Ka nts'etsopele ea The Times, ho phahama ha likoloi tse ncha tsa matla, likoloi tse ncha tsa matla li tla sebelisa tse ngatakhoele ea likhoeleho fana ka khokahanyo eohle ea motlakase oa koloi, khokahanyo ea lithapo tsa lithapo le ho fastening e tla sebelisa ho hanyetsa welding ho cheselletsa, a re e shebeng!

Ke engresistance welding?

The workpiece e lokelang ho kopanngoa e behoa pakeng tsa li-electrode tse peli tlas'a khatello, 'me sebaka sa ho tjheseletsa se futhumala ka hona joale,' me mocheso o hlahisoang ke ho hanyetsa workpiece o futhumala 'me ho qhibiliha ha sebaka kapa naha e ncha e fihlile. Ka mor'a hore matla a khaotsoe, motsoako o tiileng o thehoa tlas'a ketso e tsoelang pele ea khatello. Mokhoa ona o bitsoa resistance welding.

Melemo ea ho hanyetsa welding

Ts'ebetso e bonolo, ha ho na tlhoko ea ho eketsa ts'ireletso ea khase, ha ho na tlhoko ea ho eketsa solder ea tšepe, litšenyehelo tse tlase tsa welding, ho bonolo ho fihlella welding ea othomathiki, li-parameter tsa welding kaofela ke pono ea dijithale, li ka boloka mefuta e mengata ea foromo, lihlahisoa tse fapaneng tsa welding, li hloka feela ho nka. nomoro e lumellanang le litlhaloso kapa foromo e ka ba, litlhoko tsa bokhoni ba opareitara ha li phahame!

Khatello e tloaelehileng ea lithapo tsa likoloi tse ncha tsa matla:

Welding terata e tloaelehileng haholo khatello ea lisekoere tsa terata ke: tepi e lohiloeng ka koporo, khoele ea khatello ea square welding: litekanyo 16,25,35,50,75,95,120mm square cable, ho latela litlhoko tsa ts'ebetso ea lithapo tse fapaneng tsa terata, etsa qeto ea tekanyo ea compression bakeng sa pressure square welding.

Ke mochini ofe oa welding o sebelisoang sebakeng sa khatello?

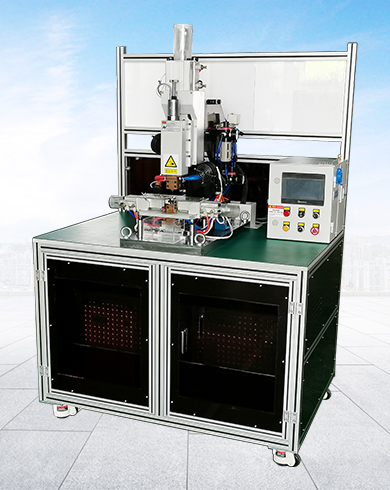

Ha sebaka sa motlakase se khethoa, mochini oa welding oa DC inverter spot welding o na le litšobotsi tse ts'eptjoang tsa welding hajoale, matla a phahameng a matla le ho theoha ha voltage e nyane ho grid. Ho ea ka litlhoko tsa welding, lisebelisoa tse ling tse khethehileng tsa welding li ka etsoa, e le hore manonyeletso a nang le welded a be boreleli le a matle, hape a ka ntlafatsa katleho ea tlhahiso.

Na wire harness fihlellwewelding ka ho iketsa?

Karabo ke e, hangata thapo ea rona, tepi e lohiloeng ka koporo ke lisebelisoa tsa coil, wire harness automatic welding le mochini oa ho itšeha, o ka etsa phepelo ea othomathiki, welding othomathike, ho itšeha. Ho itšeha ho ka ipapisa le litlhoko tsa bareki, bolelele bo behiloeng, ho fihlela litlhoko tsa tjheseletsa tsa bareki tsa litlhaloso tse fapaneng. Karolo ea taolo ea lisebelisoa e na le skrine e kholo ea ho ts'oara skrineng, li-parameter tsa welding li bonts'oa ka dijithale, ho ka khethoa mefuta e mengata ea liforomo, liforomo tse fapaneng li ka bolokoa ho latela lihlahisoa tse fapaneng, 'me nomoro ea foromo e lumellanang e ka bitsoa nakong e tlang. , e bonolo le e loketseng, e sebetsang hantle haholo!

Batch e nyane, litlhaloso tse ngata, mokhoa oa ho khetha lisebelisoa tsa welding?

Qalong ea bareki ba bangata, ke sehlopha se senyenyane, mefuta e fapaneng ea litlhaloso tsa lihlahisoa, ka nako ena, nakong ena, re ka khetha mochine o le mong oa khatello ea lisekoere, likarolo: o ka nkela sebaka sa motlakase ka potlako ho finyella litlhoko tsa mefuta e sa tšoaneng. lihlahisoa, sebopeho se bonolo, phello e ntle ea welding, litšenyehelo tsa ho reka ha li bapisoa le theko ea lisebelisoa tsa ho tjheseletsa ka mokhoa o itekanetseng li na le molemo o moholo!

Haeba u batla mokhoa oa terata oa koporo oa khatello ea lisekoere, u ka leka ho sebelisa mochine oa welding oa ho hanyetsa, e ka 'na eaba ha u e-s'o o ame pele, empa ka sebele o tla u makatsa.

Nako ea poso: Sep-05-2024