Spot weldersmidziyo inowanzoshandiswa mumaindasitiri akasiyana-siyana, inoshandiswa zvakanyanya kunyatso uye kubatanidza zvikamu zvesimbi, kuitira kuti ive nechokwadi chekushanda kwayo kwakanakisisa uye hupenyu hwebasa, kuongorora nguva dzose nekugadzirisa midziyo yakakosha, chinyorwa ichi chichataura pamusoro pezvinofanira kuteerera kana kuitisa spot welder inspection.

- Chengetedzo kutanga:Usati watanga chero kuongorora, zvinodikanwa kuve nechokwadi chekuti muchina wabviswa kubva pamagetsi ekudzivirira netsaona kutanga-up panguva yekuongorora. Mukuwedzera, pfeka zvakakodzeramidziyo yekuzvidzivirira nayo(PPE), senge magirovhosi uye magirazi ekuchengetedza. Zvidzivirire kubva kune njodzi dzinogona kuitika.

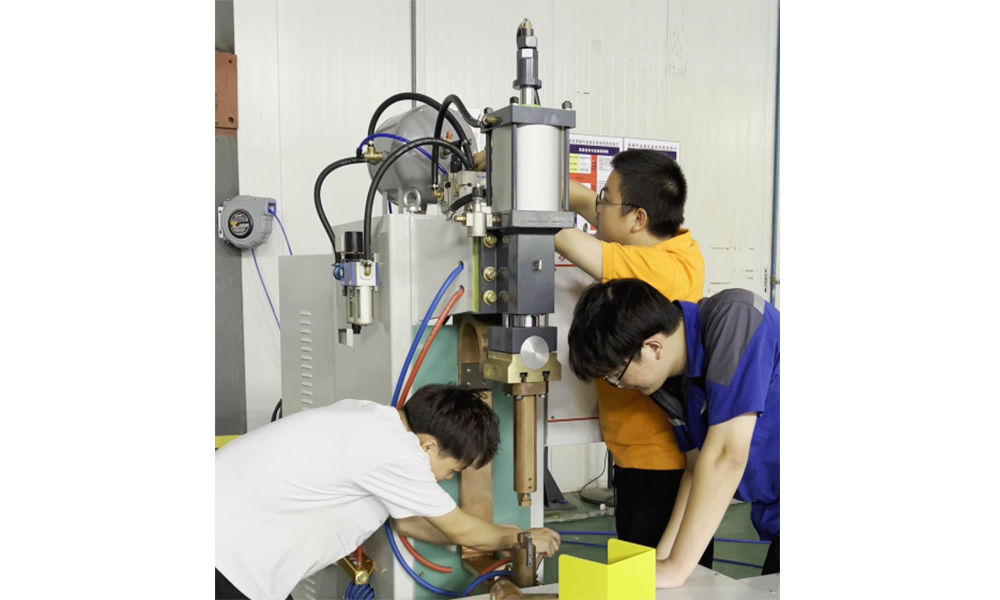

- Kuongorora kwekunze:Chekutanga nemaziso tarisa zvinhu zvekunze zvewelder, tarisa tambo, zvinobatanidza, maelectrodes uye zvigadziriso kuona zviratidzo zviri pachena zvekusakara kana kukuvadzwa, uye ona kuti gadziriro yekudziya iri kushanda nemazvo uye kutenderera kunotonhorera hakuna kukanganisa.

- Electrode condition: Electrode mamiriro ane kukosha kukuru pamhando yewelding. Tarisa kana electrode ine kukanganisa, deformation kana pitting zviratidzo, kana electrode ine kupfeka chiitiko, inogona pasi kuti ichengetedze kuwirirana uye kuvimbika kwewelding.

- Cable uye kuongororwa kwekubatanidza:Tarisa tambo dzakaiswa welded nemakonekisheni kuti uone zviratidzo zvekukuvadzwa, kubuda pachena, kana kuregedzera kubatanidza. Kutadza kwetambo kunogona kukonzera arcing, izvo zvinogona kuve nengozi uye kukanganisa weld mhando.

- Simba rekupa uye kutonga:Tarisa magetsi uye control panel pane kukanganisa. Tarisa kuti mabhatani ese, ma switch, nema knob ari kushanda nemazvo kuti ave nechokwadi chekuti anopindura sezvanga zvichitarisirwa.

- Kutonhodza system:Iyo yekutonhora system inofanirwa kudzivirira kupisa mukati menguva refu yekushanda. Tarisa kuti nhanho yekutonhodza mumudziyo unotonhodza yakajairika, uye tarisa kuti tambo yekutonhodza haina kuvharika, uye kana zvichidikanwa, unofanira kuichenesa kana kuitsiva.

- Grounding uye insulation: Kudzika kwakakodzera kwakakosha zvakanyanya pakuchengetedzwa kwemagetsi uye kukwenenzvera welding. Tarisa kubatanidza pasi uye ona kuti tambo newaya zvakasimba uye hazvina ngura kudzivirira magetsi mapfupi maseketi.

- Weld mhando:Weld bvunzo dzinoitwa pane sampuli zvinhu kuongorora weld mhando uye kuenderana. Kana paine zvisizvo zvikawanikwa, zvinogona kuratidza dambudziko nemaseta emuchina, maelectrodes, kana zvimwe zvikamu.

- Maintenance:Tarisa gadziriso yemuchina kuti uve nechokwadi chekugadzirisa uye kuenzanisa, izvo zvaunofanirwa kuita panguva yakakodzera kudzivirira mamwe matambudziko.

- Kuongororwa nenyanzvi:Kunyange zvazvo nguva dzose kuongorora kwekuona kwakakosha, zvinokurudzirwa kuti michina igare ichiongororwa nenyanzvi inokwanisa. Ongororo yehunyanzvi inogona kuburitsa matambudziko anogona kusaonekwa panguva yekutarisa kwekuona.Kudzora welder muavhareji chinzvimbo kazhinji kunoda kunyatsotarisisa kune ese maficha, kubva pakuchengetedza matanho kusvika kumamiriro emagetsi, tambo, zvidzoreso uye kutonhora masisitimu. Nehutongi hwakakwana uye hwakagadziridzwa, unogona kuvandudza mashandiro uye kuwedzera hupenyu hweiyo welder, kuderedza nguva yekudzikira uye kuve nechokwadi chekushanda kwakachengeteka. Izvo zvinodiwa mumhando dzakasiyana dzemaindasitiri.

Kudzora welder muavhareji chinzvimbo kazhinji kunoda kunyatsotarisisa kune ese maficha, kubva pakuchengetedza matanho kusvika kumamiriro emagetsi, tambo, zvidzoreso uye kutonhora masisitimu. Nehutongi hwakakwana uye hwakagadziridzwa, unogona kuvandudza mashandiro uye kuwedzera hupenyu hweiyo welder, kuderedza nguva yekudzikira uye kuve nechokwadi chekushanda kwakachengeteka. Izvo zvinodiwa mumhando dzakasiyana dzemaindasitiri.

Nguva yekutumira: Aug-20-2024