Metal sheet welding ke karolo ea bohlokoa ea ts'ebetso ea tlhahiso ea lihlahisoa tse fapaneng tsa tšepe. Spot welding e sebelisoa haholo indastering ea tlhahiso ea likoloi, indastering ea lisebelisoa tsa lapeng, le indastering ea mabokose a tšepe. Theknoloji ea sejoale-joale e hloka boleng bo phahameng ba welding. Sehloohong sena, re tla hlalosa ts'ebetso ea ho cheselletsa letheba ka botlalo le ho tšohla melemo eaho tjheseletsa lethebaindastering ea likoloi.

Spot Welding ke Eng

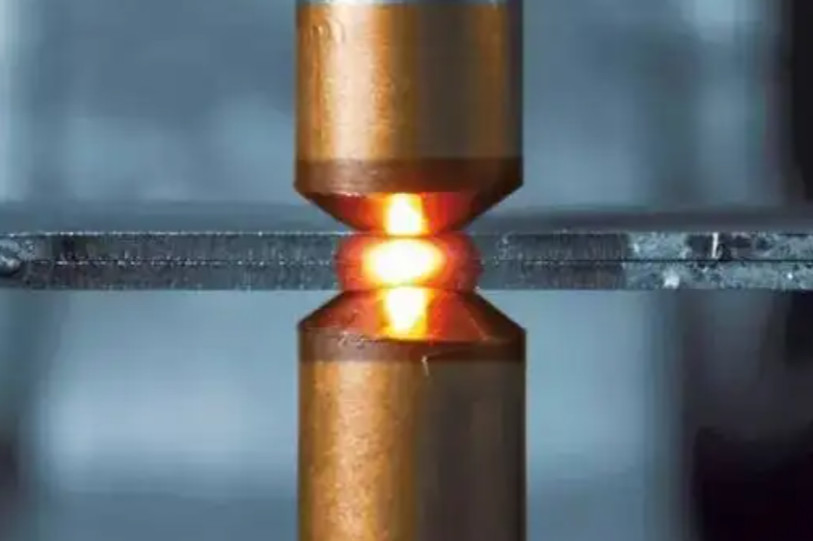

Spot welding ke mofuta oaresistance welding. E kenyelletsa ho beha li-workpieces tse peli pakeng tsa li-electrode tse ka holimo le tse ka tlaase, ho li futhumatsa ka motlakase, le ho sebelisa khatello ea ho theha boemo ba polasetiki sebakeng sa ho kopana sa lisebelisoa tsa mosebetsi, ho li lumella hore li kopane hammoho. Molao-motheo oa eona o bonolo: ka ho tsamaisa motlakase ka li-electrode tse peli tsa koporo, ho hanyetsa ho eketsa mocheso oa li-workpieces, ho etsa hore li qhibilihe ebe li tlamahane hammoho. Ke kahoo hape e bitsoang resistance welding. Ha ho bapisoa le tse lingmekhoa ea ho cheselletsa, ho tjheseletsa ha letheba ha ho hloke ho eketsa dintho tse tjheseletsang, mme tshebetso e bonolo.

Mokhoa oa ho bona Weld?

1: Ho Hloekisa Sebaka sa Mosebetsi

Spot Welding Hangata Materials

Aluminium: Aluminium e tloaelehile haholo sebakeng sa ho cheselletsa letheba, haholo indastering ea likoloi, moo litšobotsi tsa eona tse bobebe li ka nkang sebaka sa meaho e thata. Leha ho le joalo, aluminium ea ho tjheseletsa e thata haholo ka lebaka la conductivity ea eona e phahameng, e hlokang hoo e ka bang habeli hona joale ea thepa e tloaelehileng. Ka hona, ha u cheselletsa aluminium, u tlameha ho khetha lisebelisoa tse nang le matla a phahameng.

Tšepe: Tšepe ke lisebelisoa tse atileng haholo ho tjheseletsa matheba. Ke thepa e thata, 'me likarolo tse ngata tsa likoloi li sebelisa tšepe. Spot welding hangata e sebelisoa bakeng sa ho cheselletsa 'mele ea koloi le likarolo tse thata tsa linate.

Koporo: Spot welding koporo e hloka mekhoa e khethehileng. Koporo e na le conductivity e phahameng ea mocheso le motlakase, e etsang hore e sekamele ho khomarela li-electrode. Ka hona, re khetha li-electrode tsa tungsten kapa molybdenum. Nakong ea welding, lisebelisoa tsa brazing li hloka ho eketsoa pakeng tsa lisebelisoa tse peli tsa mosebetsi, kahoo ho sebelisoa ha koporo hangata.

