Seam welding inzira yakaoma yewelding.Chinyorwa ichi chinoongorora kuomarara kweseam welding, kubva pamisimboti yayo yekushanda kusvika kumashandisirwo ayo, zvakanakira, uye zvinonetsa. Kunyangwe iwe uri mutsva pawelding kana kutsvaga kudzamisa kunzwisisa kwako kweiyi yakakosha maindasitiri tekinoroji, gwara iri rinokupa ruzivo rwakakosha rwekuti musono welding unoshanda sei uye kwainowanzo shandiswa.

Nhanganyaya yeSeam Welding

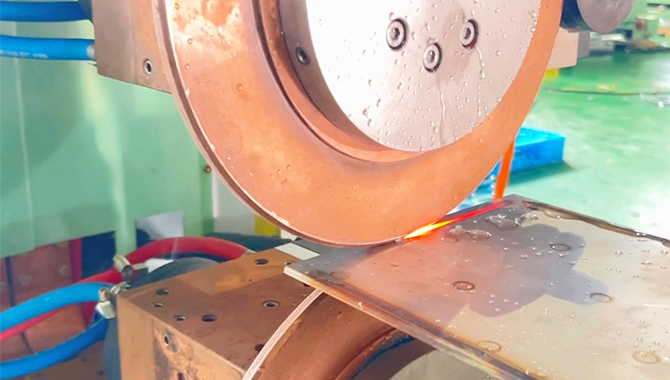

Seam welding imhando yakasarudzika yeresistance welding processapo zvidimbu zviviri kana kupfuura zvesimbi zvinobatanidzwa pamwe chete pamwe chete neanoenderera mberi seam kana nhevedzano yezvinopindirana nzvimbo welds. Inoshandiswa zvakanyanya mumaindasitiri anoda mhepo kana majoini asina mvura, akadai semotokari, aerospace, uye zvikamu zvekugadzira. Kusiyana nechinyakare nzvimbo welding, izvo zvinogadzira munhu ega weld points, musono welding inoburitsa inoenderera, yakasimba weld nekushandisa maelectrodes anotenderera anofamba pamwe nejoinhi, achibatanidza zvinhu zvacho.

Iyo Seam Welding Inoshanda Sei

Seam welding inoshanda pane imwecheteyo musimboti seresitorendi welding:Kupikisa kwemagetsi kunoshandiswa kugadzira kupisa, izvo zvinonyungudusa zvinhu zviri kubatanidza pamwe chete. Nekudaro, seam welding inozvisiyanisa nemabatirwo anoitwa weld nguva dzose neurefu hwechishandiso. Pazasi pane kupatsanurwa kweiyo core components uye kuti hurongwa uhwu hunoshanda sei.

Kutenderera Electrodes:Mwoyo weiyo seam welding process ndeye kushandisa maviri cylindrical, anotenderera emagetsi, anowanzo gadzirwa nemhangura kana zvimwe zvinoitisa zvinhu. Aya maelectrode anodzvanya achipokana nezvimedu zvesimbi, achipa ese magetsi emagetsi uye mechanical simba rinodiwa kugadzira weld. Sezvo ma electrode anotenderera, anofamba pamwe nehurefu hwejoini, achishandisa kumanikidza uye ikozvino nguva dzose.

Ikozvino Application:Mhepo yemagetsi inopfuudzwa kuburikidza nemagetsi, ichigadzira kupikisa panzvimbo iyo zvidimbu zviviri zvesimbi zvinogunzva. Kupikisa kunounza kupisa, zvichiita kuti simbi dzinyunguduke uye dzisanganise pamwechete. Mukugadzira seam, iyi yemazuva ano inoshandiswa nenzira inoputika kana inopfuurira, zvichienderana nemhando chaiyo yewelding (inokurukurwa mberi pasi apa).

Pressure uye Kutonhora:Sezvo ikozvino inoyerera, ma electrode anotenderera anoshandisa nguva dzose kumanikidzika kune workpiece, kuve nechokwadi chokuti zvinhu zvakanyungudutswa zvinosimbiswa kuita weld yakasimba, inoenderera mberi. Ma electrode anoshandawo senzira yekutonhodza, anobatsira kugadzirisa tembiricha uye kudzivirira kupisa, izvo zvinogona kukuvadza weld kana zvinhu zvakapoteredza.

Continuous Movement:Kutenderera kunoitwa maelectrodes ndiko kunoita kuti seam welding isiyane kubva kune mamwe maitiro ekuramba. Maelectrodes anofamba achitevedza mutsara wejoinhi pakukurumidza kudzorwa, kuve nechokwadi chekuti kupisa kunoshandiswa zvakaenzana pahurefu hwese hweseam. Iyo inokonzeresa weld yakasimba, inowirirana, uye kazhinji mhepo- kana mvura-yakasimba.

