Ngati ndinu watsopano ku kukana kuwotcherera kapena mukuyang'ana kuti mumvetsetse bwino, ndiye kuti muyenera kuwerenga nkhaniyi mosamala. Nkhaniyi idzakutengerani mozama mu dziko la resistance welding. Kaya ndinu woyamba kapena mukufuna kukulitsa chidziwitso chanu, nkhaniyi ikupatsani chidziwitso chofunikira.

Kodi Resistance Welding ndi Chiyani?

Resistance welding ndi njira yolumikizira zitsulo zothamanga kwambiri, yotsika mtengo. Njira yowotcherera iyi ndi yoyenera pamiyendo, zolumikizira matako, kapena zolumikizira zomwe sizifuna kulimba kwa mpweya, zokhala ndi makulidwe osakwana 6mm pamapepala owonda. Zachidziwikire, imatha kuwotcherera zitsulo zokulirapo komanso zazikulu, koma magwiridwe ake onse sangakhale abwino ngati njira zina zowotcherera.

Tanthauzo ndi Zoyambira

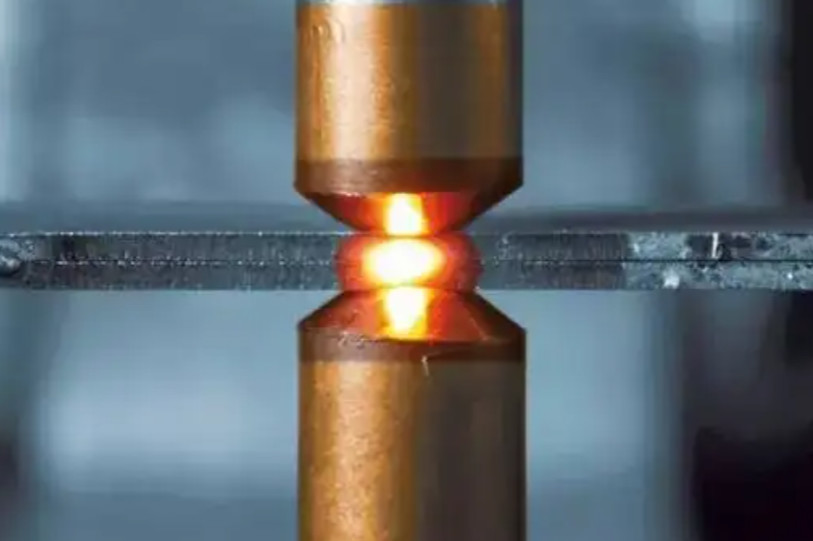

Kukaniza kuwotchererandi njira yomwe zida zolumikizirana zimayikidwa pakati pa maelekitirodi awiri. Podutsa pano pazigawo zogwirira ntchito ndi malo olumikizirana, kutenthetsa kukana kumachitika, kumatulutsa kutentha pamgwirizano wa zida zogwirira ntchito. Kutentha komweku kumapangitsa kuti derali lisungunuke kapena kuti lisungunuke, pomwe kukakamiza kochokera ku ma elekitirodi awiri kumalumikiza chitsulo pamodzi.

Pamene panopa ikuyenda kudzera mu conductor, imatulutsa kutentha chifukwa cha kukana. Kukwera kukana pamene panopa kuli kosalekeza, kutentha kumapangidwa. Pamalo omwe zitsulo zimagwirizana, kukana kumakhala kwakukulu kwambiri kuposa mkati mwazitsulo zokha. Choncho, mphamvu yaikulu ikadutsa polumikizana pakati pa chitsulo ndi electrode, chitsulocho chimatentha mofulumira chifukwa cha kutentha kwakukulu. Panthawiyi, chitsulocho chimakhala ductile kwambiri, ndipo ndi kukakamizidwa kogwiritsidwa ntchito, zidutswa ziwiri zazitsulo zimagwirizanitsa bwino.