Tšepe e entsoeng ka galvanized: Welding galvanized steel e thata ho feta tjheseletsa tshepe, hloka phahameng hona joale. Sebaka se qhibilihisang sa sekontiri se tlaase ho feta sa tšepe, kahoo ho bonolo ho phalla le ho etsa li-splashes nakong ea welding.

Ho Hloekisa Sebaka sa Mosebetsi

Pele ho tjheseletsa, ho bohlokoa ho lekola hore na li-workpiece li na le mafome kapa oxidation. Haeba li etsoa, li-workpieces li hloka ho phekoloa. U ka sebelisa sandpaper kapa grinder ho etsa hore bokaholimo bo be boreleli. Ho seng joalo, ho tla ba le splatter e ngata, e ka amang boleng ba welding.

2: Ho Nahana ka Liphetoho tse 4 Pele ho Welding le ho Beha Paramethara

Khatello

Ho bohlokoa ho khetha khatello e nepahetseng. Haeba khatello ea electrode e phahame haholo kapa e le tlase haholo, e ka fokolisa matla a weld le ho eketsa ho hasana ha eona. Ha u etsa welding, ho bohlokoa ho nahana ka litšobotsi tsa "workpiece" ha u beha khatello.

Nako ea ho Welding

Ho bohlokoa haholo ho beha nako e nepahetseng ea welding. Haeba nako ea ho tjheseletsa e le khutšoanyane haholo, workpiece e ka 'na ea se ke ea qhibiliha ka ho lekaneng ho finyella litlhoko tsa welding. Ka lehlakoreng le leng, haeba nako ea tjheseletsa e le telele haholo, workpiece e na le tšekamelo ea ho senyeha, e leng se bakang matšoao a maholo a weld.

Welding Current

The tjheseletsa hona joale le nako ea tlatsana mong ho e mong, empa le tsona li na le meeli ea tsona. Ho fumana tekanyo e nepahetseng pakeng tsa tse peli ke senotlolo sa ho hlahisa li-welds tse phethahetseng.

3: Spot Welding Machine

Thepa e hlokahalang bakeng sa ho cheselletsa letheba ke amochini tjheseletsa letheba, e tlang ka mefuta e fapaneng. Ho khetha mochini o tjheseletsang letheba le nepahetseng ho ipapisitse le litšobotsi tsa sesebediswa sa mosebetsi le litlhoko tsa welding. Ka mohlala, haeba u batla ho tjheseletsa lipoleiti tse peli tsa tšepe tse sa hloekang tsa 2mm ho fihlela matla a hlokahalang a botsoali, u tla hloka ho khetha mochini oa tjheseletsa o nang le matla a holimo. Mochini o tloaelehileng oa ho cheselletsa letheba o nang le 130KVA o ka etsa sena. Leha ho le joalo, haeba u hloka ho tjheseletsa lipoleiti tsa aluminium tse boima ba 2mm, u tla hloka mochine o tloaelehileng oa ho cheselletsa letheba o nang le 260KVA.

4: Beha Workpiece Pakeng tsa Electrodes 'me U Qala ho Welding

Hang ha u se u khethile mochine o loketseng oa ho cheselletsa letheba, ke nako ea ho qala ho tjheseletsa. Ka mor'a ho kopanya motlakase le ho lokisa li-parameter, beha mosebetsi o lokiselitsoeng pakeng tsa tse pelisekoahelo sa electrode. Tobetsa konopo ea pedal ea leoto, 'me li-electrode li tla hatella fatše, li futhumatsa le ho hatella li-workpieces, ka tsela eo li kopanya lintlha tsa ho kopana tsa li-workpieces tse peli hammoho.

5: Tlhahlobo ea Peel Ka mor'a Welding

Ka mor'a ho tjheseletsa workpiece, ho thata ho hlahloba matla a weld ka leihlo le hlobotseng feela. Ke nakong eo o hlokang ho sebelisa lisebelisoa ho lekola matla a weld. Teko ea peel ke mokhoa o motle. Nakong ea tlhahlobo ea peel, hlokomela matla a maholo a ho tsitsa a fihletsoeng ha u ebola sesebelisoa. Likarolo tse ling tsa mosebetsi li na le litlhoko tse ikhethang tsa boleng bona ho nka hore weld e amoheleha.

