Haeba u le mocha oa ho hanyetsa welding kapa u batla kutloisiso e hlakileng haholoanyane ea eona, joale u hloka ho bala sengoloa sena ka hloko. Sengoliloeng sena se tla u isa botebong ba lefats'e la ho hanyetsa welding. Hore na o ea qalang kapa o batla ho holisa tsebo ea hau, sengoloa sena se tla u fa leseli la bohlokoa.

Resistance Welding ke Eng?

Resistance welding ke mokhoa oa ho kopanya tšepe o potlakileng haholo, o nang le chelete e ngata. Mokhoa ona oa tjheseletsa o loketse liropeng, manonyeletso a butt, kapa manonyeletso a sa hlokeng ho tiea moea, ka botenya bo ka tlase ho 6mm bakeng sa meaho e mesesaane ea lakane. Ehlile, e ka boela ea tjheseletsa lisebelisoa tsa tšepe tse teteaneng le tse kholoanyane, empa ts'ebetso ea eona ka kakaretso e kanna ea se be ntle joalo ka mekhoa e meng e meng ea tjheseletsa.

Tlhaloso le Metheo

Ho hanyetsa weldingke mokhoa oo li-workpieces tse lokelang ho kopanngoa li behoa pakeng tsa li-electrode tse peli. Ka ho fetisa hona joale ka li-workpieces le libaka tsa ho kopana, ho futhumatsa ho hanyetsa ho etsahala, ho hlahisa mocheso mateanong a li-workpieces. Ho futhumatsa sebakeng sena ho etsa hore sebaka se qhibilihe kapa se fetohe, ha khatello e tsoang ho li-electrode tse peli e kopanya tšepe hammoho.

Ha hona joale e phalla ka conductor, e hlahisa mocheso ka lebaka la ho hanyetsa. Ha ho ntse ho e-na le khanyetso e phahameng, mocheso o ntse o eketseha. Ha litšepe li kopana, khanyetso e kholo haholo ho feta ka hare ho tšepe ka boeona. Ka hona, ha motlakase o moholo o feta pakeng tsa tšepe le electrode, tšepe e chesa ka potlako ka lebaka la mocheso o moholo. Ka nako ena, tšepe e fetoha ductile haholo, 'me ka khatello e sebelisoang, likotoana tse peli tsa tšepe li tlamahane ka mokhoa o sireletsehileng.

Resistance Welding Molao-motheo oa ho sebetsa

Molao-motheo oa ho hanyetsa letheba tjheseletsa le ho thehoa ha manonyeletso ho bontšitsoe Figure 1-1. Metal A le tšepe B li behoa pakeng tsa li-electrode tse peli, 'me khatello e sebelisoa ho li-electrode. Nako e matla e fetisoa pakeng tsa li-electrode tse peli ke transformer ea welder ea ho hanyetsa. Libaka tsa ho kopana tsa li-workpieces li etsa sebaka sa ho kopana le 'mele, seo butle-butle se ntseng se atoloha ha hona joale se chesa. Deformation ea polasetiki le mocheso li tsoela pele ho kenya liathomo sebakeng sa ho kopana, se lebisang ho thehoeng ha motheo o qhibilihisitsoeng. Mokotla o qhibilihisitsoeng o hola ka sebopeho sa likristale tse kholo, o sutumelletsa likarolo tse phahameng tsa alloy ho ea ho tse ling. Ha li-electrode tsa welder li tloha holim'a tšepe, 'me tšepe e pholile, li-workpieces li kopantsoe hammoho, ho theha maqhama a matla a tšepe. Sebaka se kopantsoeng se nyamela, se siea nugget ea weld.

