Spot weldingrudzi rwekupikisa welding, senzira yakanyatsogadziriswa inoshandiswa kubatanidza simbi dzakasiyana-siyana, zvichiita kuti ive nzira yakakosha mukushanda kwesimbi kwemazuva ano. Ichi chinyorwa chinopa mamwe matipi ekuwana akasimba, anoyevedza, uye akagadzikana kuramba welds:

Sarudza ChakaruramaSpotWeldingMachine

Kusarudza iyo yakakodzera yekudzivirira nzvimbo welding mudziyo kwakakosha. Dzivisa michina yakakurisa ine zvinhu zvakawandisa, sezvo izvi zvinogona kutambisa mari. Saizvozvo, usasarudza muchina wakangokwana, sezvo usingatenderi kuwedzera mune ramangwana kana kuve nekuneta kuneta.

Sarudzo yakanakisa ndeye muchina unokwanisa kuomesesa kududzira welding, ine ingangoita 25% yekuwedzera huwandu muwelding ikozvino uye kumanikidza kupfuura ikozvino.sheet metal welding.

Kushandisa muchina wakakura zvakanyanya kunogona kukonzera nyaya dzakawanda semuchina mudiki. Semuenzaniso, kana silinda dhayamita yakakurisa, inofanirwa kushanda pamhepo iri pasi pe 0.2 MPa kuti iwane inodiwa welding pressure. Izvi zvinogona kuguma nekupindura kwakashata kubva kune yekumanikidza application mechanism. Kana iyo silinda isingaite nekukurumidza kana simbi yasvika kune yepurasitiki mamiriro uye inoda kukurumidza kuumbwa, iyo weld simba uye kugadzikana kunogona kutambura.

Makambani mazhinji, kuitira kurerutsira manejimendi emidziyo uye yunifomu welding paramita, sarudza michina inoenderana neyakajairwa modhi pane welding process zvinodiwa. Izvi zvinogona kutungamira mukusaenderana zvakanaka kana welding zvikamu zvakakura uye zvidiki. Uku kukanganisa kwakajairika nevanjiniya vasina ruzivo. Iyo chaiyo nzira ndeyekufananidza saizi yemidziyo kune iyo workpieces ari welded.

Dzidzisa kupindaSpotWelding

Chekutanga, zvakakosha kuti udzidziswe mune welding misimboti uye matekiniki. Kunzwisisa misimboti yekupokana nzvimbo welding kwakakosha pakugadzirisa nemazvo maitirwo ewelding uye kushandisa michina nemazvo.

Spot welding inogona kuita seyakatwasuka, nekuti zvinoita sekunge munhu wese anogona kushanda uye kugadzirisanzvimbo welding muchina: isa zvikamu pakati pe electrode, tinya bhatani rekutanga, uye zvikamu zvakabatanidzwa pamwe chete. Zvisinei, izvi zvinonyengera. Izvo zvakakosha kuti unzwisise kukosha kwewelding zvinhu uye paramita uye kugadzirisa imwe neimwe kune yayo yakakwana kukosha.

Funga nezvayo sekubika: zvinhu zvakafanana, asi zvinonhuwira zvakasiyana, mazinga ekupisa, uye nguva yekubika zvinogona kuburitsa zvinonaka zvakasiyana!

Zvinhu zvitatu zvakakosha zvespot welding ndeye welding current, welding time, uye welding pressure. Mamwe ma parameter anosanganisira pre-pressure time, welding interval time, uye post-welding hold time.

Nekusanganisa aya ma paramita, unogona kuwana zvakaomarara, zvepakati, kana zvinyoro zvekushongedza, zvichikonzera akasiyana welding mhedzisiro, senge:

Zvakaoma zvirevo:Minimal chikamu deformation, yakaderera kupisa kukanganisa, kukurumidza welding kumhanya, asi inoda yakakwirira-simba, yakasimba, uye yakakwirira-kumanikidza michina.

Soft specifications:Yakakosha chikamu deformation, yakadzika weld indentation, discoloration, inononoka welding kumhanya, asi yakaderera simba uye rigidity zvinodiwa zvemidziyo.

Zvepakati zvakatemwa:Mhedzisiro uye zvinodiwa zvemidziyo zvinowira pakati pezviviri zvakanyanyisa pamusoro.

