Nekuenderera mberi kwekuenderera mberi kwesainzi uye tekinoroji uye kuwedzera kukwenenzverwa kwekugadzirwa kwemaindasitiri, tekinoroji yekudzivirira welding, senzira yakakosha yewelding, yakashandiswa zvakanyanya munzvimbo dzakasiyana siyana. Nekudaro, iyo yechinyakare kuramba welding tekinoroji ine mamwe matambudziko, senge yakaderera kudzora kurongeka, kushandiswa kwesimba kwakanyanya uye kusagadzikana welding mhando. Kuti ugadzirise matambudziko aya, tekinoroji yedhijitari inounzwa mune yekudzivirira welding tekinoroji, iyo inovandudza zvakanyanya iyo otomatiki nhanho uye welding mhando yekupokana welding.

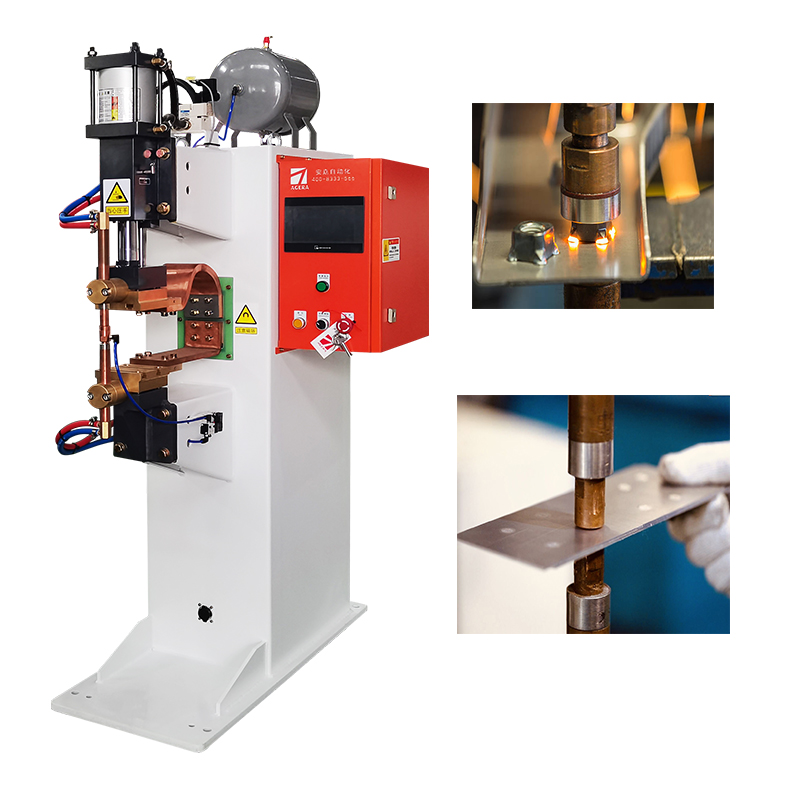

Digital resistance welding

Digital resistance welding imhando yewelding tekinoroji inoshandisa tekinoroji yedhijitari kunyatso kudzora uye kukwidziridza maitiro ekudzivirira welding. Iyo inogona kuona chaiyo-nguva yekutarisa uye otomatiki gadziriso yewelding process nedhijitari kugadziridzwa kwewelding paramita, process data, mamiriro emidziyo uye rumwe ruzivo. Digital resistance welding ine zvinotevera hunhu:

1. Kururamisa kwepamusoro-soro: digital resistance welding inogona kunyatso kudzora welding ikozvino, voltage, nguva uye mamwe maparameter kuti ave nechokwadi chekugadzikana uye kuwirirana kwehutano hwekushongedza.

2. High degree of automation: iyo digital resistance welding system inogona kuona kudzora otomatiki kweiyo welding process, kuderedza kupindira kwemanyorero uye kunatsiridza kugadzirwa kwakanaka.

3. Kuchengetedza magetsi uye kuchengetedzwa kwezvakatipoteredza: Nekugadzirisa maparamendi ekugadzirisa uye maitiro, digital resistance welding inogona kuderedza kushandiswa kwesimba uye kuderedza kubudiswa kwezvinhu zvinosvibisa zvakadai semarara gasi uye slag.

4. Strong traceability: iyo digital resistance welding system inogona kurekodha iyo data muwelding process, ichipa rutsigiro rwakasimba rwechigadzirwa chemhando traceability.

Kukosha kwedigitization mukatiresistance welding

1. Kuvandudza welding yemhando: tekinoroji yedhijitari inogona kunyatso kudzora maparamita uye maitiro ekuona kugadzikana uye kuenderana kwemhando yewelding uye kuvandudza kunaka kwechigadzirwa.

