Ma sheet Metal kuwotcherera amagwiritsidwa ntchito m'mafakitale ambiri. Nthawi zonse mukafuna kujowina zitsulo, mumaganizira momwe mungawotchere. Ukadaulo wowotcherera wapita patsogolo kwambiri, ndipo kusankha njira yoyenera kuwotcherera kungapangitse ntchito yanu kukhala yosavuta komanso yothandiza kwambiri. Nkhaniyi ikuthandizani kumvetsetsa kuwotcherera kwachitsulo ndikukuthandizani kupeza njira yoyenera yowotcherera.

Kodi Welding Metal Metal N'chiyani?

Mapepala metal kuwotchererandi zipangizo processing luso, amene amatanthauza kugwirizana kwaawirikapena kulekanitsa mbali zachitsulo kukhala imodzi mwa njira zina. Ndi chitukuko cha teknoloji ya mafakitale, teknoloji yowotcherera ikugwiritsidwa ntchito kwambiri, yomwe ndi njira yofunika kwambiri pakupanga zitsulo zamakampani opanga zinthu.

Kodi njira zowotcherera zitsulo ndi ziti?

Pali mitundu yambiri ya njira zowotcherera zitsulo, malinga ndi momwe zinthu zilili ndi ndondomeko yazitsulo muzitsulo zowotcherera, njira zowotcherera zitsulo zimagawidwa m'magulu atatu: kuphatikizika kuwotcherera, kuwotcherera kuthamanga ndi kuwotcherera.

Kuwotcherera kwa Fusion

Fusion welding ndi njira yolumikizira mbali zachitsulo pozitenthetsa ndi kuzisungunula palimodzi. Njira imeneyi sikutanthauza kukakamizidwa. Zolumikizira ziwirizi zimatenthedwa, zomwe zimapangitsa chitsulo kupanga mphamvu yayikulu ya atomiki, kupanga madzi amadzi pamalo otentha. Ma atomu achitsulo a zida ziwirizi amafalikira ndikuphatikizana. Chitsulo chosungunukacho chikazizira, chimakhala cholumikizira mwamphamvu.

Njira zowotcherera zophatikizika zimaphatikiza kuwotcherera kwa arc, kuwotcherera gasi, ndi kuwotcherera kwa laser.

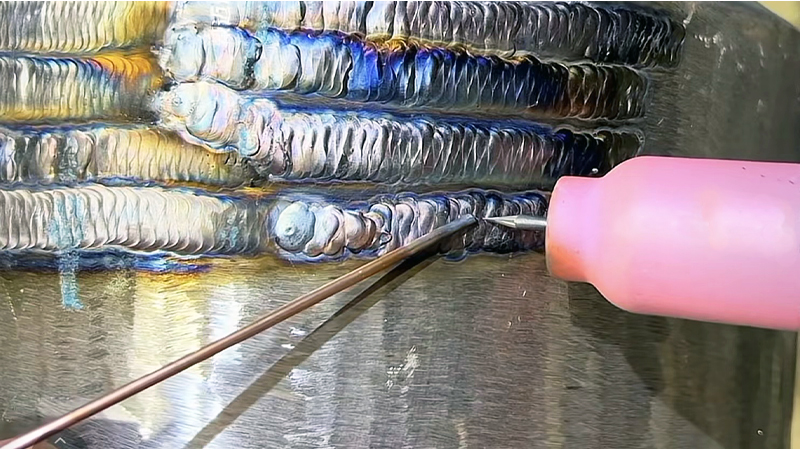

Kuwotcherera kwa Arc

Kuwotcherera kwa arcimayendetsedwa ndi gwero lamagetsi lomwe limatuluka pakati pa ma elekitirodi ndi zida ziwirizo kupanga arc. Arc iyi imasandulika kutentha, kusungunula ma elekitirodi ndi ma workpieces, kulumikiza zitsulo pamodzi. Panthawi yowotcherera, magetsi otsika komanso apamwamba kwambiri amatulutsa kutentha kwambiri komanso kuwala kwambiri, kuyatsa ma elekitirodi ndi zida zogwirira ntchito kuti apange dziwe losungunuka lomwe limazizira kuti lipange weld.

