Kusanganiswa kusina kukwana, inowanzozivikanwa se "cold weld" kana "kushaya fusion," inyaya yakakomba inogona kuitika panguva yekugadzira nzvimbo uchishandisa.nzvimbo welding michina. Zvinoreva mamiriro ekuti simbi yakanyungudutswa inotadza kunyatsobatana nehwaro zvinhu, zvichikonzera mubatanidzwa usina kusimba uye usingavimbike. Ichi chinyorwa chine chinangwa chekuongorora zvakasiyana siyana izvo zvinogona kutungamira kune isina kukwana fusion mukatinzvimbo welding.

Welding Current

Welding ikozvino ndeimwe yeanonyanya kukosha paramita muwelding process, uye ine yakawedzera mhedzisiro pakupisa kunogadzirwa panguva yewelding. Kusakwana welding ikozvino ndicho chimwe chezvikonzero zvikuru zvekusa-fusion. Kana iyo welding ikozvino yakadzikira, inogona kusaburitsa kupisa kwakakwana kunyungudutsa zvizere substrate. Nekuda kweizvozvo, iyo simbi yakanyungudutswa haigone kupinda nekusevha zvakanaka, zvichikonzera kusakwana kusanganiswa pane welding interface.

Kusakwana Electrode Pressure

Simba remagetsi risina kukwana rinogonawo kutungamirira kune fusion isina kukwana. Kudzvinyirirwa kwemagetsi kunoiswa kune workpiece kuti ive nechokwadi chekubata kwakaringana uye kupinda mukati mewelding. Kana simba remagetsi rakanyanya kuderera, nzvimbo yekubatanidza pakati pe workpiece uye workpiece idiki, kana welding, kufamba kweatomu yejoint solder inenge isina kukwana, kuitira kuti majoini maviri ekutengesa angangodaro asina kunyatsobatanidzwa.

Electrode Alignment haina kururama

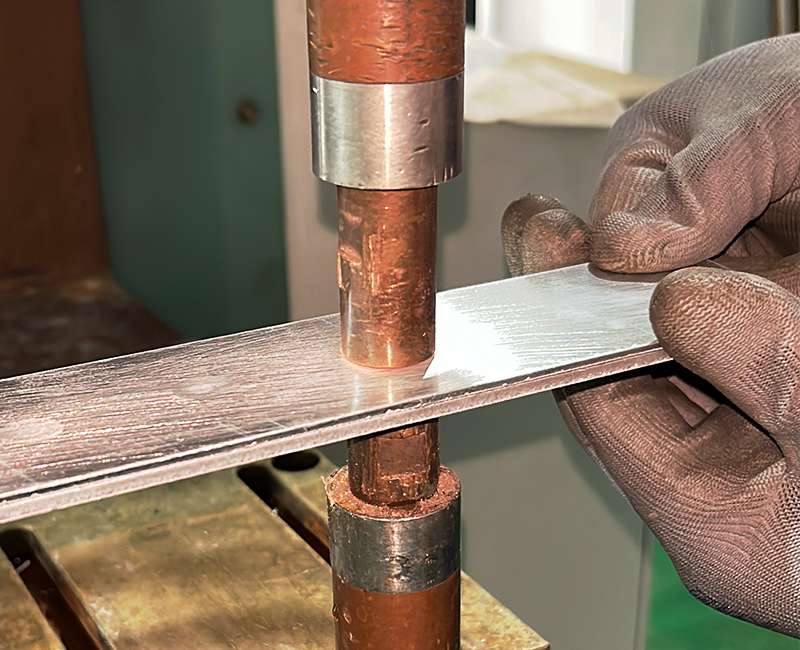

Kurongeka kwakashata kwema electrode kunogona kutungamirira mukusaenzana kwekupisa kwekugovera, zvichikonzera kusanganiswa kusina kukwana. Kana ma electrode asina kurongeka, kupisa kunogadzirwa panguva yewelding process hakugone kugoverwa zvakaenzana munzvimbo yese yekushongedza. Uku kugoverwa kwekupisa kusina kuenzana kunogona kutungamirira mukusanganiswa kusina kukwana munzvimbo dzemunharaunda. Nokudaro, basa rekugadzira risati ratanga, iva nechokwadi chekutarisa kana ma electrode epamusoro uye ezasi akarurama, kana asina kurongeka, zvakakosha kuagadzirisa kuburikidza nechishandiso.

Workpiece Surface Kusvibiswa Kana Oxidation

Kusvibiswa kana oxidation yenzvimbo yebasa inogona kukanganisa fusion yakajairwa panguva yewelding. Zvinosvibisa, zvakadai semafuta, tsvina, kana zvipfeko, zvinoshanda sechivharo pakati pesimbi yakanyungudutswa uye substrate, inodzivisa kunyunguduka. Saizvozvo, oxidation yepamusoro inogona kuumba dhizaini yeokisidhi inodzivirira kusungirirana kwakakodzera uye fusion. Semuenzaniso, kana iwe uchida weld iyo fin yakagadzirwa nefinchubhumuchinapachubhu, kana pamusoro pechubhu ine ngura, iyo welding inofanira kunge isiri-fusion, kuitira kuti iyo welded joint ive isina kugadzikana uye inokanganisa kunaka kwechigadzirwa.

Short Welding Nguva

Kusakwana welding nguva inodzivirira simbi yakanyungudutswa kuti isayerera zvakakwana uye ichibatanidza nehwaro zvinhu. Kana iyo yelding nguva ipfupi, iyo simbi yekubata haina kusanganiswa zvizere isati yapera, uye iyi isina kukwana kusanganiswa inotungamirira kune isina simba uye isingavimbike welding.

Kunzwisisa izvo zvinotungamira kune isina kukwana spot welding fusion kwakakosha kuti uve nechokwadi chemhando yepamusoro welds. Nekugadzirisa matambudziko ekusakwana kwemagetsi emagetsi, simba remagetsi risina kukwana, kurongeka kwe electrode, kusvibiswa kwepamusoro kana oxidation, uye nguva isina kukwana welding, unogona kuderedza kuitika kwekusakwana kusina kukwana kana welding basa, kuitira kuti hutsika hwehuputi hunogona kuvandudzwa zvikuru.

Nguva yekutumira: Sep-24-2024