There are many ways to join metals, and welding is a necessary technique for connecting many metal parts. If you’re new to the welding industry, you might not realize how many different welding processes exist to connect metals. This article will explain the main 8 welding processes, giving you a deeper understanding of the welding industry.

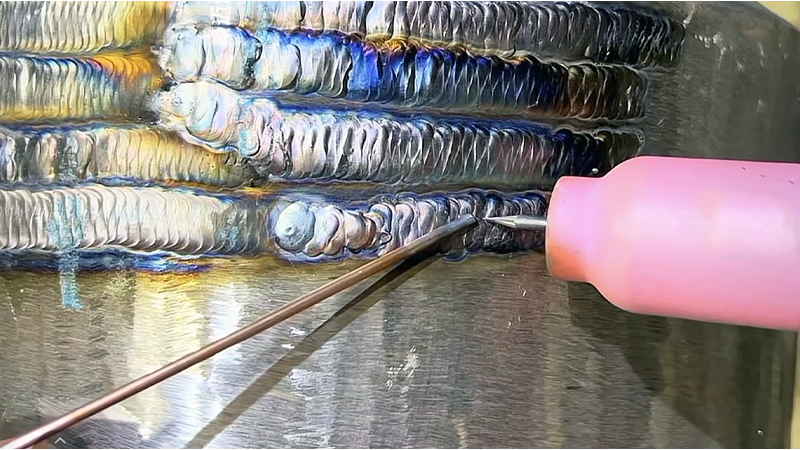

Arc Welding

Arc welding uses an electric arc to generate heat, melting and fusing metals together. This is the most common welding process and includes techniques like manual arc welding and gas-shielded welding.

Manual arc welding is ideal for structural steel.

Gas-shielded welding works well for materials like stainless steel and aluminum.

Tips: Protect the weld area from oxidation and sparks, and control the current and voltage settings to achieve the best results.

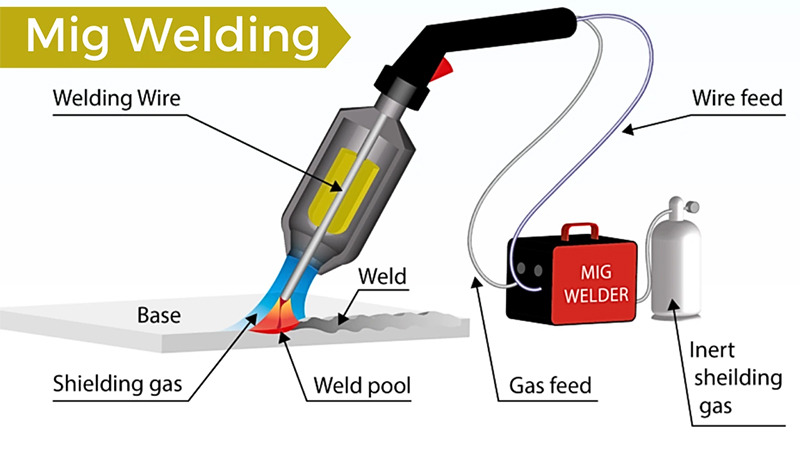

MIG/MAG Welding

MIG/MAG welding involves feeding a continuous wire electrode through the welding torch while an arc melts the wire and the metal surface to create a weld. Shielding gas flows through the torch to protect the weld from contamination.

MIG welding is popular in industries like shipbuilding, pipeline construction, and steel structures.

Great for large, immovable workpieces and repair projects.

TIG Welding

TIG welding, or Tungsten Inert Gas welding, uses a non-consumable tungsten electrode to create high-precision welds. A protective gas, like argon, shields the weld area from contamination.

High precision makes it ideal for delicate materials like aluminum and stainless steel.

Commonly used in automotive, aerospace, and precision manufacturing industries.

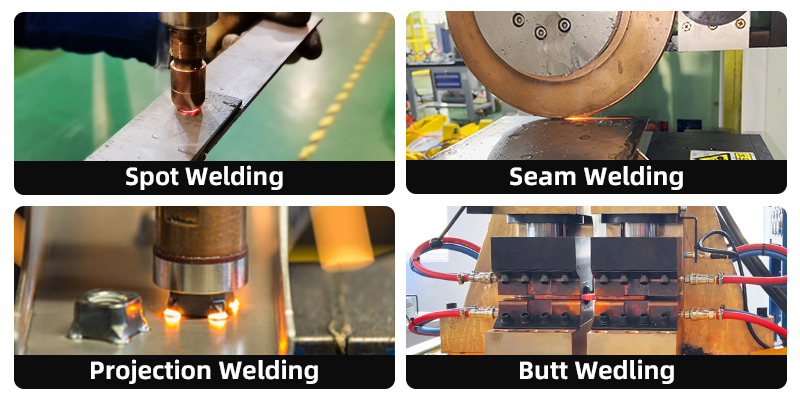

Resistance Welding

In resistance welding, two metal pieces are pressed between electrodes, and an electric current creates heat to join them. The main types include spot welding, projection welding, butt welding, and seam welding.

Resistance welding is fast, doesn’t need filler material, and is easy to automate.

It’s widely used in automotive parts, electronics, and home appliances. For example, it’s perfect for welding car nuts.

