Ho tjheseletsa butte sebelisoa le ho feta ts'ebetsong ea tšepe ea morao-rao, ka thekenoloji ea ho tjheseletsa butt, tšepe e tšoanang kapa tšepe e sa tšoaneng e kang koporo le aluminium e ka khomarela ka thata hammoho. Ka nts'etsopele ea indasteri, theknoloji ea welding ea butt e sebelisoa haholoanyane ho elektroniki le motlakase, likoloi tse ncha tsa matla le liindasteri tse ling. Sengoliloeng se latelang se tla araba tsebo ea ho tjheseletsa butt bakeng sa hau ka botlalo.

MotheoChang kaButtWelding

Seo ho thoeng ke tjheseletsa butt ke ho beha lipheletsong tse peli tsa workpiece mabapi le tse ling, ho sebelisa khatello ka nako e le 'ngoe, ho sebelisa tjheseletsa hona joale ho futhumatsa, ebe ho theha motsoako oa tjheseletsa tlas'a khatello ea khatello, e sebetsang hantle le e bonolo ho e finyella. mokhoa oa ts'ebetso ea welding.

The Mefuta of ButtWelding

Butt welding e arotsoe haholo kaho tjheseletsa butt buttleho tjheseletsa butt butt

Resistance butt welding

Resistance butt welding ke mofuta o tiileng oa tjheseletsa sebakeng sa mocheso o phahameng oa polasetiki, 'me khokahanyo e kopanetsoeng e ka ba recrystallization le ho fapanyetsana ha e le hantle, empa kaofela ke khokahanyo e tiileng ea mohato.

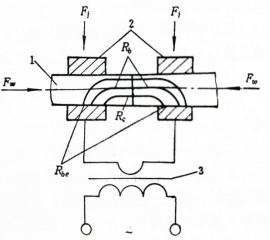

Molao-motheo oa ho hanyetsa butt welding le sebopeho sa manonyeletso se bontšoa ho Setšoantšo sa 1.

Setšoantšo sa 1. Setšoantšo sa schematic resistance butt welding

1- Ho chesoa

2 - Electrode

3- Solder resistance transformer

4-Ff- clamping force

Fw- forging force

Rb- weldment resistance

RC-Contact khanyetso

Rbe- Kopana le khanyetso pakeng tsa weldment le workpiece

Flash Butt Welding

Motsoako oa khokahano oa lenonyeletso la tjheseletsa la flash butt o ts'oana le oa lenonyeletso la ho tjheseletsa butt, leo hape e leng khokahano e tiileng ea mohato, empa mokhoa oa ho theha o na le litšobotsi tsa ona. Qetellong ea khanya, ho entsoe lera la tšepe la metsi sefahlehong sa ho qetela. Nakong ea ho etsoa ka holimo, tšepe ea sefahleho ea ho qetela e qala ho kopanngoa tlas'a karolo ea mokelikeli. Ka nako eo mokelikeli mohato lera tla pepeta tsoa kopanetsweng qetellong sefahleho tlas'a ketso ea holimo forging khatello.Ka mor'a horemochini o tjheseletsang butt flashlikarolo tse cheselitsoeng, lenonyeletso le matla haholo, joalo ka tube ea tšepe ka ho cheselletsa flash, ebe ka homochini o kobehang ka tubeho kobeha lenonyeletsong, lenonyeletso le ke ke la robeha.

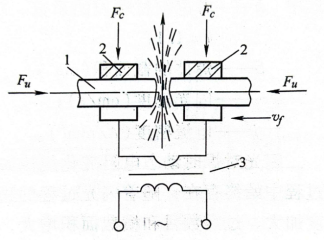

Molao-motheo oa ho tjheseletsa ha flash butt le ho thehoa ha manonyeletso ho bontšoa setšoantšong sa 2:

