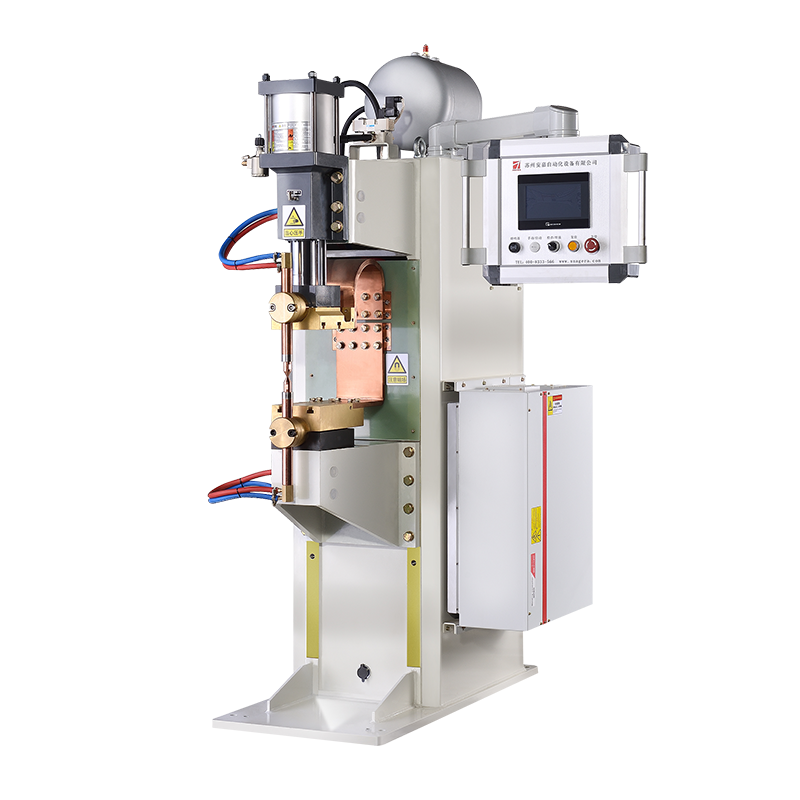

ADB-460 Resistance ntụpọ ịgbado ọkụ igwe

Okwu Mmalite ngwaahịa

Okwu Mmalite ngwaahịa

-

n'ụzọ dị irè ebelata ịgbado ọkụ spatter

Ọkụ na-ekpo ọkụ na-aga n'ihu na-emepụta site na mmepụta dị larịị nke ugbu a nke IF ntụpọ welder na-eme ka okpomọkụ nke nugget na-ebili na-aga n'ihu. N'otu oge ahụ, njikwa ziri ezi nke mkpọda na-arị elu ugbu a na oge agaghị eme ka spatter n'ihi okpomọkụ jumps na enweghị nchịkwa ugbu a na-ebili oge.

-

Ike dị mkpụmkpụ oge, arụmọrụ ọkụ dị elu

Ọ BỤRỤ na ntụpọ welder nwere ewepụghị mmepụta ịgbado ọkụ ugbu a, nke ana achi achi na elu-arụmọrụ na-aga n'ihu ọkọnọ nke ịgbado ọkụ okpomọkụ. Na ike-na oge dị mkpụmkpụ, na-eru ms larịị, nke na-eme ka ịgbado ọkụ okpomọkụ emetụta mpaghara obere, na solder nkwonkwo na-guzobere mara mma.

-

Nhazi njikwa dị elu

N'ihi na elu na-arụ ọrụ ugboro (na-emekarị 1-4KHz) nke intermediate ugboro Inverter ntụpọ welder, nzaghachi akara ziri ezi bụ 20-80 ugboro nke izugbe AC ntụpọ ịgbado ọkụ igwe na nke abụọ rectification ntụpọ ịgbado ọkụ igwe, na kwekọrọ ekwekọ mmepụta akara. izi ezi dịkwa oke elu.

-

Nchekwa ike 30%

Chekwa ike, chekwaa ike ịgbado ọkụ n'oge ọ bụla, wee belata okirikiri ịgbado ọkụ, ọkachasị dabara adaba maka ịgbado ọkụ siri ike na ọla ndị na-eduzi oke.

-

Ibu itule nke akụrụngwa

Ọ na-eji maka ntụpọ ịgbado ọkụ na nut projection ịgbado ọkụ nke elu-ike ígwè na-ekpo ọkụ kpụrụ ígwè na ụgbọala n'ichepụta ụlọ ọrụ, ntụpọ ịgbado ọkụ na multi-point projection ịgbado ọkụ nke nkịtị ala-carbon ígwè efere, igwe anaghị agba nchara efere, aluminum efere na waya, iguzogide. brazing na ntụpọ ịgbado ọkụ nke ọla kọpa waya na elu na ala voltaji eletriki ụlọ ọrụ, ọla kọpa efere brazing, mejupụtara ọlaọcha ntụpọ ịgbado ọkụ, wdg.

