Ho tjheseletsa lethebake mofuta oa ho hanyetsa tjheseletsa, joalo ka ts'ebetso e thehiloeng hantle e sebelisetsoang ho kopanya litšepe tse fapaneng, ho e etsa mokhoa oa bohlokoa ts'ebetsong ea tšepe ea morao-rao ea indasteri. Sengoliloeng sena se fana ka malebela a ho fihlela li-welds tse matla, tse khahlang le tse tsitsitseng tsa ho hanyetsa:

Khetha E nepahetsengLethebaWeldingMochini

Ho bohlokoa ho khetha sesebelisoa sa ho tjheseletsa sebaka se nepahetseng sa ho hanyetsa. Qoba mechine e meholo haholo e nang le likarolo tse ngata, kaha sena se ka senya matsete. Ka mokhoa o ts'oanang, u se ke ua khetha mochine o lekaneng feela, kaha o ka 'na oa se ke oa lumella ho atolosoa ha nako e tlang kapa ho ba le khanyetso e ntle ea mokhathala.

Khetho e ntle ka ho fetisisa ke mochini o khonang ho tjheseletsa ka thata, o nang le matla a eketsehileng a 25% ho tjheseletsa hajoale le khatello e fetang ea hajoale.tjheseletsa la tshepe.

Ho sebelisa mochini o moholo ho ka baka mathata a mangata joalo ka mochini o monyane haholo. Mohlala, haeba bophara ba silinda e le kholo haholo, e tlameha ho sebetsa ka khatello ea moea e ka tlase ho 0.2 MPa ho fihlela khatello e hlokahalang ea welding. Sena se ka fella ka karabelo e mpe ho tsoa mochineng oa kopo ea khatello. Haeba silinda e sa sebetse ka potlako ha tšepe e fihla boemong ba polasetiki 'me e hloka ho etsoa ka potlako, matla a weld le botsitso li ka senyeha.

Lik'hamphani tse ngata, bakeng sa boiketlo ba tsamaiso ea lisebelisoa le litekanyetso tse tšoanang tsa ho tjheseletsa, li khetha lisebelisoa tse thehiloeng ho mehlala e tloaelehileng ho e-na le litlhoko tsa ts'ebetso ea welding. Sena se ka etsa hore ho se tsamaisane hantle ha ho tjheseletsa likarolo tse kholo le tse nyane haholo. Ena ke phoso e tloaelehileng ea baenjiniere ba se nang phihlelo. Mokhoa o nepahetseng ke ho bapisa boholo ba lisebelisoa le li-workpieces tse ntseng li chesetsoa.

Koetlisetsoa ho kenaLethebaWelding

Taba ea pele, ho bohlokoa ho etsa koetliso ea melao-motheo le mekhoa ea ho cheseletsa. Ho utloisisa melao-motheo ea "resistance spot welding" ho bohlokoa bakeng sa ho lokisa lits'ebetso tsa welding le ho sebelisa lisebelisoa hantle.

Spot welding e ka 'na ea bonahala e le bonolo, kaha ho bonahala eka motho e mong le e mong a ka sebetsa le ho fetolamochini tjheseletsa letheba: beha likarolo pakeng tsa li-electrode, tobetsa konopo ea ho qala, 'me likarolo li kopantsoe hammoho. Leha ho le joalo, sena sea thetsa. Ho bohlokoa ho utloisisa bohlokoa ba likarolo le liparamente tsa welding le ho fetola e 'ngoe le e' ngoe ho ea ka boleng ba eona bo nepahetseng.

Nahana joalo ka ho pheha: metsoako e tšoanang, empa linoko tse fapaneng, maemo a mocheso le linako tsa ho pheha li ka hlahisa litatso tse fapaneng haholo!

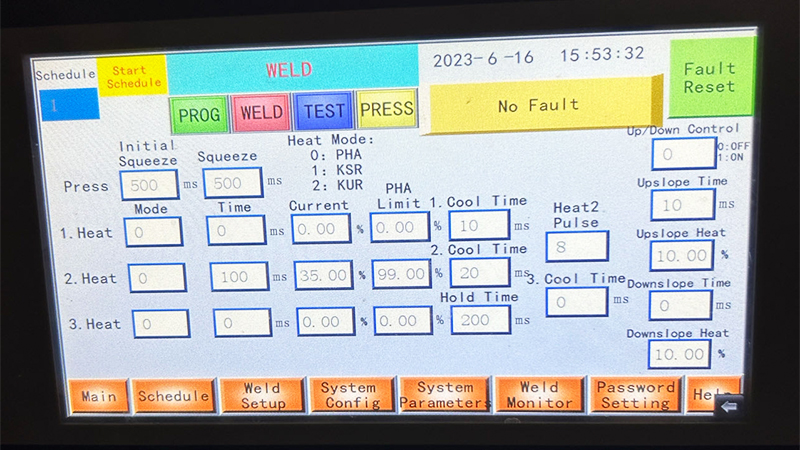

Lintlha tse tharo tsa bohlokoa tsa ho tjheseletsa ha letheba ke nako ya welding, nako ya welding, le kgatello ya welding. Mekhahlelo ea tlatsetso e kenyelletsa nako ea pele ho khatello, nako ea nako ea welding, le nako ea ho ts'oara ka morao.

