Kana iwe uri mutsva pakuramba welding kana kutsvaga kunzwisisa kwakajeka kwazviri, saka iwe unofanirwa kunyatsoverenga chinyorwa ichi. Ichi chinyorwa chinokutora iwe mukati menyika yekurwisa welding. Kunyangwe iwe uri wekutanga kana kutsvaga kuwedzera ruzivo rwako, chinyorwa ichi chinokupa ruzivo rwakakosha.

Chii chinonzi Resistance Welding?

Resistance welding inzira inomhanya-mhanya, ine mari yekubatanidza simbi. Iyi nzira yewelding inokodzera majoini epamakumbo, majoini emabutt, kana majoini asingade kusimba kwemhepo, ane ukobvu husingasviki 6mm kune matete mapepa zvimiro. Ehe, inogona zvakare weld yakakora uye yakakura simbi workpieces, asi kuita kwayo kwese kunogona kunge kusiri kwakanaka sedzimwe nzira dzewelding.

Tsanangudzo uye Zvinokosha

Resistance weldinginzira iyo maworkpieces ekubatanidza anoiswa pakati pema electrode maviri. Nekupfuura ikozvino kuburikidza neworkpieces uye nzvimbo dzekusangana, kupokana kupisa kunoitika, kuburitsa kupisa pakusangana kweworkpieces. Kudziya kwenzvimbo iyi kunoita kuti nzvimbo inyunguduke kana kuchinjika, ukuwo kudzvanywa kubva kuma electrode maviri kunosungira simbi pamwechete.

Kana ikozvino ichiyerera kuburikidza nekondukita, inogadzira kupisa nekuda kwekupikisa. Iyo yakakwirira kupikisa kana ikozvino inogara isingagumi, kupisa kwakanyanya kunogadzirwa. Panguva iyo masimbi ari kusangana, kushorwa kwakanyanya kudarika mukati mesimbi pachayo. Naizvozvo, kana hombe iripo ichipfuura nekusangana pakati pesimbi ne electrode, simbi inokurumidza kupisa nekuda kwekupisa kukuru. Panguva ino, simbi inova yakanyanyisa ductile, uye nekumanikidza kunoshandiswa, zvidimbu zviviri zvesimbi zvinobatana zvakachengeteka.

Resistance Welding Working Principle

Nheyo yekupikisa nzvimbo welding uye kuumbwa kwemajoini inoratidzwa muMufananidzo 1-1. Metal A nesimbi B zvinoiswa pakati pemaelectrode maviri, uye kudzvanywa kunoiswa kuma electrode. Ikozvino ine simba inopfuudzwa pakati pema electrode maviri ne transformer ye resistance welder. Iyo yekubata kumeso kweiyo workpieces inoumba yemuviri yekubata nzvimbo, iyo zvishoma nezvishoma inowedzera sezvo ikozvino inopisa iyo. Plastic deformation uye kupisa zvinoramba zvichishandisa maatomu panzvimbo yekusangana, zvichitungamira pakuumbwa kwesimbi yakanyungudutswa. Iyo yakanyungudutswa musimboti inokura muchimiro checolumnari makristasi, ichisundira kunze iyo yepamusoro alloy yekumisikidza zvikamu kune imwe neimwe. Apo ma electrode e welder anofamba kubva panzvimbo yesimbi, uye simbi inotonhora pasi, ma workpieces anobatanidzwa pamwe chete, achigadzira chisungo chakasimba chesimbi. Iyo yakabatana pamusoro inonyangarika, ichisiya kumashure kwe weld nugget.

1-1

Zvinhu Zvinokanganisa Resistance Welding

Resistance weldinginzira yewelding inoshandisa magetsi kugadzira kupisa kujoina zvinhu zvesimbi. Sezvambotaurwa, musimboti wekupokana welding unonyanya kubva kumutemo waJoule wekupisa, uko chizvarwa chekupisa kupisa kunonyanya kutariswa nematanho akadai seazvino, kuramba, uye nguva yewelding. Inogona kuratidzwa nenzira inotevera:

Q = I²Rt

Zvinoreva yega yega welding parameter:

Q - Kupisa (J)

Ini - Welding ikozvino (A)

R - Kupokana (Ω)

t - Welding nguva (s)