1-1

Lintlha tse Amang Resistance Welding

Ho hanyetsa weldingke mokhoa oa ho cheselletsa o sebelisang motlakase ho hlahisa mocheso ho kopanya likarolo tsa tšepe. Joalokaha ho boletsoe pejana, molao-motheo oa ho hanyetsa welding haholo-holo o bakoa ke molao oa Joule oa ho futhumatsa, moo moloko oa mocheso oa ho futhumatsa o khethoa ka ho khetheha ke litekanyetso tse kang nako ea hona joale, ea ho hanyetsa le ea ho cheselletsa. E ka hlalosoa ka foromo e latelang:

Q = I²Rt

Moelelo oa parameter ka 'ngoe ea welding:

Q - Mocheso (J)

I - Welding current (A)

R - Resistance (Ω)

t - Nako ea ho cheselletsa (s)

Welding Current

Hona joale ho na le tšusumetso e kholo mocheso o hlahisoang nakong ea ho cheselletsa, joalokaha ho bontšitsoe ka foromo. Boleng ba lisekoere ba hona joale bo ama mocheso, ho bolelang hore ha e ntse e phahama, mocheso o tla eketseha ka potlako. Ka hona, ha u lokisa liparamente tsa welding pele ho welding, ho bohlokoa ho beha mochini o nepahetseng. Haeba hona joale welding e le nyane haholo, weld e ke ke ea qhibiliha, 'me ha ho na motheo oa fusion o tla theha. Haeba hona joale e le kholo haholo, motsoako oa motsoako o tla hōla ka potlako, o baka ho hasana ho feteletseng nakong ea ho cheselletsa le ho senya li-electrode.

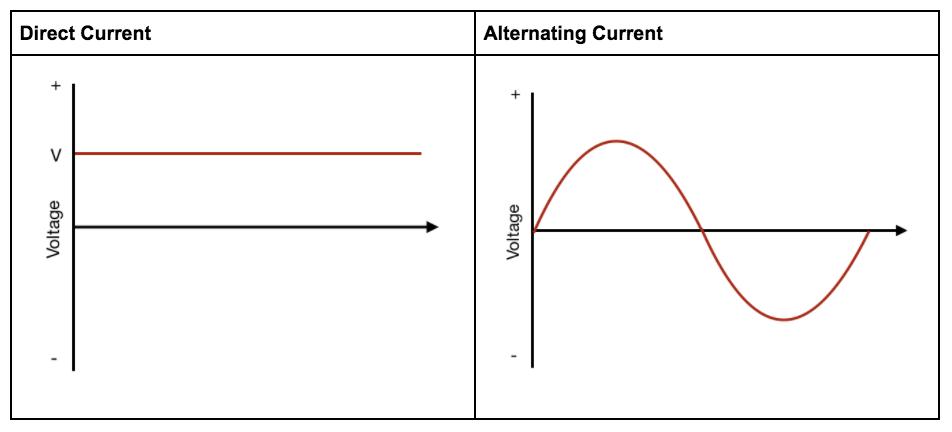

Hona joale welding e arotsoe haholo ka alternating current (AC) le direct current (DC), joalokaha ho bontšitsoe setšoantšong se ka tlase. Themetjhini e tjheseletsang lethebare sebelisa li boetse li arotsoe ka ho toba hona joale letheba tjheseletsa mechine le alternating hona joale letheba tjheseletsa mechine. Mechini ea li-welding ea hajoale e sebelisa matla a mekhahlelo e meraro, e netefatsa phepelo e leka-lekaneng ea matla, 'me e khona ho fihlella maqhubu a tjheseletsa a fetang 1000 Hz, e leng se bakang ho nepahala ho holimo. Ba boetse ba na le monyetla oa ho ba le tlhokahalo e tlase ea matla ho tsoa ho marang-rang a matla, e leng se etsang hore li-welders tsena tse bolokang matla li tumme haholo har'a baetsi ba indasteri ea tlhahiso. Mechini e chenchang ea hona joale ea li-welding e na le phallo ea karolo e le 'ngoe ea 50Hz, matla a mangata a tsoelang pele, le litlhoko tse phahameng tsa marang-rang a matla. Ho feta moo, li na le matla a tlase a ho cheselletsa, a hlokang nako e telele ea ho cheselletsa.

