Sheet Metal welding e sebelisoa liindastering tse ngata. Nako le nako ha u hloka ho kopanya likarolo tsa tšepe, u tla nahana ka mokhoa oa ho li tjheseletsa. Theknoloji ea welding e se e tsoetse pele haholo, 'me ho khetha mokhoa o nepahetseng oa ho cheselletsa ho ka etsa hore mosebetsi oa hau o be bonolo le ho sebetsa hantle haholoanyane. Sengoliloeng sena se tla u tataisa ho utloisisa welding ea tšepe le ho u thusa ho fumana mokhoa o nepahetseng oa ho tjheseletsa.

Sheet Metal Welding ke Eng?

Leqephe la metal weldingke thekenoloji ea ts'ebetso ea thepa, e bolelang ho hokahanya hatse pedikapa likarolo tse ngata tse arohaneng tsa tšepe ka mokhoa o le mong. Ka nts'etsopele ea theknoloji ea indasteri, theknoloji ea welding e sebelisoa haholo le ho feta, e leng ts'ebetso ea bohlokoa ts'ebetsong ea tšepe ea indasteri ea tlhahiso.

Mekhoa ea ho cheselletsa tšepe ke efe?

Ho na le mefuta e mengata ea mekhoa ea ho cheselletsa tšepe, ho ea ka boemo le litšoaneleho tsa ts'ebetso ea tšepe ts'ebetsong ea welding, mekhoa ea ho tjheseletsa ea tšepe e arotsoe haholo ka mekhahlelo e meraro: fusion welding, welding khatello le brazing.

Fusion Welding

Fusion welding ke mokhoa oa ho kopanya likarolo tsa tšepe ka ho futhumatsa le ho li qhibilihisa hammoho. Mokhoa ona ha o hloke khatello. Li-interfaces tsa li-workpieces tse peli li futhumetse, li etsa hore tšepe e hlahise matla a bohlokoa a athomo, e etsa boemo ba mokelikeli sebakeng se futhumetseng. Liathomo tsa tšepe tsa lisebelisoa tse peli tsa mosebetsi li hasana ka botlalo 'me lia kopana. Ha tšepe e qhibilihisitsoeng e pholile, e etsa lenonyeletso le tiileng le kolobisitsoeng.

Mekhoa e tloaelehileng ea fusion welding e kenyelletsa welding ea arc, welding ea khase le welding ea laser.

Arc Welding

Arc weldinge tsamaisoa ke mohloli oa motlakase o phallang pakeng tsa electrode le lisebelisoa tse peli tsa mosebetsi ho etsa arc. Arc ena e fetoha mocheso, e qhibilihisa electrode le lisebelisoa tsa mosebetsi, e kopanya litšepe hammoho. Nakong ea ts'ebetso ea ho tjheseletsa, motlakase o tlase le oa hona joale o phahameng o hlahisa mocheso o phahameng le khanya e matla, ho chesa li-electrode le li-workpieces ho theha letamo le qhibilihisitsoeng le pholileng ho etsa weld.

Mokhoa ona oa ho tjheseletsa o na le lisebelisoa tse ngata tse fapaneng 'me o ka sebelisoa ho cheselletsa litšepe tse fapaneng tse kang tšepe e sa jeleng paate, aluminium, koporo le tšepe e nang le k'habone e phahameng. Hobane lisebelisoa tsa ho cheselletsa li-arc lia nkeha ebile ho bonolo ho li sebetsa, li sebelisoa haholo liindastering tse kang ho etsa mechini, kaho le kaho ea likepe. Ka mohlala, e sebelisoa bakeng sa likhokahano tsa rebar ha ho hahoa. Ho feta moo, arc welding e sebelisoa khafetsa ho lokisa lisebelisoa le ho lokisa seporo sa terene.

Arc welding hangata e hloka mochini oa welding oa arc, lithupa tsa welding, le thebe ea sefahleho. Ke mokhoa o theko e tlase ebile o sebelisoa haholo oa ho cheselletsa. Leha ho le joalo, ka lebaka la bothata ba eona ba tekheniki, boleng ba weld bo itšetlehile haholo ka boemo ba bokhoni ba welder.