Welding Current

Ikozvino ine simba guru pakupisa kunogadzirwa panguva yewelding, sezvinoratidzwa mufomu. Kukosha kwesquare kwezvino kunokanganisa kupisa, zvinoreva kuti iyo yakakwirira ikozvino, kukurumidza kupisa kuchawedzera. Naizvozvo, kana uchigadzirisa welding parameters usati welding, zvakakosha kuseta yakakodzera ikozvino. Kana iyo welding ikozvino idiki, iyo weld haizonyungudika, uye hapana fusion musimboti uchaumba. Kana iyo yazvino yakakurisa, iyo fusion core inokura nekukurumidza, zvichikonzera kupfachura kwakanyanya panguva yewelding uye kukuvadza maelectrodes.

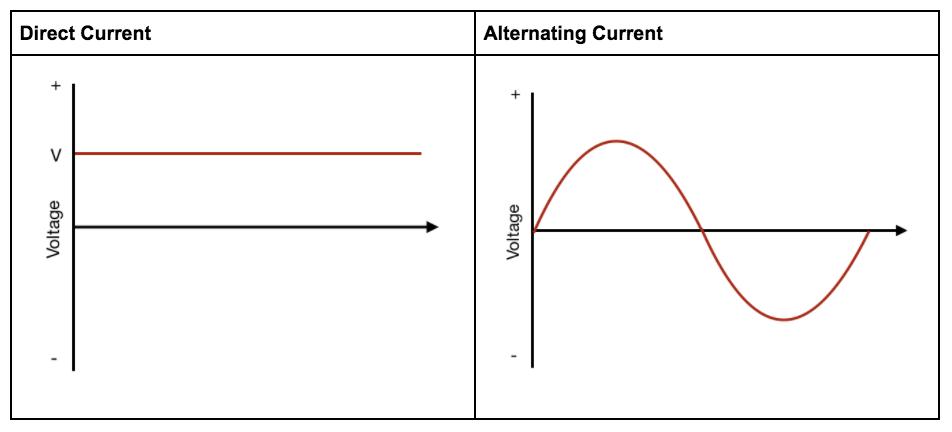

Welding ikozvino inonyanya kukamurwa kuita alternating current (AC) uye yakananga ikozvino (DC), sezvinoratidzwa mumufananidzo uri pazasi. Thenzvimbo welding michinaIsu tinoshandisa zvakare yakakamurwa kuita yakananga ikozvino nzvimbo welding michina uye alternating ikozvino nzvimbo welding michina. Yakananga ikozvino nzvimbo welding michina inoshandisa matatu-chikamu magetsi, kuve nechokwadi chekugovera magetsi akaenzana, uye inokwanisa kuwana welding frequencies inopfuura 1000 Hz, zvichikonzera kunyatsoita welding. Ivo zvakare vane mukana wekushomeka kwesimba kudiwa kubva kune gidhi remagetsi, zvichiita kuti aya ekuchengetedza simba-welders awedzere kufarirwa pakati pevagadziri veindasitiri yekugadzira. Alternating azvino nzvimbo welding michina ine imwe-chikamu 50Hz kubuda, yakakwirira inoenderera inotakura huwandu, uye yakakwirira zvinodiwa kune gidhi remagetsi. Pamusoro pezvo, ivo vane yakaderera welding simba, inoda nguva yakareba yewelding.

Bata Resistance

Kubva pane fomula, zviri nyore kuona kuti kuramba kwakanangana nekupisa kunogadzirwa. Iyo yakakwirira yekupikisa, iyo yakakura kupisa kunogadzirwa panguva yewelding. Resistance inogoverwa munzvimbo dzakasiyana dze electrode uye workpiece. Munguva yewelding, kupikisa kwepamusoro kunoitika panzvimbo yekubatana yeworkpiece, zvichikonzera kupisa kwakanyanya. Inotevera ndeyekupikisa panzvimbo yekubatana pakati pe workpiece uye electrode. Zvisinei, sezvo electrode iri mvura-yakanyorova uye inokurumidza kutonhora pasi, kutonhora kunoderera nokukurumidza. Kune rumwe rutivi, kupikisa kwekubatana pakati pezvishandiso zvebasa, kunyange zvazvo zvichinyangarika, zvine hurombo hwekupisa kupisa, zvichiita kuti kutonhora kwakanyanya. Naizvozvo, inzvimbo diki chete pakati pemaworkpieces inogona kusvika kune tembiricha inodiwa kuti igadzire fusion musimboti uye weld pamwe chete.