Resistance Welding Working Mfundo

Mfundo ya kukana kuwotcherera malo ndi mapangidwe olumikizira akuwonetsedwa mu Chithunzi 1-1. Chitsulo A ndi zitsulo B zimayikidwa pakati pa maelekitirodi awiri, ndipo kupanikizika kumagwiritsidwa ntchito pamagetsi. Mphamvu yamagetsi imadutsa pakati pa ma electrode awiri ndi transformer ya welder resistance. Malo okhudzana ndi zogwirira ntchito amapanga malo okhudzana ndi thupi, omwe amakula pang'onopang'ono pamene akuwotcha. Kupindika kwa pulasitiki ndi kutentha kumayendetsa maatomu mosalekeza pamalo olumikizirana, zomwe zimapangitsa kuti pakhale chitsulo chosungunuka. Pachimake chosungunuka chimakula ngati makhiristo a columnar, ndikukankhira kunja kwa zigawo zapamwamba za alloy kwa wina ndi mzake. Pamene ma elekitirodi a welder amachoka pazitsulo pamwamba pa zitsulo, ndipo zitsulo zimazizira, zogwirira ntchito zimagwirizanitsidwa pamodzi, kupanga mgwirizano wamphamvu wachitsulo. Kulumikizana pamwamba kutha, kusiya kumbuyo weld nugget.

1-1

Zinthu Zomwe Zimakhudza Kuwotcherera Kwa Resistance

Kukaniza kuwotchererandi njira yowotcherera yomwe imagwiritsa ntchito magetsi kuti apange kutentha kuti agwirizane ndi zitsulo. Monga tanenera kale, mfundo yotsutsa kuwotcherera makamaka imachokera ku lamulo la Joule la kutentha, kumene kutentha kwa kutentha kumatsimikiziridwa makamaka ndi magawo monga panopa, kukana, ndi nthawi yowotcherera. Itha kuwonetsedwa ndi njira iyi:

Q = I²Rt

Tanthauzo la gawo lililonse la kuwotcherera:

Q - Kutentha (J)

I - Welding current (A)

R - Kukana (Ω)

t - Nthawi yowotcherera (s)

Welding Current

Zamakono zimakhudza kwambiri kutentha komwe kumapangidwa panthawi yowotcherera, monga momwe tawonetsera mu ndondomekoyi. Mtengo wapakati wamakono umakhudza kutentha, kutanthauza kuti pamwamba pakali pano, kutentha kumawonjezeka mofulumira. Chifukwa chake, mukamakonza zowotcherera musanayambe kuwotcherera, ndikofunikira kukhazikitsa njira yoyenera. Ngati kuwotcherera komweko kuli kochepa kwambiri, weld sidzasungunuka, ndipo palibe phata la fusion lomwe lidzapangike. Ngati mphamvuyi ndi yayikulu kwambiri, phata la maphatikizidwe limakula mwachangu, zomwe zimapangitsa kuti pakhale kumwaza kwambiri panthawi yowotcherera ndikuwononga maelekitirodi.