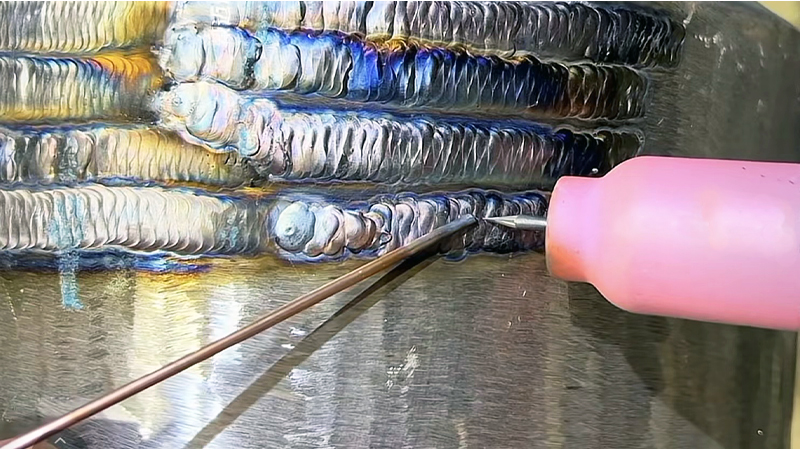

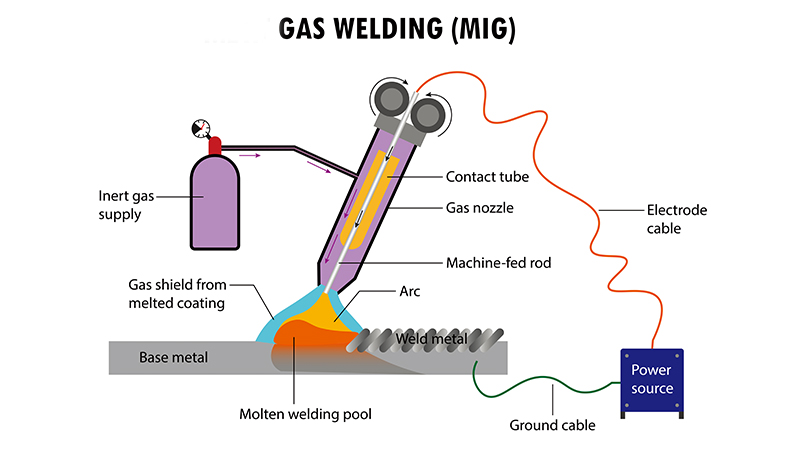

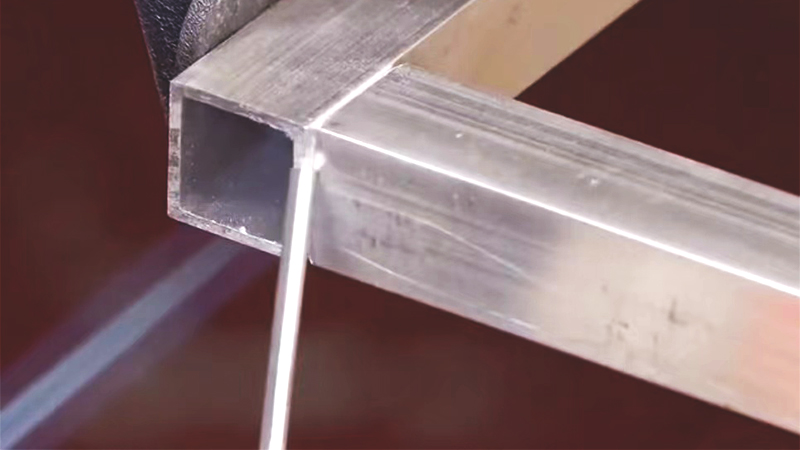

Ho Welding ka Khase

Ho cheseletsa khasee sebelisa mefuta e 'meli ea khase: khase ea mafura le khase ea oxidizing. Ho tuka ha khase ena ho hlahisa mocheso, o sebelisetsoang ho qhibiliha lisebelisoa tsa tšepe le molamu oa ho tjheseletsa o tsoelang pele ho feptjoa pakeng tsa li-workpieces tse peli, ho tlatsa khokahanyo ea tšepe.