Njira yowotcherera imeneyi imakhala ndi ntchito zambiri ndipo imatha kugwiritsidwa ntchito powotcherera zitsulo zosiyanasiyana monga chitsulo chosapanga dzimbiri, aluminiyamu, mkuwa, ndi chitsulo cha carbon. Chifukwa zida zowotcherera arc ndizosavuta kugwiritsa ntchito, zimagwiritsidwa ntchito kwambiri m'mafakitale monga kupanga makina, kupanga, ndi kupanga zombo. Mwachitsanzo, imagwiritsidwa ntchito polumikizana ndi rebar pomanga. Kuphatikiza apo, kuwotcherera kwa arc kumagwiritsidwa ntchito nthawi zambiri kukonza zida ndi kukonza njanji.

Kuwotcherera kwa Arc kumafuna makina owotcherera arc, ndodo zowotcherera, ndi chishango chakumaso. Ndi njira yotsika mtengo komanso yogwiritsidwa ntchito kwambiri kuwotcherera. Komabe, chifukwa cha zovuta zake zamakono, ubwino wa weld umadalira kwambiri luso la wowotchera.

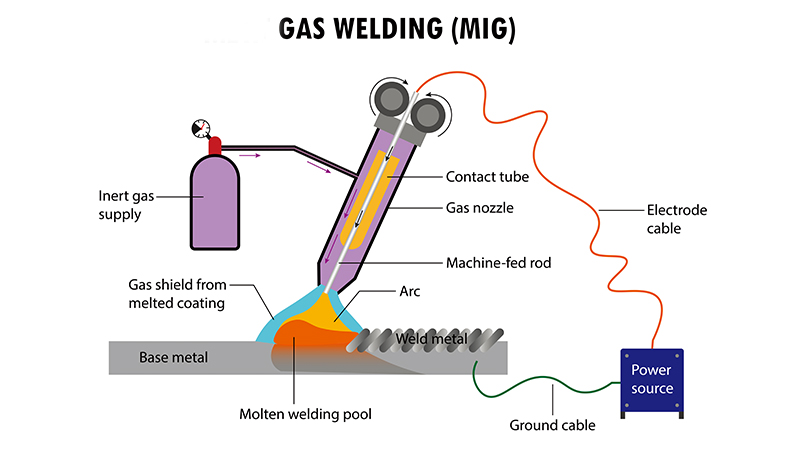

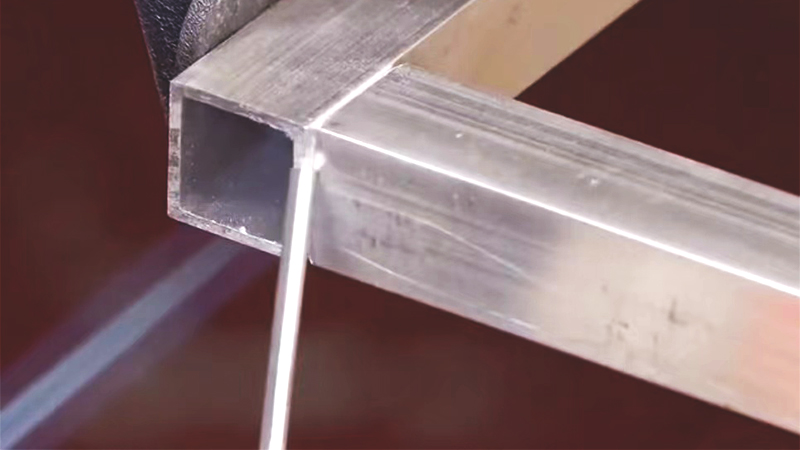

Kuwotcherera Gasi

Kuwotcherera gasiamagwiritsa ntchito mitundu iwiri ya gasi: gasi wamafuta ndi mpweya wa okosijeni. Kuyaka kwa gasi kumatulutsa kutentha, komwe kumagwiritsidwa ntchito kusungunula zitsulo ndi ndodo yowotcherera yomwe imadyetsedwa mosalekeza pakati pa zida ziwirizi, ndikumaliza kugwirizana kwachitsulo.