Ikopanye le Resistance

Ho tsoa ho foromo, ho bonolo ho bona hore khanyetso e lekana ka kotloloho le mocheso o hlahisoang. Ha khanyetso e phahame, mocheso o moholo o hlahisoang nakong ea welding. Resistance e ajoa likarolong tse fapaneng tsa electrode le workpiece. Nakong ea welding, khanyetso e phahameng ka ho fetisisa e etsahala sebakeng sa ho kopana sa workpiece, e leng se hlahisang mocheso o phahameng ka ho fetisisa oa mocheso. E latelang ke ho hanyetsa sebakeng sa ho kopana pakeng tsa workpiece le electrode. Leha ho le joalo, kaha electrode e pholile ka metsi 'me e potlakela ho pholile, mocheso o fokotseha ka potlako. Ka lehlakoreng le leng, khanyetso ea ho kopana pakeng tsa li-workpieces, le hoja e nyamela, e na le mocheso o fokolang oa mocheso, o lebisang ho mocheso o phahameng. Ka hona, ke sebaka se senyenyane feela lipakeng tsa li-workpieces se ka fihlelang mocheso o hlokahalang ho theha motsoako oa fusion le weld hammoho.

Ho feta moo, mocheso le khatello ea electrode li ama khanyetso. Ha mocheso o ntse o phahama, matla a tlhahiso ea tšepe a fokotseha, a eketsa sebaka sa ho ikopanya pakeng tsa lisebelisoa tsa mosebetsi le pakeng tsa workpiece le electrode, e leng se etsang hore ho fokotsehe ho hanyetsa. Ho eketsa khatello ea electrode ho etsa hore sebaka sa mosebetsi se be bonolo, se holisa sebaka sa ho ikopanya le ho fokotsa ho hanyetsa. Ka lebaka leo, ho na le ntho e makatsang moo, nakong ea ho cheselletsa thepa e tloaelehileng, khanyetso e eketseha nakoana ka mor'a ho sebetsa, 'me ha matla a tima le mefuta ea mantlha ea fusion, khanyetso e qala ho fokotseha.

Nako ea ho Welding

Ha nako e ntse e feta, mocheso o hlahisoang o phahame. Ka mokhoa ona, hona joale le nako li ka tlatsana. Ha o batla weld e matla, o ka seta motlakase o phahameng ka nako e khuts'oane ho hlahisa mocheso ka potlako le ho theha motsoako oa motsoako ho phethela welding. Ntle le moo, o ka beha nako e tlase nako e telele, empa mokhoa ona o na le moeli. Haeba nako e behiloe nako e telele haholo, e ka lebisa ho qhaqhoa ho feteletseng 'me e ka etsa hore electrode e khomarele. Ebang ke ea hona joale kapa ea nako, ho na le meeli. Ha u beha litekanyo, u lokela ho nahana ka thepa le botenya ba workpiece, hammoho le matla a mochine oa welding.

Thepa Thepa

Thepa ea workpiece e ama haholo resistivity lona, e leng o phetha karolo ea bohlokoa ho tjheseletsa tlhahiso mocheso. Ha tjheseletsa tšepe e sa hloekang, e nang le resistivity e phahameng le conductivity e fokolang ea mocheso, ho bonolo ho hlahisa mocheso empa ho thata ho o qhala, kahoo maqhubu a manyenyane a hlokahala. Ha ho cheselletsa li-alloys tsa aluminium tse nang le resistivity e tlase le conductivity e ntle ea mocheso, ho thata ho hlahisa mocheso empa ho bonolo ho o qhala, kahoo ho hlokahala maqhubu a maholo. Litšepe tse kang silevera le koporo li na le conductivity e phahameng ea mocheso le resistivity e tlaase, kahoo esita le ka maqhubu a phahameng, ha li hlahise mocheso o mongata empa li ka o tsamaisa. Ka hona, litšepe tsena ha li tšoanelehe bakeng sa tjheseletsa ea ho hanyetsa empa li ka sebelisoa e le lisebelisoa tsa elektrode.