Hangata tjheseletso ya kgase e sebediswa bakeng sa tshepe, aluminium le koporo. E fana ka melemo e kang ho feto-fetoha ha maemo ts'ebetsong, ha ho na meeli tikolohong ea ho sebetsa, le ts'ebetso e bonolo. Ho feta moo, ha e hloke motlakase, e leng se etsang hore e sebelisoe haholo bakeng sa mosebetsi oa ka ntle le libakeng tsa kaho bakeng sa likhokahano tsa tšepe. Haeba o hloka ho lokisa phala ea tšepe, ho cheselletsa khase ke khetho e babatsehang.

Leha ho le joalo, ho cheselletsa khase ho na le mefokolo ea eona. Boleng ba weld bo susumetsoa haholo ke boleng ba molamu oa welding, 'me manonyeletso a cheselitsoeng a atisa ho fetoha. Ho feta moo, katleho ea tlhahiso e batla e le tlase.

Laser Welding

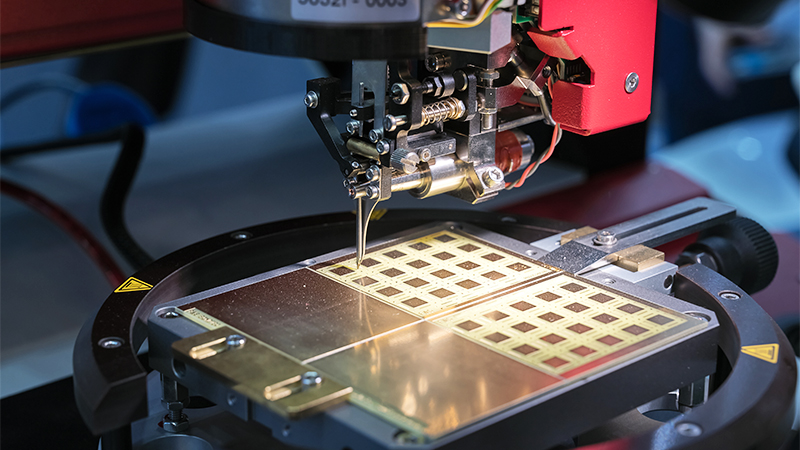

Ho chesoa ka lasere sebelisa lebone la laser e le mohloli oa mocheso oa eona. Lebone la laser le otla mathōko a lisebelisoa tsa tšepe, le hlahisa mocheso le ho etsa letamo la weld. Ha laser e tloha, tšepe e qhibilihisitsoeng e ea pholile 'me e tlamahane. Mokhoa ona o ka sebelisoa bakeng sa li-welds tse fetang, butt welds, le li-welds tse tiisitsoeng lits'ebetsong tse fapaneng tsa indasteri.

Ho tjheseletsa ka laser ho na le lebelo le potlakileng la ho tjheseletsa le ho sebetsa hantle haholo, hape e ka sebediswa bakeng sa tjheseletsa tse se nang ditshipi. Ke theknoloji e tsoetseng pele ea ho tjheseletsa e sebelisoang haholo liindastering tse kang ho etsa likoloi, lisebelisoa tsa elektroniki le mabenyane. Leha ho le joalo, ha e khone ho phunyeletsa lisebelisoa tse teteaneng, kahoo e loketse ka ho fetisisa bakeng sa lisebelisoa tse tšesaane tse nang le marako. Ha ho bapisoa le mekhoa e meng ea ho tjheseletsa, thepa ea ho tjheseletsa ka laser e atisa ho bitsa chelete e ngata.

