Spot welding machine ke mochini o sebelisetsoang ho hokahanya tšepe, o batlang o tloaelehile ts'ebetsong ea tšepe. Le tsoelo-pele ea thekenoloji tjheseletsa le ntlafatso ea ditlhoko tjheseletsa, thepa tjheseletsa ke ho feta le ho feta mefuta e fapaneng, letheba tjheseletsa mochine ke mofuta oa thepa tjheseletsa le histori e telele, ho fihlela joale ho indasteri e boetse e phetha karolo ea bohlokoa haholo. Sehlooho sena se tla hlalosa letheba tjheseletsa mochine ka ho qaqileng, nka u ho utloisisa molao-motheo oa eona, mefuta, melemo, joalo-joalo.

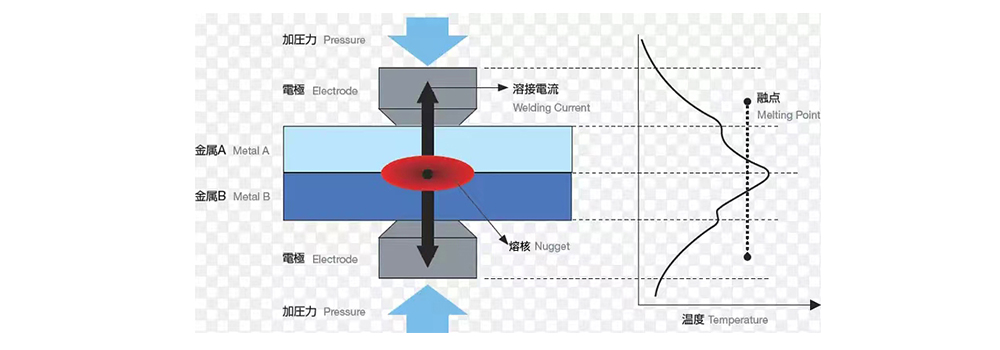

Molao-motheo oa mochini oa ho tjheselletsa letheba

Spot welding machine ke mofuta oamochine oa ho tjheseletsa ho hanyetsa, thepa ena tjheseletsa ke tshebediso ya hona joale ka eleketrode le tšepe workpiece ho hlahisa ho hanyetsa mocheso ho fana ka mocheso mohloli, ka tsela ea ho futhumatsa le pressurizing tse peli tse tšepe kopana e amana hammoho. Electrode clamps tse peli overlapping tšepe workpieces, ketso ena e finyelloa ka ho sebelisa khatello ea moea ka khatello ea moea, boholo ba khatello ea clamping workpiece haholo-holo itšetlehile ka botenya ba lintho tse bonahalang le ho thatafala ha lintho tse bonahalang, e kholoanyane botenya, le ho feta. boleng ba khatello e hlokahalang, boima bo boholo ba thepa, ho feta khatello e hlokahalang. Ha u cheselletsa sehlahisoa se secha se nang le welder ea letheba, butle-butle u ka fetola khatello ho tloha ho e nyenyane ho ea ho e kholo, nakong eo sehlahisoa sa welded se lekoang. Ho fihlela u weld sehlahisoa solder kopanetsoe holim'a boreleli, le ho tiea ho kopana le ditlhoko, lekhetlong lena boleng ba khatello ke ka ho fetisisa loketseng.

Ho phaella ho tjheseletsa khatello, tjheseletsa hona joale, nako tjheseletsa, ho kopana ho hanyetsa e boetse e le parameter ea bohlokoa ea letheba tjheseletsa mosebetsi oa mochine, tsohle ama mocheso tjheseletsa, meedi tlatsana, beha meedi tjheseletsa loketseng e le hore qetellong tjheseletsa lihlahisoa tšoanelehang.

Mofuta oa tjheseletsa sebakeng

Ka lebaka la mefuta e fapaneng ea ho sebetsa, re arolelitse mochini oa tjheseletsa oa letheba2mekhahlelo,Standard letheba tjheseletsa mochini le customized letheba tjheseletsa mochini.

