Pali njira zambiri zolumikizira zitsulo, ndipo kuwotcherera ndi njira yofunikira yolumikizira zitsulo zambiri. Ngati ndinu watsopano pantchito yowotcherera, mwina simungazindikire kuti pali njira zingati zowotcherera zolumikizira zitsulo. Nkhaniyi ifotokoza njira zazikulu 8 zowotcherera, kukupatsani kumvetsetsa mozama zamakampani azowotcherera.

Kuwotcherera kwa Arc

Kuwotcherera kwa arcamagwiritsa ntchito arc yamagetsi kupanga kutentha, kusungunuka ndi kusakaniza zitsulo pamodzi. Iyi ndiye njira yowotcherera yodziwika kwambiri ndipo imaphatikizanso njira monga kuwotcherera pamanja ndi kuwotcherera kwa gasi.

Kuwotcherera arc pamanja ndikwabwino pazitsulo zamapangidwe.

Zowotcherera zotetezedwa ndi gasi zimagwira ntchito bwino pazinthu monga chitsulo chosapanga dzimbiri ndi aluminiyamu.

Malangizo: Tetezani malo owotcherera ku makutidwe ndi okosijeni ndi moto, ndikuwongolera makonzedwe apano ndi magetsi kuti mukwaniritse zotsatira zabwino.

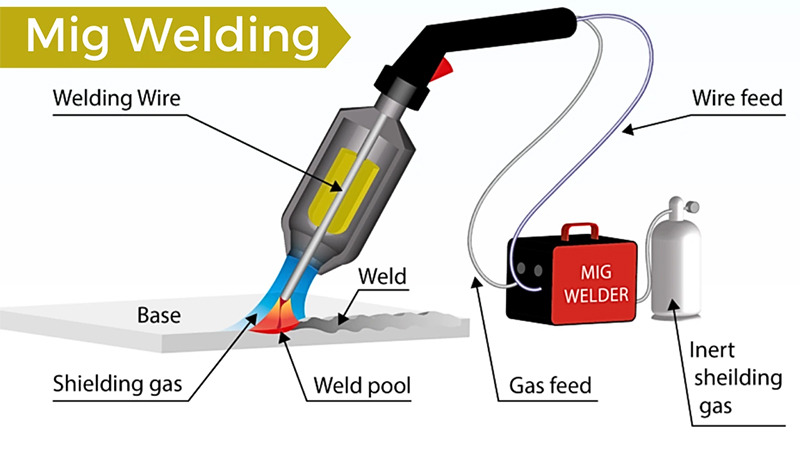

Kuwotcherera kwa MIG/MAG

Kuwotcherera kwa MIG/MAG kumaphatikizapo kudyetsa ma elekitirodi wawaya mosalekeza kudzera mu tochi yowotcherera pomwe arc imasungunula waya ndi chitsulo pamwamba kuti apange chowotcherera. Gasi wotchinga amadutsa munyaliyo kuteteza weld kuti asaipitsidwe.

kuwotcherera MIGndi yotchuka m'mafakitale monga omanga zombo, kupanga mapaipi, ndi zitsulo.

Zabwino kwambiri pazogwirira ntchito zazikulu, zosasunthika komanso kukonza mapulojekiti.