Ka ho kopanya liparamente tsena, o ka fihlela lintlha tse thata, tse mahareng, kapa tse bonolo, tse hlahisang litlamorao tse fapaneng tsa welding, joalo ka:

Litlhaloso tse thata:Karolo e nyane ea deformation, tšusumetso e tlase ea mocheso, lebelo le potlakileng la welding, empa e hloka lisebelisoa tse matla, tse matla le tse nang le khatello e phahameng.

Litlhaloso tse bonolo:Karolo ea bohlokoa ea deformation, indentation e tebileng ea weld, discoloration, lebelo le liehang ho tjheseletsa, empa matla a tlase le litlhoko tsa ho tiea bakeng sa lisebelisoa.

Litlhaloso tse mahareng:Liphello le litlhoko tsa lisebelisoa li oela pakeng tsa tse peli tse feteletseng tse ka holimo.

Libuka tsa profeshenale joalo ka "Welding Handbook" li fana ka likhothaletso tsa paramethara, 'me lienjineri tsa litšebeletso tsa tekheniki tsa Agera li fana ka koetliso le tataiso ho basebelisi.

Khetha E nepahetsengSpot WeldingLi-electrode

Ho bapisa lisebelisoa tsa elektrode le karolo ea karolo ho bohlokoa bakeng sa liphetho tse nepahetseng tsa welding le matla a matla.

Bakeng sa tjheseletsa sebakengaluminiumlemasenke a masenke, sebelisa li-electrode tsa koporo tse qhalakaneng tsa alumina, tse hanang ho khomarela.

Bakeng sats'epe e sa beng le mabalile lishiti tsa tšepe tse tlaase tsa carbon, li sebelisa li-electrode tsa koporo tsa chromium zirconium, tse fanang ka katleho e phahameng ea litšenyehelo.

Bakeng sakoporo, li-electrode tsa tungsten le molybdenum lia hlokahala ho thusa ka ho cheseletsa ka lebaka la thepa ea tsona ea mocheso.

Moralo le boqapi ba libopeho tsa li-electrode le tsona li bohlokoa, kaha li khetholla boholo le ponahalo ea weld nugget le matla a eona.

Beha Li-parameter tsa Welding

Mekhahlelo ea welding e ka beoa ho ipapisitsoe le boiphihlelo kapa data ho tsoa mehloling ea sechaba. Haeba ho se na litšupiso tse fumanehang, u ka fumana liparamente tse ntle ka ho fetisisa tsa welding ka li-welds tse ngata tsa liteko tse nang le litlhophiso tse fapaneng. Ha u etsa liteko, latela melao-motheo ena:

Qala ho Nyenyane: Qala ka litekanyetso tse tsitsitseng, tse nyenyane bakeng sa li-parameter tse kang ho cheselletsa hona joale, nako le khatello, 'me butle-butle u li eketse. Mokhoa ona o thusa ho qoba tšenyo ea lisebelisoa, li-electrode le likarolo.

Fetola Parameter e le 'ngoe ka Nako: Ho fetola li-parameter tse ngata ka nako e le' ngoe ho ka lebisa ho likahlolo tse fosahetseng, haholo-holo ho basebetsi ba se nang phihlelo. Haeba tokiso e le 'ngoe e sa sebetse, leka e 'ngoe ha u ntse u shebile ka hloko liphetoho tsa boleng ba welding.

Lumella Mekhahlelo ea Mekhahlelo: Netefatsa hore ho na le moeli bakeng sa liparamente ho amohela ho fapana ha likarolo.

Hang ha litekanyo tse ntle ka ho fetisisa tsa welding li netefalitsoe, tiisa lintlha tsena 'me u li sebelise e le motheo oa tlhahiso.

Boloka li-Electrode

Kamehla fetola li-electrode tse holofetseng ho li boloka ka boholo ba tsona tse neng li entsoe qalong, 'me u hloekise litšila le masala a alloy ea koporo holim'a tsona. Tlhokomelo ena ke ea bohlokoa bakeng sa welding e tsitsitseng.

Li-electrode tse sebetsang tlas'a khatello e phahameng le mocheso li ka holofala, tsa eketsa sebaka sa tsona sa ho ikopanya le likarolo le ho fokotsa sets'oants'o sa hona joale sa welding. Ho feta moo, liphahlo tse holim'a metsi, oli le mafome tse tsoang likarolong li ka khomarela li-electrode, tsa eketsa khanyetso ea ho kopana le ho fokotsa mocheso oa hona joale oa welding. Litaba tsena li ama boleng ba welding ka kotloloho.