Moqapi oa Electrode le Geometry

Sebopeho le thepa ea eleketrode e boetse e ama ho hlahisa mocheso. Sebaka sa ho kopana pakeng tsa electrode le workpiece e ama sekhahla sa hona joale. Tšebeliso ea khafetsa ea li-electrode e ka lebisa ho senyeha le ho senyeha, ho eketsa sebaka sa ho ikopanya le ho fokotsa matla a ho cheselletsa. Ka hona, re hloka ho lokisa le ho khutlisa malebela a li-electrode hang-hang. The mocheso conductivity le ho hanyetsa eleketrode ama mocheso phetiso. Ka hona, re lokela ho khetha lisebelisoa tse nang le conductivity e ntle ea mocheso le ho hanyetsa ho tlaase.

Tokiso ea Sefahleho

Sebopeho le thepa ea li-electrode li boetse li ama ho hlahisa mocheso. Sebaka sa ho kopana pakeng tsa electrode le workpiece e ama sekhahla sa hona joale. Ha li-electrode tsa rona li sebelisoa khafetsa 'me li felloa ke matla, li eketsa sebaka sa ho ikopanya, e leng se lebisang ho fokotseng matla a ho cheselletsa. Ka hona, re hloka ho lokisa le ho fetola malebela a li-electrode hang-hang. The conductivity ea mocheso le resistivity ea li-electrode li ama ho fetisoa ha mocheso. Ka hona, re lokela ho khetha thepa e nang le conductivity e ntle ea mocheso le resistivity e tlaase.

Mefuta ea Resiboemo Welding

Ka lebaka la litlhaloso tse fapaneng tsa sehlahisoa le litlhoko tsa welding, mekhoa e fapaneng ea li-welding e sebelisoa ho phethela mosebetsi. Resistance welding e ka aroloa ka li-welding tsa spot, welding projection, seam welding, le butt welding ho ipapisitsoe le ts'ebetso ea welding.

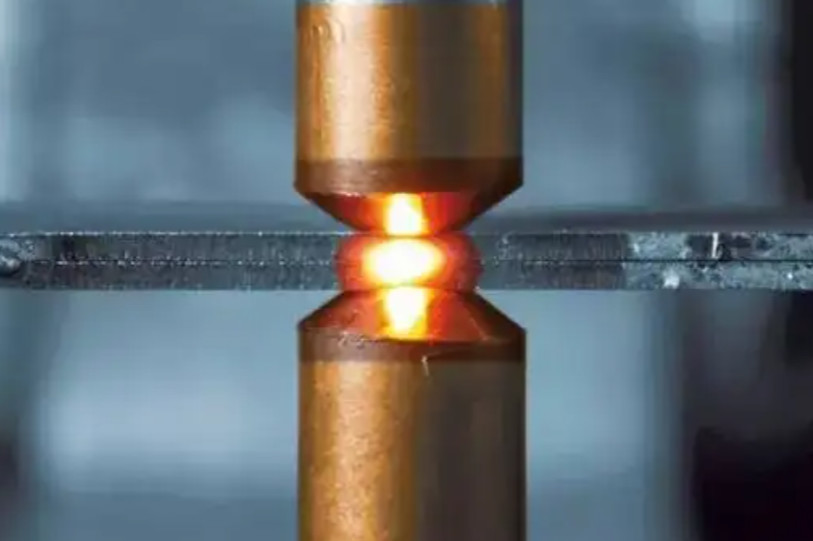

Spot Welding

Ho tjheseletsa lethebake mokhoa oa ho tjheseletsa moo tšepe e hatelloang hammoho ke li-electrode tse ka holimo le tse ka tlaase ebe li kenngoa ka ho feta hona joale ho eona. Ke mokhoa o tloaelehileng oa ho tjheseletsa, o bonolo ho o sebetsa, mme o hloka maemo a tlase ho basebetsi. Ka lebaka la ts'ebetso ea eona e ikhethang, welding ke khetho ea mantlha bakeng sa likarolo tsa tšepe tsa welding boenjiniere ba sefofane mme e sebelisoa haholo ho tjheseletsa 'mele oa likoloi le likarolo tse ling. Hangata e sebelisoa ho tjheseletsa lilakane tse tšesaane tsa tšepe e tlase ea khabone, aluminium, tšepe e sa jeleng paate, galvanized steel, le lipoleiti tse ling tse tšesaane, hangata botenya ba limilimithara tse 3.

