ADB-260 MFDC letheba mochini tjheseletsa

Kenyelletso ea Sehlahisoa

Kenyelletso ea Sehlahisoa

-

01 E khona ho hatella spatter ea welding ka katleho le ho fumana liphetho tse tsitsitseng le tsa boleng bo holimo

Phepelo e tsoelang pele ea mocheso e hlahisoang ke sekhahla se sephara sa mochini oa welding oa maqhubu a mahareng se etsa hore mocheso oa nugget o tsoele pele. Ka nako e ts'oanang, taolo e nepahetseng ea moepa oa hona joale o ntseng o phahama le nako e ke ke ea baka spatter ka lebaka la ho tlola mocheso le nako e sa laoleheng ea ho phahama hona joale. Lihlahisoa.

-

02 Nako e khuts'oane ea matla, ts'ebetso e phahameng ea mocheso, sebopeho se setle sa welding

The intermediate frequency inverter spot welder e na le sehlahisoa se bataletseng sa welding hajoale, se netefatsang ts'ebetso e phahameng le phepelo e tsoelang pele ea mocheso oa welding. 'Me matla a nako e khutšoanyane, a fihla boemong ba ms, e leng se etsang hore sebaka sa welding se amehang ke mocheso se senyenyane,' me manonyeletso a solder a thehoa ka mokhoa o motle.

-

03 Ho nepahala ha taolo e phahameng

Ka lebaka la maqhubu a phahameng a ho sebetsa (hangata 1-4KHz) ea mochini oa tjheseletsa oa maqhubu a mahareng, taolo ea maikutlo e nepahetse ka makhetlo a 20-80 ho feta mochini o tjheseletsang letheba oa AC le mochini oa tjheseletsa oa sebaka sa bobeli, le taolo e tsamaisanang le tlhahiso. ho nepahala le hona ho phahame haholo.

-

04 Ho boloka matla

ho boloka matla. Ka lebaka la ts'ebetso e phahameng ea mocheso, sesebelisoa se senyenyane sa tjheseletsa le tahlehelo e nyane ea tšepe, mochini oa tjheseletsa oa inverter o ka boloka matla a fetang 30% ho feta mochini oa tjheseletsa oa letheba la AC le mochini oa tjheseletsa oa sebaka sa bobeli ha o tjheseletsa sesebelisoa se tšoanang.

-

05 Inverter spot welding mochini o loketse ho leka-lekana ha motlakase oa grid, ntle le lisebelisoa tsa matšeliso a matla

E sebelisoa bakeng sa tjheseletsa ea matheba le tšubuhlellano ea linate tsa tšepe e matla a phahameng le tšepe e chesang e entsoeng indastering ea tlhahiso ea likoloi, ho cheselletsa letheba le lintlha tse ngata tsa tjheseletsa tsa poleiti e tloaelehileng ea tšepe e nang le khabone e tlase, poleiti ea tšepe e sa hloekang, poleiti e nang le galvanized, poleiti ea aluminium, resistance brazing le spot welding of copper wire in high and low voltage voltage, silver spot welding, copper plate brazing, composite silver spot welding, jj.