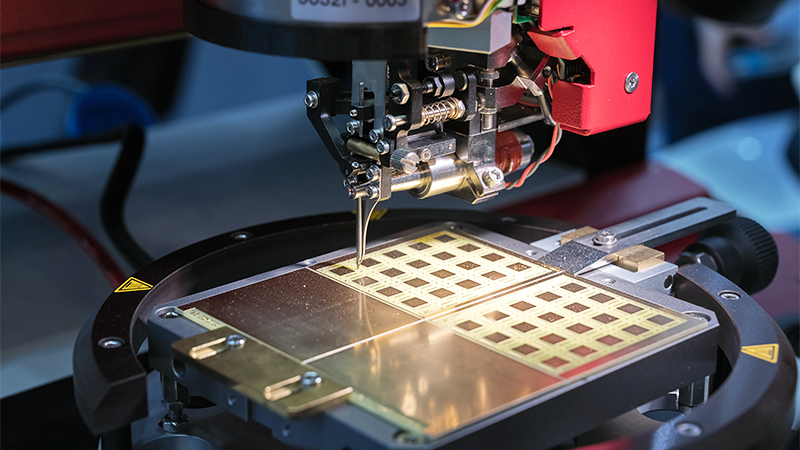

Laser Welding

Laser welding is a method that uses a laser beam as the energy source to precisely heat and join metals or plastics. Compared to traditional arc welding, laser welding is faster and more efficient. It can be easily combined with robot welder and is a key technique in laser material processing. Laser welding does not require electrodes and does not need to contact the workpiece material. When welding thin materials or fine wires, it does not cause back melting like arc welding.

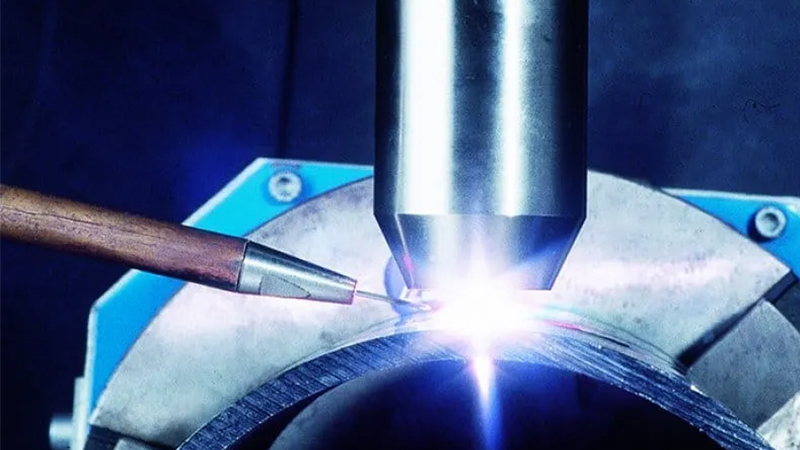

Plasma Welding

Plasma welding generates plasma through a high-energy arc, which melts the workpiece. Filler material is added to join the metals together.

Works with metals, plastics, and ceramics.

Often used in aerospace, automotive, and electronics manufacturing.

Ultrasonic Welding

Ultrasonic welding applies high-frequency vibrations to two surfaces under pressure, causing them to fuse without melting. This technique works for metals, plastics, and even dissimilar materials.

Produces precise, clean joints and is easy to automate.

Common in industries requiring fine, solid-state welding.

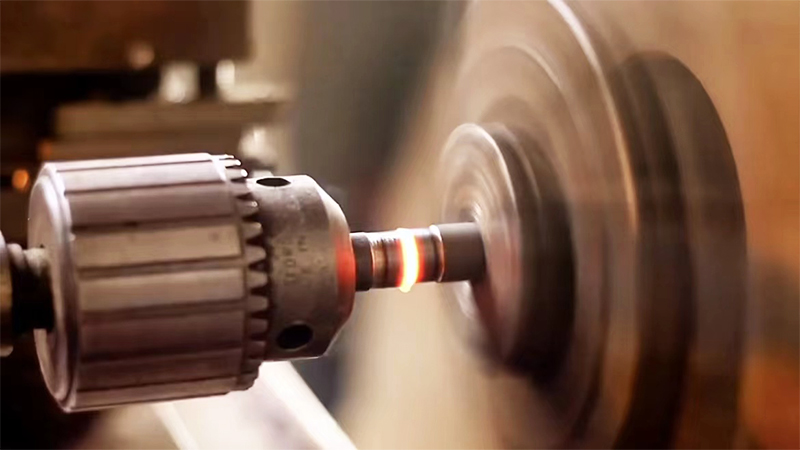

Friction Welding

Friction welding generates heat through the rapid rubbing of two surfaces, softening them to create a strong bond. This solid-state process eliminates the need for an external heat source.

Prevents defects like deformation and cracks.

Widely used in industrial production, such as aircraft wheels and railway axles.

How to Choose the Right Welding Process

When selecting a welding process, consider:

Material type (e.g., aluminum, stainless steel)

Workpiece size and thickness

Precision requirements

Whether automation is needed

Testing multiple methods can help you find the best solution for your specific project.

By understanding these 8 main welding processes, you can choose the right method for your project and explore new opportunities in the welding industry.

Frequently Asked Questions

1. Which welding process is best for automotive components?

Resistance welding is the top choice for automotive parts due to its fast speed, aesthetic finish, and easy automation.

2. What materials can be welded?

You can weld a variety of metals, including stainless steel, copper, aluminum, and galvanized steel.

3. Do all welding processes use filler rods?

No. For example, resistance welding doesn’t require filler rods.

4. Where can I learn more welding skills?

You can attend specialized vocational schools or get hands-on experience in manufacturing facilities.

Post time: Oct-21-2024