Ho na le mekhoa e mengata ea ho kopanya litšepe, 'me welding ke mokhoa o hlokahalang oa ho hokahanya likarolo tse ngata tsa tšepe. Haeba u le mocha indastering ea ho cheselletsa litšepe, mohlomong ha u elelloe hore na ho na le mekhoa e mekae e fapaneng ea ho hokahanya litšepe. Sengoliloeng sena se tla hlalosa lits'ebetso tsa mantlha tse 8 tsa welding, ho u fa kutloisiso e tebileng ea indasteri ea li-welding.

Arc Welding

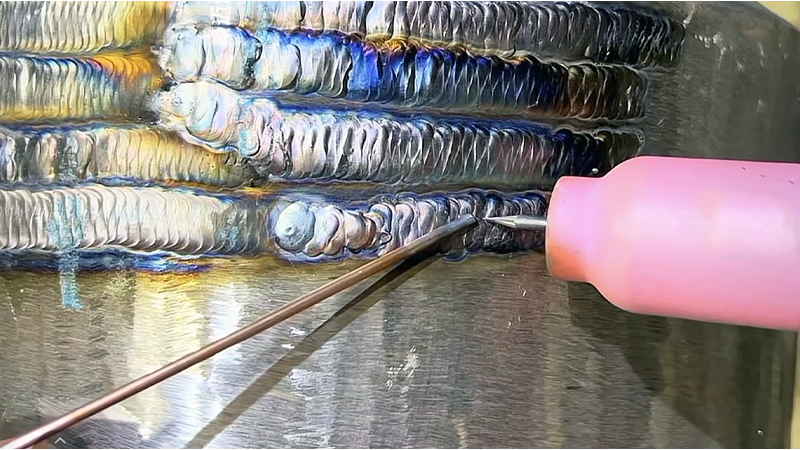

Arc weldinge sebelisa arc ea motlakase ho hlahisa mocheso, ho qhibiliha le ho kopanya litšepe. Ona ke mokhoa o atileng ka ho fetesisa oa ho cheselletsa 'me o kenyelletsa mekhoa e kang ea li-arc welding le welding e sirelelitsoeng ka khase.

Manual arc welding e loketse bakeng sa tšepe ea sebopeho.

Welding e sirelelitsoeng ka khase e sebetsa hantle bakeng sa lisebelisoa tse kang tšepe e sa hloekang le aluminium.

Malebela: Sireletsa sebaka sa weld ho tsoa ho oxidation le litlhase, 'me u laole litlhophiso tsa hajoale le tsa voltage ho fihlela litholoana tse ntle.

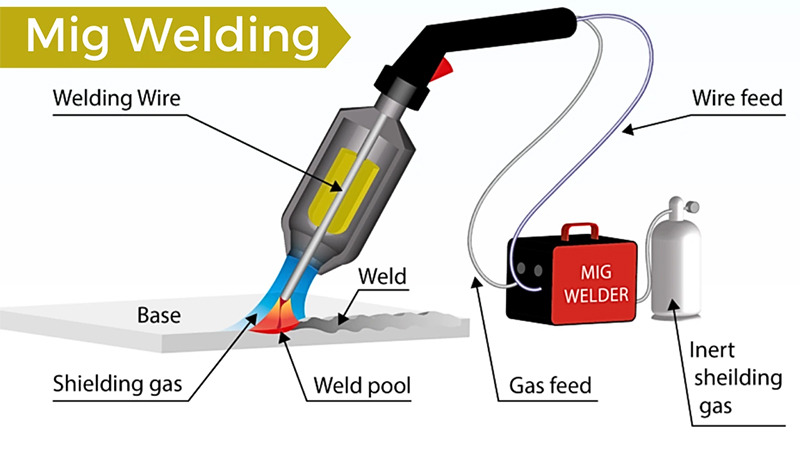

MIG/MAG Welding

MIG/MAG welding e kenyelletsa ho fepa electrode ea terata e tsoelang pele ka toche ea welding ha arc e qhibilihisa terata le bokaholimo ba tšepe ho etsa weld. Khase e sireletsang e phalla ka har'a toche ho sireletsa weld hore e se ke ea silafala.

tjheseletsa MIGe tumme liindastering tse kang tsa likepe, kaho ea liphaephe, le litšepe.

E ntle bakeng sa lisebelisoa tse kholo, tse sa sisinyeheng le merero ea ho lokisa.

TIG Welding

TIG tjheseletsa, kapa Tungsten Inert Gas welding, e sebelisa electrode ea tungsten e sa sebelisoeng ho etsa li-welds tse nepahetseng haholo. Khase e sireletsang, joalo ka argon, e sireletsa sebaka sa weld hore se se ke sa silafala.

Ho nepahala ho phahameng ho etsa hore e lokele lisebelisoa tse bonojoana joalo ka aluminium le tšepe e sa hloekang.