Ho sebelisa mochini o khethehileng oa li-electrode ho ka khutlisa sebopeho sa electrode kapele le ho tlosa litšila tse kaholimo. Qoba ho sebelisa faele bakeng sa ho hloekisa ka letsoho, kaha e ke ke ea netefatsa sebopeho se nepahetseng le ho qetela ha li-electrode.

Sebelisa Thepa ea Tlhahlobo ea Welding

Hangata manonyeletso a Spot tjheseletsa ha a etse tlhahlobo e sa senyeheng. Mekhoa e tloaelehileng ea ho hlahloba e kenyelletsa tlhahlobo ea pono, li-wrenches tsa torque (bakeng sa linate tse cheselletsang), mechini ea ho etsa liteko tse thata, le liteko tsa metallographic.

Teko ea Tensile le Compression: Etsa liteko tsena pele u qala letsatsi le felletseng la tlhahiso ho netefatsa ho ts'epahala ha li-parameter tsa welding ka sete ea data ea liteko. Qetellong ea phetoho e 'ngoe le e' ngoe, leka likarolo tse cheselitsoeng ka li-parameter tsa hona joale hape ho netefatsa ho tsitsisa. Bakeng sa likarolo tsa bohlokoa tse nang le litlhoko tsa boleng bo holimo, eketsa khafetsa liteko tse senyang.

Tlhokomelo ea Ts'ebetso: Ho sebelisa li-monitor tsa boleng ba welding ke khetho e 'ngoe, e ntseng e tsoela pele ho ananeloa le ho sebelisoa haholo. Ka ho beha leihlo li-parameter tsa welding ka nako ea 'nete le ho beha meeli e holimo le e tlase, ho kheloha leha e le hofe ho ka tsosa li-alarm, ho fokotsa liphoso tsa welding. Lintlha tsena tsa welding le tsona li ka bolokoa bakeng sa traceability ea boleng.

Tlhokomelo le Tlhahlobo ea Kamehla

Kamora ts'ebeliso ea nako e telele, lisebelisoa tsa ho cheselletsa Spot li hloka ho hlahlojoa khafetsa libakeng tsena:

- Conductive Circuit:Li-welding spatter li ka hlasela likarolo le likheo tse sirelelitsoeng, tsa baka ho phunya, ho fokotsa le ho thefula ha hona joale oa welding. Tlosa weld slag. Liphetoho tse etsahalang khafetsa tsa li-electrode li ka roala le ho oxidize likhokahano tsa conductive, tse hlokang ho ntlafatsoa hape. Tiisa liboutu holim'a likhoele tse bonolo tsa koporo le litšepe tse thata tsa koporo ho qoba ho lokoloha ts'ebelisong ea nako e telele.

- Tataiso ea Silinda ea Welding:Sheba ho tsamaea ha bonolo le likheo. Ho se thelle hantle ho ama ts'ebetso ea weld; likheo tse feteletseng li ama sebopeho sa weld le ho tsamaisana ha karolo.

- Potoloho ea Metsi:Etsa bonnete ba hore metsi a phalla hantle. Hloekisa limithara tsa phallo bakeng sa ho hlaka, hlahloba tsela e 'ngoe le e 'ngoe ea phallo, 'me u hloekise litšitiso kapa u fetole liphaephe. Metsi a pholileng a sa lekaneng a ka chesa li-transformer le li-electrode, a fokotsa nako ea bophelo kapa a baka mokhathala. Hlahloba le ho lokisa dutla.

- Hona Joale Welding:Netefatsa tjheseletso ya hona jwale ka motho wa boraro ho etsa bonnete ba hore e fihlella maemo. Tšebeliso ea nako e telele e ka fokotsa tlhahiso ea hona joale, kahoo ho ka 'na ha hlokahala hore ho hlahlojoe nako le nako le ho ntlafatsa kapa ho lokisoe.

- Potoloho ea Moea:Hlahloba le ho lokisa ho dutla ha moya, kaha ho dutla ho baka kgatello e sa tsitsang le tahlehelo ya matla.

- Bohloeki:Boloka thepa e hloekile. Matšoao a hlakileng le lisebelisoa tse hloekileng li fokotsa liphoso tsa batho.

Lehlabula

Tsena ke tse ling tsa likhothaletso bakeng sa basebelisi ba lisebelisoa tsa welding tsa resistance. Ka lilemo tse fetang 20 tsa boiphihlelo ba indasteri ea welding, re fana ka lits'ebeletso tse fapaneng tse felletseng, ho kenyeletsoa ho lokisoa ha sampole ea welding, khetho ea mochini, lisebelisoa tsa tloaelo tse sa tloaelehang tse ikemetseng, ho kenya le ho laela, tlhokomelo, lisebelisoa tse tšehetsang le likarolo. Ikutloe u lokolohile ho ikopanya le rona!

Nako ea poso: Jul-09-2024