Sheet Metal welding inoshandiswa mumaindasitiri mazhinji. Pese paunoda kujoinha simbi zvidimbu, unozofunga mabatirwo azvo. Welding tekinoroji yave yepamusoro-soro, uye kusarudza nzira yewelding chaiyo inogona kuita kuti basa rako rive nyore uye rishande. Ichi chinyorwa chinokutungamira kuburikidza nekunzwisisa sheet simbi welding uye kukubatsira iwe kuwana iyo chaiyo welding nzira.

Chii chinonzi Sheet Metal Welding?

Sheet metal weldinginyanzvi yekugadzira zvinhu, iyo inoreva kubatana kwepirikana zvimwe zvikamu zvesimbi zvakapatsanurwa kuita imwe neimwe nzira. Nekuvandudzwa kwehunyanzvi hwekugadzira maindasitiri, tekinoroji yewelding inowedzera uye yakanyanya kushandiswa, inova nzira yakakosha mukugadzirwa kwesimbi yeindasitiri yekugadzira.

Ndedzipi nzira dzesimbi welding?

Kune mhando dzakawanda dzesimbi welding nzira, zvichienderana nemamiriro uye maitiro ekuita kwesimbi mune welding process, simbi welding nzira dzakakamurwa muzvikamu zvitatu: fusion welding, pressure welding uye brazing.

Fusion Welding

Fusion welding inzira yekubatanidza nhengo dzesimbi nekudziisa nekunyungudusa pamwechete. Iyi nzira haidi kumanikidzwa. Iyo yekupindirana kweaviri maworkpiece anopisa, zvichiita kuti simbi ibudise yakakura atomu simba, ichigadzira mamiriro emvura panzvimbo inopisa. Maatomu esimbi ezvishandiso zviviri zvinopararira zvizere uye zvinobatana. Kana simbi yakanyungudutswa yatonhora, inoita mubatanidzwa wakasimba wakasungwa.

Yakajairika fusion welding matekiniki anosanganisira arc welding, gasi welding, uye laser welding.

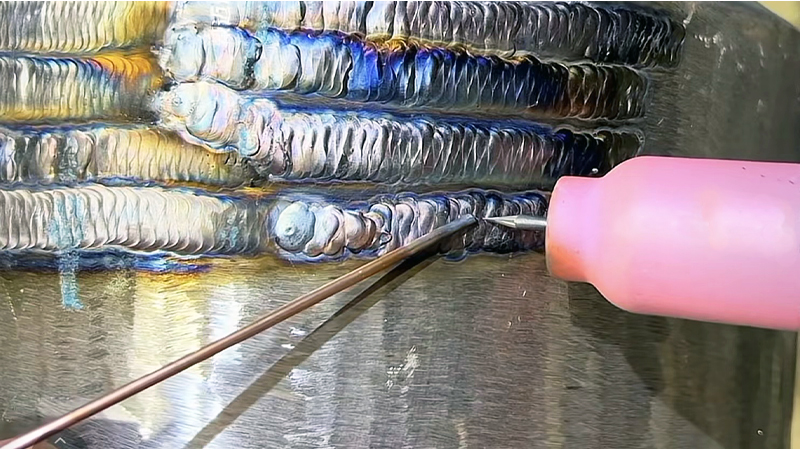

Arc Welding

Arc weldinginofambiswa nemagetsi sosi inobuda pakati pe electrode uye maviri maworkpieces kuita arc. Iyi arc inoshandura kupisa, ichinyungudutsa electrode uye maworkpieces, ichibatanidza simbi pamwechete. Munguva yewelding process, yakaderera voltage uye yakakwira ikozvino inoburitsa tembiricha yakakwira uye chiedza chakanyanya, kupisa electrode uye workpiece kugadzira dziva rakanyungudutswa rinotonhora kuita weld.

Iyi nzira yewelding ine huwandu hwakawanda hwekushandisa uye inogona kushandiswa kupinza simbi dzakasiyana-siyana sesimbi isina tsvina, aruminiyamu, mhangura, uye yakakwirira-kabhoni simbi. Nekuti arc welding midziyo inotakurika uye iri nyore kushandisa, inoshandiswa zvakanyanya mumaindasitiri akaita sekugadzira michina, kuvaka, uye kuvaka ngarava. Semuenzaniso, inoshandiswa kune rebar yekubatanidza mukuvaka. Pamusoro pezvo, arc welding inowanzo shandiswa mukugadzirisa midziyo uye kugadzirisa njanji.