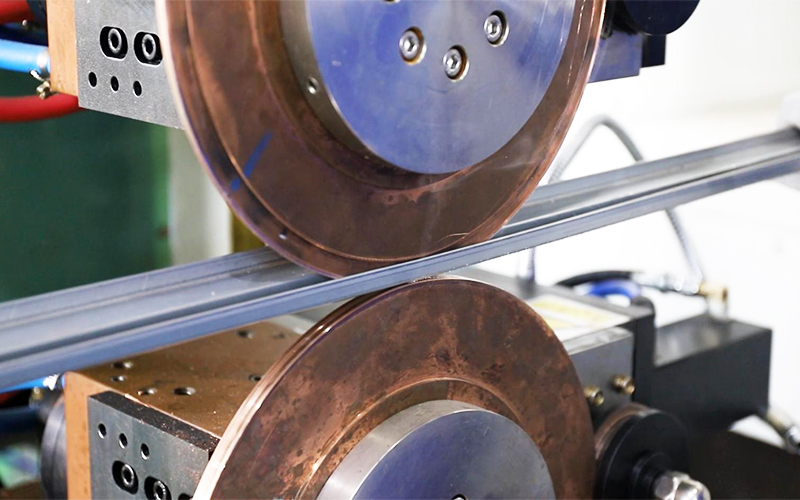

Seam Welding

Seam weldinghangata e kenyelletsa ho kopanya likarolo tse peli tsa tšepe. Lisebelisoa tse peli tsa tšepe li behiloe pakeng tsa li-electrode tse peli tsa rolara. Ha elektrode e le 'ngoe e bilika ebe e sebelisa khatello, ho tsoa ho sa khaotseng kapa ka nakoana ho etsahala. Mocheso o hlahisoang sebakeng sa ho roala ha electrode o qhibilihisa lisebelisoa ebe o li kopanya, ho etsa seam e tsoelang pele ea weld. Mokhoa ona o sebelisoa haholo bakeng sa likarolo tsa tšepe tsa welding tse hlokang manonyeletso a tiisitsoeng. Kaha sebaka sa ho tjheseletsa se batla se le selelele, ho thibela ho se tsamaisane hantle, hangata re sebedisa tjheseletsa ya letheba bakeng sa ho beha maemo pele ho seam welding.