Kuwotcherera gasi nthawi zambiri kumagwiritsidwa ntchito powotcherera zitsulo monga chitsulo, aluminiyamu, ndi mkuwa. Imapereka maubwino monga kusinthasintha pakugwiritsa ntchito, palibe malire pa malo ogwirira ntchito, komanso ntchito yosavuta. Kuonjezera apo, sichifuna magetsi, ndikupangitsa kuti igwiritsidwe ntchito kwambiri panja komanso pamapangidwe opangira zitsulo. Ngati mukufuna kukonza chitoliro chachitsulo, kuwotcherera gasi ndi chisankho chabwino kwambiri.

Komabe, kuwotcherera gasi kuli ndi malire ake. Ubwino wa weld umakhudzidwa kwambiri ndi mtundu wa ndodo yowotcherera, ndipo zolumikizira zowotcherera zimatha kusinthika. Kuonjezera apo, kupanga bwino kumakhala kochepa.

Kuwotcherera kwa Laser

Kuwotcherera kwa laseramagwiritsa ntchito mtengo wa laser ngati gwero la kutentha kwake. Mtengo wa laser umagunda m'mphepete mwa zitsulo zogwirira ntchito, kutulutsa kutentha ndikupanga dziwe la weld. Laser ikachoka, m'mphepete mwazitsulo zosungunula zimazizira komanso zimalumikizana. Njirayi ingagwiritsidwe ntchito pophatikizana ma welds, ma welds, ndi zomata zomata pamafakitale osiyanasiyana.

Laser kuwotcherera ali kudya kuwotcherera liwiro ndi dzuwa mkulu, ndipo angagwiritsidwenso ntchito kuwotcherera sanali zitsulo. Ndiukadaulo wapamwamba wowotcherera womwe umagwiritsidwa ntchito kwambiri m'mafakitale monga kupanga magalimoto, zamagetsi, ndi zodzikongoletsera. Komabe, sichingalowe m'zinthu zolimba, choncho ndizoyenera kwambiri pazitsulo zopyapyala. Poyerekeza ndi njira zina zowotcherera, zida zowotcherera za laser zimakhala zodula kwambiri.

Press Welding

Mosiyana ndi kuwotcherera kwa fusion, kuwotcherera kukakamiza kumafunika kukakamiza zitsulo kuti zitheke panthawi yowotcherera. Zida zachitsulo sizimasungunuka kukhala madzi koma zimakhala zolimba. Kuwotcherera kokakamiza kumaphatikizanso kutenthetsa mfundo zachitsulo kuti ziwonjezeke pulasitiki, ndiyeno kukakamiza zitsulo zapulasitiki, zomwe zimapangitsa kuti pakhale cholumikizira champhamvu kwambiri. Chifukwa chake, kupanikizika kumagwira ntchito yofunika kwambiri pakuchita izi.

Ndi chitukuko cha chuma cha mafakitale, zida zambiri zatsopano ndi zinthu zatuluka, zomwe zapangitsa kuti pakhale zotsogola mosalekeza muukadaulo wazowotcherera. Njira zazikulu zowotcherera pakali pano zikuphatikiza kuwotcherera kukana, kuwotcherera kufalikira, kuwotcherera kwa mikangano, ndi kuwotcherera kwa ultrasonic.

