Ọ bụrụ na ị bụ ọhụrụ na-eguzogide ịgbado ọkụ ma ọ bụ na-achọ a doo anya nghọta ya, mgbe ahụ ị maa mkpa na-agụ isiokwu a nke ọma. Isiokwu a ga-eme ka ị banye n'ime ụwa nke ịgbado ọkụ na-eguzogide. Ma ị bụ onye mbido ma ọ bụ na-achọ ịgbasa ihe ọmụma gị, akụkọ a ga-enye gị nghọta bara uru.

Gịnị bụ Nguzogide Welding?

Ịgbado ọkụ na-eguzogide bụ ụzọ dị elu, nke na-eme ka ọla na-ejikọta ọnụ. Usoro ịgbado ọkụ a dabara adaba maka nkwonkwo ụkwụ, nkwonkwo ụkwụ, ma ọ bụ nkwonkwo na-achọghị ike ikuku, yana ọkpụrụkpụ na-erughị 6mm maka ihe owuwu mpempe akwụkwọ dị mkpa. N'ezie, ọ nwekwara ike weld thicker na ibu metal workpieces, ma ya n'ozuzu arụmọrụ nwere ike ọ gaghị adị mma dị ka ụfọdụ ndị ọzọ ịgbado ọkụ ụzọ.

Nkọwa na ihe ndabere

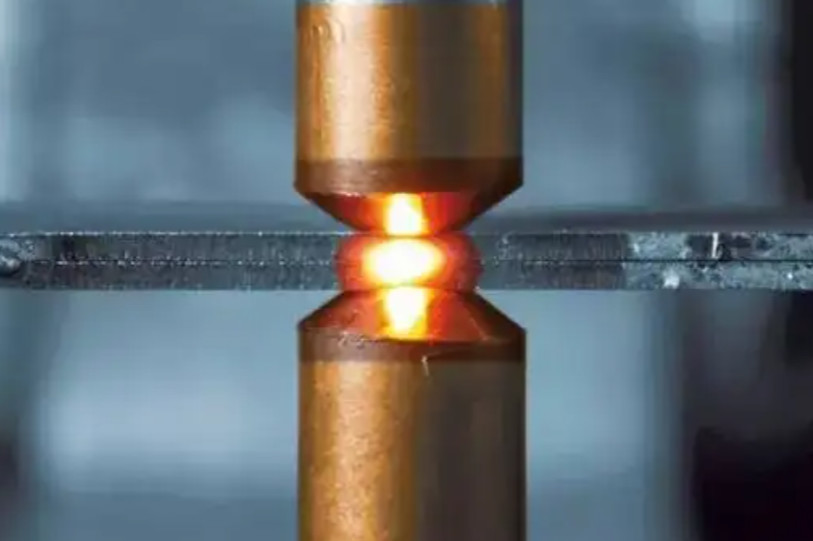

ịgbado ọkụ na-eguzogidebụ usoro ebe workpieces ga-ejikọta na-etinye n'etiti abụọ electrodes. Site na-agafe ugbu a site na workpieces na kọntaktị kọntaktị, iguzogide okpomọkụ na-eme, na-emepụta okpomọkụ na nkwụsị nke workpieces. Igwe ọkụ a na-ekpo ọkụ na-eme ka mpaghara ahụ gbazee ma ọ bụ na-agbanwe agbanwe, ebe nrụgide sitere na electrodes abụọ na-ejikọta ígwè ahụ ọnụ.

Mgbe ugbu a na-agafe na onye nduzi, ọ na-emepụta okpomọkụ n'ihi nguzogide. Ihe dị elu na-eguzogide mgbe ihe dị ugbu a na-adịgide adịgide, otú ahụ ka a na-emepụta okpomọkụ. N'ebe a na-ejikọta ọla na kọntaktị, nguzogide dị ukwuu karịa n'ime metal n'onwe ya. Ya mere, mgbe nnukwu ugbu a na-agafe na kọntaktị dị n'etiti metal na electrode, ígwè ahụ na-ekpo ọkụ ngwa ngwa n'ihi nnukwu okpomọkụ. N'ebe a, ígwè ahụ na-aghọ nke ukwuu ductile, na site n'itinye nrụgide, ígwè abụọ ahụ na-ejikọta ọnụ.