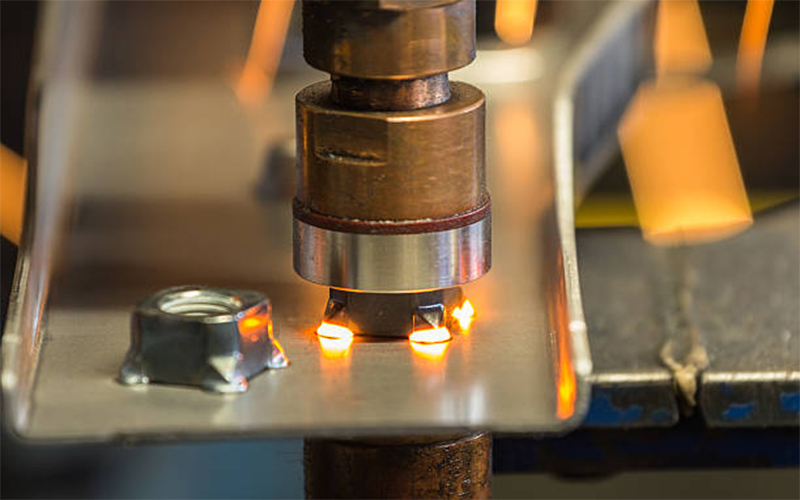

Projection Welding

Ho tjheseletsa projekeke mefuta e fapaneng ea ho cheselletsa letheba, moo sebopeho sa sebaka sa weld se ts'oanang le ho cheselletsa matheba, empa projeke ea projeke e sebelisoa hangata bakeng sa lisebelisoa tse nang le lintlha tse phahamisitsoeng. Ho ba teng ha lintlha tsena tse phahamisitsoeng ho fokotsa sebaka seo hona joale se fetang ho sona, ho eketsa sekhahla sa hona joale sebakeng sa welding. Mocheso ona o tsepamisitsoeng o thusa ho hokahanya ha motsoako. Mokhoa ona oa welding o tsejoa e le projection welding. Projection welding e ka etsa fusion cores e le 'ngoe kapa ho feta moo lenonyeletsong hang. Nakong ea tjheseletsa, motlakase o hlokahalang bakeng sa projeke ea ho tjheseletsa sebakeng se le seng sa weld o tlase ho feta oa ho cheselletsa matheba. Leha ho le joalo, pele setšoantšo se seng le se seng se pshatleha, hona joale ho hloka ho qhibilihisa projeke; ho seng joalo, ho ka ba le palo e kholo ea spatter. Projection welding e ka sebelisoa ho cheselletsa linate, liboutu kapa lipoleiti tse nang le lintlha tse phahamisitsoeng, 'me e sebelisoa haholo ha ho etsoa lisebelisoa tsa elektroniki le tsa likoloi.

Butt Welding

Ho tjheseletsa butte kenyelletsa ho hokahanya lifahleho tsa ho qetela tsa li-workpieces tse peli tsa tšepe, ho li beha pakeng tsa li-electrode, ho tiisa li-workpieces tse peli ka mokhoa o sireletsehileng, le ho sebelisa boemo bo phahameng ba hona joale ho hlahisa mocheso, ho qhibiliha sebaka sa ho kopana sa li-workpieces le ho li kopanya hammoho. The butt welding e arotsoe hape ka flash butt welding le resistance butt welding.

Flash butt welding ke ts'ebetso e potlakileng ea ho tjheseletsa e sebelisang matla a holimo ho qhibilihisa lisebelisoa tsa mosebetsi ka potlako, ho sebelisa khatello ea ho theha khokahano ea mohato o tiileng. E atisa ho sebelisoa bakeng sa ho tjheseletsa libaka tse kholo tsa lithupa tsa tšepe, maqephe le liphaephe, tse nang le libaka tse ngata tse fihlang ho 20,000mm² ho ea holimo. Nakong ea ts'ebetso ea ho tjheseletsa, litlhase li hlahisoa sebakeng sa ho kopana, ka hona lebitso la flash butt welding. E ka tjheseletsa tšepe e phahameng ea khabone, tšepe e sa hloekang, lialloi tsa aluminium, hape e ka tjheseletsa litšepe tse sa tšoaneng tse kang koporo le aluminium.

Resistance butt welding e sebelisa mocheso oa ho hanyetsa ho tlisa manonyeletso a workpiece sebakeng sa polasetiki ka mocheso o phahameng, ho phethela ts'ebetso ea welding ka matla a forging. E loketse lihokelo tsa ho tjheseletsa tse nang le libaka tse fapaneng ka har'a 250mm², hangata e sebelisetsoa ho tjheseletsa lithapo tse nyane tsa tšepe, lithupa le likhoele.

Bohlokoa ho Tlhahiso

- Resistance welding ha e hloke ho eketsoa ha tšepe nakong ea ts'ebetso ea welding, e leng se bakang katleho e phahameng ea welding le tšilafalo e fokolang.

- Ka lebaka la ho tsitsisa le botsitso ba eona, li-welding tsa ho hanyetsa li bonolo ho iketsetsa, li kopantsoe ka mokhoa o se nang moeli le li-automation ho ntlafatsa ts'ebetso ea tlhahiso le ho boloka mosebetsi.

- Ha ho bapisoa le mekhoa e meng ea ho tjheseletsa, ho tjheseletsa tjheseletsa ho na le tjhelete e ngata. Ntlha ea pele, litšenyehelo tsa thepa bakeng sa ho tjheseletsa tjheseletsa li batla li le tlaase, 'me ea bobeli, ho na le litšila tse fokolang tsa thepa nakong ea ts'ebetso ea ho hanyetsa. Sena se fokotsa haholo litšenyehelo tsa tlhahiso bakeng sa baetsi ba indasteri ea tlhahiso.

- Resistance welding e sebelisoa haholo liindastering tse fapaneng 'me e bohlokoa haholo makaleng a kang sefofane, tlhahiso ea likoloi le tse ling.