Nkọwa welder

Nkọwa welder

Oke ịgbado ọkụ

Oke ịgbado ọkụ

| Nlereanya | ADB-5 | ADB-10 | ADB-75T | ADB100T | ADB-100 | ADB-130 | ADB-130Z | ADB-180 | ADB-260 | ADB-360 | ADB-460 | ADB-690 | ADB-920 | |

| Enyere ike | KVA | 5 | 10 | 75 | 100 | 100 | 130 | 130 | 180 | 260 | 360 | 460 | 690 | 920 |

| Ịnye ọkụ | ø/V/HZ | 1/220V/50Hz | 3/380V/50Hz | |||||||||||

| Igwe ọkụ nke mbụ | mm2 | 2×10 | 2×10 | 3×16 | 3×16 | 3×16 | 3×16 | 3×16 | 3 × 25 | 3 × 25 | 3×35 | 3×50 | 3×75 | 3×90 |

| Max Primary Ugbu a | KA | 2 | 4 | 18 | 28 | 28 | 37 | 37 | 48 | 60 | 70 | 80 | 100 | 120 |

| Enyere okirikiri ọrụ | % | 5 | 5 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 | 20 |

| Nha Silinder Welding | Ø*L | Ø25*30 | Ø32*30 | Ø50*40 | Ø80*50 | Ø100*60 | Ø125*100 | Ø160*100 | Ø160*100 | Ø160*100 | Ø200*100 | Ø250*150 | Ø250*150*2 | Ø250*150*2 |

| Nrụgide arụ ọrụ kacha (0.5MP) | N | 240 | 400 | 980 | 2500 | 3900 | 6000 | 10000 | 10000 | 10000 | 15000 | 24000 | 47000 | 47000 |

| Oriri ikuku emetụtara | Mpa | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 | 0.6-0.7 |

|

Oriri mmiri jụrụ oyi | L/min | - | - | 6 | 6 | 8 | 12 | 12 | 12 | 12 | 15 | 20 | 24 | 30 |

|

Oriri ikuku emetụtara | L/min | 1.23 | 1.43 | 1.43 | 2.0 | 2.28 | 5.84 | 5.84 | 5.84 | 5.84 | 9.24 | 9.24 | 26 | 26 |

Usoro omenala

Usoro omenala

Welder FAQ

Welder FAQ

- Ajụjụ: Ọ dị mkpa ka e kpoo ọkụ eletrik nke igwe ịgbado ọkụ ntụpọ?

A: The electrode anaghị achọ preheating, ma n'ọnọdụ ụfọdụ, preheating nwere ike imeziwanye welding results.

- Ajụjụ: Olee ụdị mkpọtụ ga-emepụta n'oge usoro ịgbado ọkụ nke ntụpọ welder?

A: Usoro ịgbado ọkụ nke igwe ịgbado ọkụ ntụpọ ga-emepụta mkpọtụ, a na-achọkwa ihe nchebe dị ka earplugs.

- Ajụjụ: Enwere ike ịrụzi igwe ịgbado ọkụ ntụpọ n'onwe gị?

A: Enwere ike ịrụ ụfọdụ ọrụ mmezi n'onwe gị, mana ọ ga-adị mkpa ka onye ọkachamara rụọ ọrụ ndị dị mgbagwoju anya.

- Ajụjụ: Ebee ka ekwesịrị itinye welder ntụpọ?

A: Ekwesịrị itinye welder ntụpọ ahụ n'ebe a na-ekpo ọkụ nke ọma, ebe akọrọ ma jikọọ ya na eriri ọkụ.

- Ajụjụ: Ogologo oge ole ka ọ na-ewe iji rụkwaa welder ntụpọ?

A: Oge mmezi na-adabere na mgbagwoju anya nke ọrụ nrụzi na ịdị njọ nke ọdịda akụrụngwa, na-ewekarị awa ruo ụbọchị.

- Ajụjụ: Olee otu esi ehichapụ ihe welders ntụpọ?

A: Ekwesịrị iji ikuku abịakọrọ ma ọ bụ ncha sachaa ihe ndị na-agbapụta ntụpọ, na e kwesịghị iji mmiri ma ọ bụ ihe ndị ọzọ na-ehicha ya.

Zitere anyị email

Zitere anyị email