Setšoantšo sa 2. Sets'oants'o sa schematic sets'oants'o sa Flash butt

1- Ho chesoa

2 - Electrode

3- Solder resistance transformer

4- Fc- clamping force Fu- forging force Vf flash speed

Melemo eaButtWelding

a) Thepa ea resistance butt welding e bonolo, e na le likarolo tse fokolang tsa welding, ho bonolo ho e tseba, ho bonolo ho e fihlela taolo ea othomathiki;

b) Phokotso e nyane ea likarolo tsa welding butt, lisebelisoa tsa ho boloka, li-burrs tse fokolang, tse thusang ho nolofatsa mokhoa oa ho qetela;

c) flash butt welding e na le ts'ebetso e phahameng ea mocheso, e khona ho chesella likarolo tse kholo, 'me e kile ea sebelisoa bakeng sa liphaephe tsa khase tse nang le sebaka se fapaneng sa 100000mm2;

d) flash butt tjheseletsa hobane lesela le teng ka nako e khutšoanyane, ke milliseconds tse seng kae feela, boemo ba eona bo fetoha ka mokhoa o sa reroang, 'me nako eohle ea ho futhumatsa ho pholletsa le sefahleho sa ho qetela sa tjheseletsa ho na le junifomo ho feta, kahoo ho tsoela pele ho tjheseletsa flash ha ho khonehe feela karolo ea compact, empa hape le li-welds tse nang le likarolo tse atolositsoeng (tse kang lishiti tse tšesaane, joalo-joalo);

e) Qetellong ea khanya, ho tla thehoa lesela le tšesaane la tšepe ea mokelikeli holim'a weldment, e le hore litšila tsa oxide tse holim'a metsi li be bonolo ho li ntša ka tšepe ea metsi karolong e ka holimo ea sebopeho, kahoo. hore lenonyeletso la tjheseletsa la flash butt ke la boleng bo holimo, 'me mefuta ea li-welding e ka ba ngata,' me mefuta e fapaneng ea lisebelisoa tse fapaneng e ka chesoa.

f) Ha ho na filler e hlokahalang ts'ebetsong ea welding, mme sekhahla sa ts'ebeliso ea thepa se phahame;

Kopo eaButtWelding

Ho Etsa Likoloi

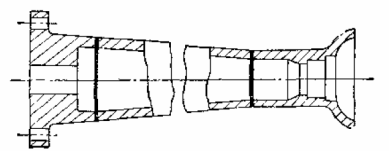

Setšoantšo sa 3. Automobile cardan shaft shell flash butt welding

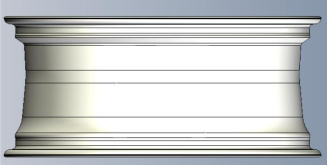

Setšoantšo sa 4. Koloi, sethuthuthu lebili flash butt welding

Indasteri ea sepakapaka

Setšoantšo sa 5. Ho tjheseletsa butt butt ea sefofane

Indasteri ea peterole

Setšoantšo sa 6. Lipeipi tsa tšepe li tjheseletsa butt

Sebaka sa boenjiniere ba kaho

Setšoantšo sa 7. End plate flange butt welding

Indasteri ea ho haha likepe

Setšoantšo sa 8. Anchor chain butt welding

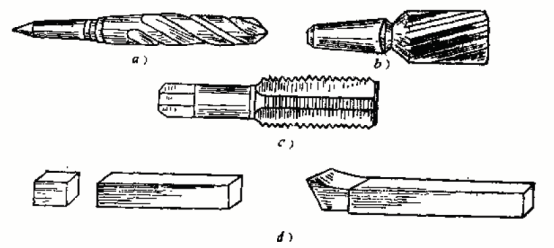

lisebelisoa tsa hardware

Setšoantšo sa 9. Ho cheselletsa butt ea lisebelisoa

StlhalosoPli-arameter kaButtWeldingProcess

Ha ho khethoa litekanyo tse nepahetseng tsa li-welding tsa butt, ho ka fumanoa manonyeletso a boleng bo holimo a nang le thepa e batlang e lekana le lisebelisoa tsa motheo.

a) Lintlha tse ka sehloohong tse hlalosang ts'ebetso ea "resistance butt welding" ke:

bolelele ba ho otlolla, ts'ebeliso ea hona joale ea welding (kapatjheseletsa jwale), nako ea ho cheselletsa, khatello ea welding le top forging pressure.

b) Mekhahlelo ea mantlha ea ho cheselletsa flash butt ke:

Sethala sa Flash: ho lokisa bolelele ba ho otlolla, ho boloka lebone, lebelo la flash, letsoalo la hona joale;

Mokhahlelo o holimo oa ho qhekella: tumello ea ho forging e holimo, lebelo le holimo la ho forging, khatello e holimo ea forging, clamping force;

Preheating sethaleng: preheating mocheso, preheating nako.