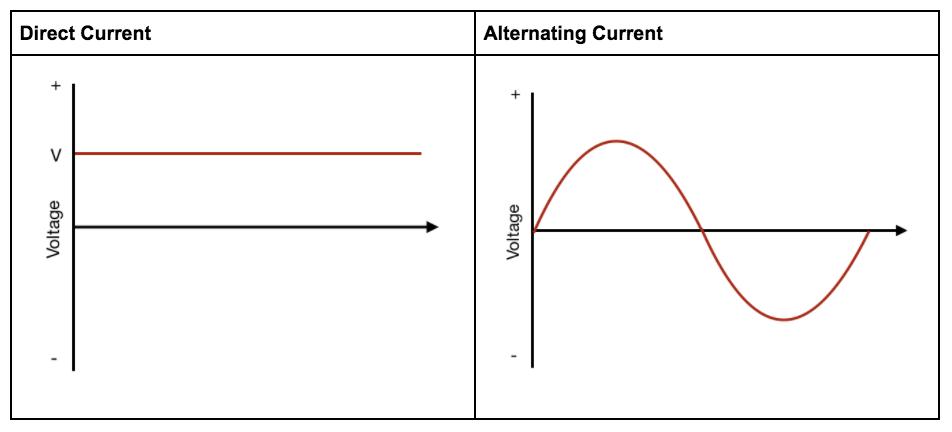

Kuwotcherera pakali pano kumagawidwa kukhala alternating current (AC) ndi Direct current (DC), monga momwe tawonera m’chithunzichi. Themakina owotcherera malotimagwiritsa ntchito akugawidwa mwachindunji malo kuwotcherera malo makina ndi alternating panopa malo kuwotcherera makina. Makina owotcherera omwe ali pano omwe amagwiritsa ntchito magawo atatu, kuwonetsetsa kuti magetsi agawidwe moyenera, ndipo amatha kukwaniritsa mafunde amtundu wopitilira 1000 Hz, zomwe zimapangitsa kuti kuwotcherera kukhale kolondola kwambiri. Amakhalanso ndi mwayi wosowa mphamvu zochepa kuchokera ku gridi yamagetsi, zomwe zimapangitsa kuti zowotcherera zopulumutsa mphamvuzi zikhale zodziwika kwambiri pakati pa opanga mafakitale. Makina osinthira apano omwe amawotcherera amakhala ndi gawo limodzi lotulutsa 50Hz, kuchuluka kwapang'onopang'ono kosalekeza, komanso zofunikira pagululi yamagetsi. Kuphatikiza apo, ali ndi mphamvu zochepa zowotcherera, zomwe zimafunikira nthawi yayitali yowotcherera.

Contact Resistance

Kuchokera pamapangidwewo, ndizosavuta kuwona kuti kukana kumagwirizana mwachindunji ndi kutentha komwe kumapangidwa. Kuchuluka kwa kukana, kumapangitsanso kutentha komwe kumapangidwa panthawi yowotcherera. Kukaniza kumagawidwa m'malo osiyanasiyana a electrode ndi workpiece. Pa kuwotcherera, kukana kwakukulu kumachitika pamalo olumikizirana ndi chogwirira ntchito, zomwe zimapangitsa kuti pakhale kutentha kwambiri. Chotsatira ndi kukana pa malo olumikizana pakati pa workpiece ndi electrode. Komabe, popeza electrode imakhazikika m'madzi ndipo imazizira mofulumira, kutentha kumachepa mofulumira. Kumbali inayi, kukana kukhudzana pakati pa zida zogwirira ntchito, ngakhale kutha, kumakhala ndi kutentha koyipa, komwe kumatsogolera kutentha kwambiri. Choncho, kadera kakang'ono kokha pakati pa workpieces akhoza kufika kutentha koyenera kuti apange maphatikizidwe pachimake ndi kuwotcherera pamodzi.

Kuphatikiza apo, kutentha ndi kuthamanga kwa electrode kumakhudza kukana. Pamene kutentha kumakwera, mphamvu yotulutsa zitsulo imachepa, ndikuwonjezera malo okhudzana ndi pakati pa zogwirira ntchito ndi pakati pa workpiece ndi electrode, zomwe zimapangitsa kuchepa kwa kukana. Kuchuluka kwa ma electrode kumapangitsa kuti malo ogwirira ntchito azikhala osalala, kukulitsa malo olumikizirana komanso kuchepetsa kukana. Zotsatira zake, pali chodabwitsa pomwe, pakuwotcherera kwa zida zomwe zimapangidwira, kukana kumawonjezeka pakangotha kuyatsa, ndipo mphamvu ikazimitsidwa ndi mawonekedwe apakati ophatikizika, kukana kumayamba kuchepa.

Nthawi Yowotcherera

Kutalikirana kwa nthawi yowotcherera, kumapangitsanso kutentha kwambiri. Mwanjira iyi, zamakono ndi nthawi zimatha kuthandizirana. Mukafuna chowotcherera cholimba, mutha kukhazikitsa magetsi kwakanthawi kochepa kuti mupange kutentha mwachangu ndikupanga chophatikizira kuti mumalize kuwotcherera. Kapenanso, mutha kukhazikitsa kutsika kwapano kwa nthawi yayitali, koma pali malire panjira iyi. Ngati nthawiyo yayikidwa motalika kwambiri, imatha kuyambitsa kutaya kwambiri ndipo kungayambitse ma elekitirodi kumamatira. Kaya ndi zamakono kapena nthawi, pali malire. Mukayika magawo, muyenera kuganizira zakuthupi ndi makulidwe a workpiece, komanso mphamvu ya makina owotcherera.

