Ka indasteri ea li-welding, ho na le tse ngatamefuta ea ho tjheseletsa. Ho tjheseletsa arc le ho tjheseletsa matheba ke tse ding tsa mekgwa e atileng haholo. Hangata li sebelisoa libakeng tse fapaneng 'me li phetha karolo ea bohlokoa liindastering tse fapaneng. Joaloka ea qalang, ho ka ba thata ho utloisisa phapang. Haeba u batla ho ithuta ka phapang lipakeng tsa welding arc le spot welding, sengoloa se latelang se tla li hlalosa ka botlalo.

Arc Welding ke Eng?

Arc weldingke ts'ebetso e sebelisang mocheso o hlahisoang ke arc ea motlakase ho qhibiliha le ho kopanya litšepe. Mohloli oa matla oa arc welding o ka fana ka hona joale (DC) kapa alternating current (AC). Ho ipapisitse le litlhoko tsa welding, welding ea arc e ka sebelisa li-electrode tse ka jeoang kapa tse sa sebelisoeng. E thehiloe qetellong ea lekholo la 19th, arc welding e phethile karolo e kholo ho aheng likepe mme e boetse e sebelisoa haholo indastering ea likoloi le tse boima.

Spot Welding ke Eng?

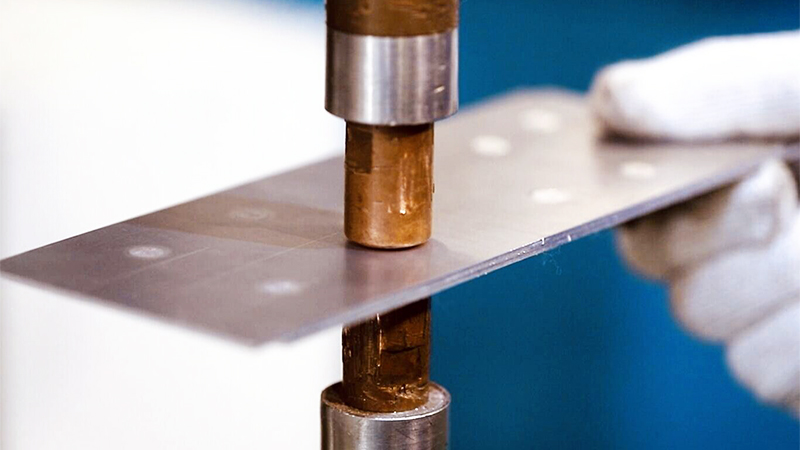

Spot welding ke mofuta oaresistance weldinge sebelisang motlakase oa motlakase ho hlahisa mocheso le ho kenya khatello, e leng se etsang hore libaka tsa ho kopana pakeng tsa lisebelisoa tsa mosebetsi li thehe nugget ea weld kapa boemo ba polasetiki le ho kopanya hammoho. Ke mokhoa o tloaelehileng oa tjheseletsa oo haholo-holo o sebelisang li-electrode tsa koporo ho tsamaisa motlakase. Motlakase oa motlakase o feta ka li-workpieces, o li qhibilihisa libakeng tsa ho kopana, 'me ha hona joale o emisa, khatello e tsoela pele ho tšoara lintlha tsa ho kopana hammoho, ho etsa motsoako.

Phapang lipakeng tsa Welding ea Arc le Spot Welding

Molao-motheo oa ho Welding

Arc welding le spot welding li sebetsa ka melao-motheo e fapaneng. Arc welding e sebelisa electrode le workpiece ho theha arc ea motlakase, e hlahisang mocheso. Thempereichara e phahameng e qhibilihisa eleketrode hore e be mokelikeli o tlatsang motsoako oa tšepe 'me o pholile ho etsa weld, o kopanya likarolo tse peli tsa tšepe. Ena ke mofuta oa li-welding tsa boemo ba metsi.