Melemo ea Spot Welding Bakeng sa Indasteri ea Likoloi

Manonyeletso a Tiileng Le a Nako e telele

Likarolo tse cheselitsoeng ho sebelisa li-welding tsa ho hanyetsa li theha manonyeletso a matla le a tšoarellang. Lihlahisoa tse entsoeng ka tsela ena li tiile ebile li tsitsitse, e leng ntho ea bohlokoa indastering ea likoloi. Ka mohlala, haeba nate e sa chesoa ka tsela e sireletsehileng, e ka baka likotsi tseleng. Ho nepahala le ho tšepahala ke tsa bohlokoa haholo lefapheng la likoloi, moo esita le phoso e nyenyane e sa amoheleheng. Ka hona, resistance welding e bapala karolo ea bohlokoa ho netefatsa hore litekanyetso tsena lia fihlelleha.

Ho Kopana ka Manonyeletso

Likarolong tsa likoloi tsa welding, ha ho bohlokoa feela hore li-welds li be matla empa hape le hore lihlahisoa tse cheselitsoeng li shebahale li le monate. Resistance welding e ka finyella tlhokahalo ena. Haholo-holo bakeng sa ho cheselletsa 'mele oa koloi, ntlha e' ngoe le e 'ngoe ea weld e lokela ho ba e sa bonahaleng, kaha e ama ts'ebetso e latelang le ponahalo ea koloi ka kakaretso.

Ho Kopanya Lintho Tse sa Tšoaneng

Resistance welding e boetse e loketse ho tjheseletsa lisebelisoa tse sa tšoaneng. Ka indasteri ea likoloi, ho na le likarolo tseo litšepe tse fapaneng li hlokang ho kopanngoa hammoho. Mona ke moo ho tjheseletsa tjheseletsa ho sebetsang hantle, kaha e ka kopanya thepa e sa tshwaneng, e kang tshepe le aluminium.

Lebelo la Welding

Resistance welding ha e hloke terata ea ho tlatsa. E potlakile bakeng sa ho cheselletsa likarolo tse nyane. Indastering ea likoloi, moo boholo ba likaroloana tse nyane li cheselitsoeng, ts'ebetso e potlakile ebile e bonolo, e boloka mosebetsi le ho matlafatsa ts'ebetso ea welding.

Pheta-pheta

Ka lebaka la ho tšoaneleha ha eona bakeng sa lihlahisoa tse pheta-phetoang, ho hanyetsa tjheseletsa ho ka hloka hore ho fetoloe paramethara le lisebelisoa ha u fetohela ho lintlha tse fapaneng. Ka hona, e loketse haholo bakeng sa ho cheselletsa lihlahisoa tsa boleng bo holimo. Likarolo tsa likoloi, hantle ka lebaka la tšobotsi ena, li fumana li-welding tsa ho hanyetsa li loketse haholo indasteri ea likoloi.

Resistance welding e ntse e sebelisoa haholo makaleng a kajeno a indasteri. Theknoloji ea eona e lula e ntlafatsoa ho ikamahanya le nts'etsopele ea indasteri, e lebisang ho automation. Ho ithuta haholoanyane ka resistance welding, ka kopo latela lintlafatso tsa rona.

LBH:

1,Ke mokhoa ofe oa ho tjheseletsa oo ke lokelang ho o sebelisa ho tjheseletsa moqomo oa oli oa tšepe o sa hloekang o hlokang ho koaloa ka thata?

Bakeng sa litlhoko tse thibelang moea, o ka sebelisa seam welding, aseam weldere ka e etsa.

2,Ke mochini oa mofuta ofe oa welding o atisang ho sebelisoa bakeng sa likarolo tsa 'mele oa koloi?

Hangata 'mele oa koloi o sebelisoalethebasethunya se tjheseletsang, tse tenyetsehang le tse bonolo ho iketsetsa.

3,Ke welder efe ea matla e hlokahalang ho tjheseletsa tšepe e se nang tšepe e teteaneng ea 2mm?

A 130kVA sebaka weldmochini o kenyange tla sebetsa hantle.

4,Nka tjheseletsa nate ea M8 joang poleiting ea tšepe ea 2mm?

U ka sebelisa projeke ea weldmochini o kenyang.

5,Nka fetola joang liparamente tsa tjheseletsa sebakeng?

Fetola li-parameter ho ipapisitse le lintlha tsa mosebetsi oa hau le litlhoko tsa welding.

6,Joangtoletheba weld ntle le welder?

U ka sebelisa roboto bakeng sa ho kenya le ho tjheseletsa.

7,Joangtoweld aluminium?

Aluminium e na le sebaka se tlase sa ho qhibiliha, kahoo o hloka matla a phahameng. AMFDCSpot welder e ka sebelisoa.

Nako ea poso: May-30-2024