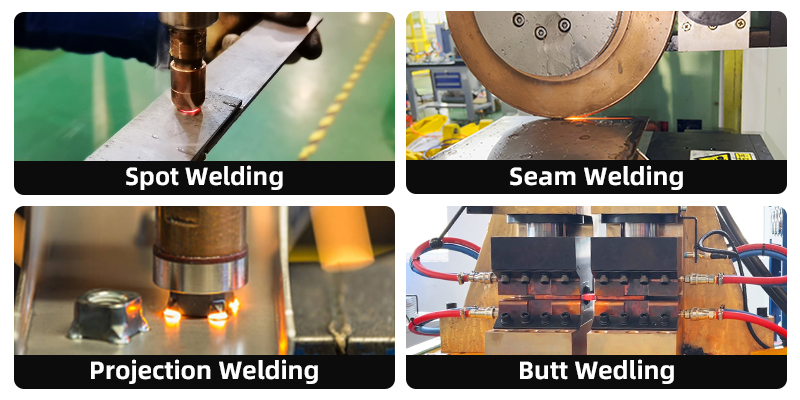

Resistance Welding

Kukaniza kuwotchereraimagwiritsa ntchito magetsi kutenthetsa polumikizira zitsulo zogwirira ntchito kwinaku ikugwiritsa ntchito ma elekitirodi kuti amalize kuwotcherera. Nthawi zambiri amagwiritsidwa ntchito kuwotcherera chitsulo chosapanga dzimbiri, mkuwa, aluminiyamu, ndi chitsulo cha carbon. Chifukwa cha mawonekedwe ake apamwamba komanso osasinthasintha, kuwotcherera kumagwira ntchito yofunika kwambiri pamagalimoto, zamagetsi, ndi zamlengalenga. Ndi kupita patsogolo kwaukadaulo, kukana kuwotcherera kwaphatikizira ma automation, kukulitsa luso la kupanga.

Kukaniza kuwotcherera kungagawidwe m'njira zinayi:kuwotcherera malo, kuwotcherera projekiti,kuwotcherera msoko,ndikuwotcherera matako. Mwachitsanzo, ngati mukufuna kuwotcherera mbali yagalimoto, monga kuyika nati ku mbale yachitsulo, mutha kugwiritsa ntchito kuwotcherera. Komabe, zida zowotcherera zokana nthawi zambiri zimakhala zokulirapo komanso sizisunthika, zomwe zimalepheretsa kugwiritsidwa ntchito kwake kuzinthu zinazake. Nthawi iliyonse mukawotcherera zida zachitsulo kapena makulidwe osiyanasiyana, magawowo amayenera kusinthidwa, kuti akhale oyenera kuwotcherera kwamphamvu kwambiri kwazinthu zachitsulo.

Diffusion Welding

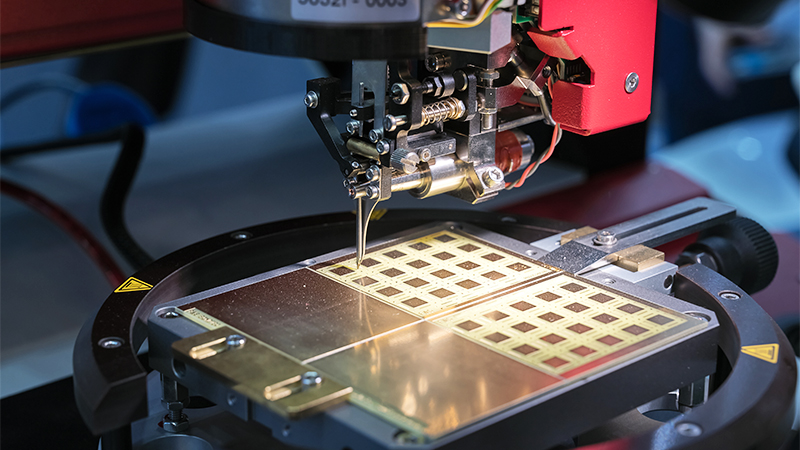

Kuwotcherera kwapakati, yomwe imadziwikanso kuti diffusion bonding, imaphatikizapo kutenthetsa ndi kuyika mphamvu pazitsulo panthawi yowotcherera. Njirayi imalola maatomu ndi mamolekyu azinthu zachitsulo kuti azifalikira ndikumangirira pansi pa kutentha kwakukulu ndi kupanikizika. Kuwotcherera kwa diffusion kumatha kugwiritsidwa ntchito pazinthu zonse zofananira komanso zosiyana, zomwe nthawi zambiri zimalumikiza mkuwa, aluminiyamu, ndi zida zophatikizika.