Ụkpụrụ Ọrụ Nguzogide ịgbado ọkụ

Ụkpụrụ nke ịgbado ọkụ ntụpọ na-eguzogide na nhazi nke nkwonkwo na-egosi na Figure 1-1. A na-etinye metal A na metal B n'etiti electrodes abụọ, a na-etinyekwa nrụgide na electrodes. A na-agafe ugbu a dị ike n'etiti electrodes abụọ site na onye na-agbanwe ihe nke na-eguzogide. Ebe kọntaktị nke workpieces na-etolite ebe kọntaktị anụ ahụ, nke na-eji nwayọọ nwayọọ gbasaa ka nke ugbu a na-ekpo ọkụ. Nrụrụ plastik na ikpo ọkụ na-aga n'ihu na-eme ka atom na-arụ ọrụ na ebe kọntaktị, na-eduga n'ichebe isi mgbaze. Isi a wụrụ awụ na-etolite n'ụdị kristal kọlụm, na-ebupụ akụkụ mkpokọta alloy dị elu n'ebe ibe ya nọ. Mgbe electrodes nke welder pụọ na metal elu, na metal cools ala, workpieces na-welded ọnụ, na-eke a siri ike metal njikọ. Elu nkwonkwo na-apụ n'anya, na-ahapụ n'azụ weld nugget.

1-1

Ihe na-emetụta ịgbado ọkụ na-eguzogide

ịgbado ọkụ na-eguzogidebụ usoro ịgbado ọkụ nke na-eji ọkụ eletrik na-emepụta okpomọkụ iji jikọta ihe ndị na-emepụta ígwè. Dị ka e kwuru na mbụ, ụkpụrụ nke iguzogide ịgbado ọkụ tumadi ị ga Joule iwu nke kpo oku, ebe ọgbọ nke ịgbado ọkụ okpomọkụ bụ isi kpebisiri ike site parameters dị ka ugbu a, iguzogide, na ịgbado ọkụ oge. Enwere ike igosipụta ya site na usoro a:

Q = I²Rt

Pụtara nke oke ịgbado ọkụ ọ bụla:

Q - Okpomọkụ (J)

I - Welding current (A)

R - Nguzogide (Ω)

t - Oge ịgbado ọkụ (s)

Welding Ugbu a

Ihe dị ugbu a nwere mmetụta dị ukwuu na okpomọkụ a na-emepụta n'oge ịgbado ọkụ, dị ka egosiri na usoro. Uru square nke ugbu a na-emetụta okpomọkụ, nke pụtara na elu dị ugbu a, ngwa ngwa ọkụ ga-abawanye. Ya mere, mgbe ukpụhọde welding parameters tupu ịgbado ọkụ, ọ dị oké mkpa ịtọ kwesịrị ekwesị ugbu a. Ọ bụrụ na ịgbado ọkụ ugbu a dị oke obere, weld agaghị agbaze, ọ nweghịkwa isi njikọ ga-etolite. Ọ bụrụ na ihe dị ugbu a buru ibu nke ukwuu, isi njikọ ahụ ga-eto ngwa ngwa, na-eme ka ọgbaghara dị ukwuu n'oge ịgbado ọkụ na imebi electrodes.