- Resistance welding e loketse bakeng sa ho tjheseletsa mefuta e fapaneng ea litšepe indastering ea tlhahiso, ho kenyeletsoa tšepe e sa hloekang, tšepe ea k'habone, aluminium, koporo le tse ling, e etsa hore e sebetsane le ts'ebeliso ea eona.

Lisebelisoa

Resistance welding e sebelisoa haholo, haholo liindastering tse kang lisebelisoa tsa likoloi, sefofane, lisebelisoa tsa elektroniki le indasteri e boima. Ha tlhoko ea likarolo tsa tšepe tse cheselitsoeng liindastering tse fapaneng e ntse e hola, ho behiloe litekanyetso tse phahameng tsa theknoloji ea welding, e tsamaisang tsoelo-pele le nts'etsopele ea ho hanyetsa welding.

Likopo tsa Indasteri ea Likoloi

Ha ho etsoa likoloi, moo polokeho le botsitso e leng tsa bohlokoa, ho hanyetsa welding ke mokhoa o sebelisoang hangata. Hangata e sebelisoa bakeng sa ho kopanya likarolo tse fapaneng tsa tšepe 'meleng oa likoloi, joalo ka marulelo, mamati, lishiti le litšepe. Resistance welding e fana ka ts'ebetso e phahameng, boleng bo tsitsitseng ba welding, 'me e sebetsa habonolo, e etsa hore e be ts'ebetso ea bohlokoa indastering ea tlhahiso ea likoloi.

Likopo tsa Indasteri ea Aerospace

Resistance welding e sebelisoa khafetsa ho hokahanya likarolo tsa tšepe lifofaneng le liroketeng, joalo ka ho kopanya mapheo a sefofane le li-fuselage, hammoho le likarolo tse fapaneng tsa tšepe. Likarolo tsena li tlameha ho ba le matla a phahameng le ho tšoarella, tse nang le litlhoko tse thata bakeng sa boleng ba manonyeletso, e leng moo ho hanyetsanang le welding ho ipabolang. Resistance welding e bapala karolo ea bohlokoa indastering ea lifofane, 'me tsoelo-pele lebaleng lena e boetse e thusoa ke lekala la lifofane.

Lisebelisoa tsa Indasteri ea Elektronike

Resistor welding e sebelisoa hangata bakeng sa likarolo tsa elektroniki le likarolo tse ling tsa tšepe lisebelisoa tsa elektroniki. E fana ka ts'ebetso e phahameng ea welding 'me e loketse ho hokela likaroloana tse nyane joalo ka li-chips tsa elektroniki le likhoele. Mehleng ea kajeno e fetohang ka potlako ea lisebelisoa tsa elektroniki, resistor welding e potlakisa kopano ea likarolo tsa elektroniki, e tsamaisang tsoelo-pele ea indasteri.

Likopo tse boima tsa indasteri

Resistance welding e atisa ho sebelisoa bakeng sa ho tjheseletsa likarolo tse kholo tsa tšepe ka marokho le mehaho, joalo ka li-flanges tse ka tlaase tsa borokho le matla a tšepe. E boetse e sebelisoa ha ho etsoa mechine e meholo ea ho hokahanya likarolo tsa tšepe. Ka theknoloji ea eona e sebetsang hantle le e tsitsitseng ea ho tjheseletsa, ho hanyetsa welding e fetohile e 'ngoe ea mekhoa ea bohlokoa ea ho sebetsana le indasteri e boima. E netefatsa polokeho ea lisebelisoa tse boima le mehaho.

Thepa le Likaroloana

Mechini ea ho Welding

Mechini ea li-welding tse hanyetsanangli arotsoe ka mekhahlelo e mene e meholo: mechini ea ho tjheseletsa matheba, metjhini e tjheseletsang projeke, metjhini ya ho tjheseletsa seam, le metjhini ya ho tjheseletsa butt, e ipapisitseng le ditshebetso tse fapaneng. Khetha lisebelisoa tse loketseng tsa ho cheselletsa ho latela litšobotsi tsa thepa le libopeho.

