Welding yemagaroinoshandiswa zvakanyanya uye yakawanda mukugadzirwa kwesimbi yemazuva ano, kuburikidza ne-butt welding tekinoroji, simbi imwechete kana simbi isina kufanana semhangura nealuminium inogona kusimba pamwe chete. Nekuvandudzwa kweindasitiri, butt welding tekinoroji inoshandiswa zvakanyanya kune zvemagetsi nemagetsi, mota nyowani dzesimba uye mamwe maindasitiri. Chinyorwa chinotevera chichapindura ruzivo rwebutt welding kwauri zvakadzama.

BasicCpamusoro peButtWelding

Iyo inonzi butt welding ndeyekuisa iyo maviri workpiece inogumira kune mumwe nemumwe, isa kumanikidza panguva imwe chete, shandisa welding ikozvino kupisa, uye wozogadzira welding yejoini pasi pekuita kwekumanikidza, inoshanda uye nyore kuita otomatiki. welding process nzira.

The Types of ButtWelding

Butt welding inonyanya kukamurwa kuitaresistance butt weldinguyeflash butt welding

Resistance butt welding

Resistance butt welding imhando yakasimba yechikamu welding mune yakakwira tembiricha yepurasitiki mamiriro, uye kubatana kwakabatana kunogona kuve recrystallization uye kuwirirana kupararira muhunhu, asi ese akasimba chikamu chekubatanidza.

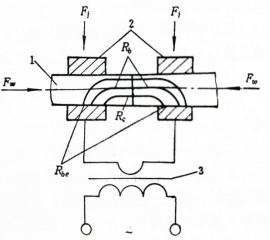

Iyo musimboti wekupokana butt welding uye kuumbwa kwemajoini inoratidzwa muMufananidzo 1.

Mufananidzo 1. Resistance butt welding schematic diagram

1- Weldment

2- Electrode

3- Solder resistance transformer

4-Ff- clamping simba

Fw- kuumba simba

Rb- weldment resistance

RC-Contact kuramba

Rbe- Bata kuramba pakati peiyo weldment uye workpiece

Flash Butt Welding

Iyo yekubatanidza essence yeflash butt welding joint yakafanana neyeyekupokana butt welding joint, inova zvakare yakasimba chikamu chekubatanidza, asi maitiro ekugadzira ane maitiro ayo. Pakupera kwekupenya, mvura yesimbi yesimbi yakaumbwa pamagumo echiso. Munguva yekugadzira yepamusoro, iyo yekupedzisira kumeso simbi inotanga kubatanidzwa pasi pechikamu chemvura. Ipapo iyo yemvura chikamu layer inosvinwa kunze kweiyo yakabatana yekupedzisira kumeso pasi pekuita kwepamusoro forging pressure.Mushure meflash butt welding muchinawelded parts, the joint is very strong, senge simbi chubhu kuburikidza neflash welding, ipapo kuburikidza nechubhu bending muchinakukotama pajoinhi, mubatanidzwa haungatyoki.

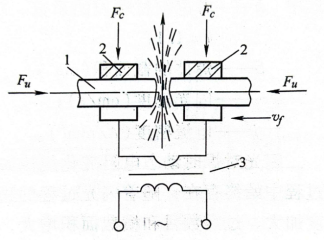

Nheyo yeflash butt welding uye kuumbwa kwemajoini inoratidzwa muMufananidzo 2:

Mufananidzo 2. Flash butt welding schematic diagram

1- Weldment

2- Electrode

3- Solder resistance transformer

4- Fc- clamping simba Fu- forging force Vf flash speed

Zvakanakira zveButtWelding

a) Resistance butt welding midziyo iri nyore, mashoma welding paramita, nyore kubata, nyore kuwana otomatiki kudzora;

b) Kudzikisira kudiki kwekupokana butt welding zvikamu, zvekuchengetedza zvinhu, mashoma maburrs, ayo anobatsira kurerutsa iyo yekupedzisira maitiro;

c) flash butt welding ine yakakwira yekupisa yekupisa, inogona kupinza zvikamu zvakakura-nzvimbo, uye yakashandiswa kugadzira mapaipi egasi ane mhiri-chikamu nzvimbo ye100000mm2;

d) flash butt welding nekuti iyo lintel iripo kwenguva pfupi, mashoma milliseconds chete, chinzvimbo chayo chinochinja zvisina tsarukano, uye iyo yakazara nguva yekupisa mukati mekupedzisira kwechiso che weldment yakawedzera yunifomu, saka inoenderera flash welding haingogone chete weld a. compact chikamu, asiwo weld welds ane zvikamu zvakawedzerwa (senge mapepa matete, nezvimwewo);

e) Pakupera kwekupenya, danda rakatetepa resimbi yemvura richaumbwa pamusoro peiyo weldment, kuitira kuti iyo oxide tsvina iri pamusoro iri nyore kuburitsa neiyo simbi simbi iri pamusoro chikamu cheiyo interface, saka. kuti iyo flash butt welding joint ndeyemhando yepamusoro, uye mhando dzewelding dzinogona kuva dzakawanda, uye zvakasiyana-siyana zvezvinhu zvakasiyana zvinogona kuiswa.

f) Hapana filler inodiwa mukuita welding, uye mwero wekushandisa zvinhu wakakwira;