Zinthu Zakuthupi

Zakuthupi za workpiece zimakhudza kwambiri resistivity ake, amene amathandiza kwambiri kuwotcherera kutentha m'badwo. Mukawotcherera zitsulo zosapanga dzimbiri, zomwe zimakhala ndi resistivity yayikulu komanso kusayenda bwino kwamafuta, zimakhala zosavuta kupanga kutentha koma zovuta kuzichotsa, kotero kuti mafunde ang'onoang'ono amafunikira. Mukawotcherera zotayira za aluminiyamu zokhala ndi resistivity yochepa komanso matenthedwe abwino, zimakhala zovuta kupanga kutentha koma kosavuta kuzitaya, kotero kuti mafunde akulu amafunikira. Zitsulo monga siliva ndi mkuwa zimakhala ndi matenthedwe apamwamba komanso kutsika kwamphamvu, kotero ngakhale ndi mafunde apamwamba, sizimapanga kutentha kwakukulu koma zimatha kuzichotsa. Chifukwa chake, zitsulo izi sizoyenera kuwotcherera kukana koma zitha kugwiritsidwa ntchito ngati zida zamagetsi.

Electrode Design ndi Geometry

Maonekedwe ndi zinthu za elekitirodi zimakhudzanso kutentha m'badwo. Malo okhudzana pakati pa electrode ndi workpiece amakhudza kachulukidwe kameneka. Kugwiritsa ntchito maelekitirodi pafupipafupi kumatha kupangitsa kuvala ndi kusinthika, kukulitsa malo olumikizirana komanso kuchepetsa mphamvu zowotcherera. Chifukwa chake, tiyenera kukonza ndikusintha nsonga za electrode mwachangu. The matenthedwe madutsidwe ndi kukana ma elekitirodi zimakhudza kutentha kutengerapo. Choncho, tiyenera kusankha zipangizo zabwino matenthedwe madutsidwe ndi kukana otsika.

Kukonzekera Pamwamba

Maonekedwe ndi zinthu za maelekitirodi zimakhudzanso m'badwo wa kutentha. Malo okhudzana pakati pa electrode ndi workpiece amakhudza kachulukidwe kameneka. Ma electrode athu akagwiritsidwa ntchito pafupipafupi ndikutha, zimawonjezera malo olumikizana, zomwe zimapangitsa kuti mphamvu zowotcherera zichepe. Chifukwa chake, tiyenera kukonza ndikusintha nsonga za electrode mwachangu. The matenthedwe madutsidwe ndi resistivity ma elekitirodi amakhudza kutentha kutengerapo. Choncho, tiyenera kusankha zipangizo zabwino matenthedwe conductivity ndi otsika resistivity.

Mitundu ya Resikuyimilira Welding

Chifukwa cha kusiyanasiyana kwazinthu komanso zofunikira pakuwotcherera, njira zosiyanasiyana zowotcherera zimagwiritsidwa ntchito kuti amalize ntchitoyi. Resistance kuwotcherera amatha kugawidwa mu kuwotcherera malo, kuwotcherera projekiti, kuwotcherera msoko, ndi kuwotcherera matako kutengera njira yowotcherera.

Spot Welding

kuwotcherera malondi njira yowotcherera pomwe chitsulo chimakanizidwa pamodzi ndi maelekitirodi apamwamba ndi apansi ndikuwotchedwa podutsa panopa. Ndi njira yachikhalidwe yowotcherera, yosavuta kugwiritsa ntchito, ndipo imafunikira luso lochepa kuchokera kwa ogwira ntchito. Chifukwa cha njira yake yowotcherera yapadera, kuwotcherera pamalo ndiye njira yoyamba yowotcherera zitsulo muukadaulo wazamlengalenga ndipo imagwiritsidwa ntchito kwambiri pakuwotcherera magalimoto ndi zida zina. Amagwiritsidwa ntchito powotcherera mapepala opyapyala achitsulo chochepa cha carbon, aluminiyamu, chitsulo chosapanga dzimbiri, malata, ndi mbale zina zoonda, nthawi zambiri zokhuthala pafupifupi mamilimita atatu.