Mehlala ea Welding

Mehlala ea Welding

Letlapa la aluminium

letlapa la koporo la kamore ea mouoane

French hex nut

matla a phahameng tšepe setulo teko poleiti

ho matlafatsa kgopo

nate e chitja

motho ea lokisang setulo

ho kopana le silevera

poleiti e entsoeng ka silevera

ts'epe e sa beng le mabali

terata ea ho qetela

thermoformed tšepe square nut

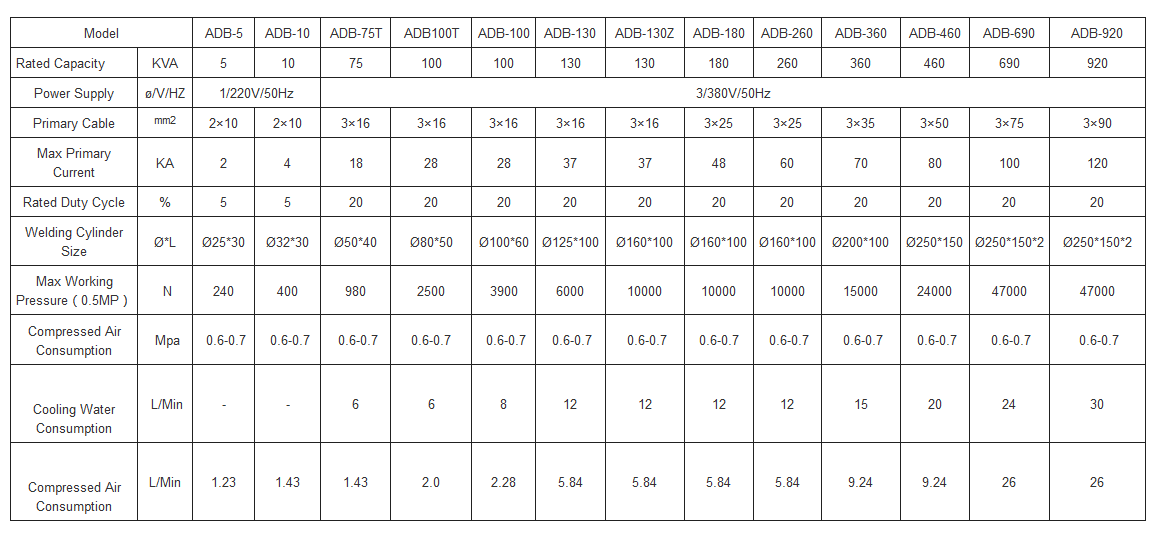

Lintlha tsa Welder

Lintlha tsa Welder

Mokhoa o Tloaelehileng

Mokhoa o Tloaelehileng

Welder FAQ

Welder FAQ

- Q: Joang ho etsa bonnete ba polokeho ea letheba tjheseletsa mochini?

K: Mekhoa e sireletsehileng ea ts'ebetso e lokela ho lateloa ha ho sebelisoa mochini o cheselletsang litšepe, ho kenyelletsa le ho roala lisebelisoa tsa tšireletso, ho etsa bonnete ba hore sesebelisoa se sebetsa hantle, le ho qoba ho tšoara lithapo tse pepeneneng.

- P: Na Spot Welders e Hloka Tlhokomelo ea Kamehla?

K: E, tlhokomelo ea kamehla e tla boloka sebaka sa hau sa marang-rang se sebetsa hantle le ho lelefatsa bophelo ba lisebelisoa tsa hau.

- Q: Ho hlokomela mochine oa tjheseletsa oa letheba ho kenyelletsa eng?

K: Ho hlokomela mochini o cheselletsang litšepe ho kenyelletsa ho hloekisa thepa, ho kenya likarolo tse tsofetseng, ho lekola lithapo tsa motlakase le tsa motlakase le ho lekola boemo ba ts'ebetso ea sesebelisoa nako le nako.

- P: Ke hloka electrode efe bakeng sa welder ea letheba?

A: Khetho ea li-electrode e lokela ho khethoa ho latela mofuta le thepa ea morero oa welding.

- P: Joang ho sebetsana le ho roala ha electrode nakong ea ts'ebeliso ea mochini oa welding oa letheba?

A: Ha electrode e felile, e lokela ho nkeloa sebaka ka nako ho netefatsa ts'ebetso e ntle ea lisebelisoa.

- Q: Joang ho khetha khatello e nepahetseng ea mochini oa tjheseletsa letheba?

A: Khatello e nepahetseng e lokela ho khethoa ho latela mofuta le thepa ea morero oa welding ho netefatsa liphello tse ntle ka ho fetisisa tsa welding.

Re romelle lengolo-tsoibila

Re romelle lengolo-tsoibila