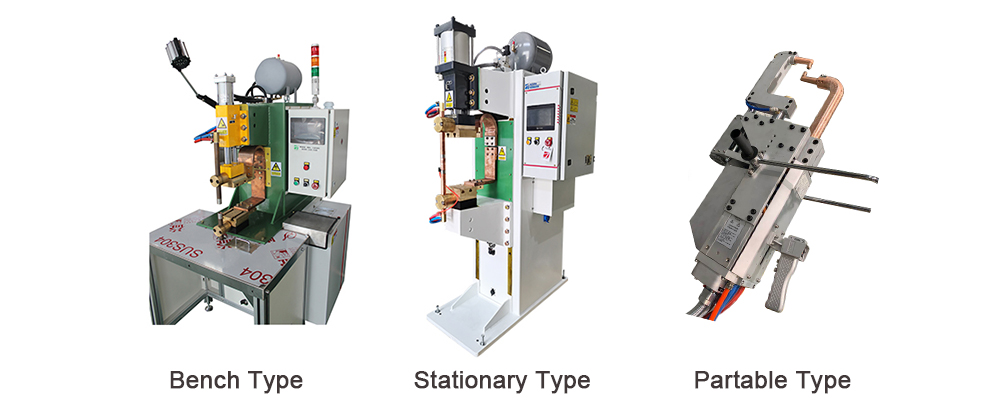

Sebaka se tloaelehilengwelder

Welder ea mofuta oa benche

Benchtop letheba tjheseletsa mochini ka kakaretso e batla e le nyenyane matla, ho feta loketseng bakeng sa ho tjheseletsa lihlahisoa tse nyenyane tsa tšepe, tse kang likarolo tsa elektronike. 'Mele ona oa mochini oa tjheseletsa o nyane, o bonolo ho o tsamaisa, hangata o beoa holim'a benche ea mosebetsi kapa tafoleng ho sebelisoa, opareitara a ka lula ho phethela mosebetsi oa tjheseletsa.

E lutsengletheba welder

Fuselage e kholo ebile e boima, mochine ha o bonolo ho tsamaea, 'me ka kakaretso o behiloe sebakeng se itseng fekthering, kahoo o bitsoae emisitsengletheba welder. Ha ho bapisoa le mochini oa welding oa desktop, oae emisitsengmochini tjheseletsa letheba ka kakaretso matla a maholo, matla ho feta tjheseletsa bokgoni, 'me ka kakaretso likarolo tšepe tjheseletsa le botenya kholoanyane. Bakeng sa mabaka a ts'ireletso, li-switches tsa maoto li kenngoa, 'me mosebeletsi a ka boela a nka le ho lokolla mosebetsi ka letsoho.

E nkehangletheba weldsethunya

E boetse e bitsoa suspended spot welder, hobane hangata e emisoa hore e sebetse.Mmele wa se nkehangmochini tjheseletsa letheba e nyenyane, e ka sisinyeha likhato 360, ka kakaretso sebelisoa bakeng sa ho tjheseletsa ha ho bonolo ho tsamaea kapa ka nģ'ane ho sebaka sa lihlahisoa tse khōlō tjheseletsa mochini tjheseletsa, tse kang 'mele tjheseletsa tla hangata sebelisa thepa ena. U ka fetola bophahamo sebakeng se nepahetseng, ho hokahanya karolo e lokelang ho ts'oaroa, tšoara switch switch, 'me u ka phethela mosebetsi oa welding.

Mochini oa ho tjheseletsa letheba o iketseditseng

Multi-head spot welder

Ho phaella ho lisebelisoa tsa ho tjheseletsa letheba tse ka holimo, u ka boela ua etsa mochine oa ho tjheseletsa ka mokhoa o ikhethileng bakeng sa sehlahisoa sa hau ho latela sehlahisoa sa hau le litlhoko tsa welding. Ka mohlala, haeba u batla ho tjheseletsa lakane tšepe ea boholo bo batlang bo le boholo, tšebeliso ea mochine o tloaelehileng oa tjheseletsa ha o lokele ho sebetsa 'me lebelo la tjheseletsa le lieha. U ka kopa moetsi oa hau hore a u etsele mochini o nang le lihlooho tse ngata tsa semi-automatic spot welder, o ka khonang ho kenya lintlha tse ngata ka nako e le 'ngoe, kahoo o ntlafatsa ts'ebetso ea welding. Mochini ona oa ho tjheselletsa letheba hangata o sebelisoa bakeng sa ho tjheseletsa mabokose a tšepe a lakane, 'me theko ea thepa e phahame ho feta mochini o tloaelehileng hobane o hloka ho hlophisoa ho latela tlhoko.

XY axis mochini tjheseletsa letheba

Ho welding ea semi-automatic spot, theknoloji e atisang ho sebelisoa ke XY axis moving feed. Ka mantsoe a bonolo, mochini ona ke mochini o tloaelehileng oa tjheseletsa oa letheba o nang le tafole ea Xy axis e tsamaeang, tafole e entsoe ho latela boholo ba sesebelisoa. Mosebetsing oa welding, opareitara e hloka feela ho beha workpiece holim'a workbench e tsitsitseng, konopo ea pneumatic switch, mochine o tla romela likarolo ka mokhoa o ikemetseng sebakeng sa welding, boemo bo nepahetseng, ebe o qala ho tjheseletsa. Hangata mochini ona o sebelisoa bakeng sa ho cheselletsa liforeimi tsa tšepe, tšepe ea pampiri le letlooeng la terata.

Haeba u ikutloa hore mochini o tloaelehileng o ke ke oa kopana le litlhoko tsa hau tsa tjheseletsa, mme o batla ho ntlafatsa ts'ebetso le ho potlakisa, o ka nahana ka mochini o khethehileng oa tjheseletsa oa letheba. Romela likarolo tsa hau tsa tšepe feela ho bona baetsi ba mochini oa welding joalo ka Agera, re tla buisana le uena ka ts'ebetso le litlhoko tsa welding, 'me u iketsetse moralo oa welding ho ea ka litlhoko tsa hau,' me u rale sebaka sa weld.er mochiniseo ke se khethehileng ho uena.

