Kune nzira dzakawanda dzekubatanidza simbi, uye welding inzira inodiwa yekubatanidza masimbi akawanda. Kana iwe uri mutsva kuindasitiri yewelding, ungasaziva kuti ingani dzakasiyana nzira dzekubatanidza simbi. Ichi chinyorwa chinotsanangura maitiro makuru 8 welding, zvichikupa kunzwisisa kwakadzama kweindasitiri yewelding.

Arc Welding

Arc weldinginoshandisa arc yemagetsi kugadzira kupisa, kunyunguduka uye kusanganisa simbi pamwechete. Iyi ndiyo yakajairika welding process uye inosanganisira matekiniki akaita semanual arc welding uye gasi-yakadzivirirwa welding.

Manual arc welding yakanakira simbi yezvimiro.

Gasi-yakadzivirirwa welding inoshanda nemazvo kune zvinhu zvakaita sesimbi isina tsvina nealuminium.

Mazano: Chengetedza nzvimbo yeweld kubva kune oxidation uye sparks, uye dzora zvazvino uye voltage marongero kuti uwane zvakanakisa mhedzisiro.

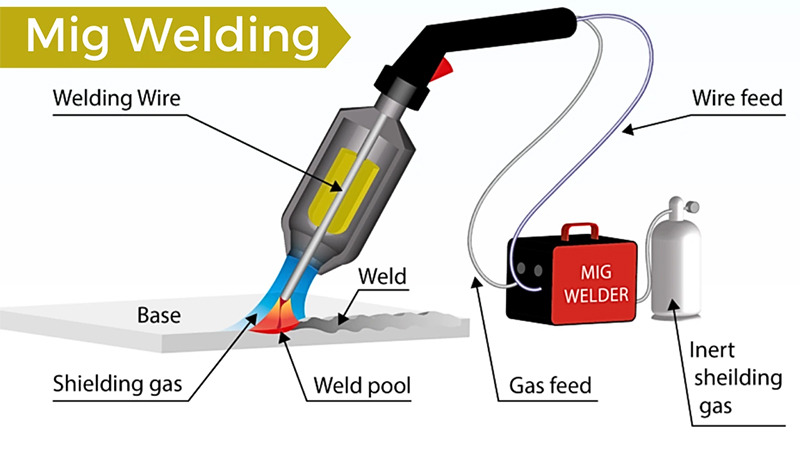

MIG/MAG Welding

MIG/MAG welding inosanganisira kudyisa tambo yemagetsi inoenderera kuburikidza netochi yewelding nepo arc ichinyungudutsa waya uye nepamusoro pesimbi kugadzira weld. Gasi rekudzivirira rinoyerera nemutochi kudzivirira weld kubva pakusvibiswa.

MIG weldinginozivikanwa mumaindasitiri akaita sekuvaka ngarava, kuvakwa kwepombi, uye zvivakwa zvesimbi.

Yakakura kune yakakura, isingazungunuke workpieces uye kugadzirisa mapurojekiti.

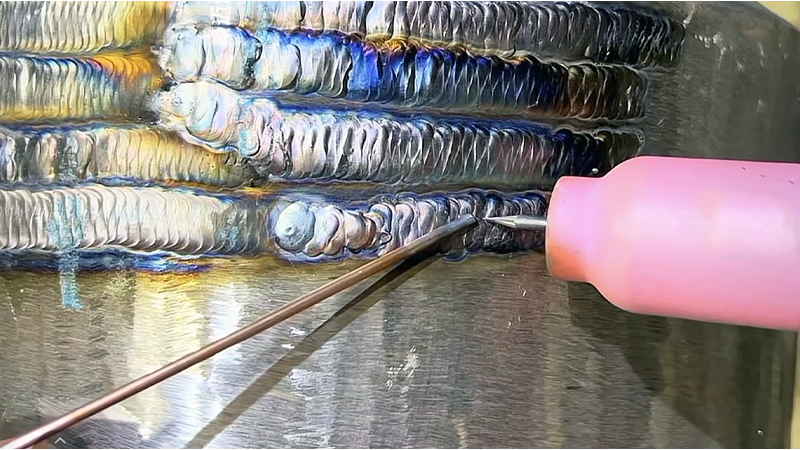

TIG Welding

TIG welding, kana Tungsten Inert Gas welding, inoshandisa isingashandisi tungsten electrode kugadzira yakakwirira-chaiyo welds. Gasi rinodzivirira, senge argon, rinodzivirira nzvimbo yeweld kubva pakusvibiswa.

Kurongeka kwepamusoro kunoita kuti ive yakanaka kune zvinhu zvakapfava sealuminium uye simbi isina tsvina.