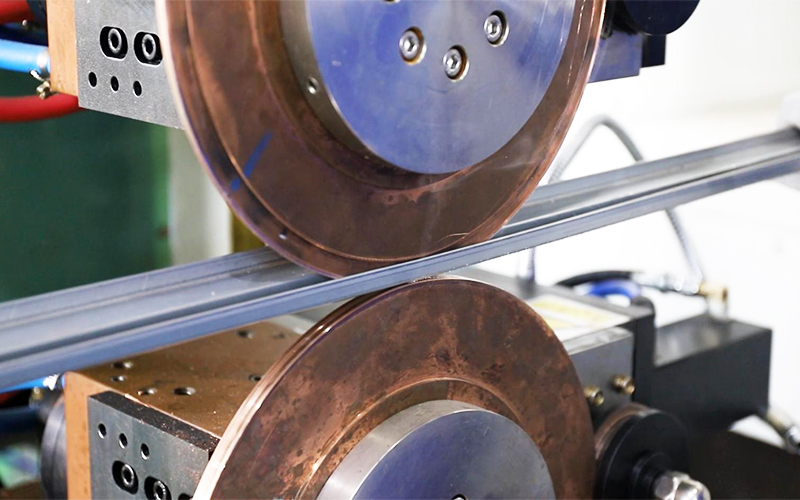

Kuwotcherera Msoko

Kuwotcherera msokoNthawi zambiri amaphatikiza kulumikiza m'mphepete mwa zigawo ziwiri zachitsulo. Zida ziwiri zachitsulo zimayikidwa pakati pa ma electrode awiri odzigudubuza. Pamene electrode imodzi imagudubuza ndikugwiritsa ntchito kukakamiza, kutulutsa kosalekeza kapena kwapakatikati kumachitika. Kutentha kopangidwa pamalo opangira ma elekitirodi kumasungunula zogwirira ntchito ndikuziphatikiza pamodzi, kupanga msoko wopitilira. Njirayi imagwiritsidwa ntchito kwambiri pakuwotcherera mbali zachitsulo zomwe zimafunikira mfundo zomata. Popeza malo owotcherera ndi aatali, kuti tipewe kusokonekera, nthawi zambiri timagwiritsa ntchito kuwotcherera kwa malo kuti tiyike pamaso pa kuwotcherera kwa msoko.