Mokhoa oa ho khetha welder e nepahetseng

Ke mofuta ofe oa welder oo u ka o khethang o ipapisitse le sehlahisoa seo u batlang ho se cheselletsa, se lateloa ke litlhoko tsa hau tsa welding.

Pele ho tsohle, o lokela ho fumana hore na sehlahiswa hao ka tjheseletsa ka letheba tjheseletsa thekenoloji, sebopeho makatsang kapa likarolo tse khōlō ha ba a loketse bakeng sa letheba thepa tjheseletsa, o ka buisana letheba tjheseletsa mochini moetsi hore na u ka tjheseletsa, u ka boela nka likarolo ho letheba mochini tjheseletsa moetsi bakeng sa sampole.

Haeba u etsa qeto ea hore sehlahisoa sa hau se ka chesetsoa ka mochini o cheselletsang letheba, mohato o latelang ke ho tseba hore na mochini oa welder ke oa mofuta ofe. Ka nako ena, ho ke ke ho hlokahala hore ho sheba lintho tse bonahalang, botenya le boholo ba sehlahiswa, likarolo tse teteaneng lokela ho sebelisa phahameng-matla letheba welder, 'me likarolo tse nang le liforeimi tse khōlō tse ha e ntle ho fallela khetha selefouno letheba welder. U ka boela ua sisinya mehopolo e meng ea ho etsa sesebelisoa sa welding sa sebaka ka boiketsetso.

Melemo ea spot welder

Lebelo la welding le potlakile.Ha ho bapisoa le lisebelisoa tse ling tsa tjheseletsa tse kang mochini oa tjheseletsa oa laser, lebelo la ho tjheseletsa letheba le potlakile haholo, nako ea ho tjheseletsa e ka phethoa ka motsotsoana o le mong, esita le lintlha tse ngata li ka chesetsoa ka nako e le 'ngoe, ho ntlafatsa haholo ts'ebetso ea ho cheselletsa.

Matshwao a manyane a tjheseletsa.Hafeela u fetola li-parameter tse loketseng, sehlahisoa se cheselitsoeng se setle, se na le deformation e nyenyane, ha ho na li-burrs, ka kakaretso ha ho hlokahale hore u etse ts'ebetso ka mor'a ho tjheseletsa, ho boloka mokhoa oa ho sebetsa.

Ha ho hlokahale ho tlatsa solder.The spot welder e hloka feela ho hokahanya likotoana tse peli tsa tšepe hore li tsoe, 'me li ka chesoa ntle le ho eketsa solder. Mekhoa e meng ea welding e tšoana le ea arc welding, hoa hlokahala ho eketsa solder ts'ebetsong ea welding ho weld, ka tsela ena lebelo la welding le lieha, 'me litlhoko tsa tekheniki tsa welder li phahame.

Tshebetso e bonolo.Ts'ebetso ea mochini oa ho tjheseletsa oa letheba o bonolo haholo, o hloka feela ho lokisa methati ea ho tjheseletsa pele ho tjheseletsa, o ka qala welding e kholo, mosebetsi ona oa tjheseletsa o ka phethoa ke basebetsi ba tloaelehileng.

Tšebeliso ea mochini oa tjheseletsa sebakeng

Lintho tse chesehang

Spot tjheseletsa mochini e sebediswa bakeng sa tjheseletsa thepa tšepe, hangata sebelisoa bakeng sa tjheseletsa tšepe e sa hloekang, tlaase carbon tšepe, galvanized tšepe, koporo, aluminium le thepa e 'ngoe, ho phaella ho tjheseletsa thepa e tšoanang, ka boela hokela litšepe tse sa tšoaneng. Ho phaella hotjheseletsa la tshepe, tjheseletsa e kopanetsoeng ea linate, liboutu le lishiti le tsona li ka sebelisa li-welders tsa letheba.

Tšebeliso ea indasteri

Mochini oa welding oa Spot o sebelisoa haholo indastering, mme ts'ebetso ea tšepe hangata e ka bona palo ea eona. Mochini oa welding oa Spot o sebelisoa haholo ho etsa likoloi, tsa elektroniki le tsa motlakase, lisebelisoa tsa ka tlung, likhabinete tsa tšepe, ho etsa mechini le liindasteri tse ling. Nako le nako ha u hloka khokahano ea tšepe, ho ka etsahala hore u sebelise mochini o cheselletsang letheba.

Kakaretsomonate

Ka holimo ke kenyelletso e khuts'oane ea mochini oa tjheseletsa oa letheba, haeba u batla mochine o loketseng oa tjheseletsa, sehlooho sena se lokela ho fumana karabo. Ho khetha mochine o loketseng oa ho tjheseletsa letheba ho bohlokoa haholo, mochine o motle oa ho tjheseletsa o ka etsa sehlahisoa se nang le tlhōlisano bakeng sa hau, mochine o mobe o tla fokotsa katleho ea mosebetsi oa hau. U ka boela ua ikopanyaAgerabahlahisi ba mochini oa tjheseletsa letheba, re tla khothaletsa mohlala o nepahetseng bakeng sa hau.

Nako ea poso: Jul-26-2024