Tobetsa Welding

Ho fapana le fusion welding, khatello ea welding e hloka ho sebelisa khatello e itseng ho tšepe nakong ea ts'ebetso ea welding. Lisebelisoa tsa tšepe ha li qhibilihe ho ba mokelikeli empa li lula li tiile. Khatello ea tjheseletsa e kenyelletsa ho futhumatsa manonyeletso a tšepe ho eketsa polasetiki ea bona, ebe o kenya khatello ho tšepe e entsoeng ka polasetiki, e leng se hlahisang motsoako o matla oa weld. Ka hona, khatello e phetha karolo ea bohlokoa ts'ebetsong.

Ka nts'etsopele ea moruo oa indasteri, lisebelisoa le lihlahisoa tse ngata tse ncha li hlahile, tse lebisang ho nts'etsopele e tsoelang pele ea theknoloji ea ho cheselletsa khatello. Mekhoa ea mantlha ea ho cheselletsa khatello hajoale e kenyelletsa welding ea ho hanyetsa, welding ea diffusion, welding ea likhohlano le welding ea ultrasonic.

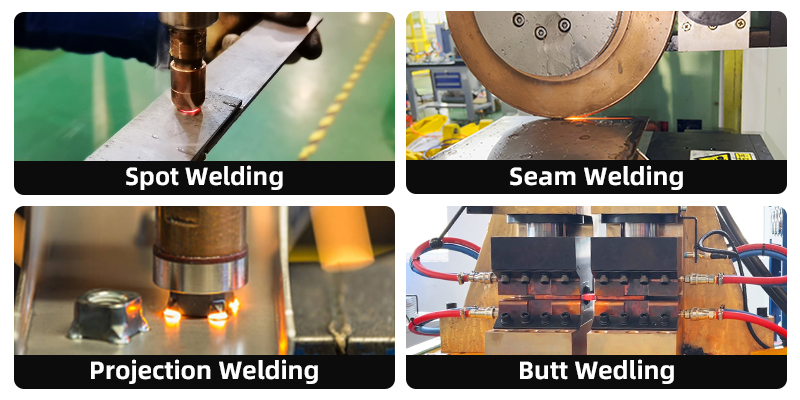

Resistance Welding

Ho hanyetsa weldinge sebelisa motlakase ho futhumatsa ntlha ea khokahanyo ea lisebelisoa tsa tšepe ha e ntse e sebelisa khatello ka li-electrode ho phethela weld. Hangata e sebelisoa bakeng sa ho cheselletsa tšepe e sa hloekang, koporo, aluminium le tšepe ea carbon. Ka lebaka la boleng ba eona bo holimo le bo sa fetoheng, welding e bapala karolo ea bohlokoa indastering ea likoloi, tsa elektroniki le tsa sefofane. Ka tsoelo-pele ea mahlale a morao-rao, li-welding tsa ho hanyetsa li ntse li kenyelletsa li-automation, 'me li eketsa katleho ea tlhahiso.

Resistance welding e ka aroloa ka mekhoa e mene:ho tjheseletsa letheba, projection welding,ho tjheseletsa seam, leho tjheseletsa butt. Mohlala, haeba o hloka ho cheselletsa karolo ea koloi, joalo ka ho hokela nate poleiti ea tšepe, o ka sebelisa welding ea projection. Leha ho le joalo, lisebelisoa tsa ho tjheseletsa ho hanyetsa hangata li ngata ebile ha li tsamaee habonolo, li fokotsa tšebeliso ea tsona ho maemo a itseng. Nako le nako ha u tjheseletsa lisebelisoa tse fapaneng tsa tšepe kapa botenya, li-parameter li hloka ho lokisoa, e leng ho etsang hore e be e loketseng haholoanyane bakeng sa ho tjheseletsa ka bongata bo boholo ba likarolo tsa tšepe.

Diffusion Welding

Ho tjheseletsa ho pharalletseng, e tsejoang hape e le diffusion bonding, e kenyelletsa ho futhumatsa le ho kenya khatello holim'a tšepe nakong ea ho cheselletsa. Ts'ebetso ena e lumella liathomo le limolek'hule tsa lisebelisoa tsa tšepe ho hasana le ho tlamahanngoa tlas'a mocheso o phahameng le khatello. Diffusion welding e ka sebelisoa bakeng sa lisebelisoa tse tšoanang le tse sa tšoaneng, tse atisang ho hokela koporo, aluminium le lisebelisoa tse kopaneng.

