Rau cov ntaub ntawv tuab, lwm cov txheej txheem vuam, xws li MIG lossis TIG vuam, yuav tsim nyog dua.

Electrode Hnav:Kev sib hloov tas li thiab siab ntawm cov electrodes tuaj yeem ua rau hnav lub sijhawm, tshwj xeeb tshaj yog thaum vuam cov ntaub ntawv xws li hlau uas tuaj yeem ua rau electrode degradation. Kev saib xyuas tsis tu ncua thiab hloov cov electrodes yog tsim nyog los xyuas kom meej kev ua tau zoo.

Xaus

Seam welding yog txheej txheem tseem ceeb hauv kev tsim khoom niaj hnub, muab txoj hauv kev txhim khu kev qha, muaj txiaj ntsig los tsim kom muaj zog, txuas ntxiv welds. Nws cov ntawv thov yog qhov loj, nthuav dav kev lag luam xws li automotive, aerospace, thiab ntim khoom, qhov xav tau rau airtight lossis watertight pob qij txha yog qhov tseem ceeb. Nrog nws lub peev xwm los tsim tau zoo ib yam, ruaj khov welds sai, seam welding yog cov txheej txheem nyiam rau qhov chaw tsim khoom ntau.

Txawm li cas los xij, nws yog ib qho tseem ceeb uas yuav tsum xav txog cov kev txwv ntawm kev sib txuas ntawm cov seam welding, tshwj xeeb tshaj yog nyob rau hauv cov nqe lus ntawm cov khoom siv thiab cov khoom siv sib xws. Rau cov tuam txhab nrhiav kev nqis peev hauv seam welding, cov txiaj ntsig ntawm kev tsim khoom muaj zog, muaj zog weld kev ncaj ncees, thiab kev sib raug zoo nrog automation ua rau nws muaj txiaj ntsig ntxiv rau kev tsim khoom.

Post lub sij hawm: Oct-09-2024