Li-electrode

Theelectrodeke karolo ea bohlokoa ho netefatsa boleng ba welding. Thepa e ka sehloohong bakeng sa li-electrode tse tjheseletsang ke: chromium zirconium koporo, aluminium oxide koporo, beryllium cobalt koporo, tungsten, molybdenum, graphite, joalo-joalo Ho itšetlehile ka li-workpieces tse fapaneng tse nang le li-welded, li-electrode li arotsoe ka li-electrode tse bataletseng, li-electrode tse chitja, li-electrode tsa linate, bolt. li-electrode, joalo-joalo Ka tloaelo, ho lokisa li-electrode ho kenyelletsa ho kenngoa ha tapered, ka taper ratios hangata ka 1:10 le 1:5.

Mekhoa ea ho Pholisa

Nakong ea ts'ebetso, mechini ea tjheseletsa ea ho hanyetsa e hloka metsi a potolohang ho likarolo tse pholileng joalo ka li-electrode le li-transformer. Ka hona, re kenya sistimi e pholileng bakeng sa mechini ea welding ea ho hanyetsa. Mocheso oa metsi a pholileng o lokela ho ba ka tlase ho 30 ° C. Haeba mocheso o phahame haholo, o ka etsa hore mochine oa welding o koalehe. Ho molemo ho sebelisa metsi a pholiso a se nang litšila bakeng sa ho potoloha ho thibela matheba a metsi le ho thiba ha lipeipi.

Joang ho Khetha The Right Welding Process?

Khetho ea mokhoa oa welding e itšetlehile ka lintlha tse ngata.

Botenya le Sebopeho sa Mosebetsi: Li fapanemekhoa ea ho cheselletsali loketse li-workpieces tsa botenya le libopeho tse fapaneng. Mohlala, ho tjheseletsa tjheseletsa ka kakaretso ho loketse feela bakeng sa tjheseletsa mashiti a tshesane a tshesane, athe disebediswa tse bopehileng ka mokgwa o sa tlwaelehang le tse teteaneng hangata di tjhesetswa ho sebedisa arc welding.

Litlhoko tsa Boleng ba Welding: Boleng bo lakatsehang ba tjheseletsa bo boetse bo laela khetho ea mokhoa oa ho tjheseletsa. Bakeng sa li-workpieces tse hlokang tiiso e phahameng le matla a kopantsoeng, mekhoa ea ho tjheseletsa e finyellang litlhoko tsena e lokela ho khethoa.

Ntlafatso ea Tlhahiso le Litšenyehelo: Haeba ho hlokahala tlhahiso e phahameng ea selemo le selemo, hoa hlokahala ho khetha mokhoa oa ho tjheseletsa ka katleho e phahameng. Litšenyehelo le tsona li lokela ho nkoa.

Mabaka a Tikoloho: Mekhoa e meng ea ho cheselletsa litšepe e hlahisa litšila le mesi, e bakang tšilafalo ea tikoloho. Ka hona, lintlha tsa tikoloho li lokela ho tsotelloa ha ho khethoa mokhoa oa ho tjheseletsa.

LBH:

Mefokolo ea resistance welding ke efe?

Resistance welding ha e loketse ho tjheseletsa likarolo tse kholo tsa tšepe.

U etsa bonnete ba tšireletseho joang ho resistance welding?

Ha u sebelisa tjheseletsa ea ho hanyetsa, roala helmete ea tšireletso le likhalase tsa tšireletso.

Nka fumana koetliso ea li- resistance welding joang?

U ka kena thupelong ka hoho hanyetsa moetsi oa tjheseletsa.

Mathata a ka sehloohong a boleng ba ho hanyetsa manonyeletso a tjheseletsa ke afe?

Lenonyeletso le batang la solder, matla a sa lekaneng, deformation ea welding, oxidation.

Mekhoa ea tlhahlobo ea ho hanyetsa manonyeletso a welding

Teko e senyang, tlhahlobo ea microscopic, tlhahlobo ea pono, tlhahlobo ea metallographic, tlhahlobo ea ultrasonic.

Nako ea poso: Apr-02-2024