Aluminium yakashandiswa munzvimbo dzakasiyana-siyana nekuda kwehuremu hwayo huremu, kusagadzikana kwekuora, kunaka kwemagetsi conductivity uye mamwe maitiro, nekukwira kwesimba idzva, kushandiswa kwealuminium kwakasimbiswa, uye kubatana kwealuminium kuwedzera kune riveting, bonding is. welding, yekubatanidza aluminium plateresistance weldinginzira yakakosha, mamiriro ekushandisa mukuwedzera kune akajairwa maindasitiri ekushandisa, Inoshandiswa zvakanyanya mumagetsi matsva emagetsi, aerospace uye mamwe minda.

Misimboti yeAaluminiumWelding

Zvakanakira zvealuminium plate resistancenzvimbo weldingzviri pachena, pasina kuwedzera ebetsero zvinhu, chete nehwaro simbi kunyunguduka anogona kuumba yakasimba solder akabatana.Aluminiummumhepo kazhinji ine mutsetse we oxide firimu, aruminiyamu inonyunguduka inosvika 660 madhigirii celsius, uye iyo oxide firimu ialuminium oxide, nzvimbo yayo yekunyunguduka inenge 2000 madhigirii, uye inonyungudutsa base zvinhu kuti iite musimboti kutanga kutyora iyo oxide layer. , inova zvakare iyo aluminium spot welding process inoonekwa seyakanyanya kuoma chikonzero.

WeldingEquipmentSsarudzo

Kusarudzwa kwealuminium ndironzvimbo welding muchina, yepakati frequency inverter DC magetsi emagetsi nekuda kwekubuda kwayo ikozvino iDC, ine yakanyanya kupisa kunyatsoshanda, saka ndiyo yekutanga sarudzo yealuminium plate spot welding. Iyo yechinyakare-chikamu chechipiri chechipiri chekugadzirisa magetsi ihafu-wave rectifier, capacitive simba rekuchengetedza simba rekupa kunyangwe iyo inobuda iri DC asi nguva ipfupi kwazvo, saka kuita kwayo kwakazara hakuna kunaka seyepakati frequency inverter DC spot welder, idzi. magetsi ekushandisa ane maapplication mukutanga nhanho, iyo ramangwana application mamiriro achange ari mashoma uye mashoma.

PointsTo NoteWhenAaluminiumSpotoWelding

Aluminium plate spot welding process, aruminiyamu ndiro conductivity uye thermal conductivity reshiyo yakakwira, saka kudiwa kweazvino uye kwakakodzera nguva yewelding, inoda kutariswa kune zvinotevera pfungwa:

1. Simba remidziyo rinofanira kunge rakakura zvakakwana kuti rive nechokwadi chekuti inobuda inogona kuve yakanyanya munguva pfupi, kazhinji 2-3 nguva yazvino yecarbon steel spot welding;

2. Iyo electrode inoda kutonhora kwemvura kwakasimba, uye kupisa kunogona kutorwa nokukurumidza mushure mekuputika;

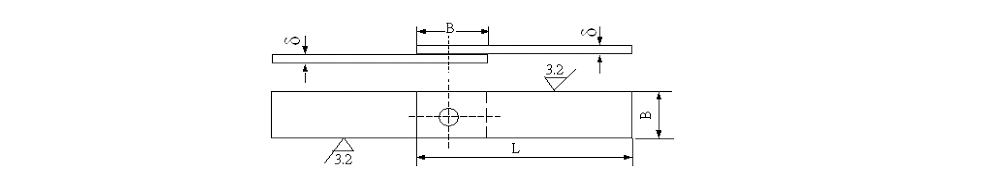

3. Iyo dhayamita yedenderedzwa yepamberi yekupedzisira ye electrode inofanira kufananidzwa, uye akasiyana ndiro thickens inofanira kuva nemativi akasiyana, uye nheyo haifaniri kunge yakaderera pane SR25;