Arc welding inowanzoda muchina wearc welding, welding rods, uye face shield. Iyo yakaderera-mutengo uye yakashandiswa zvakanyanya welding nzira. Nekudaro, nekuda kwekuoma kwayo kwehunyanzvi, kunaka kweiyo weld kunonyanya kuenderana nehunyanzvi hunyanzvi hweiyo welder.

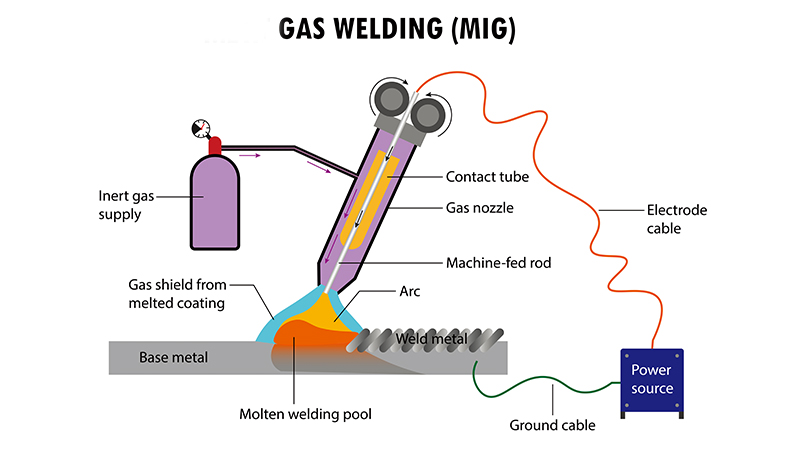

Gasi Welding

Gasi weldinginoshandisa marudzi maviri egasi: gasi remafuta uye gasi rinoita oxidizing. Kupisa kwegasi uku kunogadzira kupisa, iyo inoshandiswa kunyungudutsa simbi zvinhu uye welding tsvimbo inoramba ichidyiswa pakati pezvishandiso zviviri, kupedzisa kubatana kwesimbi.

Gasi welding inowanzo shandiswa kugadzira simbi dzakaita sesimbi, aluminium, uye mhangura. Inopa mabhenefiti senge kuchinjika mukushandisa, hapana zvipimo pane yekushanda nharaunda, uye nyore kushanda. Uyezve, haidi magetsi, zvichiita kuti ishandiswe zvakanyanya kumabasa ekunze uye panzvimbo dzekuvaka dzekubatanidza simbi. Kana iwe uchida kugadzirisa pombi yesimbi, gasi welding isarudzo yakanaka.

Zvisinei, gasi welding ine painogumira. Hunhu hweiyo weld hunonyanya kukanganiswa nemhando yetsvimbo yewelding, uye majoini akashongedzwa anowanzoita deformation. Uyezve, kubudirira kwekugadzira kwakaderera.

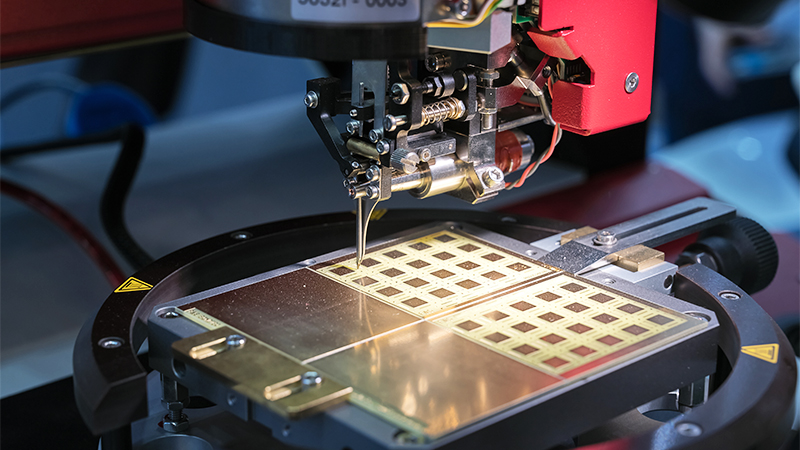

Laser Welding

Laser weldinginoshandisa laser danda seyayo kupisa sosi. Laser beam inorova mipendero yesimbi yekushanda, ichigadzira kupisa uye kugadzira dziva re weld. Kana iyo laser painosimuka, simbi yakanyungudutswa inotonhorera uye inobatana pamwechete. Iyi nzira inogona kushandiswa kupindirana welds, butt welds, uye zvakanamirwa welds mune akasiyana maindasitiri maapplication.