Mabhuku ehunyanzvi senge "Welding Handbook" anopa parameter kurudziro, uye Agera's technical service mainjiniya anopa kudzidziswa kwehunyanzvi uye kutungamira kune vashandisi.

Sarudza ChakaruramaSpot WeldingElectrodes

Kufananidza iyo electrode zvinhu kune chikamu chemidziyo kwakakosha kune yakakwana welding mhedzisiro uye kushanda nesimba.

Yekushongedza nzvimboaluminiumuyemarata, shandisa alumina-yakapararira mhangura electrodes, iyo inoramba kunamatira.

Forsimbi isina ngurauye pasi-carbon steel sheets, shandisa chromium zirconium copper electrodes, iyo inopa mari yakawanda-inoshanda.

Formhangura, tungsten uye molybdenum electrodes inodiwa kuti ibatsire nekuputika nekuda kwekupisa kwavo.

Magadzirirwo uye kugadzirwa kwema electrode maumbirwo akakosha zvakare, sezvo ivo vachiona saizi uye kutaridzika kweiyo weld nugget uye simba rayo.

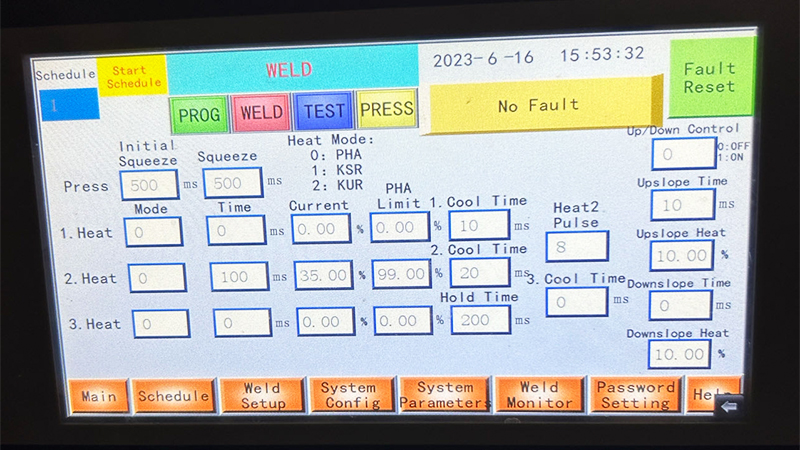

Isa Welding Parameters

Welding parameters inogona kusetwa zvichibva pane zvakaitika kana data kubva kuruzhinji masosi. Kana pasina mareferensi aripo, unogona chete kuwana akanakisa welding paramita kuburikidza neakawanda mayedzo welds ane akasiyana marongero. Paunenge uchiyedza, tevera misimboti iyi:

Tanga Diki: Tanga nekuchengetedza, zvidiki zvimiro zveparamita senge welding ikozvino, nguva, uye kudzvanywa, uye zvishoma nezvishoma zviwedzere. Iyi nzira inobatsira kudzivirira kukuvadzwa kwemidziyo, electrode, uye zvikamu.

Gadzirisa Paramita Imwe Panguva: Kugadzirisa akawanda paramita panguva imwe chete kunogona kutungamirira kune zvisiri izvo kutonga, kunyanya kune vasina ruzivo rwevashandisi. Kana imwe gadziriso ikasashanda, edza imwe uchinyatso tarisa shanduko mumhando yewelding.

Bvumira Parameter Margins: Ita shuwa kuti pane muganho wemaparamita kuti agone kusiyanisa muzvikamu.

Kana iyo yakanakisa welding paramita yasimbiswa, simbisa idzi data uye uzvishandise sehwaro hwekugadzira.

Chengetedza Electrodes

Gara uchigadzirisa maelectrode akaremara kuti arambe ari pakukura kwawo akagadzirwa uye kuchenesa tsvina nemhangura alloy masara kubva paari. Kugadzirisa uku kwakakosha pakutsikisa welding.

Electrodes inoshanda pasi pekumanikidzwa kwakanyanya uye tembiricha inogona kukanganisa, ichiwedzera nzvimbo yavo yekusangana nezvikamu uye kuderedza welding ikozvino density. Pamusoro pezvo, machira epamusoro, oiri, uye ngura kubva muzvikamu zvinogona kunamatira kuma electrode, kuwedzera kupikisa kuramba uye kudzikamisa welding ikozvino. Idzi nyaya dzinobata zvakananga welding kunaka.