Mhando dzeSeam Welding

Seam welding inogona kuiswa mumhando mbiri huru zvichienderana nemashandisirwo azvino uno:

Kuenderera mberi Seam Welding

Munzira iyi, magetsi anogara aripo anoshandiswa apo ma electrodes achifamba pamwe chete nejoini. Izvi zvinoita kuti irambe ichiita weld yakafanana nebead. Kuenderera mberi seam welding inowanzoshandiswa kana chisimbiso chisina mhepo kana kuti chisina mvura chinodikanwa, senge mumatangi kana pombi dzemafuta.

Intermittent Seam Welding

Iyo inozivikanwawo sekuti roll spot welding, nzira iyi inoshandisa magetsi mumhepo apo maelectrodes anofamba. Mhedzisiro yacho inoteedzana yeanopindirana nzvimbo welds inoumba musono. Iri rudzi rwe seam welding rinowanzo shandiswa kana kuvimbika kwechimiro kwakakosha pane kusapinda mhepo, senge mune mamwe maapplication emotokari.

Zvishandiso Zvinokodzera Seam Welding

Seam welding muchinainonyanya kushanda pasimbi dzinofambisa magetsi zvakanaka uye dzine nzvimbo yakaderera yekunyungudika. Zvishandiso zvakajairika zvinosanganisira:

Simbi:Ese ari maviri akaderera-kabhoni uye simbi isina tsvina anowanzo seam akasungwa mumotokari uye maindasitiri ekushandisa.

Aluminium:Kunyange zvichinyanya kunetsa nekuda kwekukwirira kwayo, aluminiyamu inowanzoiswa musono mumhepo uye kugadzira.

Copper Alloys:Mhangura's yakanakisa conductivity inoita kuti ive yakakodzera kushandiswa muzvikamu zvinoda kupisa kwakanyanya uye kushanda kwemagetsi, senge maradiator uye magetsi akavharirwa.

Zvishandiso zveSeam Welding

Seam welding inoshandiswa zvakanyanya mumaindasitiri anoda simba rakanyanya, airtight, kana mvura-yakasimba majoini. Pazasi pane mamwe anonyanya kushandiswa:

Indasitiri yemotokari:Seam welding inowanzoshandiswa mukugadzira zvinhu zvemotokari zvakaita sematangi emafuta, mufflers, uye marimu emavhiri. Iyo inoenderera weld inova nechokwadi chekuti zvikamu izvi hazvina mhepo uye yakasimba, inokwanisa kutsungirira nharaunda dzakaomarara uye kumanikidza kwakanyanya.

Aerospace:Indasitiri yezvemuchadenga inowanzoda zvinhu zvisingaremi asi zvakasimba, uye seam welding inoshandiswa kujoinha mapepa matete ealuminium nesimbi. Mundima iyi, kudiwa kwemajoini akavimbika, asina mhepo, uye asina mvura kwakakosha kune masisitimu emafuta uye zvimiro.

Kugadzira matangi nemidziyo:Seam welding inoshandiswa zvakanyanya kugadzira matangi emafuta, matangi emvura, uye zvigubhu zvemakemikari zvinoda kuvharwa zvachose kudzivirira kubuda. Iyo inoenderera weld line inovimbisa kutendeseka kwetangi, ichiita kuti ive yakakodzera kubata zvinwiwa kana magasi pasi pekumanikidzwa.

Metal Pipes uye Tubes:Seam welding inoshandiswa kugadzira mapaipi esimbi nemachubhu kumaindasitiri akasiyana, anosanganisira oiri negesi, pombi dzemvura, uye kuvaka. Iyo nzira inochengetedza inoenderera, inodonhedza-isingabvumirwe musono inogona kumira mukati mekumanikidza.

Chikafu uye Chinwiwa Packaging:Muindasitiri yekurongedza, musono welding unoshandiswa kugadzira magaba esimbi, midziyo, uye mavharo. Kurongeka uye nekumhanyisa kweseam welding kunoita kuti ive sarudzo yakanaka yekugadzirwa kwakakura, kuve nechokwadi chekuti zvigadzirwa zvakavharwa zvakachengeteka uye zvinoramba zvisina hutachiona.

Magetsi Zvikamu:Seam welding inoshandiswawo kugadzira zvinhu zvakaita semaradiator, zvinhu zvekudziya, uye zvivharo zvemagetsi. Iyo inoenderera seam inovimbisa kuenderera kwemagetsi uye kuvimbika kwechimiro.