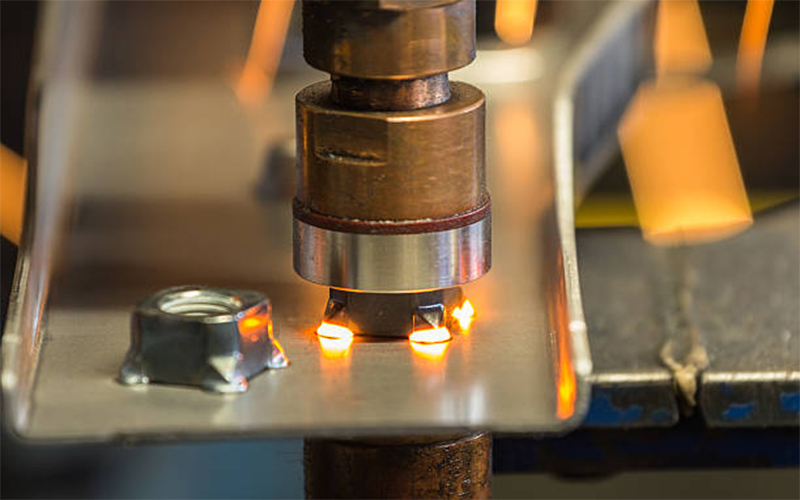

Projection Welding

Projection kuwotchereraNdi mtundu wa kuwotcherera kwa malo, pomwe mapangidwe ake amafanana ndi kuwotcherera kwa malo, koma kuwotcherera kwa projekiti nthawi zambiri kumagwiritsidwa ntchito ngati zida zokhala ndi mfundo zokwezeka. Kukhalapo kwa mfundo zokwezerazi kumachepetsa malo omwe magetsi akudutsa, ndikuwonjezera kuchuluka kwazomwe zikuchitika m'dera lakuwotcherera. Izi anaikira Kutentha facilitates kugwirizana olowa. Njira yowotcherera iyi imatchedwa projekiti kuwotcherera. Kuwotcherera kwa projection kumatha kupanga cholumikizira chimodzi kapena zingapo pamalo olumikizirana nthawi imodzi. Panthawi yowotcherera, zomwe zimafunikira pakuwotcherera pamalo omwewo ndizochepera kuposa zowotcherera. Komabe, chiwonetsero chilichonse chisanaphwanyidwe, zomwe zilipo zimayenera kusungunuka; apo ayi, pangakhale kuchuluka kwakukulu kwa spatter. Kuwotcherera kwa projection kumatha kugwiritsidwa ntchito kuwotcherera mtedza, mabawuti, kapena mbale zokhala ndi mfundo zokwezeka ndipo zimagwiritsidwa ntchito kwambiri popanga zida zamagetsi ndi zamagalimoto.

Kuwotcherera matako

Kuwotcherera matakokumaphatikizapo kugwirizanitsa nkhope za mapeto a zitsulo ziwiri zogwirira ntchito, kuziyika pakati pa maelekitirodi, kumangiriza zogwirira ntchito ziwirizo, ndikugwiritsa ntchito mphamvu zamakono kuti apange kutentha, kusungunula malo okhudzana ndi zogwirira ntchito ndikuzigwirizanitsa pamodzi. Kuwotcherera matako kumagawidwanso kukhala kuwotcherera kwa matako ndi kuwotcherera kwa matako.

Kuwotcherera kwa Flash butt ndi njira yowotcherera yofulumira yomwe imagwiritsa ntchito kuchuluka kwamakono kuti isungunuke mwachangu zida zogwirira ntchito, ndikukakamiza kuti mupange kulumikizana kolimba. Amagwiritsidwa ntchito kwambiri pakuwotcherera madera akuluakulu azitsulo, mapepala, ndi mapaipi, okhala ndi malo opitilira 20,000mm² ndi kupitilira apo. Panthawi yowotcherera kumaliseche, zonyezimira zimapangidwa pamalo olumikizirana, motero amatchedwa kuwotcherera kwa butt. Imatha kuwotcherera zitsulo zambiri za kaboni, chitsulo chosapanga dzimbiri, ma aloyi a aluminiyamu, komanso imatha kuwotcherera zitsulo zosiyanasiyana monga mkuwa ndi aluminiyamu.

Resistance butt kuwotcherera kumagwiritsa ntchito kutentha kwamphamvu kubweretsa zolumikizira zogwirira ntchito kukhala pulasitiki pamalo otentha kwambiri, ndikumaliza kuwotcherera ndi mphamvu. Ndioyenera kuwotcherera mafupa okhala ndi madera ozungulira mkati mwa 250mm², omwe amagwiritsidwa ntchito nthawi zambiri kuwotcherera mawaya achitsulo ang'onoang'ono, ndodo, ndi mizere.

Kufunika Pakupanga

- Kukaniza kuwotcherera sikufuna kuwonjezera zitsulo panthawi yowotcherera, zomwe zimapangitsa kuti pakhale kutentha kwambiri komanso kuipitsidwa kochepa.

- Chifukwa cha kusasinthika kwake komanso kukhazikika kwake, kuwotcherera kukana ndikosavuta kupanga, kuphatikiza mosasunthika ndi makina kuti apititse patsogolo kupanga bwino ndikupulumutsa antchito.

- Poyerekeza ndi njira zina zowotcherera, kukana kuwotcherera ndikotsika mtengo. Choyamba, mtengo wa zida zowotcherera kukana ndizotsika, ndipo kachiwiri, pali zinyalala zazing'ono zakuthupi panthawi yowotcherera kukana. Izi zimachepetsa kwambiri ndalama zopangira kwa opanga makampani opanga zinthu.