2. Kuvandudza kugadzirwa kwehunyanzvi: tekinoroji yedhijitari inogona kuona iyo otomatiki kutonga uye optimization yewelding process, kuderedza kupindira kwemaoko, uye kuvandudza kushanda kwekugadzira.

3. Deredza mutengo wekugadzira: Nekugadzirisa maparamendi ekugadzira uye maitiro, digital resistance welding inogona kuderedza kushandiswa kwesimba uye kushandiswa kwezvinhu, uye kuderedza mari yekugadzira.

4. Kuwedzera kukwikwidza kwemabhizinesi: dhijitari kuramba welding tekinoroji inogona kuvandudza tekinoroji nedanho rekutonga remabhizinesi, uye kuwedzera kukwikwidza kwemusika uye kugona kusimudzira kwemabhizinesi.

Kushandiswa kwedigitization mukupikisa welding

1. Welding parameter control

Mukuita kwekupokana welding, kutonga kwewelding paramita kune yakakosha mhedzisiro pamhando yewelding. Digital tekinoroji inogona kutarisa uye kugadzirisa welding ikozvino, voltage, nguva uye mamwe ma paramita munguva chaiyo kuti ive nechokwadi chekugadzikana uye kuenderana kweiyo welding process.

2. Welding process optimization

Iyo tekinoroji yedhijitari inogona kugadzirisa otomatiki welding maparamendi zvinoenderana newelding zvinhu, workpiece chimiro uye ukobvu uye zvimwe zvinhu kuti uone optimization yewelding process. Kuburikidza nekutevedzera uye kuongororwa kwedata, iyo dijitari inopikisa welding system inogona kufanotaura tembiricha yemunda, nzvimbo yekushushikana uye dzimwe shanduko mukuita welding, uye inopa hwaro hwesainzi hwekuita optimization. Uye zvakare, tekinoroji yedhijitari inogona zvakare kuwana kure kutarisa uye kukanganisa kuongororwa kweiyo welding process, kuvandudza kuvimbika uye hupenyu hwebasa remidziyo.

3. Welding quality yekuongorora

Iyo tekinoroji yedhijitari inogona kutarisa uye kuongorora iyo welding mhando munguva chaiyo. Nekuunganidza iyo voltage, yazvino, tembiricha uye mamwe ma parameter muwelding process, iyo digital resistance welding system inogona kutonga kana mhando yewelding inosangana nezvinodiwa. Panguva imwecheteyo, tekinoroji yedhijitari inogona zvakare kuitisa isiri-inoparadza yekuyedza majoini akasungwa kuti awane kuremara uye njodzi dzakavanzwa mukuita welding.

4. Kutarisira kwakangwara

Iyo digital resistance welding system inogona kuona hungwaru manejimendi yewelding process. Kuburikidza nekubatanidzwa kweInternet yeZvinhu, data hombe, cloud computing uye mamwe matekinoroji, iyo digital resistance welding system inogona kuwana chaiyo-nguva yekutarisisa mamiriro emidziyo, kuongororwa kukanganisa uye kuchengetedzwa kwekutanga. Uye zvakare, tekinoroji yedhijitari inogona zvakare kuona kuratidzwa kwekuona uye kuongororwa kwedata kweiyo welding process, ichipa rutsigiro rwakasimba rwesarudzo dzekugadzira.

Seanotungamira pasirese simbi yekubatanidza mhinduro inopa, Agera iri kuramba ichiongorora nzira yekuvandudza yedhijitari kuramba welding, uye muna 2022, yakagadzira nekugadzira iyo welding mhando chaiyo-nguva yekutarisa system HRC650, iri chaiyo midziyo. Inogona kushandiswa kwepamusoro-kumhanya-chaiyo-nguva yekuona yeazvino, yechipiri voltage, kupesana kwekubatana, electrode displacement, electrode pressure data uye curves inobata weld quality, uye muganhu wehuwandu hwe data yega yega inogona kuiswa yega. Kana iyo data yakadarika kukosha kwakatarwa, unogona kuburitsa alarm uye kuseta envelope curve.

Iko kushandiswa kwedhijitari mukupikisa welding tekinoroji yave maitiro asingadzivisike mukusimudzira indasitiri. Nekuenderera mberi nekuvandudza uye kuvandudzwa kwedhijitari tekinoroji, kuramba welding tekinoroji inowana inoshanda, yakaringana uye nehungwaru welding process. Mune ramangwana, Agera icharamba ichiongorora mugwagwa wedhijitari kuramba welding uye nekupa rutsigiro rwakasimba rwekuchinja uye kusimudzira kwekugadzirwa kwemaindasitiri.

Nguva yekutumira: Jun-13-2024