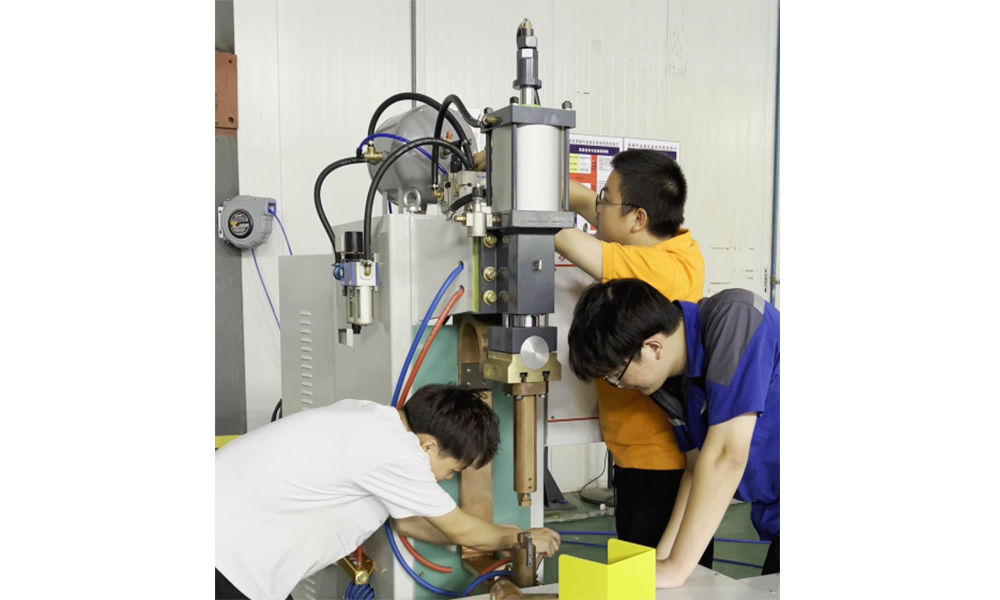

Spot welderske lisebelisoa tse sebelisoang hangata liindastering tse sa tšoaneng, tse sebelisoang haholo ho hokahanya likarolo tsa tšepe ka mokhoa o nepahetseng le ka mokhoa o nepahetseng, e le ho etsa bonnete ba hore ts'ebetso ea eona e ntle ka ho fetisisa le bophelo ba ts'ebeletso, tlhahlobo ea kamehla le tlhokomelo ea thepa ke ea bohlokoa, sehlooho sena se tla bua ka seo u lokelang ho se ela hloko ha ho etsa tlhahlobo ea li-welder.

- Tšireletseho pele:Pele o qala tlhahlobo leha e le efe, hoa hlokahala ho etsa bonnete ba hore mochine o khaotsoe ho tloha phepelong ea motlakase ho thibela ho qala ka phoso nakong ea tlhahlobo. Ho phaella moo, apara ka tsela e loketsengthepa ea ho itšireletsa(PPE), joalo ka liatlana le likhalase tsa polokeho. Itšireletse likotsing tse ka bang teng.

- Tlhahlobo ea kantle:Ntlha ea pele, hlahloba ka mahlo likarolo tsa ka ntle tsa welder, hlahloba lithapo, li-connectors, li-electrode le lisebelisoa bakeng sa matšoao a hlakileng a ho senyeha kapa ho senyeha, 'me u netefatse hore mochine oa ho futhumatsa o sebetsa hantle le hore potoloho ea pholileng ha e na liphoso.

- Boemo ba Electrode: Boemo ba Electrode bo na le phello e kholo ho boleng ba welding. Sheba hore na electrode e na le tšusumetso, deformation kapa matšoao a pitting, haeba electrode e na le ts'ebetso ea ho apara, e ka ba fatše ho boloka ho tsitsisa le ho tšepahala ha welding.

- Tlhahlobo ea thapo le khokahanyo:Sheba lithapo tse cheselitsoeng le likhokahano bakeng sa matšoao a tšenyo, ho pepeseha, kapa likhokahano tse hlephileng. Ho hloleha ha thapo ho ka baka arcing, e ka bang kotsi mme ea ama boleng ba weld.

- Phepelo le taolo ea motlakase:Hlahloba phepelo ea motlakase le phanele ea taolo bakeng sa liphoso. Etsa bonnete ba hore likonopo tsohle, li-switches, le likonopo li sebetsa hantle ho netefatsa hore li arabela kamoo ho neng ho lebelletsoe.

- Sistimi ea ho pholisa:Hoa hlokahala tsamaiso ea ho pholisa ho thibela ho chesa haholo nakong ea nako e telele ea ts'ebetso. Hlahloba hore na boemo ba se pholisang ka letamong la se pholileng ke ntho e tloaelehileng, 'me u hlahlobe hore na mohala oa sepholi ha oa koaloa, 'me haeba ho hlokahala, u lokela ho o hloekisa kapa ho o nkela sebaka.

- Grounding le insulation: Ho beha fatše ka nepo ho bohlokoa haholo bakeng sa polokeho ea motlakase le welding e sebetsang. Lekola khokahano ea fatše 'me u netefatse hore lithapo le lithapo li matla ebile ha li na kutu ho thibela li-circuits tsa motlakase.

- Boleng ba weld:Liteko tsa weld li etsoa molemong oa lisebelisoa ho lekola boleng ba weld le botsitso. Haeba ho na le mefokolo leha e le efe e fumanoang, e ka 'na ea bontša hore ho na le bothata ka mochine oa ho seta, li-electrode kapa likarolo tse ling.

- Tlhokomelo:Hlahloba tlhokomelo ea mochine ho netefatsa tlhokomelo ea kamehla le ho lekanya, tseo u lokelang ho li etsa ka nako e nepahetseng ho qoba mathata a mang.

- Litlhahlobo tsa litsebi:Le hoja tlhahlobo ea kamehla ea pono e le ea bohlokoa, ho khothalletsoa hore thepa e hlahlojoe khafetsa ke setsebi se tšoanelehang. Tlhahlobo ea setsebi e ka senola mathata a ka 'nang a se ke a bonoa nakong ea tlhahlobo ea pono.Ho laola welder ka boemo bo tloaelehileng hangata ho hloka tlhokomelo e hlokolosi likarolong tsohle, ho tloha mehatong ea tšireletso ho ea ho boemo ba li-electrode, lithapo, li-control le mekhoa ea ho pholisa. Ka litsamaiso tse felletseng le tse hlophisitsoeng, o ka ntlafatsa ts'ebetso le ho lelefatsa bophelo ba welder, ho fokotsa nako ea ho theoha le ho netefatsa ts'ebetso e bolokehileng. E hlokahala lits'ebetsong tse fapaneng tsa indasteri.

Ho laola welder ka boemo bo tloaelehileng hangata ho hloka tlhokomelo e hlokolosi likarolong tsohle, ho tloha mehatong ea tšireletso ho ea ho boemo ba li-electrode, lithapo, li-control le mekhoa ea ho pholisa. Ka litsamaiso tse felletseng le tse hlophisitsoeng, o ka ntlafatsa ts'ebetso le ho lelefatsa bophelo ba welder, ho fokotsa nako ea ho theoha le ho netefatsa ts'ebetso e bolokehileng. E hlokahala lits'ebetsong tse fapaneng tsa indasteri.

Nako ea poso: Aug-20-2024