Uyezve, tembiricha uye electrode pressure inokanganisa kuramba. Sezvo tembiricha ichikwira, simbi goho simba inoderera, kuwedzera kuonana nzvimbo pakati workpieces uye pakati workpiece uye electrode, zvichiita kuti kuderera kuramba. Kuwedzera kudzvanywa kwe electrode kunoita kuti iyo workpiece ive yakapfava, ichiwedzera nzvimbo yekubata uye kuderedza kuramba. Nekuda kweizvozvo, pane chiitiko apo, panguva yewelding yezvakajairwa zvinhu, kuramba kunowedzera nguva pfupi mushure mekuisa simba, uye kana simba radzimwa uye fusion core mafomu, kuramba kunotanga kudzikira.

Welding Nguva

Iyo yakareba nguva yewelding, inowedzera kupisa kunogadzirwa. Mune iyi fomula, zvazvino uye nguva zvinogona kuzadzana. Kana iwe uchida weld yakasimba, unogona kuseta yakakwira ikozvino kwenguva pfupi kuti igadzire kupisa nekukurumidza uye kugadzira fusion core kupedzisa welding. Neimwe nzira, iwe unogona kuseta yakaderera ikozvino kwenguva yakareba, asi pane muganho kune iyi nzira. Kana nguva yacho yakarebesa, inogona kutungamira mukupfachura zvakanyanya uye inogona kuita kuti electrode inamire. Ingave yazvino kana nguva, pane zvinogumira. Paunenge uchiisa parameters, unofanirwa kufunga nezvezvinhu uye ukobvu hweiyo workpiece, pamwe nesimba remushini wewelding.

Material Properties

Izvo zvinhu zveworkpiece zvinonyanya kukanganisa resistivity yayo, iyo inoita basa rakakosha mukupisa kupisa chizvarwa. Kana welding Stainless simbi, ine yakakwirira resistivity uye kushata kupisa conductivity, zviri nyore kugadzira kupisa asi zvakaoma kuibvisa, saka madiki mafungu anodiwa. Kana welding aruminiyamu alloys ane yakaderera resistivity uye yakanaka yekupisa conductivity, zvinonetsa kuburitsa kupisa asi zviri nyore kuibvisa, saka mafungu makuru anodiwa. Simbi dzakaita sesirivheri nemhangura dzine yakakwira yekupisa conductivity uye yakaderera resistivity, saka kunyangwe nemhepo yakakwira, haiburitse kupisa kwakawanda asi inogona kuiendesa kure. Naizvozvo, simbi idzi hadzina kukodzera kushivirira welding asi dzinogona kushandiswa semagetsi emagetsi.

Electrode Dhizaini uye Geometry

Chimiro uye zvinhu zve electrode zvinokanganisawo chizvarwa chekupisa. Nzvimbo yekubatana pakati pe electrode uye workpiece inokanganisa ikozvino density. Kugara uchishandiswa kwema electrode kunogona kutungamira mukupfeka uye deformation, kuwedzera nzvimbo yekusangana uye kuderedza welding simba. Nokudaro, tinoda kugadzirisa uye kutsiva mazano e electrode nokukurumidza. The thermal conductivity uye kuramba kwe electrode kunokanganisa kupisa kwekushisa. Naizvozvo, isu tinofanira kusarudza zvinhu zvine yakanaka thermal conductivity uye kushomeka kushoma.

Kugadzirira Kwepamusoro

Chimiro uye zvinhu zve electrode zvinokanganisawo chizvarwa chekupisa. Nzvimbo yekubatana pakati pe electrode uye workpiece inokanganisa ikozvino density. Kana maelectrode edu achishandiswa kazhinji uye kupera simba, inowedzera nzvimbo yekubatana, zvichitungamira kuderedzwa kwesimba rekushongedza. Naizvozvo, isu tinoda kugadzirisa uye kutsiva matipi e electrode nekukurumidza. The thermal conductivity uye resistivity ye electrode inokanganisa kupisa kwekushisa. Naizvozvo, isu tinofanira kusarudza zvinhu zvine yakanaka thermal conductivity uye yakaderera resistivity.

