Aluminium e 'nile ea sebelisoa likarolong tse fapa-fapaneng ka lebaka la boima ba eona bo bobebe, ho hanyetsa kutu, motlakase o motle oa motlakase le litšobotsi tse ling, ka ho phahama ha matla a macha, tšebeliso ea aluminium e matlafalitsoe,' me khokahanyo ea aluminium ho phaella ho riveting, bonding ke tjheseletsa, bakeng sa kgokelo ya poleiti aluminiumresistance weldingke ts'ebetso ea bohlokoa, maemo a kopo ho phaella lits'ebetsong tse tloaelehileng tsa indasteri, E sebelisoa haholo likoloing tse ncha tsa matla, sefofane le masimo a mang.

Melao-motheo eaAaluminiumWelding

Melemo ea ho hanyetsa poleiti ea aluminiumho tjheseletsa lethebali hlakile, ntle le ho eketsa lisebelisoa tse thusang, feela ka ho qhibiliha ha tšepe ho ka theha motsoako o matla oa solder.Aluminiummoeeng hangata ho na le lera la oxide filimi, aluminium melting ntlha ke 660 likhato Celsius, 'me filimi oxide ke aluminium oxide, ntlha ea ho qhibiliha ha eona ke hoo e ka bang 2000 likhato,' me qhibilihisa lintho tse bonahalang motheo ho theha motheo oa pele ho senya oxide lera. , eo hape e leng mokhoa oa ho cheselletsa letheba la aluminium ho nkoa e le lebaka le thata haholoanyane.

WeldingEquipmentSlikhetho

Khetho ea poleiti ea aluminiummochini tjheseletsa letheba, motlakase oa inverter oa DC oa mahareng ka lebaka la tlhahiso ea ona hajoale ke DC, e nang le ts'ebetso e phahameng ea mocheso, ka hona ke khetho ea pele bakeng sa welding ea aluminium plate spot. Motlakase oa setso oa mekhahlelo e meraro o lokisang motlakase oa halofo ea maqhubu, phepelo ea matla a polokelo ea matla le ha tlhahiso e le DC empa nako e le khuts'oane haholo, ka hona ts'ebetso ea eona e felletseng ha e ntle joalo ka mochini oa motlakase oa DC spot welder. lisebelisoa tsa motlakase li na le lits'ebetso qalong, boemo ba ts'ebeliso ea nako e tlang bo tla fokotseha.

LintlhaTo NoteWkgohoAaluminiumSpitsaWelding

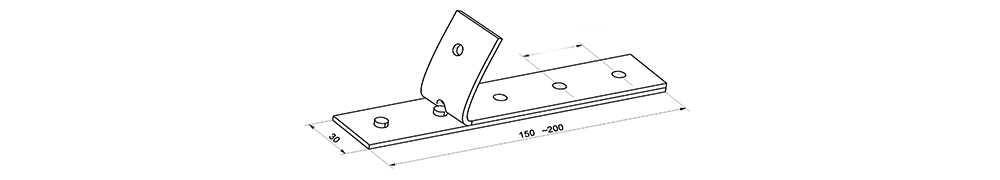

Aluminium poleiti letheba tjheseletsa tshebetso, aluminium poleiti conductivity le mogote conductivity karo-karolelano e phahameng, kahoo tlhokahalo ea nako e khōloanyane hona joale le e loketseng tjheseletsa nako, e hlokang tlhokomelo ho lintlha tse latelang:

1. Matla a thepa e lokela ho ba a maholo ka ho lekaneng ho etsa bonnete ba hore tlhahiso ea hona joale e ka ba boholo ka nako e khutšoanyane, ka kakaretso makhetlo a 2-3 ho feta a carbon steel spot welding;