Laser welding ine kukurumidza welding yekumhanyisa uye yakanyanya kushanda zvakanaka, uye inogona zvakare kushandiswa kukwenenzvera zvisiri zvesimbi. Iyo tekinoroji yemhando yepamusoro yewelding inoshandiswa zvakanyanya mumaindasitiri akadai sekugadzira mota, zvemagetsi, uye zvishongo. Zvisinei, haigoni kupinda mukati mezvinhu zvakakora, saka inonyatsokodzera zvinhu zvakatetepa-madziro. Zvichienzaniswa nedzimwe nzira dzekukuchidzira, laser welding michina inoita kunge inodhura.

Press Welding

Kusiyana nefusion welding, pressure welding inoda kuisa imwe huwandu hwekumanikidza kune simbi panguva yewelding process. Zvinhu zvesimbi hazvinyungudike kuita mvura asi zvinoramba zvakasimba. Pressure welding inosanganisira kudziyisa majoini esimbi kuti awedzere purasitiki, uyezve kushandisa kumanikidza kune simbi yepurasitiki, zvichikonzera kubatana kwakasimba kweweld. Naizvozvo, kumanikidza kunoita basa rakakosha mukuita.

Nekuvandudzwa kwehupfumi hwemaindasitiri, zvinhu zvitsva zvakawanda uye zvigadzirwa zvakabuda, zvichitungamira kuenderera mberi hunyanzvi mukumanikidza welding tekinoroji. Iwo main pressure welding matekiniki parizvino anosanganisira kuramba welding, diffusion welding, friction welding, uye ultrasonic welding.

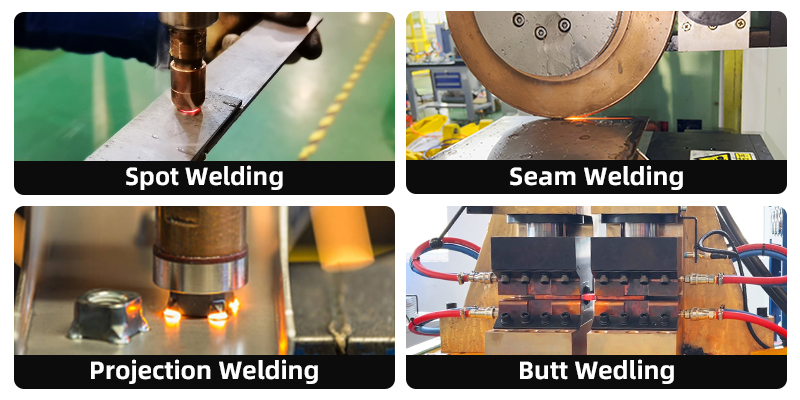

Resistance Welding

Resistance weldinginoshandisa magetsi ikozvino kupisa nzvimbo yekubatanidza yesimbi workpieces uchiisa kumanikidza kuburikidza nemagetsi kupedzisa weld. Inonyanya kushandiswa kugadzira simbi isina tsvina, mhangura, aluminium, uye kabhoni simbi. Nekuda kwekukwira kwayo uye kunoenderana welding mhando, resistance welding inoita basa rakakosha mumotokari, zvemagetsi, uye maindasitiri emuchadenga. Nekufambira mberi mune tekinoroji, kuramba welding yakawedzera kubatanidza otomatiki, ichiwedzera kuwedzera kugadzirwa kwehunyanzvi.

Resistance welding inogona kukamurwa kuva nzira ina:nzvimbo welding, projection welding,seam welding,uyebutt welding. Semuenzaniso, kana iwe uchida kubatanidza chikamu chemotokari, sekubatanidza nati mundiro yesimbi, unogona kushandisa projekiti welding. Nekudaro, midziyo yekudzivirira welding inowanzo hombe uye haifambisike nyore, ichimisa kushandiswa kwayo kune yakatarwa marongero. Nguva imwe neimwe paunopinza zvinhu zvakasiyana zvesimbi kana ukobvu, maparamendi anoda kugadziridzwa, zvichiita kuti ive yakakodzera kukwirisa-vhoriyamu welding yezvikamu zvesimbi.