Mokhoa ona o ka ka nako e le 'ngoe tjheseletsa manonyeletso a mangata kopanong, joalo ka welding 20 layers ea 0.1 mm koporo foil. Diffusion welding e theha manonyeletso a matla a hananang le deformation, hangata a felisa tlhoko ea ts'ebetso e tsoelang pele. Leha ho le joalo, e boetse e na le litšitiso, ho kenyelletsa katleho e tlase ea tlhahiso le litšenyehelo tse phahameng tsa lisebelisoa.

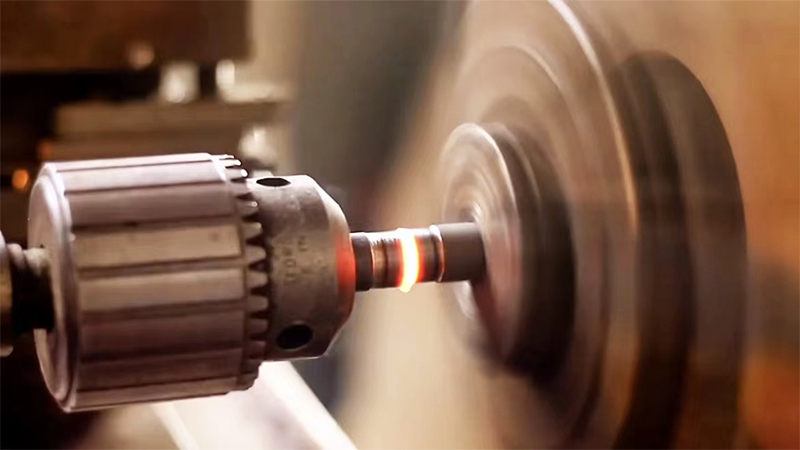

Motsoako oa ho Welding

friction weldingke ts'ebetso ea ho tjheseletsa e sebelisang mocheso o hlahisoang ke ts'ebetso e amanang le likhohlano lipakeng tsa li-workpieces tlas'a khatello. Ke mokhoa o sebetsang hantle, oa ho boloka matla o hlahisang li-welds tsa boleng bo holimo. Ha ho bapisoa le flash butt welding, friction welding e na le sebaka se senyenyane se anngoeng ke mocheso 'me e loketse ho kopanya litšepe tse sa tšoaneng.

Friction welding e ikhethile 'me e fana ka melemo e kang tšebeliso e tlase ea matla le botsoalle ba tikoloho, e leng se etsang hore e tume liindastering tse kang ho etsa mechini, sefofane le matla. Leha ho le joalo, ka kakaretso e loketse feela ho kopanya melamu ea tšepe le liphaephe tsa bophara bo tšoanang. Hang ha sebopeho le boemo ba kopano ea li-workpieces li tsitsitse, ho ba phephetso ho tjheseletsa.

Ultrasonic Welding

Ultrasonic welding e sebelisa li-vibrations tse phahameng haholo tse hlahisoang ke maqhubu a ultrasonic ho etsa hore ho be le likhohlano, deformation le mocheso libakeng tsa tšepe. Khatello e sebelisoa ke manaka a molumo a holimo le a tlase ho phethela tšebetso ea ho cheselletsa. Ona ke mokhoa o ikhethileng oa tjheseletsa o sa kenyelletseng hore motlakase o feta ka har'a lisebelisuoa kapa mehloling ea mocheso o kantle, 'me o arolelana litšoaneleho tse ling ka tšubuhlellano ea likhohlano le welding ea diffusion.

Ultrasonic weldinge ka sebelisoa bakeng sa lisebelisoa tse fapaneng, ho kenyelletsa le litšepe tse tšoanang le tse sa ts'oaneng joalo ka koporo, aluminium, khauta le silevera. Leha ho le joalo, e sebelisoa hangata bakeng sa ho cheselletsa thepa e seng ea tšepe e kang ABS, PP, le PC, moo e hlahisang litholoana tse ntle le ho feta.