2. Electrode e hloka metsi a pholileng a matla, 'me mocheso o ka tlosoa kapele ka mor'a ho cheselletsa;

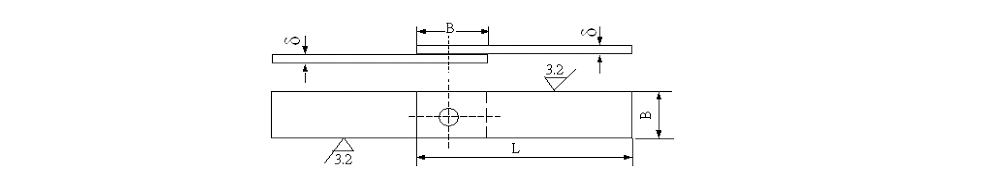

3. Bophara bo chitja ba ntlha e ka pele ea eleketrode e lokela ho ts'oana, 'me litekanyo tse fapaneng tsa poleiti li lokela ho ba le likarolo tse fapaneng,' me molao-motheo ha oa lokela ho ba tlase ho SR25;

4. Bophara ba electrode bo lokela ho lumellana le botenya ba poleiti, 'me bophara ba electrode bo ka tlase ho 1.0MM ea poleiti ke ¢ 13; Sheet botenya 1.0-1.5 Electrode bophara ke ¢16; Sheet botenya 1.5-2.0 Electrode bophara ke ¢20; Botenya ba poleiti ka holimo ho bophara ba 2.0 electrode ha bo ka tlase ho ¢25;

5. Thepa ea electrode e entsoe kamotsoako oa koporoka conductivity e phahameng kapa koporo e thata, 'me conductivity ha e ka tlase ho 80%IACS;

6. Ho kopana le lisebelisoa tsa boleng bo phahameng ba solder, bokaholimo ba poleiti ea aluminium e lokela ho ba deoxidized, pickling kapa polishing, le ho hanyetsa holimo ha motsoako oa A-level oa lihlahisoa tsa lifofane / tsa sesole li lokela ho laoloa ho 50 microohm-100 microohm;

WeldingQbopheloItlhahlobo

Aluminium plate spot welding ka mor'a tlhahlobo haholo-holo liteko tse sa senyeheng le ho lemoha tšenyo ho mekhahlelo e 'meli, e sa senyeheng haholo-holo ka pono, X-ray le ho lemoha ha ultrasonic, ho lemoha tšenyo e otlolohileng haholo, linako tse tlaase le ho lemoha tse ling, mekhoa e khethehileng ea ho lemoha ke e latelang. :

1. Tlhahlobo ea ponahalo, ho kenyelletsa le sebōpeho sa motsoako oa solder, 'mala oa motsoako oa solder, botebo ba ho indentation, joalo-joalo;

2. Ho lemoha X-ray, ho lemoha filimi ea bophara ba mokokotlo oa weld, hore na mokokotlo oa weld oa phunyeha, ho fokotseha le liphoso tse ling;

3. Ho lemoha matla a tlaase, makhetlo a 15-25 ka mor'a ho senyeha ha selae sa manonyeletso a solder, ho lemoha ho khoneha ha tjheseletsa, liphoso tsa welding, joalo-joalo;

4. Teko ea tensile, ka sehloohong teko solder matla a kopanetsweng;

5. Teko ea ho hlobola, teko ea ho hlobola kapa ea ho taboha ea manonyeletso a solder, haholo-holo a sebelisetsoang ho lemoha matla a setšeng le ho netefatsa bophara ba mantlha.

6. Ho lemoha ha Ultrasonic, ka ntlafatso ea theknoloji ea ho lemoha ultrasonic, ts'ebeliso ea ts'ebeliso ea lisebelisoa tsa letheba e ntse e tsoela pele ho matlafatsa, ka ho bapisa sebopeho sa waveform se bonts'itsoeng, hammoho le kholo ea theknoloji ea litšoantšo tsa digital, polycrystalline head ultrasonic discovery e tla ba khetho e ntle bakeng sa. tlhahlobo e sa senyeheng ea aluminium spot welding.

Kakaretso

Ka ts'ebeliso e holileng eaMochini oa welding oa MFDC, hammoho le ntlafatso ea ts'ebetso ea ho tjheseletsa le mokhoa oa ho lemoha, monyako oa ho tjheseletsa ha aluminium poleiti e tla ba tlase le ho theoha, hape e tla khothalletsa ho tjheseletsa letheba la aluminium sebakeng se bobebe sa indasteri, hammoho le matla a macha, sefofane le ho feta. sebedisoa.

Nako ea poso: Aug-07-2024