E sebelisoa hangata liindastering tsa likoloi, tsa lifofane le tse nepahetseng.

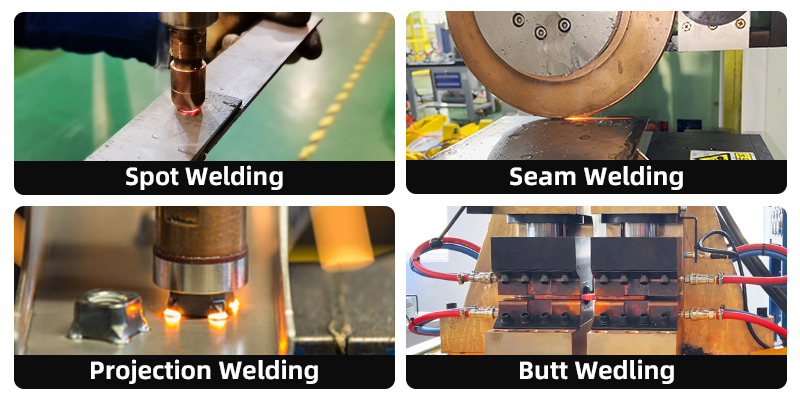

Resistance Welding

In resistance welding, likotoana tse peli tsa tšepe li hatelloa pakeng tsa li-electrode, 'me motlakase o etsa hore mocheso o kopane le tsona. Mefuta e ka sehloohong e kenyelletsa spot, projection, butt, le seam welding.

Resistance welding e potlakile, ha e hloke lisebelisoa tsa ho tlatsa, 'me ho bonolo ho iketsetsa eona.

E sebelisoa haholo likarolong tsa likoloi, lisebelisoa tsa elektroniki le lisebelisoa tsa lapeng. Mohlala, e nepahetse bakeng sa ho cheselletsa linate tsa koloi.

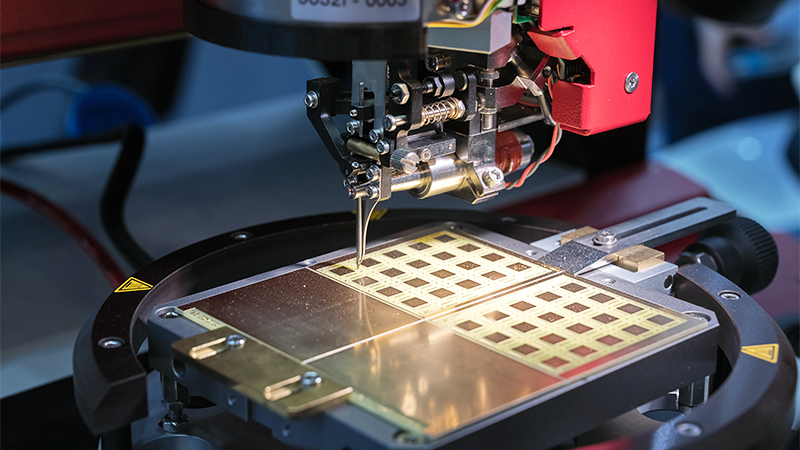

Laser Welding

Ho chesoa ka laserke mokhoa o sebelisang lebone la laser e le mohloli oa matla ho futhumatsa hantle le ho kopanya litšepe kapa polasetiki. Ha ho bapisoa le welding ea setso ea arc, welding ea laser e potlakile ebile e sebetsa hantle. E ka kopanngoa habonolo leroboto e cheseletsanghape ke mokhoa o ka sehloohong oa ts'ebetso ea lisebelisoa tsa laser. Laser welding ha e hloke li-electrode mme ha e hloke ho ikopanya le lisebelisoa tsa workpiece. Ha o tjheseletsa thepa e tshesane kapa mehala e metle, ha e etse hore mokokotlo o qhibidihe jwalo ka welding ya arc.

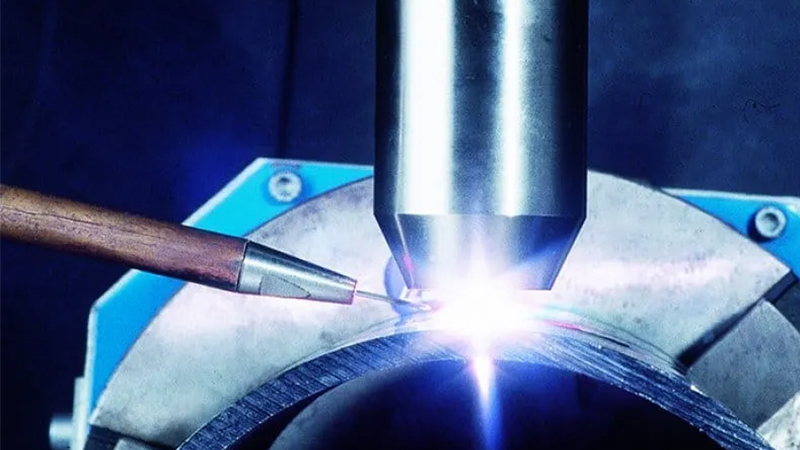

Plasma Welding

Plasma welding e hlahisa plasma ka arc e matla haholo, e qhibilihisang mosebetsi. Lisebelisoa tsa ho tlatsa li eketsoa ho kopanya litšepe hammoho.