Zvakanakira Seam Welding

Seam welding inopa mabhenefiti akati wandei pamusoro pehumwe hunyanzvi hwekushongedza, zvichiita kuti ive sarudzo yakakurumbira mumaindasitiri anoda akasimba, emhando yepamusoro majoini. Hezvino zvimwe zvakakosha zvakanakira:

Kumhanya uye Kubudirira: Seam welding inoshanda zvakanyanya, kunyanya mukuenderera mberi kwekugadzira marongero. Iyo otomatiki maitiro inobvumira kukurumidza welding pamwe nehurefu hwese hweseam, kuderedza nguva yekugadzira.

Yakasimba, Inopindirana Welds: Kuenderera mberi kwechimiro chekushongedza seam kunovimbisa kuti weld iri yunifomu pamubatanidzwa, zvichikonzera kubatana kwakasimba, kwakavimbika. Kusagadzikana uku kunoderedza njodzi yekuremara senge makatsemuka kana makwapa asina simba.

Airtight uye Watertight Seals: Seam welding yakanakira maapplication apo iyo joint inofanira kunyatsovharwa, senge mumatangi, pombi, uye midziyo. The continuous weld inova nechokwadi kuti hapana mikaha iyo mweya kana zvinwiwa zvinogona kupfuura.

Minimal Distortion: Nekuti kupisa kwewelding kunowanikwa munzvimbo uye maelectrode anopa kutonhora kunoramba kuripo, seam welding inoburitsa kushoma kukanganisa kune yakatenderedza zvinhu. Izvi zvinonyanya kukosha kana uchishanda nesimbi dzakatetepa dzinowanzoita warping.

Automation-Hushamwari: Seam welding maitiro anowirirana zvakanyanya neautomation, zvichiita kuti ive yakanakira nzvimbo dzakakura dzekugadzira. Otomatiki seam welding michina inogona kuburitsa mhedzisiro ine kushoma kupindira kwevanhu, kuderedza mutengo wevashandi uye kuwedzera kuburitsa.

Matambudziko uye Kuganhurirwa kweSeam Welding

Nepo seam welding ine akawanda mabhenefiti, inopawo mamwe matambudziko uye zvisingakwanisi:

High Equipment Mutengo:Midziyo yakasarudzika inodiwa musono welding, kunyanya yekuenderera mberi seam welding, inogona kudhura. Izvi zvinoita kuti isawanike kumashopu madiki kana makambani ane mabhajeti mashoma.

Zvinhu Zvinogumira:Seam welding inoshanda zvakanyanya pane conductive simbi sesimbi nealuminium. Zvishandiso zvisina kufambiswa zvakanaka kana kupisa-sensitive, senge mamwe mapurasitiki kana ceramics, hazvigone kusungirirwa uchishandisa nzira iyi.

Makobvu Limitations:Seam welding inonyanya kushanda pazvinhu zvitete, kazhinji pasi pe3mm mukukora. Kune zvinhu zvakakora, dzimwe nzira dzewelding, dzakadai seMIG kana TIG welding, dzinogona kunge dzakanyanya kukodzera.

Electrode Wear:Iyo inogara ichitenderera uye kudzvanywa kwema electrode kunogona kutungamira kupfeka nekufamba kwenguva, kunyanya kana welding zvinhu zvakaita sesimbi zvinogona kukonzera kupera kwe electrode. Kugara uchigadzirisa uye kutsiva ma electrode kwakakosha kuti uve nechokwadi chekuita kunoenderana.

Mhedziso

Seam welding inzira yakakosha mukugadzira kwemazuva ano, inopa yakavimbika, inoshanda nzira yekugadzira yakasimba, inoenderera welds. Zvishandiso zvaro zvakakura, zvinotenderera maindasitiri senge emotokari, aerospace, uye kurongedza, uko kudiwa kwemhepo kana majoini asina mvura kwakakosha. Nekugona kwayo kugadzira anowirirana, anogara akasimba welds nekukurumidza, seam welding inzira inosarudzika yenzvimbo dzakakwirira dzekugadzira.

Nekudaro, zvakakosha kuti titarise zvisingakwanisi seam welding, kunyanya maererano nemutengo wemidziyo uye kuenderana kwezvinhu. Kune makambani ari kutsvaga kuisa mari mu seam welding, mabhenefiti ekuwedzera chigadzirwa, yakasimba weld kutendeseka, uye kuenderana ne otomatiki kunoita kuti ive yakakosha kuwedzera kune chero maitiro ekugadzira.

Nguva yekutumira: Oct-09-2024