Mhando dzeResistance Welding

Nekuda kwekusiyana kwechigadzirwa kutsanangurwa uye zvinodiwa zvewelding, nzira dzakasiyana dzekumisa welding dzinoshandiswa kupedzisa basa. Resistance welding inogona kukamurwa kuita spot welding, projection welding, seam welding, uye butt welding zvichibva pakuita welding.

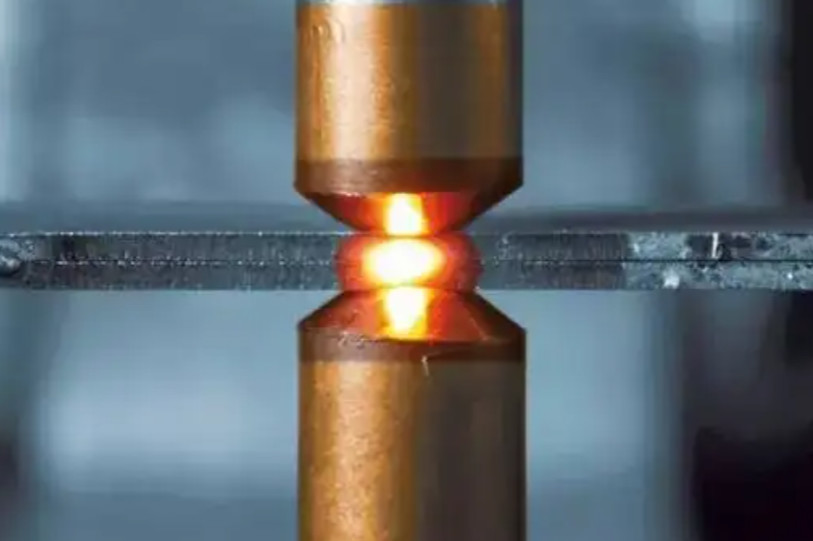

Spot Welding

Spot weldinginzira yewelding apo simbi inotsikirirwa pamwe chete nepamusoro nepamusoro ma electrodes uye inoputika kuburikidza nekupfuura ikozvino kuburikidza nayo. Inzira yechinyakare yekuramba welding, iri nyore kushandisa, uye inoda hunyanzvi hushoma kubva kuvashandi. Nekuda kweiyo yakasarudzika welding process, spot welding ndiyo yekutanga sarudzo yewelding simbi zvikamu muaerospace engineering uye inoshandiswa zvakanyanya muwelding yemotokari muviri uye zvimwe zvinhu. Inowanzo shandiswa kugadzira mashizha matete epasi kabhoni simbi, aruminiyamu, simbi isina simbi, galvanized simbi, uye mamwe mahwendefa matete, anowanzo kutenderera 3 millimita mukobvu.

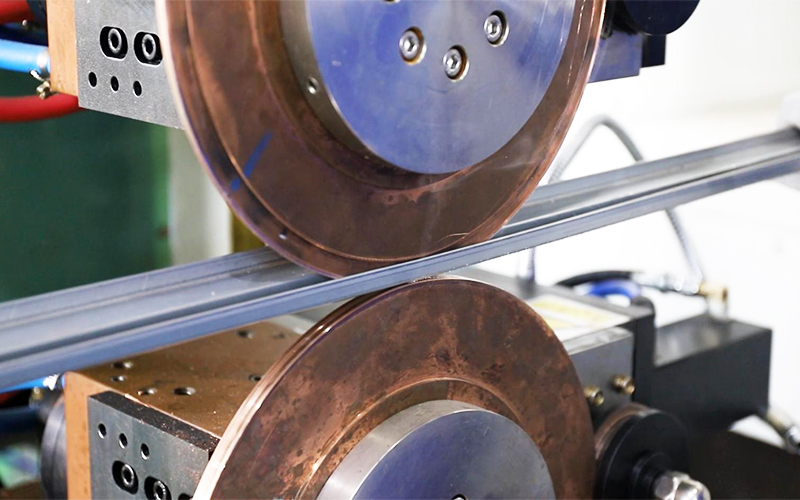

Seam Welding

Seam weldingkazhinji inosanganisira kubatanidza mipendero yezvikamu zviviri zvesimbi. Iwo maviri simbi workpieces akaiswa pakati maviri roller electrodes. Nepo imwe electrode ichikunguruka uye ichishanda kumanikidza, kubuda kunoenderera kana kwepakati kunoitika. Kupisa kunogadzirwa pane electrode's rolling point inonyungudutsa maworkpiece uye anoabatanidza pamwechete, kugadzira inoenderera weld seam. Iyi nzira inoshandiswa zvakanyanya kune welding simbi zvikamu zvinoda akavharwa majoini. Sezvo welding nzvimbo iri kurebesa, kudzivirira misalignment, tinowanzo shandisa nzvimbo welding kuti Positioning pamberi musono welding.

