Welding simbi isina tsvina inoda hunyanzvi hunyanzvi uye kunyatsogadzirira nekuda kweiyo yakasarudzika zvivakwa.Simbi isina ngurainoshandiswa zvakanyanya mumaindasitiri akadai sekugadzira chikafu, mishonga yemishonga, aerospace, uye kuvaka nekuda kwekukwirira kwayo kwekuora, simba, uye kukwezva. Nekudaro, hunhu uhu humwe hunoitawo kuti zvinyanye kunetsa kupinza zvichienzaniswa nesimbi yakapfava.

Mugwaro iri, isu'Ichavhara misimboti yakakosha yewelding simbi isina tsvina, matambudziko ainopa, uye maitiro akanakisa ekuwana emhando yepamusoro welds. Kunyangwe iwe uri wekutanga kana welder ane ruzivo, kunzwisisa idzi pfungwa kuchakubatsira kuwana mibairo inowirirana paunenge uchishanda nesimbi isina simbi.

Zvivakwa zveStainless Steel

Simbi isina tsvina ine inokwana 10.5% chromium, iyo inoumba passive oxide layer pamusoro, ichipa iyo corrosion resistance. Mhando dzakasiyana-siyana dzesimbi isina tsvina, dzakadai se austenitic, ferritic, martensitic, uye duplex, inopa misanganiswa yakasiyana yesimba, weldability, uye kuramba mukuora.

Zvinhu zveStainless steel zvinokanganisa welding zvinosanganisira:

Kuwedzera Kwekupisa Kwekupisa: Simbi isina tsvina inowedzera kupfuura kabhoni simbi kana ichipisa, ichiwedzera njodzi yehondo uye kukanganisa panguva yewelding.

Low Thermal Conductivity: Kupisa hakusi nyore kuparara, zvichiita kuti kusanganiswa kwekupisa pajoini ye weld, iyo inogona kukonzera kupisa-kuburikidza.

Sensitivity to Heat: Kuwedzera kupisa kupinza kunogona kukonzera kubuda kwemavara kana kudzikisa corrosion kuramba.

Kuumbwa kweCarbides: Chromium carbide formation inogona kuitika pakupisa kwakanyanya, kuderedza corrosion resistance (chiitiko chinozivikanwa sekunzwa).

Mhando dzeStainless Steel yeWelding

1. Austenitic Stainless Steel (300 Series)

Hunhu: Isiri-magineti, isingadzivirirwe zvakanyanya, uye iri nyore kushanda nayo.

Common Giredhi: 304 uye 316.

Weldability: Zvakanaka, asi zvinowanzokanganiswa nekuda kwekuwedzera kwekuwedzera kwekushisa.

2. Ferritic Stainless Steel (400 Series)

Hunhu: Magnetic, yakaderera corrosion kuramba pane austenitic mhando asi yakakwirira yekupisa conductivity.

Makirasi Anowanikwa: 430.

Weldability: Pakati; inoda pre- uye post-weld kupisa kurapwa kudzivirira kutsemuka.

3. Martensitic Stainless Steel

Hunhu: Kusimba kwepamusoro, kusamira kwekusapfeka, uye kushomeka kwekuora.

Makirasi Anowanikwa: 410 uye 420.

Weldability: Zvakaoma; zvinoda kunyatsodzora kupisa kuti usatsemuka.

4. Duplex Stainless Steel

Hunhu: Musanganiswa weaustenitic uye ferritic zvivakwa, zvinopa simba rakawanda uye kusagadzikana kwekuora.

Makirasi Anowanikwa: 2205.

Weldability: Inoda yakaderera kupisa kupinza kudzivirira embrittlement.

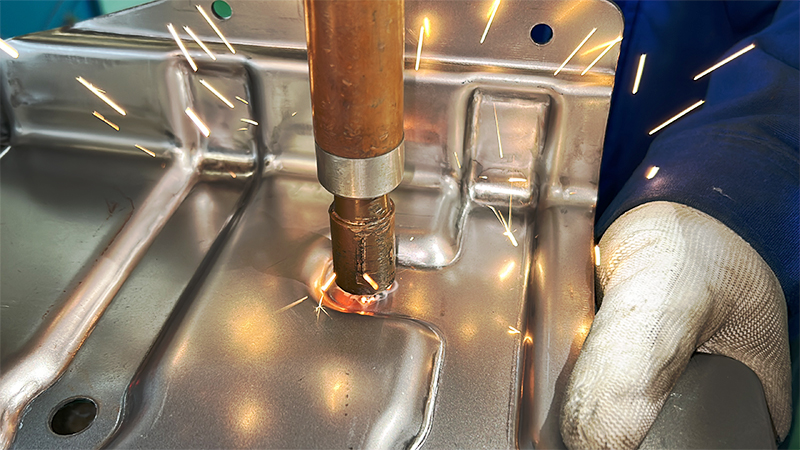

Welding Nzira dzeStainless Simbi

Zvakanakira: Mashizha matete simbi asina tsvina uye maapplication anoda kunyatsojeka.

Zvakanakira: Mawedhi akachena, chaiwo ane spatter shoma.

Kufunga: Inoda ane hunyanzvi mushandisi uye inononoka welding kumhanya.

Zvakanakira: Mapurojekiti akakura uko kumhanya kwakakosha.