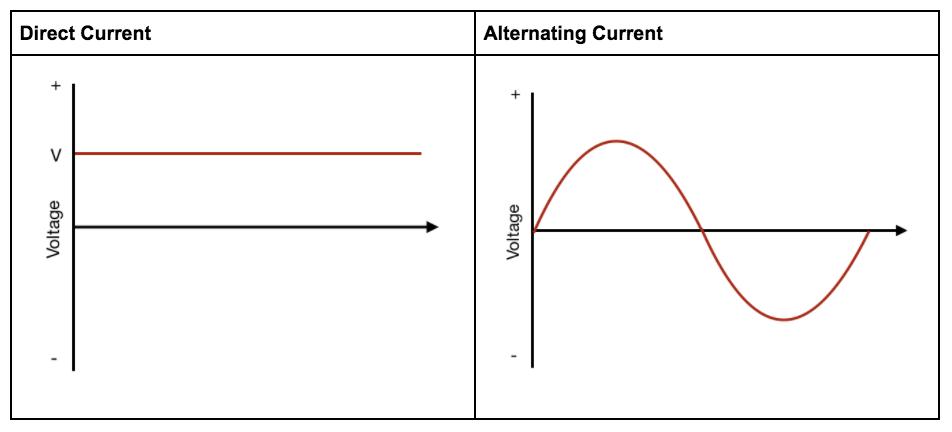

A na-ekekarị ịgbado ọkụ ugbu a ka ọ bụrụ alternating current (AC) na direct current (DC), dị ka egosiri na eserese dị n'okpuru. Nkeigwe ịgbado ọkụanyị na-eji na-ekewa kpọmkwem ugbu a ntụpọ ịgbado ọkụ igwe na alternating ugbu a ntụpọ ịgbado ọkụ igwe. Igwe ịgbado ọkụ ozugbo dị ugbu a na-eji ọkụ ọkụ nke ụzọ atọ, na-ahụ maka nkesa ike kwụ ọtọ, ma nwee ike nweta oge ịgbado ọkụ karịa 1000 Hz, na-ebute izi ezi ịgbado ọkụ. Ha nwekwara uru nke ike dị ala na-achọ site na grid ike, na-eme ka ndị a na-echekwa ike welder na-ewu ewu n'etiti ndị na-emepụta ụlọ ọrụ. Igwe ịgbado ọkụ na-agbanwe agbanwe ugbu a nwere mmepụta 50Hz nke otu oge, ikike ibu dị elu na-aga n'ihu, yana nnukwu ihe achọrọ maka grid ike. Ọzọkwa, ha nwere obere ike ịgbado ọkụ, na-achọ ogologo oge ịgbado ọkụ.

Kpọtụrụ Nguzogide

Site na usoro a, ọ dị mfe ịhụ na nguzogide na-adaba na okpomọkụ a na-emepụta. Nke dị elu nke nguzogide, otú ahụ ka ọkụ na-emepụta n'oge ịgbado ọkụ. A na-ekesa nguzogide n'akụkụ dị iche iche nke electrode na workpiece. N'oge ịgbado ọkụ, nguzogide kachasị elu na-eme na ebe kọntaktị nke workpiece, na-ebute ọgbọ okpomọkụ kachasị elu. Ọzọ bụ nguzogide na ebe kọntaktị n'etiti workpiece na electrode. Otú ọ dị, ebe ọ bụ na electrode na-eme ka mmiri dị jụụ na ngwa ngwa na-ajụ oyi, okpomọkụ na-ebelata ngwa ngwa. N'aka nke ọzọ, kọntaktị na-eguzogide n'etiti workpieces, ọ bụ ezie na ọ na-apụ n'anya, nwere adịghị mma ikpo ọkụ, na-eduga na elu okpomọkụ. Ya mere, ọ bụ naanị obere mpaghara n'etiti workpieces nwere ike iru okpomọkụ dị mkpa na-etolite a fusion isi na weld ọnụ.

Ọzọkwa, okpomọkụ na nrụgide electrode na-emetụta nguzogide ahụ. Ka okpomọkụ na-ebili, ike mkpụrụ ígwè na-ebelata, na-amụba mpaghara kọntaktị n'etiti workpieces na n'etiti workpiece na electrode, na-akpata ibelata nguzogide. Ịbawanye nrụgide electrode na-eme ka elu ọrụ ahụ dị nro, na-amụba mpaghara kọntaktị na ibelata nguzogide. N'ihi ya, e nwere a onu ebe, n'oge ịgbado ọkụ nke ahụkarị ihe, ndị na-eguzogide na-abawanye obere oge ka ike na, na mgbe ike gbanyụrụ na fusion isi ụdị, nguzogide na-amalite ibelata.

Oge ịgbado ọkụ

Ogologo oge ịgbado ọkụ, ka ọkụ na-esiwanye ike. Na usoro a, ugbu a na oge nwere ike ịkwado ibe ha. Mgbe ịchọrọ weld siri ike, ị nwere ike ịtọ ụda dị elu maka oge dị mkpirikpi iji mee ka okpomọkụ dị ngwa ngwa ma mepụta isi njikọ iji mezue ịgbado ọkụ ahụ. N'aka nke ọzọ, ị nwere ike ịtọ ụda dị ala ruo ogologo oge, mana enwere oke maka usoro a. Ọ bụrụ na edobere oge ahụ ogologo oge, ọ nwere ike iduga nfesa oke ma nwee ike ime ka electrode rapara. Ma ọ dị ugbu a ma ọ bụ oge, enwere oke. Mgbe ịtọ ntọala, ịkwesịrị ịtụle ihe na ọkpụrụkpụ nke workpiece, yana ike nke igwe ịgbado ọkụ.