Diffusion Welding

Diffusion welding, inozivikanwawo sekuti diffusion bonding, inosanganisira kudziyisa uye kuisa kumanikidza kunzvimbo dzesimbi panguva yewelding. Iyi nzira inobvumira maatomu nemamorekuru emidziyo yesimbi kuti ipararire uye ibatane pasi petembiricha yakanyanya uye kumanikidzwa. Diffusion welding inogona kushandiswa kune ese akafanana uye akasiyana zvinhu, anowanzo kubatanidza mhangura, aluminium, uye composite zvinhu.

Iyi nzira inogona panguva imwe chete kupinza majoini akawanda mugungano, senge welding 20 layers ye0.1 mm yemhangura foil. Diffusion welding inogadzira majoini akasimba anoramba deformation, kazhinji achibvisa kudiwa kwekuwedzera kugadzirisa. Nekudaro, zvakare ine zvipingamupinyi, zvinosanganisira kuderera kwekugadzira kunyatsoita uye kudhura kwemidziyo.

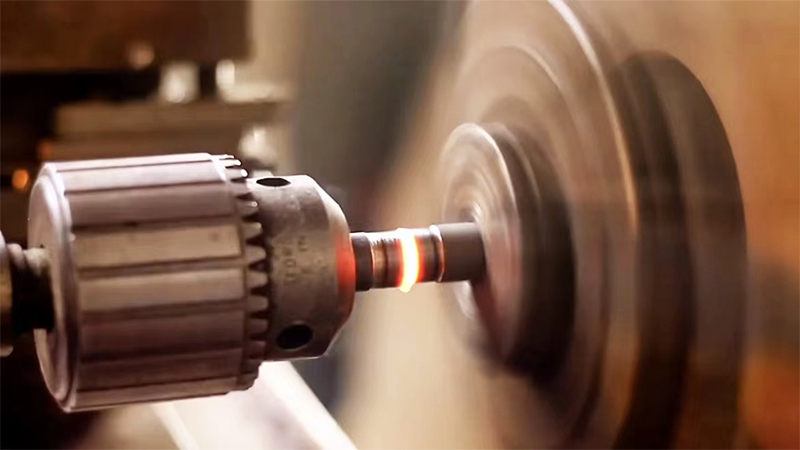

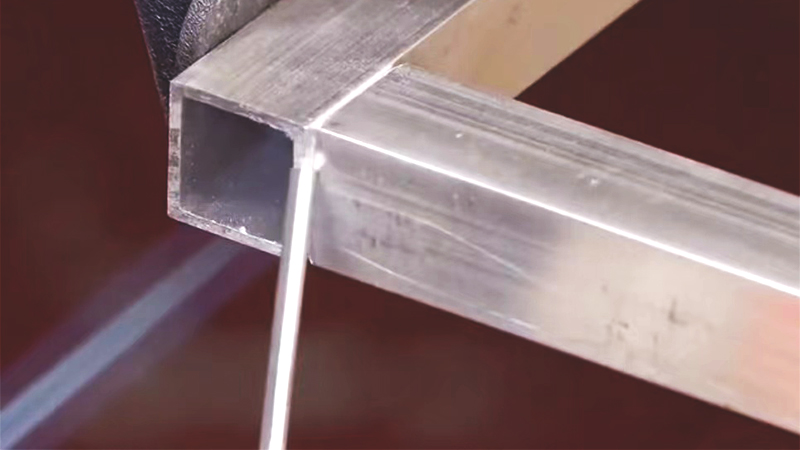

Friction Welding

Friction weldingndeye welding process inoshandisa kupisa kunogadzirwa kubva kune hama frictional motion pakati pe workpieces pasi pekumanikidzwa. Iyo inzira inoshanda, inochengetedza simba inoburitsa emhando yepamusoro welds. Kuenzaniswa neflash butt welding, friction welding ine nzvimbo diki inokanganisa kupisa uye inokodzera zvirinani kujoinha simbi dzakasiyana.

Friction welding yakasarudzika uye inopa mabhenefiti akadai sekushomeka kwemagetsi uye kushamwaridzana kwezvakatipoteredza, zvichiita kuti ive yakakurumbira mumaindasitiri akaita semechini kugadzira, aerospace, uye simba. Zvisinei, inowanzokodzera chete kubatanidza tsvimbo dzesimbi nemapombi ehupamhi hwakafanana. Kana iyo chimiro uye nzvimbo yegungano yezvishandiso zvagadziriswa, zvinova zvakaoma kupinza.