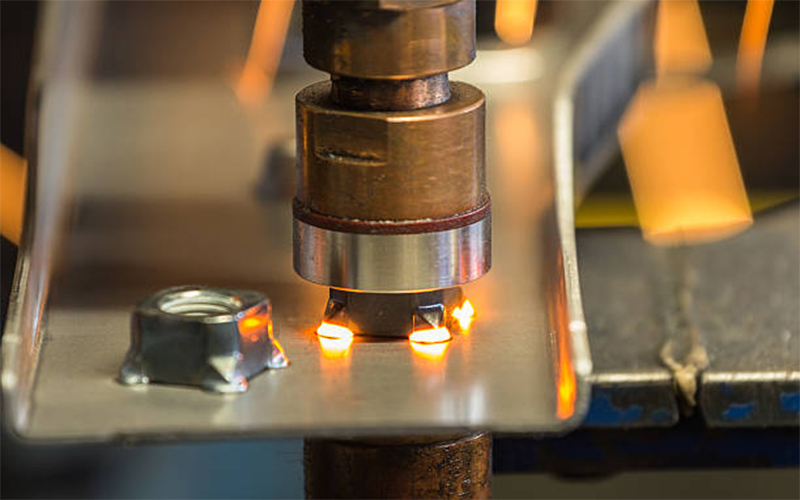

Projection Welding

Projection weldingkuchinjika kwenzvimbo welding, uko kuumbwa kwenzvimbo yeweld kwakafanana neyakaiswa welding, asi projection welding inowanzo shandiswa kune maworkpiece ane mapoinzi akasimudzwa. Kuvapo kweaya mapoinzi akasimudzwa kunoganhura nzvimbo iyo ikozvino inopfuura, ichiwedzera density iripo munzvimbo yewelding. Izvi zvakanyanya kupisa zvinofambisa kubatanidzwa kwejoini. Iyi nzira yewelding inozivikanwa sekuti projection welding. Projection welding inogona kuumba imwe kana akawanda fusion cores pajointi kamwechete. Munguva yewelding, ikozvino inodiwa paprojekiti yewelding panzvimbo imwe chete ye weld ishoma pane iyo yespot welding. Zvisinei, imwe neimwe fungidziro isati yapwanyika, ikozvino inoda kunyungudutsa fungidziro; kana zvikasadaro, panogona kunge paine huwandu hunokosha hwekupaza. Projection welding inogona kushandiswa kugadzira nzungu, mabhaudhi, kana mahwendefa ane mapoinzi akasimudzwa uye inoshandiswa zvakanyanya mukugadzira zvinhu zvemagetsi nemotokari.

Butt Welding

Welding yemagarozvinosanganisira kubatanidza zviso zvekupedzisira zvemasimbi maviri ekugadzira simbi, kuaisa pakati pema electrode, kusungirira zvakachengeteka maviri maworkpieces, uye kushandisa yakakwira ikozvino kugadzira kupisa, kunyungudutsa iyo yekusangana pamusoro pezvishandiso uye kuzvibatanidza pamwechete. Butt welding inokamurwazve kuita flash butt welding uye resistance butt welding.

Flash butt welding ndeye kukurumidza welding process inoshandisa yakakwira ikozvino kukurumidza kunyungudutsa maworkpiece, kushandisa kumanikidza kuumba yakasimba-chikamu chekubatanidza. Inowanzo shandiswa kukwenenzvera nzvimbo dzakakura dzakachinjika dzesimbi simbi, mashiti, uye pombi, nenzvimbo dzakakura dzinosvika 20,000mm² uye pamusoro. Munguva yekuburitsa welding process, sparks dzinogadzirwa panzvimbo yekusangana, nekudaro zita rekuti flash butt welding. Inogona weld yakakwira kabhoni simbi, simbi isina tsvina, aruminiyamu alloys, uye zvakare inogona kupinza simbi dzakasiyana semhangura nealuminium.