Mosebetsi oa ho otlolla bolelele ke ho etsa bonnete ba tumello e hlokahalang (karolo ea tjheseletsa e khutsufatsang) le ho lokisa sebaka sa mocheso ha ho futhumatsa bohlokoa le ts'ebetso e ka khethoa ho ea ka karolo ea tjheseletsa le thepa ea lintho tse bonahalang, tloaelo e bontša hore bolelele ba ho otlolla ha boa lokela ho ba tlase. ho feta halofo ea bophara ba karolo ea tjheseletsa, ke hore, l = 0.6 ~ 1.0d (d ke bophara ba lepolanka kapa bolelele ba lehlakoreng la lisekoere) e loketse. Ka nako e tšoanang, ha tjheseletsa disebediswa tse sa tšoaneng, e le hore ho fumana kabo e leka-lekaneng mocheso (ka linako tse ling ho nahanoa ka thata-thata ba se nang ferrous tšepe tjheseletsa), weldments tse peli lokela ho sebelisa bolelele fapaneng otlolla.

Nako ea ho cheselletsa hangata e hlahisoa ke bongata ba hona joale, 'me nako ea hona joale le nako ea ho tjheseletsa ke lintlha tse peli tse ka sehloohong tse khethollang mocheso oa ho futhumatsa,' me li ka lokisoa ka mokhoa o nepahetseng ho tse ling. Ha e le hantle, ho kgothaletswa ho boloka kamano e itseng pakeng tsa bongata ba hona joale le nako e fokolang ea welding, le ho sebelisa tlhaloso e thata ha karolo ea sefapano e fokotseha. Boima ba hona joale ba ho tjheseletsa ha butt butt, lisebelisoa tsa tšepe tse nang le conductivity e ntle ea motlakase le ea mocheso, le likarolo tse cheselitsoeng tse nang le karolo e atolositsoeng e lokela ho ba holimo. Bakeng sa ho futhumatsa li-flash butt welding le li-welds tse kholo tsa karolo, letsoalo la hajoale le lokela ho ba tlase.

Ka bobeli khatello ea welding le top forging pressure e na le phello ea ho qhibiliha ha mocheso oa sebaka sa ho kopana le deformation ea polasetiki ea libaka tse fapaneng le tse haufi. Lebelo le holimo la ho forging le khatello e phahameng ea matla a ho qhekella li ka bapisoa, 'me lebelo le holimo la ho forging le ka fokotsoa ka nepo ha lebelo le holimo la forging le le leholo ho lekana.

TheDntshetsopeleProspect eaButtWelding

Ka boithuto bo tebileng ba kamano lipakeng tsa boleng ba tjheseletsa ea ho hanyetsa le mekhoa ea ts'ebetso ea welding le thekenoloji ea ho lemoha marang-rang, ho ka fumanoa boleng bo tsitsitseng haholoanyane. Ho phaella moo, lisebelisoa tsa ho tjheseletsa li ekelitsoe ka ho eketsehileng, 'me mefuta e mengata ea ts'ebeliso ea ho hanyetsa welding e ntse e eketseha le ho feta. Ka tsoelopele e tsoelang pele eatheknoloji ea welding ea ho hanyetsa, ho hanyetsa tjheseletsa ho tla nka boemo ba bohlokoa ho feta tlhahiso ea indasteri e tlang. Haholo-holo lebaleng la tjheseletsa la litšepe tse kholo le tse sa tšoaneng, ho cheseletsa ha flash butt ho na le tebello e ntle ea nts'etsopele.

Kakaretso

Ka nts'etsopele ea indasteri e ncha ea matla, likopo tse ntseng li eketseha tsa tjheseletsa tsa koporo le aluminium, theknoloji ea ho hanyetsa tjheseletsa e lumellana feela le litlhoko tsa 'maraka, e kopantsoe le ts'ebetso e ncha ea ho hanyetsa tjheseletsa le thekenoloji ea taolo e feto-fetohang, ho hanyetsa tjheseletsa nakong e tlang ntshetsopele. fana ka matla a eketsehileng.

Nako ea poso: Aug-30-2024