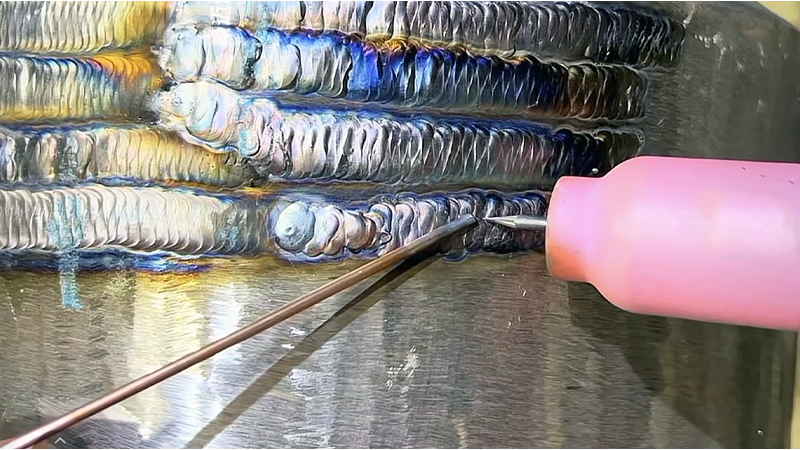

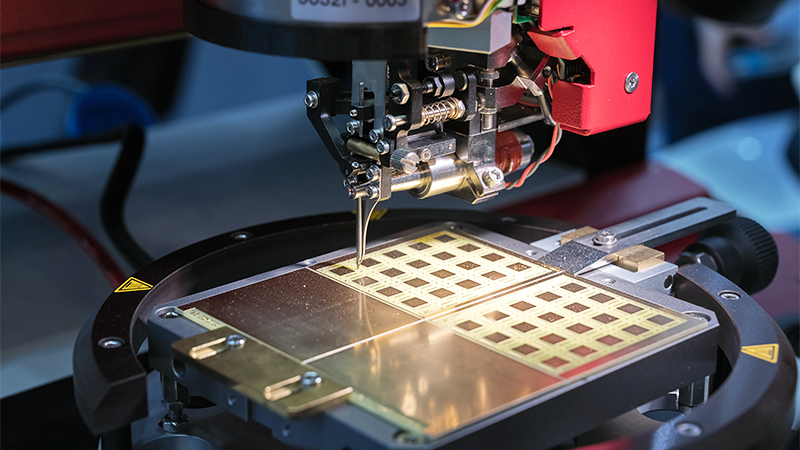

Kuwotchera kwa TIG

kuwotcherera TIG, kapena Tungsten Inert Gasi kuwotcherera, amagwiritsa ntchito electrode ya tungsten yosagwiritsidwa ntchito kuti apange ma welds olondola kwambiri. Gasi woteteza, ngati argon, amateteza malo owotcherera kuti asaipitsidwe.

Kulondola kwambiri kumapangitsa kuti ikhale yabwino pazinthu zosalimba monga aluminiyamu ndi chitsulo chosapanga dzimbiri.

Amagwiritsidwa ntchito m'mafakitale opangira magalimoto, ndege, komanso mwatsatanetsatane.

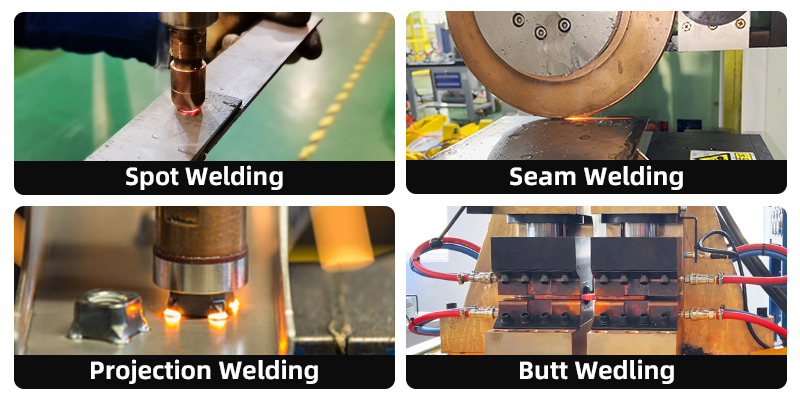

Resistance Welding

In kukana kuwotcherera, zidutswa ziwiri zazitsulo zimapanikizidwa pakati pa ma electrode, ndipo mphamvu yamagetsi imapanga kutentha kuti igwirizane nawo. Mitundu yayikulu imaphatikizapo malo, mawonedwe, matako, ndi kuwotcherera kwa msoko.

Resistance welding ndi yachangu, safuna zinthu zodzaza, ndipo ndiyosavuta kupanga makina.

Amagwiritsidwa ntchito kwambiri m'zigawo zamagalimoto, zamagetsi, ndi zida zapanyumba. Mwachitsanzo, ndi yabwino kuwotcherera mtedza galimoto.

Kuwotcherera kwa Laser

Kuwotcherera kwa laserndi njira yomwe imagwiritsa ntchito mtengo wa laser ngati gwero lamphamvu kuti litenthetse bwino ndikuphatikiza zitsulo kapena mapulasitiki. Poyerekeza ndi kuwotcherera kwachikhalidwe cha arc, kuwotcherera kwa laser ndikothamanga komanso kothandiza. Ikhoza kuphatikizidwa mosavuta ndiwowotchera robotndipo ndi njira yofunika kwambiri pakukonza zinthu za laser. Kuwotcherera kwa laser sikufuna maelekitirodi ndipo sikuyenera kulumikizana ndi zida zogwirira ntchito. Mukawotchera zinthu zoonda kapena mawaya abwino, sizimayambitsa kusungunuka kwa mmbuyo ngati kuwotcherera kwa arc.

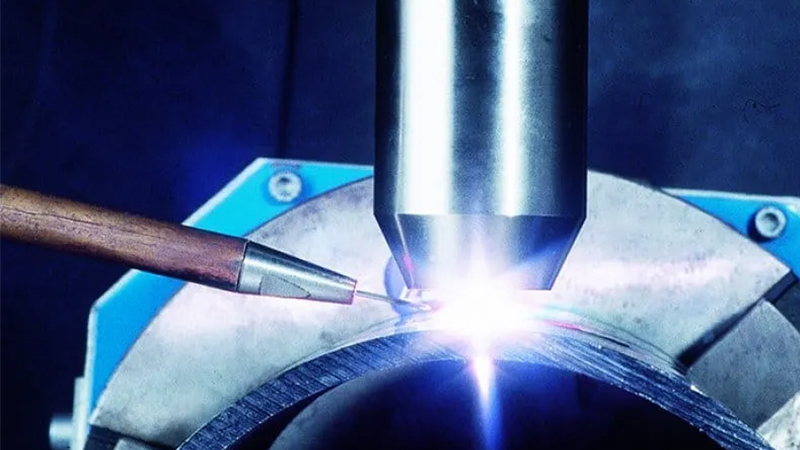

Kuwotcherera kwa Plasma

Kuwotcherera kwa plasma kumapanga madzi a m'magazi kudzera mu arc yamphamvu kwambiri, yomwe imasungunula chogwirira ntchito. Zinthu zodzaza zimawonjezeredwa kuti zilumikizane ndi zitsulo.