- Resistance welding imagwiritsidwa ntchito kwambiri m'mafakitale osiyanasiyana ndipo ndiyofunikira kwambiri m'magawo monga zakuthambo, kupanga magalimoto, ndi zina zambiri.

- Kukaniza kuwotcherera ndikoyenera kuwotcherera zitsulo zamitundu yosiyanasiyana m'makampani opanga, kuphatikiza chitsulo chosapanga dzimbiri, chitsulo cha kaboni, aluminiyamu, mkuwa, ndi zina zambiri, ndikupangitsa kuti ikhale yosunthika pakugwiritsa ntchito kwake.

Mapulogalamu

Kukaniza kuwotcherera kumagwiritsidwa ntchito kwambiri, makamaka m'mafakitale monga zida zamagalimoto, zakuthambo, zamagetsi, ndi mafakitale olemera. Pamene kufunikira kwa zigawo zazitsulo zowotcherera m'mafakitale osiyanasiyana kukukulirakulira, miyezo yapamwamba yaukadaulo wazowotcherera yakhazikitsidwa, ndikuyendetsa kupita patsogolo ndi chitukuko cha kukana kuwotcherera.

Ntchito Zamakampani Agalimoto

Pakupanga magalimoto, komwe chitetezo ndi kukhazikika ndizofunikira kwambiri, kuwotcherera kukana ndi njira yomwe imagwiritsidwa ntchito kwambiri. Nthawi zambiri amagwiritsidwa ntchito pophatikiza zitsulo zosiyanasiyana m'magalimoto agalimoto, monga madenga, zitseko, zitsulo, ndi mtedza wachitsulo. Resistance welding imapereka mphamvu zambiri, zowotcherera zokhazikika, ndipo zimangopanga zokha, zomwe zimapangitsa kuti ikhale yofunika kwambiri pamakampani opanga magalimoto.

Mapulogalamu a Aerospace Viwanda

Resistance welding imagwiritsidwa ntchito mobwerezabwereza kulumikiza zida zachitsulo mu ndege ndi maroketi, monga kulumikiza mapiko a ndege ndi ma fuselages, komanso tizigawo tating'ono tating'ono tating'ono. Zigawozi ziyenera kukhala ndi mphamvu zambiri komanso zolimba, zokhala ndi zofunikira zolimba pamtundu wamagulu, komwe kumapangitsa kuti kuwotcherera kumapambana. Resistance welding imagwira ntchito yofunika kwambiri pazamlengalenga, ndipo kupita patsogolo kwa gawoli kumathandizidwanso ndi gawo lazamlengalenga.

Electronics Industry Applications

Resistor kuwotcherera nthawi zambiri amagwiritsidwa ntchito pazinthu zamagetsi ndi zitsulo zina pazida zamagetsi. Imakhala yolondola kwambiri ndipo ndiyoyenera kulumikiza tinthu tating'ono ngati tchipisi tamagetsi ndi mawaya. Masiku ano, zida zamagetsi zomwe zikukula mwachangu, kuwotcherera kwa resistor kumafulumizitsa kuphatikiza kwa zida zamagetsi, ndikuyendetsa kupita patsogolo kwamakampani.

Mapulogalamu Olemera Kwambiri

Kukaniza kuwotcherera nthawi zambiri kumagwiritsidwa ntchito pakuwotcherera zigawo zazikulu zazitsulo m'milatho ndi nyumba, monga ma flanges apansi pa mlatho ndi kulimbitsa zitsulo. Amagwiritsidwanso ntchito popanga makina akuluakulu olumikiza zitsulo. Ndi luso lake kothandiza ndi khola kuwotcherera, kukana kuwotcherera wakhala imodzi mwa njira zofunika processing makampani katundu. Zimatsimikizira chitetezo cha zida zolemera ndi zomangamanga.