Zvakanakira: Inokurumidza kupfuura TIG welding uye zviri nyore kudzidza.

Mafungiro: Inogona kugadzira spatter uye inoda kudzivirira gasi (kazhinji argon kana musanganiswa neCO₂).

Zvakanakira: Mapurojekiti ekunze uye zvikamu zvakakora zvesimbi isina tsvina.

Zvakanakira: Haadaro't inoda kudzivirira gasi, ichiita kuti ive yakakodzera basa rekunze.

Zvekufunga: Zvinogona kunetsa kudzora pasimbi yakatetepa isina tsvina.

Zvakanakira: Mashizha matete mumotokari uye maindasitiri maapplication.

Zvakanakira: Inokurumidza uye inoshanda kune anopindirana majoini.

Kufunga: Kunogumira kune chaiwo majoini marudzi.

Zviitiko Zvakanakisisa zveWelding Stainless Steel

Kugadzirira

Chenesa nzvimbo yacho zvakakwana kubvisa tsvina, girisi, uye oxidation. Zvinosvibisa zvinogona kukonzera weld defects uye kuderedza corrosion resistance.

Shandisa maturusi akatsaurirwa (mabhurashi, maguyo) esimbi isina tsvina kudzivirira kusvibiswa kubva kune dzimwe simbi.

Kudzivirira Gasi Kusarudzwa

Kune TIG welding, shandisa 100% argon kana argon-helium musanganiswa.

YeMIG welding, musanganiswa weargon uye CO₂kana oksijeni inovandudza weld kupinda uye kugadzikana.

Dzora Heat Input

Shandisa iyo yakaderera inobvira yekuisa yekupisa kudzivirira warping, discoloration, uye carbide kugadzirwa.

Kana zvichibvira, shandisa pulse welding kudzora kupisa kuyerera zvakanyanya.

Deredza Kukanganisa

Batanidza maworkpieces zvakasimba kuti uderedze kufamba panguva yewelding.

Shandisa backstepping (welding zvidimbu zvidiki mune alternating directions) kugovera kupisa zvakanyanya zvakaenzana.

Post-Weld Kuchenesa uye Kupedza

Bvisa chero kushanduka kwemavara nesimbi isina tsvina mabhurashi kana kemikari yekuchenesa kuti udzorere kusaita ngura.

Shandisa passivation maitiro ekubvisa kusvibiswa kwepamusoro uye kuwedzera oxide layer.

Kudzivisa Cracks uye Sensitization

Kune zvikamu zvakakora, preheating simbi inogona kubatsira kuderedza njodzi yekutsemuka.

Shandisa magiredhi e-low-carbon (akadai se304L kana 316L) kudzivirira kugadzirwa kwechromium carbide.

Kukanganisa kwakajairika muStainless Steel Welding

Warping uye Distortion: Inokonzerwa nekupisa kwakanyanya kupinza uye kuwedzera kupisa.

Kupisa-Kuburikidza: Kunoitika kana kupisa kunonyunguduka kuburikidza nezvinhu, zvinowanzoonekwa nesimbi dzakatetepa.

Kutsemuka: Kazhinji nekuda kwekutadza kutonga kwekupisa kana kusvibiswa.

Porosity: Inokonzerwa nemagasi akavharirwa mudziva weld, kazhinji nekuda kwekusakwana kwekudzivirira gasi.

Discoloration: Kupisa kunogona kukonzera oxidation, zvichikonzera nzvimbo ine muraraungu-ruvara.

Zvishandiso zveStainless Steel Welding

Zvokudya Zvokugadzira Zvokudya: Simbi isina tsvina inowanzoshandiswa kumatangi, pombi, uye nzvimbo mukugadzirwa kwechikafu nekuda kwekupokana kwayo uye kureruka kwekuchenesa.

Mishonga neMidziyo Yezvokurapa: Zvishandiso zvekuvhiya, maimplants, uye midziyo isina kuchena inoda mawelds chaiwo, akachena.

Indasitiri yeAerospace: Simbi isina tsvina inoshandiswa muzvikamu zvendege nekuda kwesimba rayo uye kuramba kutonhora kwakanyanya.

Architecture uye Kuvaka: Handrails, facades, uye zvimwe zvimiro zvinoshandisa Stainless simbi yekusimba uye aesthetics.

Indasitiri yeMotokari: Masisitimu emagetsi, matangi emafuta, uye dhizaini yekushongedza zvinowanzogadzirwa kubva kusimbi isina tsvina.

Mhedziso

Welding simbi isina simbi zvese sainzi uye hunyanzvi, zvinoda kunzwisiswa kwezvakasiyana zvezvinhu uye zvinonetsa. Nemaitiro akakodzera, kugadzirira, uye midziyo, unogona kuwana emhando yepamusoro, yakasimba welds inochengetedza zvinhu's kusimba uye kusaita ngura.

Kunyangwe iwe uri kugadzira zvinhu zveindasitiri yechikafu, kugadzira dhizaini, kana kuvaka zvikamu zvemotokari zvinonyanya kushanda, simbi isina tsvina inopa musanganiswa werunako, kusimba, uye kushanda. Kutevera akanakisa maitiro uye kusarudza iyo yakakodzera welding nzira inova nechokwadi chakabudirira mhedzisiro yemapurojekiti ako eStainless simbi welding.

Nguva yekutumira: Oct-15-2024