Njirayi imatha kuwotcherera mafupa angapo pagulu, monga kuwotcherera zigawo 20 za zojambulazo zamkuwa za 0,1 mm. Diffusion kuwotcherera kumapanga mafupa amphamvu omwe amalimbana ndi mapindikidwe, nthawi zambiri amachotsa kufunika kokonzanso. Komabe, ilinso ndi zovuta zake, kuphatikiza kutsika kwapang'onopang'ono komanso kutsika mtengo kwa zida.

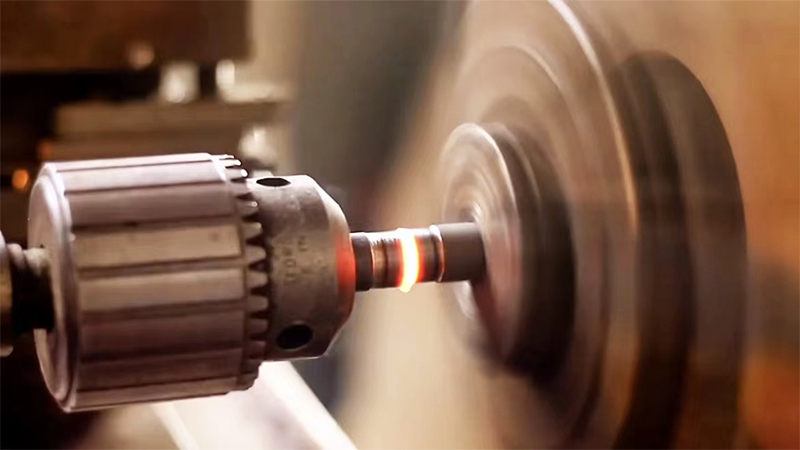

Kuwotchera kwa Friction

Kuwotcherera frictionndi njira yowotcherera yomwe imagwiritsa ntchito kutentha kochokera kumayendedwe osagwirizana pakati pa zida zogwirira ntchito. Ndi njira yabwino, yopulumutsira mphamvu yomwe imapanga ma welds apamwamba kwambiri. Poyerekeza ndi kuwotcherera kwa matako a flash, kuwotcherera kwa friction kumakhala ndi kagawo kakang'ono komwe kakhudzidwa ndi kutentha ndipo ndikoyenera kujowina zitsulo zosiyana.

Friction welding ndi yapadera ndipo imapereka zabwino monga kugwiritsa ntchito mphamvu zochepa komanso kusamala zachilengedwe, kupangitsa kuti ikhale yotchuka m'mafakitale monga kupanga makina, mlengalenga, ndi mphamvu. Komabe, nthawi zambiri ndi yoyenera kulumikiza ndodo zachitsulo ndi mapaipi amtundu womwewo. Mawonekedwe ndi malo ophatikizira a zogwirira ntchito atakhazikika, zimakhala zovuta kuwotcherera.

Akupanga kuwotcherera

Akupanga kuwotcherera amagwiritsa mkulu-pafupipafupi kugwedera kwaiye akupanga mafunde kulenga mikangano, mapindikidwe, ndi kutentha pa zitsulo kukhudzana pamalo. Kupanikizika kumagwiritsidwa ntchito ndi nyanga zapamwamba ndi zapansi kuti amalize ntchito yowotcherera. Iyi ndi njira yapadera yowotcherera yomwe simaphatikiza magetsi akudutsa pazigawo zogwirira ntchito kapena magwero otentha akunja, ndipo imagawana mawonekedwe ena ndi kuwotcherera kwa mikangano ndi kuwotcherera.

Akupanga kuwotchereraitha kugwiritsidwa ntchito pazinthu zosiyanasiyana, kuphatikiza zitsulo zofanana komanso zosiyana monga mkuwa, aluminiyamu, golide, ndi siliva. Komabe, amagwiritsidwa ntchito kwambiri pakuwotcherera zinthu zopanda zitsulo monga ABS, PP, ndi PC, komwe kumatulutsa zotsatira zabwinoko.