Njirimara ihe

Ihe nke workpiece na-emetụta n'ụzọ dị ukwuu ya resistivity, nke na-arụ ọrụ dị mkpa na ịgbado ọkụ ọgbọ. Mgbe ịgbado ọkụ igwe anaghị agba nchara, nke nwere nnukwu resistivity na adịghị mma thermal conductivity, ọ na-adị mfe n'ịwa okpomọkụ ma na-esi ike igbasa ya, ya mere a na-achọ obere mmiri iyi. Mgbe ịgbado ọkụ aluminom alloys na ala resistivity na ezigbo thermal conductivity, ọ na-esiri ike ịmepụta okpomọkụ mana ọ dị mfe ịgbasa ya, ya mere achọrọ nnukwu iyi. Ọla dị ka ọlaọcha na ọla kọpa na-enwe mmetụta dị elu nke thermal conductivity na obere resistivity, n'ihi ya, ọ bụrụgodị na mmiri dị elu, ha anaghị ewepụta okpomọkụ dị ukwuu mana ha nwere ike iduga ya. Ya mere, ọla ndị a adabaghị maka ịgbado ọkụ na-eguzogide mana enwere ike iji ya dị ka ihe electrode.

Electrode Design na geometry

Ụdị na ihe nke electrode na-emetụtakwa mmepụta okpomọkụ. Mpaghara kọntaktị n'etiti electrode na workpiece na-emetụta njupụta dị ugbu a. Iji elektrọd eme ihe ugboro ugboro nwere ike ibute iyi na nrụrụ, ịbawanye mpaghara kọntaktị yana ibelata ike ịgbado ọkụ. Ya mere, anyị kwesịrị ịrụkwa ma dochie ndụmọdụ electrode ozugbo. The thermal conductivity na iguzogide electrode na-emetụta nnyefe okpomọkụ. Ya mere, anyị kwesịrị ịhọrọ ihe ndị nwere ezigbo ọkụ ọkụ na nguzogide dị ala.

Nkwadebe elu

Ụdị na ihe nke electrodes na-emetụtakwa mmepụta okpomọkụ. Mpaghara kọntaktị n'etiti electrode na workpiece na-emetụta njupụta dị ugbu a. Mgbe a na-eji eletrọd anyị eme ihe ugboro ugboro ma na-agwụ ike, ọ na-abawanye mpaghara kọntaktị, na-eduga n'ike ịgbado ọkụ. Ya mere, anyị kwesịrị ịrụkwa na dochie electrode ndụmọdụ ozugbo. The thermal conductivity na resistivity nke electrodes na-emetụta nnyefe okpomọkụ. Ya mere, anyị kwesịrị ịhọrọ ihe nwere ezigbo thermal conductivity na ala resistivity.

Ụdị nke Resistance ịgbado ọkụ

N'ihi nkọwapụta ngwaahịa dị iche iche na ihe achọrọ maka ịgbado ọkụ, a na-eji usoro ịgbado ọkụ dị iche iche iji mezue ọrụ ahụ. Enwere ike ikewa ịgbado ọkụ na-eguzogide ka ọ bụrụ ịgbado ọkụ ntụpọ, ịgbado ọkụ amụma, ịgbado ọkụ n'ọnụ ọnụ, na ịgbado ọkụ dabere na usoro ịgbado ọkụ.

Ntụpọ ịgbado ọkụ

Ntụpọ ịgbado ọkụbụ usoro ịgbado ọkụ ebe a na-ejikọta ígwè ọnụ site na electrodes elu na nke ala ma na-agbakọta ya site na ịgafe ugbu a na ya. Ọ bụ ụdị omenala ịgbado ọkụ na-eguzogide, dị mfe iji rụọ ọrụ, ma na-achọ ọkwa nka dị ala n'aka ndị ọrụ. N'ihi na ya pụrụ iche ịgbado ọkụ usoro, ntụpọ ịgbado ọkụ bụ isi nhọrọ maka ịgbado ọkụ metal components na aerospace engineering na ọtụtụ-eji na ịgbado ọkụ akpakanamde ahu na ndị ọzọ components. A na-ejikarị ya maka ịgbado obere mpempe akwụkwọ nke obere carbon steel, aluminum, igwe anaghị agba nchara, galvanized steel, na efere ndị ọzọ dị gịrịgịrị, na-adịkarị gburugburu 3 millimeters.

