ịgbado ọkụ buttA na-eji ya eme ihe na nhazi ígwè ọgbara ọhụrụ, site na teknụzụ ịgbado ọkụ, otu ígwè ma ọ bụ metal dị iche iche dị ka ọla kọpa na aluminom nwere ike ijikọta ọnụ. Site na mmepe nke ụlọ ọrụ, teknụzụ ịgbado ọkụ butt na-etinyekarị aka na elektrọnik na eletriki, ụgbọ ala ike ọhụrụ na ụlọ ọrụ ndị ọzọ. Isiokwu na-esonụ ga-aza ihe ọmụma nke butt ịgbado ọkụ maka gị n'ụzọ zuru ezu.

IsiCma e wezụgaButtWelding

Ihe a na-akpọ butt ịgbado ọkụ bụ idobe abụọ workpiece agwụ ikwu na onye ọ bụla ọzọ, itinye nrụgide n'otu oge ahụ, na-eji ịgbado ọkụ ugbu a na-ekpo ọkụ, na mgbe ahụ na-etolite a ịgbado ọkụ nkwonkwo n'okpuru omume nke nrụgide, ihe oru oma na mfe iji nweta akpaaka. usoro ịgbado ọkụ.

The Ụdị of ButtWelding

Butt ịgbado ọkụ na tumadi kewara n'imeiguzogide butt ịgbado ọkụnaflash butt ịgbado ọkụ

Nguzogide ịgbado ọkụ

Nguzogide ịgbado ọkụ bụ ụdị siri ike na-agbado agbado na elu okpomọkụ plastic steeti, na nkwonkwo njikọ nwere ike ịbụ recrystallization na ibe diffusion na isi, ma ihe niile bụ siri ike na-adọ njikọ.

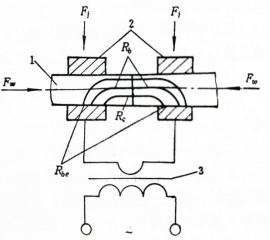

A na-egosi ụkpụrụ nke ịgbado ịgbado agbado na njikọ njikọta na eserese 1.

Onyonyo 1. Nkwenye mgbado ọkụ schematic eserese

1- Weldment

2- Electrode

3- Solder iguzogide transformer

4-Ff- ike njigide

Ike na-akpụ akpụ

Rb- ịgbado ọkụ

RC-Nguzogide kọntaktị

Rbe- Kọntaktị eguzogide n'etiti weldment na workpiece

Flash Butt ịgbado ọkụ

The njikọ kacha mkpa nke flash butt ịgbado ọkụ nkwonkwo bụ otu ihe ahụ dị ka nke na-eguzogide butt ịgbado ọkụ nkwonkwo, nke bụkwa a siri ike na-adọ njikọ, ma e guzobere usoro nwere ya àgwà. Na njedebe nke ọkụ ahụ, a na-emepụta akwa akwa mmiri mmiri na ihu njedebe. N'oge n'elu forging, ọgwụgwụ ihu metal na-akpa jikọtara n'okpuru mmiri mmiri na-adọ. Mgbe ahụ, a ga-ewepụ oyi akwa nke mmiri mmiri site na ihu njedebe nkwonkwo n'okpuru ọrụ nke nrụgide elu.Mgbeigwe ịgbado ọkụ ọkụ buttwelded akụkụ, nkwonkwo bụ nnọọ ike, dị ka a metal tube site flash ịgbado ọkụ, mgbe ahụ site natube ekwe igwena-ehulata na nkwonkwo, nkwonkwo agaghị agbaji.

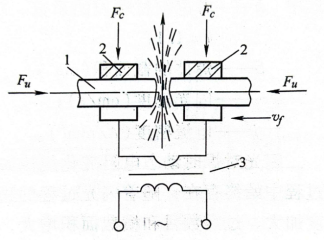

E gosipụtara ụkpụrụ nke ịgbado ọkụ butt na nhazi njikọ na eserese 2:

Onyonyo 2. Eserese eserese ịgbado ọkụ ọkụ

1- Weldment

2- Electrode

3- Solder iguzogide transformer

4- Fc- clamping force Fu- forging Force Vf flash ọsọ

Uru nkeButtWelding

a) Nguzogide butt ịgbado ọkụ akụrụngwa dị mfe, ole na ole ịgbado ọkụ parameters, mfe ịmụta, mfe nweta akpaka akara;

b) Obere mbenata nke iguzogide butt ịgbado ọkụ akụkụ, na-azọpụta ihe, obere burrs, nke na-eme ka mfe nke ikpeazụ usoro;

c) flash butt ịgbado ọkụ nwere elu thermal arụmọrụ, nwere ike ịgbado nnukwu-mpaghara akụkụ, na e ji mee ihe maka ịgbado ọkụ gas pipeline na a cross-section nke 100000mm2;

d) flash butt ịgbado ọkụ n'ihi na lintel dị maka obere oge, naanị ole na ole milliseconds, ọnọdụ ya na-agbanwe enweghị usoro, na ngụkọta oge nke kpo oku ofụri ọgwụgwụ ihu nke weldment bụ ihe edo, ya mere na-aga n'ihu flash ịgbado ọkụ nwere ike ọ bụghị naanị weld a. kọmpat ngalaba, kamakwa weld weld na gbasaa ngalaba (dị ka mkpa Ibé akwụkwọ, wdg);

e) Na njedebe nke flash ahụ, a ga-emepụta akwa akwa nke mmiri mmiri dị n'elu nke weldment, nke mere na adịghị ọcha oxide dị n'elu dị mfe iji mmiri mmiri na-agbapụta n'elu akụkụ nke interface, ya mere. na nkwonkwo ịgbado ọkụ na-egbuke egbuke dị oke mma, na ụdị ịgbado ọkụ dị iche iche nwere ike ịkarị, na ihe dị iche iche dị iche iche nwere ike ịgbanye.

f) Ọ dịghị ihe ndochi achọrọ na usoro ịgbado ọkụ, yana ọnụ ọgụgụ ihe eji eme ihe dị elu;

Ngwa nkeButtWelding

Nrụpụta ụgbọ ala

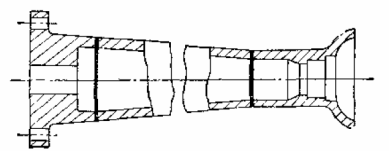

Ọgụgụ 3. Ụgbọ ala cardan shaft shei flash butt ịgbado ọkụ

Ọgụgụ 4. Ụgbọ ala, ọgba tum tum wheel flash butt ịgbado ọkụ

Ụlọ ọrụ ikuku

Onyonyo 5. Ụgbọ elu mkpịrịkpa ịgbado ọkụ

Ụlọ ọrụ Petrochemical

Ọgụgụ 6. Metal ọkpọkọ butt ịgbado ọkụ

Owuwu injinia

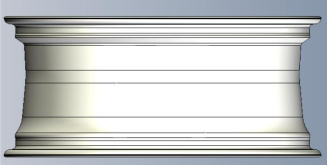

Ọgụgụ 7. Ọgwụgwụ efere flange butt ịgbado ọkụ

Ụlọ ọrụ mmepụta ụgbọ mmiri

Ọgụgụ 8. Arịlịka yinye butt ịgbado ọkụ

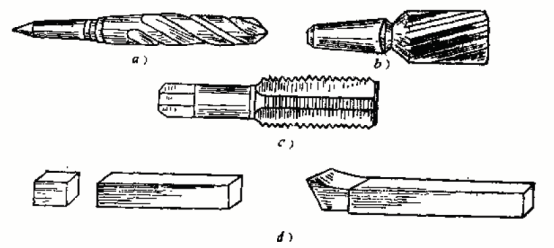

ngwaike ngwaọrụ

Ọgụgụ 9. Ngwá ọrụ ịgbado ọkụ

SpecificationParameters naButtWeldingProses

Mgbe a na-ahọrọ paramita kwesịrị ekwesị nke nkọwa ịgbado ọkụ butt, enwere ike nweta nkwonkwo dị elu nke nwere ihe fọrọ nke nta ka ọ bụrụ otu ihe dị ka isi ihe.

a) The isi nkọwapụta parameters nke iguzogide butt ịgbado ọkụ bụ:

ogologo ịgbatị, ịgbado ọkụ ugbu a njupụta (ma ọ bụịgbado ọkụ ugbu a), oge ịgbado ọkụ, ịgbado ọkụ mgbali na top forging mgbali.

b) Isi paramita nke flash butt ịgbado ọkụ bụ:

Flash ogbo: ịhazigharị ogologo gbatịa, njigide ọkụ, ọkụ ọkụ, njupụta ugbu a;

Ogbo a na-akpụ akpụ: nrịba aka n'elu, oke ịgba ọsọ, nrụgide elu, ike njigide;

Ogbo ikpo ọkụ: preheating okpomọkụ, preheating oge.