Brazing Welding

Brazingndi kuwotcherera njira kumene filler zitsulo ndi mfundo kusungunuka m'munsimu kuti workpieces ndi kutenthedwa ndi kusungunuka kudzaza mipata pakati pa workpieces zitsulo ziwiri, kumaliza zitsulo kujowina ndondomeko. Mosiyana ndi kuwotcherera maphatikizidwe ndi kuwotcherera kuthamanga, njirayi sifunikira kusungunula zogwirira ntchito kapena kukakamiza. Brazing imagwiritsidwa ntchito pophatikiza zida zophatikizika, zokhala ndi mipata yoyambira 0.01 mpaka 0.1 millimeters.

Masiku ano, brazing ikugwiritsidwa ntchito kwambiri m'mafakitale onse monga makina, zamagetsi, zida, ndi kuyatsa. Ubwino wa brazing makamaka zimadalira zitsulo zodzaza zomwe zimagwiritsidwa ntchito. Choncho, powotchera zitsulo zogwirira ntchito, ndikofunika kusankha chitsulo chodzaza ndi zinthu zabwino zonyowetsa zomwe zingathe kudzaza mafupa. Brazing imagawidwa muzitsulo zofewa komanso zolimba zolimba kutengera malo osungunuka azitsulo zodzaza.

Zofewa Soldering

Soldering yofewa imagwiritsa ntchito zitsulo zodzaza ndi malo osungunuka pansi pa 450 digiri Celsius. Malumikizidwe omwe amapangidwa kudzera mu soldering yofewa amakhala ndi mphamvu zochepa komanso amakana kutentha. Amagwiritsidwa ntchito kwambiri polumikizira magetsi muzinthu zamagetsi zolondola komanso zomangira ndi zitsulo zogulitsira. Ngati zofunikira zamphamvu sizili zovuta ndipo malo osungunuka a zitsulo zodzaza ndi apamwamba kuposa zitsulo zomwe zimagulitsidwa, soldering yofewa ingagwiritsidwe ntchito.

Zovuta Ndiyelkupempha

Brazing yokhala ndi zitsulo zodzaza kwambiri zosungunuka, zomwe zimadziwika kuti hard soldering, zimagwiritsa ntchito zitsulo zodzaza ndi malo osungunuka pamwamba pa 450 digiri Celsius. Malumikizidwe opangidwa kudzera muzitsulo zolimba amakhala amphamvu poyerekeza ndi omwe amachokera ku soldering yofewa. Kumanga molimba nthawi zambiri kumagwiritsa ntchito zinthu monga siliva, aluminiyamu, mkuwa, ndi faifi tambala. Kusankhidwa kwazitsulo zodzaza kumatengera mawonekedwe a zida zogwirira ntchito komanso zofunikira zamagulu olumikizirana. Kuwotchera molimba nthawi zambiri kumakhala koyenera chitsulo chosapanga dzimbiri, ma aluminiyamu, mkuwa, ndi zida zina zokhala ndi mphamvu zambiri. Amagwiritsidwa ntchito pamalumikizidwe omwe amagwira ntchito kutentha kwambiri ndipo amapeza ntchito zambiri muzamlengalenga, zamagetsi, ndi mafakitale amagetsi.

Mapeto

Pali mitundu yosiyanasiyana ya kuwotcherera zitsulo, ndipo zomwe tazitchula pamwambapa ndi zina mwa njira zofala kwambiri. Pamene teknoloji yowotcherera ikupita patsogolo, njira zowotcherera zikuchulukirachulukira. Poganizira mmene kuwotcherera zitsulo workpieces wanu, ndi bwino kuganizira mbali monga zinthu workpiece, mawonekedwe ake, malo ntchito, ndi zina. Kusankha njira yoyenera yowotcherera potengera izi ndikofunikira.

Nthawi yotumiza: Jun-19-2024