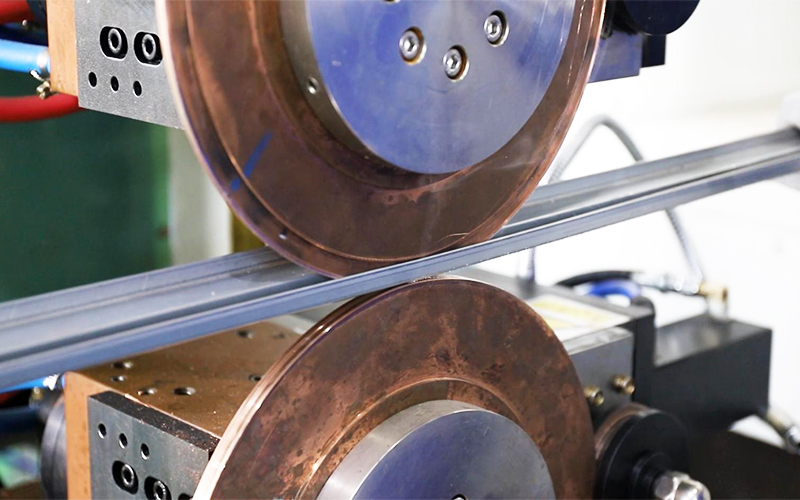

Seam Welding

Seam ịgbado ọkụna-agụnyekarị ịbanye n'ọnụ akụkụ nke ihe igwe abụọ. The abụọ metal workpieces na-enịm n'etiti abụọ rola electrodes. Mgbe otu electrode na-atụgharị ma na-etinye nrụgide, mwepu na-aga n'ihu ma ọ bụ na-adịte aka na-apụta. Okpomọkụ a na-eme na ebe a na-atụgharị eletrọd na-agbaze ihe ndị a na-arụ ọrụ ma jikọta ha ọnụ, na-akpụ eriri weld na-aga n'ihu. A na-eji usoro a eme ihe n'ọtụtụ ebe maka akụkụ ígwè ịgbado ọkụ na-achọ nkwonkwo mechiri emechi. Ebe ọ bụ na ebe ịgbado ọkụ dị ogologo, iji gbochie ndakọrịta, anyị na-ejikarị welding ntụpọ maka itinye n'ọnọdụ tupu ịgbado ọkụ.