Kushandiswa kweButtWelding

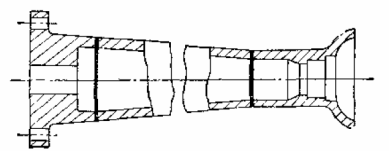

Automotive Manufacturing

Mufananidzo 3. Automobile cardan shaft shell flash butt welding

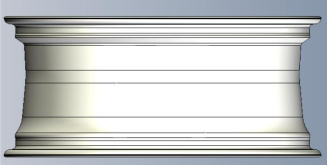

Mufananidzo 4. Motokari, mudhudhudhu vhiri flash butt welding

Aerospace industry

Mufananidzo 5. Ndege tsvimbo butt welding

Petrochemical industry

Mufananidzo 6. Metal pombi butt welding

Kuvaka engineering munda

Mufananidzo 7. End plate flange butt welding

Indasitiri yekuvaka ngarava

Mufananidzo 8. Anchor chain butt welding

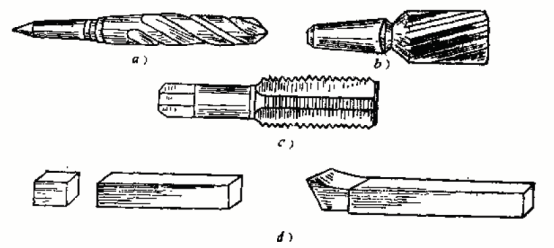

hardware zvishandiso

Mufananidzo 9. Tool butt welding

SpecificationPma aramu mukatiButtWeldingProcess

Kana ma paramita akakodzera e butt welding maratidziro asarudzwa, majoini emhando yepamusoro ane anenge akafanana zvimiro semidziyo yepasi anogona kuwanikwa.

a) Iwo makuru ekutemerwa paramita ekupikisa butt welding ndeaya:

kutambanudza kureba, welding ikozvino density (kanawelding current), welding nguva, welding pressure uye top forging pressure.

b) Iwo makuru ma paramita e flash butt welding ndeaya:

Flash nhanho: kugadzirisa kureba kwekurebesa, flash retention, flash kumhanya, flash ikozvino density;

Yepamusoro forging stage: top forging allowance, top forging speed, top forging pressure, clamping force;

Preheating stage: preheating tembiricha, preheating nguva.

Basa rekutambanudza kureba ndere kuona kubvumidzwa kunodiwa (welding chikamu kupfupisa) uye kugadzirisa tembiricha munda paunenge uchipisa kukosha uye basa rinogona kusarudzwa zvinoenderana nechikamu chewelding chikamu uye zvinhu zvemukati, kudzidzira kunoratidza kuti kutambanudza kureba hakufanirwe kuve kushoma. inopfuura hafu yedhayamita yechikamu chewelding, ndiko kuti, l = 0.6 ~ 1.0d (d ndiyo dhayamita yematanda kana kureba kweparutivi kweskweya) yakakodzera. Panguva imwe chete, kana welding dissimilar zvinhu, kuti vawane mwero tembiricha kuparadzirwa (dzimwe nguva tichifunga rigidity asiri ferrous simbi weldments), maviri weldments vanofanira kushandisa siyana kutambanudza kureba.

Ikozvino welding inowanzo kuratidzwa nehuwandu hwemazuva ano, uye ikozvino density uye welding nguva ndiyo miviri miviri mikuru inogadzirisa kupisa kwekupisa, uye inogona kugadziriswa zvakakodzera kune mumwe nemumwe. Mukuita, zvinokurudzirwa kuchengetedza humwe hukama pakati pehupamhi hwemazuva ano uye nguva shoma yekuputika, uye kushandisa chirevo chakaoma sezvo chikamu chemuchinjikwa chinoderera. Iyo yazvino density yekuenderera mberi flash butt welding, simbi zvinhu zvine yakanaka magetsi uye yekupisa conductivity, uye welded zvikamu zvine chikamu chakawedzerwa chinofanira kunge chakakwira. Kune preheating flash butt welding uye yakakura chikamu welds, density iripo inofanira kunge yakaderera.

Zvese zviri zviviri kudzvanywa kwewelding uye yekumusoro forging pressure ine chekuita pakunyungudika kwekupisa kwenzvimbo yekubata uye deformation yepurasitiki yenzvimbo dzakatarisana uye dziri pedyo. Iyo yepamusoro yekufombera kumhanya uye yekumusoro yeforging simba kudzvanywa inogona kuenderana, uye yepamusoro yekufombera kumhanya inogona kudzikiswa zvakafanira kana iyo yepamusoro forging kumhanya yakakura zvakakwana.

TheDevelopmentProspect ofButtWelding

Nekudzidza kwakadzama kwehukama pakati pekupokana welding mhando uye welding process paramita uye pa-line yekuona tekinoroji, yakanyanya kugadzikana welding mhando inogona kuwanikwa. Pamusoro pezvo, zvinhu zvewelding zvakawedzera kuwedzerwa, uye huwandu hwemashandisirwo ekudzivirira welding hunowedzera uye hwakafara. Nekuenderera mberi kweresistance welding technology, resistance welding inotora chinzvimbo chakakosha mune ramangwana rekugadzirwa kwemaindasitiri. Kunyanya mumunda wewelding wemuchinjika-chikamu uye simbi dzakasiyana, flash butt welding ine tarisiro yakanaka yekusimudzira.

Summary

Nekuvandudzwa kweindasitiri yesimba idzva, kuwedzera uye kuwedzera welding application yemhangura nealuminium yekubatanidza, kuramba welding tekinoroji inongoenderana nezvinodiwa zvemusika, zvakasanganiswa neiyo nyowani yekudzivirira welding process uye adaptive control tekinoroji, kuramba welding mune ramangwana kusimudzira kuchaita. kuunza mufaro mukuru.

Nguva yekutumira: Aug-30-2024