Amagwira ntchito ndi zitsulo, mapulasitiki, ndi ceramics.

Nthawi zambiri amagwiritsidwa ntchito muzamlengalenga, magalimoto, ndi zamagetsi.

Akupanga kuwotcherera

Akupanga kuwotcherera kumagwiritsa ntchito kugwedezeka kwapang'onopang'ono kumalo awiri opanikizika, kuwapangitsa kuti aziphatikizana popanda kusungunuka. Njirayi imagwira ntchito pazitsulo, mapulasitiki, ngakhalenso zinthu zosiyana.

Zimapanga zolumikizira zolondola, zoyera komanso zosavuta kupanga zokha.

Zofala m'mafakitale omwe amafunikira kuwotcherera bwino, kolimba.

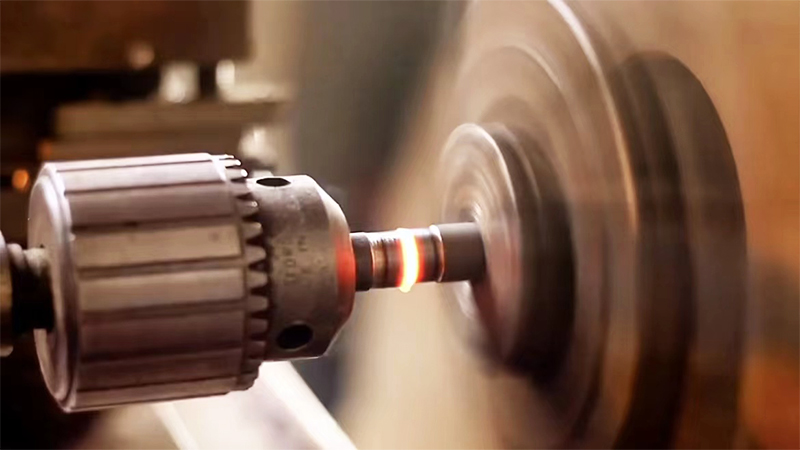

Kuwotchera kwa Friction

Friction welding imatulutsa kutentha kudzera mukusisita kofulumira kwa malo awiri, kuwafewetsa kuti apange mgwirizano wolimba. Njira yolimba iyi imathetsa kufunikira kwa gwero la kutentha kwakunja.

Amateteza zolakwika monga deformation ndi ming'alu.

Amagwiritsidwa ntchito kwambiri popanga mafakitale, monga mawilo a ndege ndi ma axle a njanji.

Momwe Mungasankhire Njira Yowotcherera Yoyenera

Posankha njira yowotcherera, ganizirani:

Mtundu wazinthu (mwachitsanzo, aluminiyamu, chitsulo chosapanga dzimbiri)

Kukula kwa workpiece ndi makulidwe

Zofunikira mwatsatanetsatane

Kaya automation ikufunika

Kuyesa njira zingapo kungakuthandizeni kupeza yankho labwino kwambiri la polojekiti yanu.

Pomvetsetsa njira zazikuluzikulu 8 zowotcherera, mutha kusankha njira yoyenera ya polojekiti yanu ndikuwunika mwayi watsopano pantchito yowotcherera.

Mafunso Ofunsidwa Kawirikawiri

1. Ndi njira iti yowotcherera yomwe ili yabwino kwambiri pazigawo zamagalimoto?

Resistance welding ndiye chisankho chapamwamba pamagawo agalimoto chifukwa chakuthamanga kwake, kumalizidwa kokongola, komanso makina osavuta.

2. Ndi zipangizo ziti zomwe zingathe kuwotcherera?

Mukhoza kuwotcherera zitsulo zosiyanasiyana, kuphatikizapo zitsulo zosapanga dzimbiri, mkuwa, aluminiyamu, ndi zitsulo.

3. Kodi njira zonse zowotcherera zimagwiritsa ntchito ndodo zodzaza?

Ayi. Mwachitsanzo, kuwotcherera kukana sikufuna ndodo zodzaza.

4. Kodi ndingaphunzire kuti luso lowotcherera?

Mutha kupita kusukulu zapadera zantchito kapena kudziwa zambiri pazopanga.

Nthawi yotumiza: Oct-21-2024