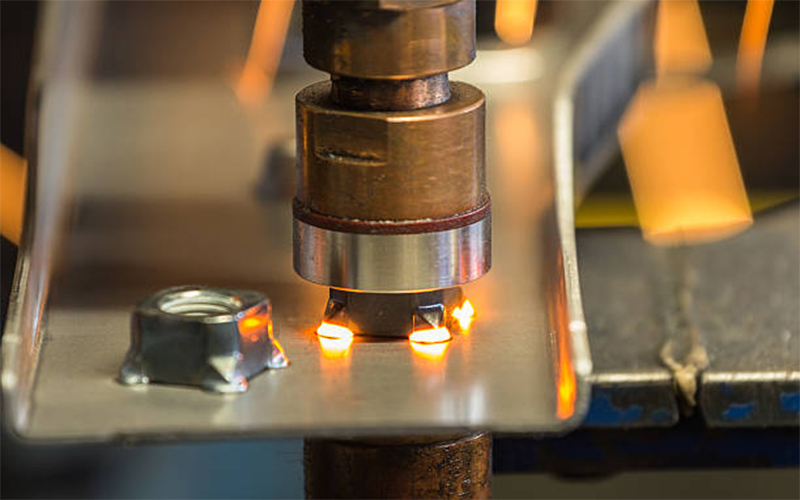

Ntụle ịgbado ọkụ

Mgbado ọkụ amụmabụ mgbanwe nke ntụpọ ịgbado ọkụ, ebe e guzobere weld n'ókè yiri ntụpọ ịgbado ọkụ, ma amụma ịgbado ọkụ na-a na-eji workpieces na welitere isi. Ọnụnọ nke isi ihe ndị a welitere na-egbochi mpaghara nke ugbu a na-agafe, na-abawanye njupụta dị ugbu a na mpaghara ịgbado ọkụ. Nke a na-ekpo ọkụ na-ekpo ọkụ na-eme ka njikọ nke nkwonkwo aka. A maara usoro ịgbado ọkụ a dị ka amụma ịgbado ọkụ. Ịgbado ọkụ n'elu nwere ike ịmalite otu ma ọ bụ karịa fusion cores n'otu oge. N'oge ịgbado ọkụ, ugbu a chọrọ maka projection ịgbado ọkụ n'otu ebe weld bụ ihe na-erughị nke maka ntụpọ ịgbado ọkụ. Otú ọ dị, tupu e mebie amụma ọ bụla, ihe dị ugbu a kwesịrị ịgbaze amụma ahụ; ma ọ bụghị ya, enwere ike ịnwe oke nfe. Enwere ike iji ịgbado ọkụ n'ihu wee were mkpụrụ, bolts, ma ọ bụ efere nwere isi ihe ewelitere ma jiri ya mee ihe n'ichepụta ngwa eletrọnịkị na ụgbọ ala.

Butt ịgbado ọkụ

ịgbado ọkụ buttna-agụnye aligning ọgwụgwụ ihu nke abụọ metal workpieces, ịtụkwasị ha n'etiti electrodes, n'enweghị ntụkwasị obi fastening abụọ workpieces, na iji elu ugbu a n'ịwa okpomọkụ, agbaze kọntaktị elu nke workpieces na ijikọta ha ọnụ. A na-ekekwa ịgbado ọkụ butt ka ọ bụrụ ịgbado ọkụ ọkụ na ịgbado ọkụ na-eguzogide.

Flash butt ịgbado ọkụ bụ a ngwa ngwa ịgbado ọkụ usoro na-eji elu ugbu a ngwa ngwa gbazee workpieces, n'itinye nrụgide na-etolite a siri ike-phase njikọ. A na-ejikarị ya maka ịgbado nnukwu akụkụ nke mkpanaka igwe, mpempe akwụkwọ na ọkpọkọ, yana mpaghara kachasị ruru 20,000mm² na karịa. N'oge usoro ịgbado ọkụ na-apụ apụ, a na-emepụta ọkụ ọkụ na ebe kọntaktị, ya mere aha ya bụ flash butt welding. Ọ nwere ike ịgbanye nnukwu carbon steel, igwe anaghị agba nchara, aluminom alloys, ma nwee ike ịgbanye ọla ndị yiri ya dị ka ọla kọpa na aluminom.

Ịgbado ọkụ na-eguzogide na-eji okpomọkụ na-eguzogide iji weta nkwonkwo workpiece na steeti rọba na okpomọkụ dị elu, na-emecha usoro ịgbado ọkụ na ike akpụ. Ọ dabara maka ịgbado ọkụ nkwonkwo na cross-section ebe n'ime 250mm², na-ejikarị maka ịgbado ọkụ obere cross-ngalaba metal wires, mkpara, na ibe.

Mkpa dị na Nrụpụta

- Ịgbado ọkụ na-eguzogide anaghị achọ mgbakwunye nke ígwè n'oge usoro ịgbado ọkụ, na-eme ka ọ dị elu nke ọma na mmetọ dị ntakịrị.

- N'ihi nkwụsi ike ya na nkwụsi ike ya, ịgbado ọkụ na-eguzogide dị mfe iji rụọ ọrụ, na-ejikọta ya na akpaaka n'enweghị nsogbu iji kwalite nrụpụta mmepụta yana chekwaa ọrụ.

- E jiri ya tụnyere ụzọ ịgbado ọkụ ndị ọzọ, ịgbado ọkụ na-eguzogide bụ ọnụ ahịa. Nke mbụ, ọnụahịa akụrụngwa maka ịgbado ọkụ na-eguzogide dị ntakịrị, na nke abụọ, enwere ntakịrị ihe mkpofu ihe n'oge usoro ịgbado ọkụ na-eguzogide. Nke a na-ebelata nke ukwuu ụgwọ ọrụ maka ndị na-emepụta ihe na ụlọ ọrụ mmepụta ihe.

- A na-eji ịgbado ọkụ na-eguzogide n'ọtụtụ ebe n'ofe ụlọ ọrụ dị iche iche ma bụrụkwa ihe dị mkpa karịsịa na mpaghara dịka ikuku ikuku, nrụpụta ụgbọ ala, na ndị ọzọ.