Resistance butt welding inoshandisa kupisa kupisa kuunza iyo workpiece majoini kune epurasitiki mamiriro epamusoro tembiricha, kupedzisa iyo welding process nefogi simba. Inokodzera majoini ekushivirira ane mhiri-chikamu nzvimbo mukati me250mm², inowanzo shandiswa kupinza waya diki-chikamu-chikamu simbi waya, tsvimbo, uye mitsetse.

Kukosha Mukugadzira

- Resistance welding haidi kuwedzerwa kwesimbi panguva yekugadzira welding, zvichiita kuti pave nepamusoro welding kunyatsoshanda uye kusvibiswa kushoma.

- Nekuda kwekuenderana kwayo uye kugadzikana, kuramba welding iri nyore kuita otomatiki, isina musono kubatanidza ne otomatiki kuti uenderere mberi nekusimudzira kushanda kwekugadzira uye kuchengetedza vashandi.

- Kuenzaniswa nedzimwe nzira dzewelding, resistance welding inodhura-inoshanda. Chekutanga, mutengo wemidziyo wekupokana welding wakadzikira, uye chechipiri, pane kushomeka kwemarara panguva yekudzivirira welding process. Izvi zvinoderedza zvakanyanya mari yekugadzira yevagadziri muindasitiri yekugadzira.

- Resistance welding inoshandiswa zvakanyanya mumaindasitiri akasiyana siyana uye inonyanya kukosha muzvikamu zvakaita seaerospace, kugadzira mota, nezvimwe.

- Resistance welding yakakodzera kupinza mhando dzakasiyana dzesimbi muindasitiri yekugadzira, kusanganisira simbi isina simbi, kabhoni simbi, aruminiyamu, mhangura, nezvimwe, zvichiita kuti ishande mukushandiswa kwayo.

Applications

Resistance welding inoshandiswa zvakanyanya, kunyanya mumaindasitiri akadai sezvinhu zvemotokari, aerospace, zvemagetsi, uye indasitiri inorema. Sezvo kudiwa kwezvinhu zvakashongedzwa zvesimbi mumaindasitiri akasiyana kuri kuramba kuchikura, zviyero zvepamusoro zvetekinoroji yewelding zvakaiswa, zvichifambisa kufambira mberi nekusimudzira kwekupokana welding.

Automotive Indasitiri Applications

Mukugadzira mota, uko kuchengetedzeka uye kugadzikana kwakakosha, kuramba welding inzira inowanzoshandiswa. Inowanzo shandiswa kujoinha masimbi akasiyana-siyana mumitumbi yemotokari, sematenga, magonhi, marata, nesimbi nzungu. Resistance welding inopa kushanda kwepamusoro, yakagadzikana welding mhando, uye iri nyore otomatiki, zvichiita kuti ive yakakosha maitiro muindasitiri yekugadzira mota.

Aerospace Industry Applications

Resistance welding inowanzoshandiswa kubatanidza zvinhu zvesimbi mundege nemaroketi, sekubatanidza mapapiro endege nemafuselage, pamwe nezvikamu zvidiki zvakasiyana-siyana zvesimbi. Izvi zvikamu zvinofanirwa kunge zvine simba repamusoro uye kusimba, zvine zvinoomesesa zvinodiwa zvemhando yemajoini, kunova uko kuramba welding kunokunda. Resistance welding inoita basa rakakosha muindasitiri yezvemuchadenga, uye kufambira mberi mundima iyi kunofambiswawo nechikamu chemuchadenga.

Electronics Indasitiri Applications

Resistor welding inowanzoshandiswa kune zvigadzirwa zvemagetsi uye zvimwe zvikamu zvesimbi mumidziyo yemagetsi. Iyo inopa yakakwira welding chaiyo uye yakakodzera kubatanidza zvidiki zvikamu semagetsi machipisi uye waya. Munguva yanhasi inokurumidza kubuda yemidziyo yemagetsi, resistor welding inomhanyisa kuungana kwezvinhu zvemagetsi, kutyaira indasitiri kufambira mberi.

Heavy Industry Applications

Resistance welding inowanzo shandiswa kupinza masimbi makuru mumabhiriji uye zvivakwa, senge bhiriji pasi flanges uye simbi yekusimbisa. Inoshandiswawo mukugadzira michina mikuru yekubatanidza simbi dzesimbi. Nehunyanzvi hwayo uye hwakagadzikana welding tekinoroji, resistance welding yave imwe yenzira dzakakosha dzekugadzirisa muindasitiri inorema. Inochengetedza kuchengetedzwa kwemidziyo inorema uye zvimiro.