Brazing Welding

Brazingke mokhoa oa ho tjheseletsa moo tšepe ea ho tlatsa e nang le ntlha e qhibilihisang ka tlase ho ea li-workpieces e futhumala le ho qhibiliha ho tlatsa likheo pakeng tsa lisebelisoa tse peli tsa tšepe, ho tlatsa ts'ebetso ea ho kopanya tšepe. Ho fapana le fusion welding le welding khatello, mokhoa ona ha o hloke ho qhibiliha lisebelisoa kapa ho sebelisa khatello. Brazing e sebelisoa haholo bakeng sa ho kopanya li-workpieces, tse nang le boholo ba lekhalo ho tloha ho 0.01 ho isa ho 0.1 millimeters.

Kajeno, brazing e ntse e sebelisoa haholo indastering e kang mechini, lisebelisoa tsa elektroniki, lisebelisoa le mabone. Boleng ba brazing bo itšetlehile haholo ka tšepe ea ho tlatsa e sebelisoang. Ka hona, ha u khabisa li-workpieces tsa tšepe, ke habohlokoa ho khetha tšepe ea ho tlatsa e nang le thepa e ntle ea ho kolobisa e ka tlatsang manonyeletso ka katleho. Brazing e arotsoe ho brazing e bonolo le brazing e thata ho latela ntlha e qhibilihang ea tšepe ea ho tlatsa.

Soldering e Bonolo

Solder e bonolo e sebelisa litšepe tse tlatsang tse nang le lintlha tse qhibilihang ka tlase ho likhato tse 450 tsa Celsius. Manonyeletso a bōpiloeng ka soldering e bonolo a na le matla a fokolang le ho hanyetsa mocheso o futsanehileng. E sebelisoa hangata bakeng sa likhokahano tsa motlakase lihlahisoa tse nepahetseng tsa elektroniki le ho solder ka litšepe tsa solder. Haeba litlhoko tsa matla li se bohlokoa 'me ntlha ea ho qhibiliha ea tšepe ea ho tlatsa e phahame ho feta ea tšepe e ntseng e rekisoa, ho ka sebelisoa soldering e bonolo.

Thata Soldering

Brazing e nang le litšepe tse phahameng tsa melting-point, tse tsejoang e le hard soldering, li sebelisa litšepe tsa ho tlatsa tse nang le lintlha tse qhibilihang ka holimo ho likhato tse 450 tsa Celsius. Manonyeletso a entsoeng ka ho soasoa ka thata a matla ha a bapisoa le a tsoang ho solder e bonolo. Ho soasoa ka thata hangata ho sebelisa lisebelisoa tse kang silevera, aluminium, koporo le nickel. Khetho ea tšepe ea ho tlatsa e itšetlehile ka litšobotsi tsa lisebelisoa tsa mosebetsi le litlhoko tsa ts'ebetso ea motsoako. Hard soldering ka kakaretso e loketse tšepe e sa hloekang, li-alloys tsa aluminium, koporo le lisebelisoa tse ling tse nang le litlhoko tse phahameng tsa matla. E sebelisoa bakeng sa manonyeletso a sebetsang ka tlas'a mocheso o phahameng 'me e fumana lisebelisoa tse pharaletseng sebakeng sa lifofane, tsa elektroniki le indastering ea motlakase.

Qetello

Ho na le mefuta e fapaneng ea litšepe tsa tšepe, 'me tse boletsoeng ka holimo ke tse ling tsa mekhoa e tloaelehileng. Ha thekenoloji ea li-welding e ntse e tsoela pele, mekhoa e mengata ea ho tjheseletsa e ntse e hlaha. Ha u nahana ka mokhoa oa ho cheselletsa li-workpieces tsa tšepe, ho bohlokoa ho nahana ka lintlha tse kang thepa ea workpiece, sebōpeho sa eona, sebaka sa mosebetsi, le tse ling. Ho bohlokoa ho khetha mokhoa o nepahetseng oa welding ho latela lintlha tsena.

Nako ea poso: Jun-19-2024