- Ịgbado ọkụ na-eguzogide dị mma maka ịgbado ụdị ọla dị iche iche na ụlọ ọrụ mmepụta ihe, gụnyere igwe anaghị agba nchara, carbon ígwè, aluminum, ọla kọpa, na ndị ọzọ, na-eme ka ọ dị irè na ngwa ya.

Ngwa

A na-eji ịgbado ọkụ na-emegide onwe ya n'ọtụtụ ebe, ọkachasị n'ụlọ ọrụ dịka akụrụngwa akụrụngwa, ikuku ikuku, ngwa elektrọnik na ụlọ ọrụ dị arọ. Ka ọchichọ maka akụrụngwa igwe welded na ụlọ ọrụ dị iche iche na-aga n'ihu, edobela ụkpụrụ dị elu maka teknụzụ ịgbado ọkụ, na-ebute ọganihu na mmepe nke ịgbado ọkụ.

Ngwa ụlọ ọrụ ụgbọ ala

N'ichepụta ụgbọ ala, ebe nchekwa na nkwụsi ike dị oke mkpa, ịgbado ọkụ na-eguzogide bụ usoro ịgbado ọkụ a na-ejikarị. A na-ewekarị ya n'ọrụ maka ijikọta ihe igwe dị iche iche n'ime ahụ ụgbọ ala, dị ka elu ụlọ, ọnụ ụzọ, mpempe ígwè, na mkpụrụ ígwè. Ịgbado ọkụ na-eguzogide na-enye arụmọrụ dị elu, ịdị mma ịgbado ọkụ kwụsiri ike, yana ngwa ngwa akpaaka, na-eme ka ọ bụrụ usoro dị mkpa na ụlọ ọrụ nrụpụta ụgbọ ala.

Ngwa ụlọ ọrụ Aerospace

A na-ejikarị welding mgbochi iji jikọọ ihe igwe dị na ụgbọ elu na rọketi, dị ka ịbanye nku ụgbọ elu na fuselages, yana obere akụkụ ọla dị iche iche. Akụkụ ndị a ga-enwerịrị ike na ịdịte aka dị elu, yana ihe siri ike chọrọ maka ogo nkwonkwo, bụ ebe ịgbado ọkụ na-eguzogide karịrị. Ịgbado ọkụ na-eguzogide na-arụ ọrụ dị oke mkpa na ụlọ ọrụ ikuku, yana ndị ọrụ ikuku na-akwadokwa ọganihu na mpaghara a.

Ngwa ụlọ ọrụ eletrọnịkị

A na-ejikarị welding resistor maka akụrụngwa eletrọnịkị yana akụkụ igwe ụfọdụ na ngwaọrụ eletrọnịkị. Ọ na-enye nkenke ịgbado ọkụ dị elu ma dabara adaba maka ijikọ obere ihe dị ka ibe eletrọnịkị na wires. N'ime oge a na-agbanwe ngwa ngwa nke ngwaọrụ eletrọnịkị taa, ịgbado ọkụ resistor na-eme ka mgbakọ elektrọnik na-aga n'ihu, ọganihu ụlọ ọrụ na-anya ụgbọ ala.

Ngwa ụlọ ọrụ dị arọ

A na-ejikarị ịgbado ọkụ na-eguzogide ọgwụ maka ịgbado nnukwu ihe igwe n'ime àkwà mmiri na ụlọ, dị ka àkwà mmiri ala flanges na nchara nkwado. A na-ejikwa ya n'ichepụta nnukwu igwe iji jikọọ akụkụ ígwè. Site na teknụzụ ịgbado ọkụ ya nke ọma ma kwụsie ike, ịgbado ọkụ na-eguzogide aghọwo otu n'ime ụzọ nhazi dị mkpa na ụlọ ọrụ dị arọ. Ọ na-eme ka nchekwa nke akụrụngwa dị arọ na ihe owuwu.

Akụrụngwa na akụrụngwa

Igwe ịgbado ọkụ

Igwe ịgbado ọkụ na-eguzogideA na-ekewa n'ime isi ụzọ anọ: igwe ịgbado ọkụ ntụpọ, igwe ịgbado ọkụ amụma, igwe ịgbado ọkụ, na igwe ịgbado ọkụ, dabere na usoro dị iche iche. Họrọ ngwa ịgbado ọkụ kwesịrị ekwesị dịka njirimara nke ihe na ụdị.