E sebetsa ka litšepe, polasetiki le lirafshoa.

Hangata e sebelisoa ho etsa lifofane, likoloi le lisebelisoa tsa elektroniki.

Ultrasonic Welding

Ultrasonic welding e sebetsa ho thothomela ha maqhubu a phahameng libakeng tse peli tse tlas'a khatello, ho etsa hore li fuse ntle le ho qhibiliha. Mokhoa ona o sebetsa bakeng sa tšepe, polasetiki, esita le thepa e sa tšoaneng.

E hlahisa manonyeletso a nepahetseng, a hloekileng 'me ho bonolo ho iketsetsa.

E tloaelehile liindastering tse hlokang hore ho be le tjheseletso e ntle, e tiileng.

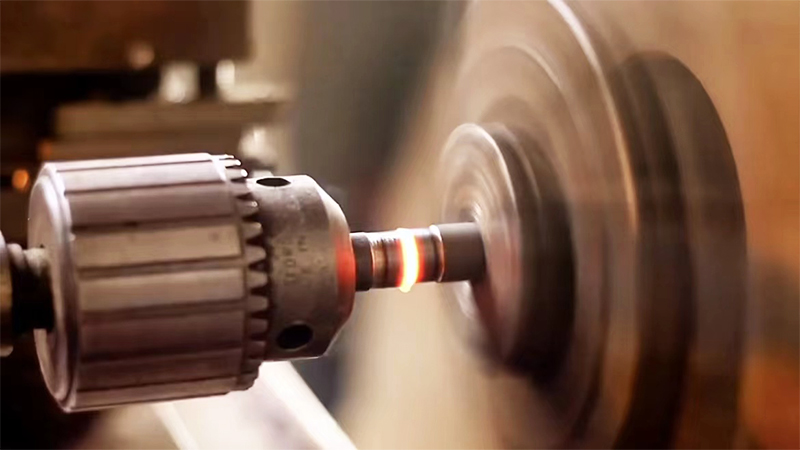

Motsoako oa ho Welding

Friction welding e hlahisa mocheso ka ho hohla ka potlako libaka tse peli, ho li nolofatsa ho theha maqhama a matla. Ts'ebetso ena ea boemo bo tiileng e felisa tlhoko ea mohloli oa mocheso o kantle.

E thibela likoli tse kang deformation le mapetsong.

E sebelisoa haholo tlhahiso ea indasteri, joalo ka mabili a lifofane le li-axle tsa terene.

Mokhoa oa ho khetha mokhoa o nepahetseng oa welding

Ha u khetha mokhoa oa welding, nahana ka:

Mofuta oa thepa (mohlala, aluminium, tšepe e sa hloekang)

Boholo le botenya ba mosebetsi

Litlhoko tse nepahetseng

Hore na othomathike ea hlokahala

Ho leka mekhoa e mengata ho ka u thusa ho fumana tharollo e molemohali bakeng sa morero oa hau o itseng.

Ka ho utloisisa lits'ebetso tsena tse 8 tsa mantlha, u ka khetha mokhoa o nepahetseng bakeng sa projeke ea hau le ho hlahloba menyetla e mecha indastering ea li-welding.

Lipotso Tse Botsoang Hangata

1. Ke mokhoa ofe oa ho tjheseletsa o molemo ka ho fetisisa bakeng sa likarolo tsa koloi?

Resistance welding ke khetho e holimo bakeng sa likarolo tsa koloi ka lebaka la lebelo la eona le potlakileng, pheletso ea botle le boiketsetso bo bonolo.

2. Ke lisebelisoa life tse ka chesetsoang?

O ka tjheseletsa mefuta e fapaneng ya dimetale, ho kenyeletswa tshepe e sa hlwekang, koporo, aluminium, le ditshipi tse entsweng ka masenke.

3. Na lits'ebetso tsohle tsa welding li sebelisa lithupa tsa ho tlatsa?

Che. Mohlala, ho tjheseletsa tjheseletsa ha ho hloke melamu ya ho tlatsa.

4. Ke hokae moo nka ithutang tsebo e eketsehileng ea ho cheselletsa litšepe?

U ka ea likolong tse khethehileng tsa mosebetsi oa matsoho kapa ua fumana boiphihlelo bo sebetsang litsing tsa tlhahiso.

Nako ea poso: Oct-21-2024