Inowanzo shandiswa mumotokari, aerospace, uye nemazvo ekugadzira maindasitiri.

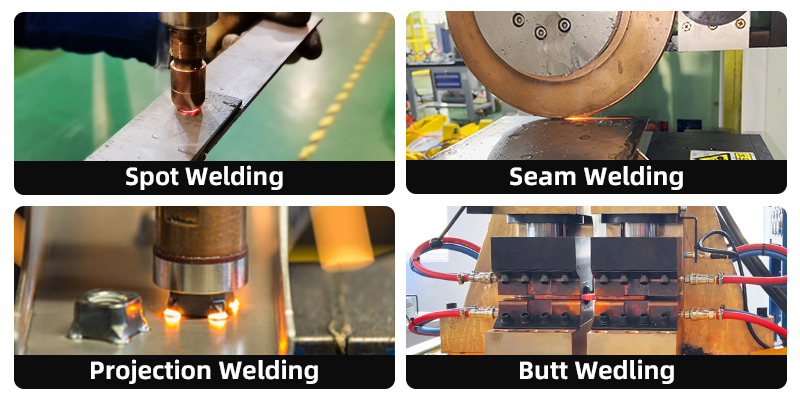

Resistance Welding

In resistance welding, zvidimbu zviviri zvesimbi zvinotsikirirwa pakati pe electrode, uye magetsi emagetsi anogadzira kupisa kuti abatanidze nawo. Mhando huru dzinosanganisira nzvimbo, fungidziro, butt, uye seam welding.

Resistance welding inokurumidza, haidi filler material, uye iri nyore kuita otomatiki.

Inoshandiswa zvakanyanya muzvikamu zvemotokari, zvemagetsi, uye midziyo yemumba. Semuyenzaniso, yakanyatsokonesesa pakusecha nzungu dzemota.

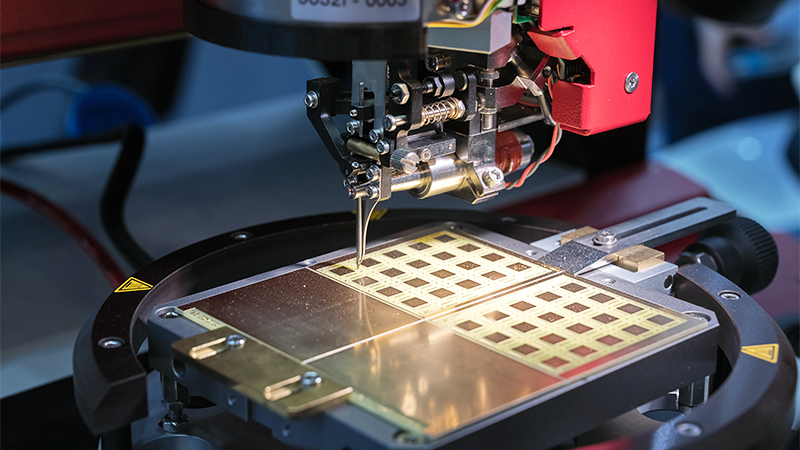

Laser Welding

Laser weldinginzira inoshandisa laser danda sesimba sosi kunyatsopisa nekujoinha simbi kana mapurasitiki. Kuenzaniswa neyechinyakare arc welding, laser welding inokurumidza uye inoshanda zvakanyanya. Inogona kusanganiswa nyore nyore nerobhoti welderuye inzira yakakosha mukugadzirisa zvinhu zvelaser. Laser welding haidi electrode uye haidi kubata iyo workpiece zvinhu. Kana welding zvinhu zvitete kana waya dzakanaka, hazvikonzerese kunyungudika senge arc welding.

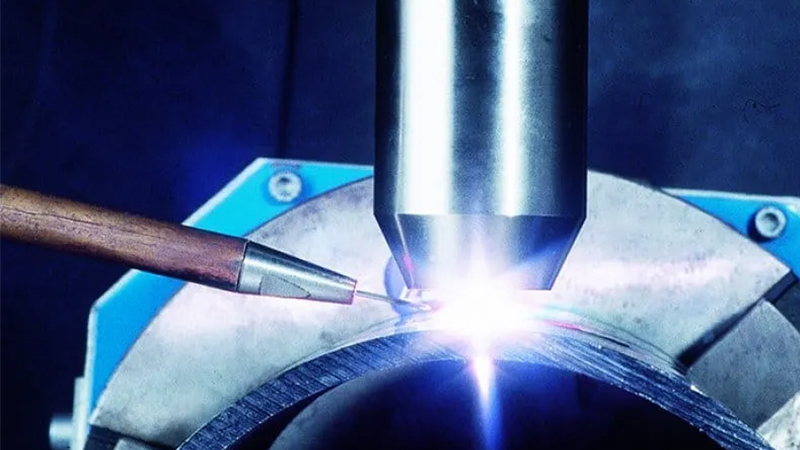

Plasma Welding

Plasma welding inogadzira plasma kuburikidza ne-high-energy arc, iyo inonyungudutsa workpiece. Filler material inowedzerwa kubatanidza masimbi pamwechete.