Electrodes

Nkeelectrodebụ ihe dị mkpa akụrụngwa iji hụ na ịgbado ọkụ àgwà. Isi ihe maka ịgbado ọkụ electrodes bụ: chromium zirconium ọla kọpa, aluminum oxide ọla kọpa, beryllium cobalt ọla kọpa, tungsten, molybdenum, graphite, wdg Dabere na dị iche iche workpieces ịbụ welded, electrodes na-ekewa n'ime ewepụghị electrodes, okirikiri electrodes, nut electrodes, bolt. Eletrọd, wdg. A na-ahụkarị, electrode fixation gụnyere taper dabara adaba, na taper oke ukwuu n'ime 1:10 na 1:5.

Sistemụ jụrụ oyi

N'oge ọrụ, igwe ịgbado ọkụ na-eguzogide chọrọ mmiri na-ekesa iji mee ka ihe dị jụụ dị ka electrodes na transformers. Ya mere, anyị na-etinye usoro jụrụ oyi maka igwe ịgbado ọkụ. Okpomọkụ mmiri jụrụ oyi kwesịrị ịdị n'okpuru 30 Celsius. Ọ bụrụ na okpomọkụ dị oke elu, ọ nwere ike ịkpalite nkwụsị nchebe nke igwe ịgbado ọkụ. Ọ kacha mma iji mmiri jụrụ oyi na-adịghị ọcha maka mgbasa iji gbochie ntụpọ mmiri na mgbochi ọkpọkọ.

Otu esi ahọrọ usoro ịgbado ọkụ nke ọma?

Nhọrọ nke usoro ịgbado ọkụ na-adabere n'ọtụtụ ihe.

Ọkpụrụkpụ na ụdị ọrụ: dị iche icheusoro ịgbado ọkụadabara workpieces nke iche iche ọkpụrụkpụ na shapes. Dịka ọmụmaatụ, ịgbado ọkụ na-eguzogide na-adabara naanị maka ịgbado mpempe ọla dị mkpa, ebe a na-ejikarị arụ ọrụ na-agbado nke ọma na nke siri ike site na iji mgbado arc.

Ọdịmma ịgbado ọkụ chọrọ: Ogo ịgbado ọkụ achọrọ na-ekpebikwa nhọrọ nke usoro ịgbado ọkụ. N'ihi na workpieces chọrọ elu akara na nkwonkwo ike, ịgbado ọkụ ụzọ na-emezu ndị a chọrọ kwesịrị họrọ.

Mmepụta arụmọrụ na ọnụ ahịa: Ọ bụrụ na achọrọ oke mmepụta kwa afọ, ịhọrọ usoro ịgbado ọkụ na arụmọrụ dị elu dị mkpa. Ekwesịrị iburu n'uche ọnụ ahịa.

Ihe kpatara gburugburu ebe obibi: Ụfọdụ ụzọ ịgbado ọkụ na-emepụta ihe mkpofu na ikuku, na-ebute mmetọ gburugburu ebe obibi. Ya mere, ekwesịrị iburu n'uche ihe gbasara gburugburu ebe obibi mgbe ị na-ahọrọ usoro ịgbado ọkụ.

Ajụjụ:

Gịnị bụ adịghị ike nke iguzogide ịgbado ọkụ?

Ịgbado ọkụ na-eguzogide adịghị mma maka ịgbado nnukwu ihe igwe.

Kedu otu ị ga-esi hụ na nchekwa na ịgbado ọkụ na-eguzogide?

Mgbe ị na-arụ ọrụ ịgbado ọkụ na-eguzogide, yi okpu agha na enyo nchekwa.

Kedu ka m ga-esi nweta ọzụzụ n'ịgbado ọkụ na-eguzogide?

Ị nwere ike nweta ọzụzụ na aiguzogide ịgbado ọkụ emeputa.

Gịnị bụ isi àgwà nsogbu nke iguzogide ịgbado ọkụ nkwonkwo?

Njikọ solder oyi, ike ezughị oke, nrụrụ ịgbado ọkụ, oxidation.

Ụzọ nyocha maka nkwonkwo ịgbado ọkụ

Nnwale na-emebi emebi, nyocha microscopic, nlele anya, nnwale metallographic, nnwale ultrasonic.

Oge nzipu: Eprel-02-2024