Zida ndi Zigawo

Makina Owotcherera

Kukaniza kuwotcherera makinaamagawidwa m'magulu anayi akuluakulu: makina owotcherera, makina owotcherera, makina owotcherera a msoko, ndi makina owotcherera matako, kutengera njira zosiyanasiyana. Sankhani zida zoyenera zowotcherera molingana ndi mawonekedwe a zida ndi mawonekedwe.

Ma electrode

Theelectrodendi gawo lofunikira kuti mutsimikizire mtundu wa kuwotcherera. Zida zazikulu zowotcherera maelekitirodi ndi: chromium zirconium mkuwa, zotayidwa okusayidi mkuwa, beryllium cobalt mkuwa, tungsten, molybdenum, graphite, etc. Malinga workpieces osiyana kuti welded, maelekitirodi anawagawa maelekitirodi lathyathyathya, maelekitirodi ozungulira, maelekitirodi mtedza, bawuti. ma elekitirodi, ndi zina zotero 1:10 ndi 1:5.

Njira Zozizira

Panthawi yogwira ntchito, makina owotcherera amafunikira madzi ozungulira kuti aziziziritsa zinthu monga ma electrode ndi ma transfoma. Chifukwa chake, timayika makina oziziritsira makina owotcherera. Kutentha kwa madzi ozizira kuyenera kukhala pansi pa 30 ° C. Ngati kutentha kuli kwakukulu, kungayambitse kutsekedwa kwa chitetezo cha makina owotcherera. Ndi bwino kugwiritsa ntchito madzi ozizira opanda chidebe kuti aziyenda kuti madzi asasokonezeke komanso kutsekeka kwa mapaipi.

Momwe Mungasankhire Njira Yowotcherera Yoyenera?

Kusankha njira kuwotcherera zimadalira zinthu zambiri.

Makulidwe ndi Mawonekedwe a Workpiece: Zosiyananjira zowotchererandi oyenera workpieces osiyanasiyana makulidwe ndi akalumikidzidwa. Mwachitsanzo, kuwotcherera kukana kumakhala koyenera kuwotcherera zitsulo zopyapyala zokha, pomwe zowoneka bwino komanso zokhuthala nthawi zambiri zimawotcherera pogwiritsa ntchito kuwotcherera kwa arc.

Zofunikira Zowotcherera: Mtundu womwe mukufuna kuwotcherera umaperekanso kusankha kwa njira yowotcherera. Kwa zida zogwirira ntchito zomwe zimafunikira kusindikiza kwakukulu komanso mphamvu zolumikizana, njira zowotcherera zomwe zimakwaniritsa izi ziyenera kusankhidwa.

Kupanga Mwachangu ndi Mtengo: Ngati kuchuluka kwapachaka kwapachaka kumafunika, kusankha njira yowotcherera yokhala ndi mphamvu zambiri ndikofunikira. Mfundo zamtengo wapatali ziyeneranso kuganiziridwa.

Zinthu Zachilengedwe: Njira zina zowotcherera zimatulutsa zinyalala ndi mpweya, zomwe zimawononga chilengedwe. Choncho, kuganizira za chilengedwe kuyenera kuganiziridwa posankha njira yowotcherera.

FAQ:

Kodi zolephera za resistance welding ndi zotani?

Kukaniza kuwotcherera sikoyenera kuwotcherera zigawo zazikulu zachitsulo.

Mumawonetsetsa bwanji chitetezo pakuwotcherera ku resistance?

Mukamagwiritsa ntchito kuwotcherera kukana, valani chisoti chachitetezo ndi magalasi oteteza chitetezo.

Kodi ndingaphunzire bwanji kuwotcherera ku resistance?

Mutha kuchita maphunziro akukana kuwotcherera wopanga.

Kodi zovuta zazikulu zamalumikizidwe olumikizirana zowotcherera ndi ziti?

Cold solder olowa, kusakwanira mphamvu, kuwotcherera mapindikidwe, makutidwe ndi okosijeni.

Njira zowunikira zolumikizira zowotcherera zotsutsana

Kuyesa kowononga, kuyezetsa pang'ono, kuyang'ana kowoneka, kuyesa kwazitsulo, kuyesa kwa ultrasonic.

Nthawi yotumiza: Apr-02-2024