4. Iyo dhayamita ye electrode inofanira kufanana nehupamhi hweplate, uye electrode dhayamita pasi pe 1.0MM yeplate ndeye ¢13; Sheet ukobvu 1.0-1.5 Electrode dhayamita iri ¢16; Sheet ukobvu 1.5-2.0 Electrode dhayamita iri ¢20; Plate ukobvu pamusoro pe 2.0 electrode dhayamita haisi pasi pe ¢25;

5. Iyo electrode zvinhu inogadzirwaalloy yemhanguranepamusoro conductivity kana mhangura yakaoma, uye conductivity haisi pasi pe80% IACS;

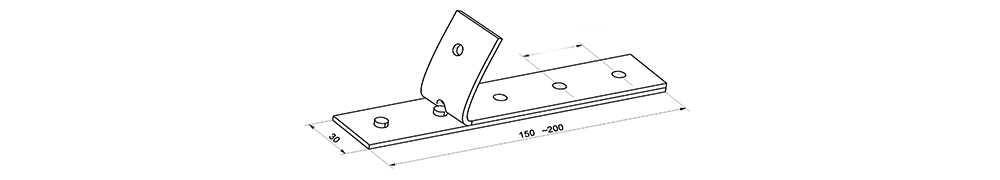

6. Kuti usangane nepamusoro-soro majoini ekutengesa, pamusoro peplate yealuminium inofanira kunge yakasvibiswa, pickling kana kupurisa, uye kupikisa kwepamusoro kweA-level joint yezvigadzirwa zvemhepo / zvehondo zvinofanira kudzorwa pa 50 microohm-100 microohm;

WeldingQualityIkuongorora

Aluminium plate spot welding mushure mekuyedzwa kunyanya kusingaparadze kuyedza uye kuona kukuvara kwemapoka maviri, asingaparadze kunyanya kuburikidza nekuona, X-ray uye ultrasonic kuona, kuona kukuvara kunonyanya kutambanudza, nguva dzakaderera uye kumwe kucherechedzwa, nzira dzekuona dzakateedzera ndedzinotevera. :

1. Chitarisiko chekuongorora, kusanganisira chimiro che solder joint, solder joint color, indentation deep, etc.;

2. X-ray yekuona, kuona firimu yedhayamita ye weld core, ingave iyo weld core inotsemuka, shrinkage uye zvimwe zvikanganiso;

3. Kuonekwa kwesimba rakaderera, 15-25 nguva mushure mekucheka kwechidimbu chejojo dzekutengesa, kuona kusvibiswa kwemagetsi, kukanganisa kwemagetsi, nezvimwewo;

4. Tensile bvunzo, iyo huru bvunzo solder simba rekubatana;

5. Kubvisa bvunzo, kubvisa kana kubvarura bvunzo yemasolder majoini, anonyanya kushandiswa pa-saiti kuona simba uye kusimbiswa kwepakati dhayamita.

6. Ultrasonic kuona, nekuvandudzwa kwe ultrasonic monitoring teknolojia, kushandiswa kwekuona welding yekuona kunoramba kuchisimbisa, kuburikidza nekuenzanisa kwekuratidzira kwakaratidzwa waveform, pamwe chete nekukura kwekombiyuta yemifananidzo ye digital, polycrystalline head ultrasonic kuonekwa ichava sarudzo yakanaka kune. kusiri-kuparadza kuyedzwa kwealuminium spot welding.

Summary

Nekushandiswa kwakakura kweMFDC welding muchina, pamwe nekuvandudzwa kwenzira yewelding uye nzira yekuona, chikumbaridzo chealuminium plate spot welding chichava chakaderera uye chakaderera, uye chichasimudzirawo aluminium plate spot welding mumaindasitiri lightweight, pamwe nesimba idzva, nzvimbo yemhepo uye yakawanda yakawanda. kushandiswa.

Nguva yekutumira: Aug-07-2024