Zvishandiso uye Zvikamu

Welding Machines

Resistance welding michinaakakamurwa kuita zvikamu zvina zvikuru: michina yemoto welding, michina yekukweshesa michina, muchina we welding wemuchina, uye butt welding michina, zvichienderana nemaitiro akasiyana. Sarudza yakakodzera welding midziyo zvinoenderana nehunhu hwezvinhu uye maumbirwo.

Electrodes

Theelectrodechinhu chakakosha kuita kuti welding mhando. Zvinhu zvikuru zvekugadzira magetsi emagetsi ndezvi: chromium zirconium mhangura, aluminium oxide mhangura, beryllium cobalt mhangura, tungsten, molybdenum, graphite, etc. Zvichienderana nemhando dzakasiyana dzekushanda dziri kugadzirwa, ma electrodes akakamurwa kuita magetsi emagetsi, spherical electrodes, nut electrodes, bolt. ma electrode, etc. Kazhinji, electrode fixation inosanganisira tapered fitting, ne taper ratios kazhinji mu1:10 uye 1:5.

Cooling Systems

Panguva yekushanda, michina yekudzivirira welding inoda kutenderera mvura kuti inotonhorera zvinhu senge maelectrode uye ma transformer. Naizvozvo, isu tinoisa inotonhorera sisitimu yekudzivirira welding michina. Tembiricha yemvura inotonhorera inofanira kunge iri pasi pe30°C. Kana tembiricha yakawandisa, inogona kukonzeresa kuvharika kwekudzivirira kwemuchina wewelding. Zvakanakisa kushandisa mvura inotonhodza isina tsvina isina kuchena kutenderera kudzivirira mavara emvura nekuvharika kwepombi.

Nzira Yekusarudza Iyo Yakakodzera Welding Maitiro?

Sarudzo yewelding nzira inoenderana nezvinhu zvakawanda.

Workpiece Ukobvu uye Chimiro: Yakasiyanawelding nziraakakodzera maworkpieces emhando dzakasiyana uye maumbirwo. Semuyenzaniso, resistance welding inowanzokodzera chete kupinza simbi dzakatetepa masheets, ukuwo zvimiro zvisingaite uye zvikobvu zvebasa zvinowanzoiswa welded uchishandisa arc welding.

Welding Quality Zvinodiwa: Iyo inodiwa welding mhando inorairawo sarudzo yewelding nzira. Kune maworkpieces anoda kuvharwa kwepamusoro uye kusimba kwekubatana, nzira dzekushongedza dzinosangana nezvinodiwa izvi dzinofanirwa kusarudzwa.

Kubudirira Kwekugadzira uye Mutengo: Kana yakakwira gore rega yekugadzira vhoriyamu ichidikanwa, kusarudza nzira yewelding ine hunyanzvi hwepamusoro inodiwa. Kufunga kwemitengo kunofanirawo kuverengerwa.

Zvakatipoteredza Zvinhu: Dzimwe nzira dzevelding dzinoburitsa tsvina uye kuburitsa, zvichikonzera kusvibiswa kwezvakatipoteredza. Naizvozvo, kufunga kwezvakatipoteredza kunofanirwa kuverengerwa pakusarudza nzira yewelding.

FAQ:

Ndeipi mipimo yeresistance welding?

Resistance welding haikodzeri welding yakakura simbi zvikamu.

Iwe unoita sei shuwa chengetedzo muresistance welding?

Paunenge uchishanda resistance welding, pfeka ngowani yekudzivirira uye magirazi ekuchengetedza.

Ndingaite sei kuti ndidzidziswe zve resistance welding?

Unogona kudzidziswa paresistance welding mugadziri.

Ndeapi matambudziko makuru emhando yeresistance welding joints?

Cold solder joint, simba risina kukwana, welding deformation, oxidation.

Kuongorora nzira dzekupikisa welding majoini

Kuparadza kuyedzwa, microscopic bvunzo, yekuona kuongorora, metallographic kuyedza, ultrasonic bvunzo.

Nguva yekutumira: Kubvumbi-02-2024