Ultrasonic Welding

Ultrasonic welding inoshandisa yakakwira-frequency vibrations inogadzirwa nemasaisai e ultrasonic kugadzira kukweshera, deformation, uye kupisa panzvimbo yesimbi yekubata. Dzvinyiriro inoshandiswa nenyanga dzepamusoro nedzepasi dzinonzwika kuti dzipedze basa rekugadzira. Iyi inzira yakasarudzika yewelding isingabatanidzi magetsi achipfuura nepakati pezvishandiso kana kunze kwekudziya kwekunze, uye inogovera humwe hunhu ne friction welding uye diffusion welding.

Ultrasonic weldinginogona kushandiswa kune zvakasiyana siyana zvezvinhu, zvinosanganisira ese akafanana uye akasiyana simbi semhangura, aruminiyamu, goridhe, uye sirivheri. Nekudaro, inonyanya kushandiswa kugadzira zvinhu zvisiri-simbi senge ABS, PP, uye PC, kwainoburitsa zvirinani.

Brazing Welding

Brazingis a welding methodwhere simbi yekuzadza ine nzvimbo yakanyunguduka pazasi iyo yezvishandiso inodziya uye yakanyungudutswa kuti izadze maburi pakati pemarata maviri esimbi, kupedzisa simbi yekubatanidza maitiro. Kusiyana nefusion welding uye kudzvanywa welding, iyi nzira haidi kunyungudutsa maworkpiece kana kushandisa kumanikidza. Brazing inonyanya kushandiswa kujoinha maworkpieces akapetwa, ane gap saizi anowanzo kubva 0.01 kusvika 0.1 millimeters.

Nhasi, brazing iri kuwedzera kushandiswa mumaindasitiri akadai semuchina, zvemagetsi, zviridzwa, uye mwenje. Hunhu hwekubhuroka zvakanyanya hunoenderana nesimbi yekuzadza inoshandiswa. Nokudaro, kana uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchinge uchigadzira simbi workpieces , zvakakosha kuti usarudze simbi yekuzadza ine yakanaka yekunyorova zvinhu zvinogona kunyatso kuzadza majoini. Brazing yakakamurwa kuita yakapfava brazing uye yakaoma brazing zvichibva pane inonyungudika yesimbi yekuzadza.

Soft Soldering

Yakapfava solder inoshandisa simbi dzekuzadza dzine nzvimbo dzekunyungudika dziri pasi pe450 degrees Celsius. Majoini akagadzirwa kuburikidza nesoda yakapfava ane simba rakaderera uye kushomeka kwekupisa. Inowanzo shandiswa kubatanidza magetsi mune chaiyo zvigadzirwa zvemagetsi uye solder nemasimbi ekusimbisa. Kana zvinodikanwa zvesimba zvisingakoshesi uye nzvimbo yekunyungudika yesimbi yekuzadza yakakwira kupfuura iyo yesimbi iri kutengeswa, solder yakapfava inogona kushandiswa.

Zvakaoma Soldering

Brazing ine high-melting-point filler metals, inozivikanwa seyakaoma soldering, inoshandisa simbi dzekuzadza dzine nzvimbo dzakanyunguduka pamusoro pe450 degrees Celsius. Majoini akagadzirwa kuburikidza neakaoma solder akasimba kana achienzaniswa neaya kubva munyoro solder. Hard soldering inowanzo shandisa zvinhu zvakaita sesirivha, aluminium, mhangura, uye nickel. Kusarudzwa kwesimbi yekuzadza kunoenderana nehunhu hweiyo workpiece zvinhu uye nekuita zvinodiwa zvejoint. Hard soldering inowanzokodzera simbi isina tsvina, aruminiyamu alloys, mhangura, uye zvimwe zvinhu zvine yakakwira simba zvinodiwa. Inoshandiswa kune majoini anoshanda pasi pekupisa kwakanyanya uye anowana maapplication akakura muaerospace, zvemagetsi, uye maindasitiri emagetsi.

Mhedziso

Kune marudzi akasiyana-siyana esimbi welding, uye idzo dzataurwa pamusoro apa dziri pakati penzira dzakajairika. Sezvo welding tekinoroji ichiramba ichifambira mberi, nzira dzakawanda dzekushongedza dziri kubuda. Paunenge uchifunga mabatiro esimbi yako yekushanda, zvakakosha kuti utarise zvinhu zvakaita sechinhu chebasa, chimiro chayo, nharaunda yebasa, nezvimwe. Kusarudza yakafanira welding nzira yakavakirwa pazvinhu izvi kwakakosha.

Nguva yekutumira: Jun-19-2024