Ọrụ nke ịgbatị ogologo bụ iji hụ na ohere dị mkpa (ịgbado ọkụ akụkụ shortening) na mezie okpomọkụ ubi mgbe kpo oku mkpa na ọrụ nwere ike họrọ dị ka welding akụkụ akụkụ na ihe onwunwe Njirimara, omume na-egosi na ịgbatị ogologo ekwesịghị ịbụ obere. karịa ọkara nke dayameta nke ịgbado ọkụ akụkụ, ya bụ, l = 0.6 ~ 1.0d (d bụ dayameta nke osisi ma ọ bụ n'akụkụ ogologo nke square) kwesịrị ekwesị. N'otu oge ahụ, mgbe ịgbado ọkụ dissimilar ihe, iji nweta a kwesịrị ekwesị okpomọkụ nkesa (mgbe ụfọdụ na-atụle rigidity nke na-abụghị ferrous metal weldments), abụọ welding kwesịrị iji dị iche iche na-agbatị ogologo.

A na-egosipụtakarị ịgbado ọkụ ugbu a site na njupụta dị ugbu a, na njupụta ugbu a na oge ịgbado ọkụ bụ ihe abụọ bụ isi nke na-ekpebi ikpo ọkụ ịgbado ọkụ, enwere ike ịhazigharị ibe ya n'ụzọ kwesịrị ekwesị. Na omume, a na-atụ aro ka ịnọgide na-enwe mmekọrịta dị n'etiti njupụta kachasị ugbu a na oge ịgbado ọkụ kacha nta, na iji nkọwa siri ike dị ka akụkụ obe na-ebelata. Njupụta dị ugbu a nke ịgbado ọkụ na-aga n'ihu na-aga n'ihu, ihe igwe nwere ezigbo ọkụ eletrik na ọkụ, yana akụkụ welded nwere ngalaba gbasaa kwesịrị ịdị elu. Maka ịgbado ọkụ ọkụ butt ịgbado ọkụ na nnukwu welds ngalaba, njupụta dị ugbu a kwesịrị ịdị ala.

Ma nrụgide ịgbado ọkụ na n'elu forging nrụgide nwere mmetụta na okpomọkụ mgbasa nke kọntaktị elu na plastic deformation nke na-abụghị na n'akụkụ akụkụ. Enwere ike ijikọ ọsọ kachasị elu na nrụgide ike ịgha mkpụrụ, yana enwere ike ibelata ọsọ akpụ akpụ n'ụzọ kwesịrị ekwesị ma ọ bụrụ n'ịsọ ọsọ dị elu zuru oke.

NkeDmmepePechiche nkeButtWelding

Na omimi ọmụmụ nke mmekọrịta dị n'etiti iguzogide ịgbado ọkụ àgwà na ịgbado ọkụ usoro parameters na online nchọpụta technology, ọzọ mụ ịgbado ọkụ àgwà nwere ike nweta. Tụkwasị na nke ahụ, a na-agbasawanye ihe ndị na-agbado ọkụ, na ngwa ngwa nke ịgbado ọkụ na-eguzogide na-abawanye ụba. Na-aga n'ihu na-aga n'ihu nketeknụzụ ịgbado ọkụ na-eguzogide, ịgbado ọkụ na-eguzogide ga-anọ n'ọnọdụ dị mkpa na mmepụta mmepụta ihe n'ọdịnihu. Karịsịa na ịgbado ọkụ ubi nke nnukwu cross-ngalaba na dissimilar ọla, flash butt ịgbado ọkụ nwere ezi mmepe atụmanya.

Nchịkọta

Na mmepe nke ọhụrụ ume ụlọ ọrụ, ọzọ na ndị ọzọ ịgbado ọkụ ngwa nke ọla kọpa na aluminum njikọ, iguzogide ịgbado ọkụ technology dị nnọọ kwekọọ na mkpa nke ahịa, jikọtara na ọhụrụ iguzogide ịgbado ọkụ usoro na adaptive akara technology, iguzogide ịgbado ọkụ n'ọdịnihu mmepe ga- webata ọganihu ka ukwuu.

Oge nzipu: Ọgọst-30-2024