Ka lehlakoreng le leng, welding ea Spot e kenyelletsa ho bokella lisebelisoa tse peli tsa mosebetsi le ho sebelisa khatello ka li-electrode tse peli. Motlakase oa motlakase o futhumatsa libaka tsa ho kopana pakeng tsa li-electrode le li-workpieces, e leng se etsang hore li qhibilihe. Ha ho pholile, likarolo li kopantsoe hammoho, ho etsa hore e be khokahanyo ea boemo bo tiileng.

Tlhokahalo ea Boitsebiso ba Filler

Ts'ebetsong ea welding, welding ea arc e ka sebelisa tšepe ea ho tlatsa kapa che. Ha o tjheseletsa li-workpiece tse peli hammoho, lisebelisoa tsa ho tlatsa li ka 'na tsa se ke tsa hlokahala. Spot welding ha e hloke lisebelisoa tsa ho tlatsa; e futhumatsa ka ho toba li-workpieces ho boemo ba polasetiki ho li kopanya.

Sebaka sa kopo

Spot welding le arc welding li na le lits'ebetso tse fapaneng. Arc welding e loketse ho chesella libopeho tse rarahaneng le lisebelisoa tse kholo tsa tšepe, e etsa hore e be e loketseng ho lokisa le ho boloka likarolo tse kholo le lits'ebetso tse boima tsa indasteri. Spot welding e atisa ho sebelisoa bakeng sa likaroloana tse nyane tse ka bang 3 millimeters 'me e molemo bakeng sa ho cheseletsa ka bongata bo phahameng. E sebelisoa hangata indastering ea likoloi le lisebelisoa tsa lapeng.

Nako ea ho Welding

Arc welding metal e nka nako e telele mme ha se ts'ebetso ea nako e le 'ngoe. Spot welding e potlakile haholo 'me e ka qeta sehlahisoa ka motsotso kapa metsotsoana e seng mekae.

Litšenyehelo tsa Welding

Arc welding e na le litšenyehelo tse tlase tse batlang li le tlase, empa ka lebaka la bothata ba eona ba tekheniki, litšenyehelo tsa basebetsi bakeng sa li-welder tse nang le tsebo li holimo. Spot welding e na le litšenyehelo tse phahameng ka kakaretso, ka e le 'ngoemochini tjheseletsa lethebae bitsang chelete e kaalo ka mechini e mengata ea li-arc welding. Leha ho le joalo, litšenyehelo tsa basebetsi bakeng sa basebetsi li tlaase, tse ka bolokang litšenyehelo ka nako e telele.

Tlhokahalo ea Khatello ea Kantle

Bakeng sa litlhoko tsa khatello ea kantle, welding ea arc hangata ha e hloke khatello ea kantle. Arc e hlahisoang ke mohloli oa matla e qhibilihisa sesebelisoa sa mosebetsi le lisebelisoa tsa ho tlatsa. Spot welding, leha ho le joalo, e hloka khatello ea moea ho hatella lisebelisoa tse peli hammoho, ebe mocheso o hlahisoa ka hona joale.

Tšireletseho ea ts'ebetso

Arc welding ke phephetso ka botekgeniki 'me e hloka litšepe tse nang le tsebo. Haeba u batla ho sebelisa arc welding, u tlameha ho fumana koetliso ea litsebi. Spot welding e bonolo ebile e bolokehile, e hloka tsebo e fokolang. Basebelisi ba hloka feela koetliso ea mantlha hore ba qale.

Qetello:

Tse ka holimo ke phapang e kholo lipakeng tsa welding ea arc le welding spot. Ha u khetha mokhoa oa welding, u lokela ho nahana ka lintlha tsena. Hore na u khetha ho cheselletsa matheba kapa arc welding haholo-holo ho ipapisitse le sehlahisoa seo u hlokang ho se tjheseletsa, thepa ea sona le litšobotsi. Ka mohlala, haeba u batla ho cheseletsa phala e kholo ea tšepe e sa hloekang, ho molemo ho khetha arc welding, hobane ho cheseletsa sebakeng ho loketse likaroloana tse nyane feela. Kahoo pele u khetha mokhoa oa ho tjheseletsa, etsa bonnete ba hore u sekaseka boemo bo bong le bo bong ho tsoa lintlheng tse ngata.

Nako ea poso: Jun-13-2024