Inoshanda nesimbi, mapurasitiki, uye ceramics.

Kazhinji inoshandiswa muaerospace, mota, uye zvemagetsi kugadzira.

Ultrasonic Welding

Ultrasonic welding inoshandisa yakakwira-frequency vibrations kunzvimbo mbiri pasi pekumanikidzwa, zvichiita kuti dzibatane pasina kunyungudika. Iyi nzira inoshanda kune simbi, mapurasitiki, uye kunyange zvinhu zvakasiyana.

Inogadzira majoini chaiwo, akachena uye ari nyore kuita otomatiki.

Yakajairika mumaindasitiri anoda yakanaka, solid-state welding.

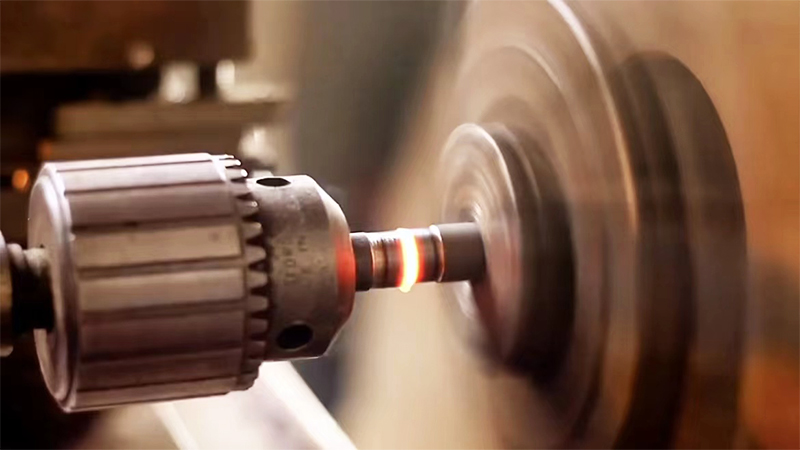

Friction Welding

Friction welding inogadzira kupisa kuburikidza nekukwesha nekukurumidza kwenzvimbo mbiri, ichinyorovesa kuti igadzire chisungo chakasimba. Iyi solid-state process inobvisa kudiwa kwekunze kwekupisa sosi.

Inodzivirira kuremara senge deformation uye makatsemuka.

Inoshandiswa zvakanyanya mukugadzirwa kwemaindasitiri, senge mavhiri endege uye njanji axles.

Maitiro ekusarudza iyo Yakakodzera Welding Maitiro

Paunosarudza welding process, funga nezve:

Rudzi rwezvinhu (semuenzaniso, aluminium, simbi isina tsvina)

Saizi yebasa uye ukobvu

Precision zvinodiwa

Kana otomatiki inodiwa

Kuedza nzira dzakawanda kunogona kukubatsira kuwana mhinduro yakanaka kune yako chaiyo purojekiti.

Nekunzwisisa aya 8 main welding process, unogona kusarudza nzira chaiyo yepurojekiti yako uye kuongorora mikana mitsva muindasitiri yewelding.

Mibvunzo Inowanzo bvunzwa

1. Ndeipi welding process yakanakira zvikamu zvemotokari?

Resistance welding ndiyo sarudzo yepamusoro yezvikamu zvemotokari nekuda kwekukurumidza kwayo, kupera kwekunaka, uye nyore otomatiki.

2. Ndezvipi zvinhu zvinogona kuiswa welding?

Unogona kubatanidza simbi dzakasiyana-siyana, kusanganisira simbi isina tsvina, mhangura, aluminium, uye galvanized simbi.

3. Ko ese maitirwo ewelding anoshandisa mafiller rods?

Kwete. Semuenzaniso, resistance welding haidi mafiller rods.

4. Ndekupi kwandingadzidza humwe hunyanzvi hwekushongedza?

Iwe unogona kuenda kuzvikoro zvehunyanzvi zvehunyanzvi kana kuwana maoko-pane ruzivo muzvivakwa zvekugadzira.

Nguva yekutumira: Oct-21-2024