Kushandisa yakasarudzika electrode dresser kunogona kukurumidza kudzoreredza chimiro che electrode uye kubvisa tsvina yepamusoro. Dzivisa kushandisa faira yekuchenesa kwemanyorero, sezvo isingakwanise kuve nechokwadi chechimiro chakakodzera uye kupera kwepamusoro kwema electrode.

Shandisa Welding Inspection Equipment

Spot welding majoini kazhinji haaitirwe bvunzo dzisiri dzekuparadza. Nzira dzekuongorora dzakajairwa dzinosanganisira yekutarisa yekuona, torque wrenches (yewelding nzungu), tensile yekuyedza michina, uye metallographic testers.

Tensile uye Compression Testing: Ita bvunzo idzi usati watanga zuva rakazara rekugadzira kuratidza kuvimbika kweiyo welding paramita ine seti yedata rekuyedza. Pakupera kwekuchinja kwega kwega, edza zvikamu zvakasungwa neazvino paramita zvakare kuti uve nechokwadi chekuenderana. Kune zvikamu zvakakosha zvine zvemhando yepamusoro zvinodiwa, wedzera kuwanda kwekukuvadza kuyedzwa.

Maitiro Ekutarisa: Kushandisa welding quality monitors ndeimwe sarudzo, iyo iri kuwedzera kukoshesa uye kushandiswa zvakanyanya. Nekutarisa welding paramita munguva chaiyo uye kuseta yepamusoro uye yakaderera miganho, chero kutsauka kunogona kukonzeresa maalarm, kudzikisa hurema hwewelding. Idzi data rekugezesa rinogona zvakare kuchengeterwa kunaka kuteedzera.

Kugara Kuchengetedza uye Kuongorora

Mushure mekushandiswa kwenguva refu, Spot welding midziyo inoda kugara ichiongororwa munzvimbo idzi:

- Conductive Circuit:Welding spatter inogona kupinda mukati me insulated zvikamu uye magapu, zvichikonzera shunting, kuderedza uye kudzikamisa welding ikozvino. Bvisa weld slag. Kakawanda electrode shanduko inogona kupfeka uye oxidize conductive kubatanidza, inoda kudzokorora. Simbisa mabhaudhi patambo dzakapfava dzemhangura uye mbariro dzakaoma dzemhangura kuti usasununguke kubva mukushandiswa kwenguva refu.

- Welding Cylinder Guide:Tarisa mafambiro akatsetseka uye maburi. Kutsvedza kwakashata kunokanganisa weld kutevera-kuburikidza; mapeji akawandisa anokanganisa weld chimiro uye chikamu kurongeka.

- Dunhu reMvura:Iva nechokwadi chekuyerera kwemvura yakatsetseka. Chenesa mamita ekuyerera kuti ajekese, tarisa nzira yega yega yekuyerera, uye bvisa mavharogi kana kutsiva mapaipi. Mvura yekutonhodza isina kukwana inogona kupisa matransformer uye maelectrode, kuderedza hupenyu kana kukonzera kupera simba. Tarisa uye gadzirisa zvinobuda.

- Welding Current:Simbisa iyo welding ikozvino neyechitatu-bato tester kuti uone kuti inoenderana nezviyero. Kushandiswa kwenguva refu kunogona kuderedza kubuda kwazvino, saka kuongororwa nguva dzose uye kukwidziridzwa kana kugadzirisa kunogona kudikanwa.

- Mhepo Circuit:Tarisa uye gadzirisa kubuda kwemhepo, sezvo kudonha kunokonzera kusagadzikana kusagadzikana uye kurasikirwa kwesimba.

- Hutsanana:Chengeta midziyo yakachena. Makaka akajeka uye midziyo yakachena inoderedza kukanganisa kwevanhu.

Zhizha

Aya ndiwo mamwe kurudziro kune vashandisi ve resistance welding equipment. Neanopfuura makore makumi maviri eruzivo rweindasitiri yewelding, isu tinopa huwandu hwakazara hwesevhisi, kusanganisira welding sampuli kugadzirira, kusarudzwa kwemichina, tsika isiri-yakajairwa otomatiki welding michina, kuisirwa uye kutumira, kugadzirisa, kutsigira midziyo, uye zvikamu. Inzwa wakasununguka kutibata nesu!

Nguva yekutumira: Jul-09-2024