ADB-100T Platform indawo welding machine

Intshayelelo yeMveliso

Intshayelelo yeMveliso

-

cinezela ngokufanelekileyo i-welding spatter kwaye ufumane iziphumo ezizinzileyo nezikumgangatho ophezulu

Ukunikezelwa kobushushu obuqhubekayo obuveliswa yi-flat output current yomatshini we-welding we-IF wenza ukuba ukushisa kwe-nugget kuphakame ngokuqhubekayo. Ngexesha elifanayo, ulawulo oluchanekileyo lwe-slope yangoku ekhulayo kunye nexesha aliyi kubangela i-spatter ngenxa yokutsiba kobushushu kunye nexesha elingalawulekiyo lokunyuka kwangoku.

-

Amandla amafutshane-ngexesha, ukusebenza kakuhle kwe-thermal, imilo emihle ye-welding

I-IF spot welder ine-flat output welding current, eqinisekisa ukusebenza kakuhle kunye nokubonelela ngokuqhubekayo kobushushu be-welding. Kwaye ixesha-ngexesha lifutshane, lifikelela kwinqanaba le-ms, elenza ukuba indawo ye-welding ichaphazele ukushisa encinci, kwaye i-solder joints yenziwe kakuhle.

-

Ulawulo oluchanekileyo oluchanekileyo

Ngenxa yokusebenza rhoqo (ngokuqhelekileyo i-1-4KHz) yomatshini wokuwelda indawo ye-Inverter, ukuchaneka kokulawulwa kwengxelo ngama-20-80 amaxesha omatshini wokuwelda we-AC jikelele kunye nomatshini wokuwelda wendawo yesibini, kunye nokuchaneka kokulawulwa kwemveliso. nayo iphezulu kakhulu.

-

Ukonga amandla

Ngenxa yokusebenza kakuhle kwe-thermal, i-welding encinci ye-welding kunye nelahleko encinci yentsimbi, umatshini we-inverter welding unokugcina amandla angaphezu kwama-30% kunomatshini we-AC we-welding kunye nomatshini wokuwelda indawo yesibini xa udibanisa umsebenzi ofanayo.

-

I-inverter welder ifanelekile kwibhalansi yokunikezelwa kwamandla egridi, ngaphandle kwezixhobo zembuyekezo yamandla

Isetyenziselwa ukuwelda indawo kunye ne-nut projection welding yentsimbi ephezulu-yomelele kunye nentsimbi eshushu eyenziweyo kwishishini lokwenziwa kweemoto, ukuwelda indawo kunye ne-multi-point projektha ye-welding yeplate yentsimbi ephantsi kwekhabhoni, ipleyiti yentsimbi, ipleyiti enamagqabhagqabha, intsimbi yokumelana kunye ukuwelda indawo yocingo lobhedu kushishino lombane oluphezulu noluphantsi, ukuwelda indawo yesilivere, ukuwelda indawo yesilivere ehlanganisiweyo, njl.

Iisampulu zeWelding

Iisampulu zeWelding

Iphakheji ye-TO46

Iphepha lobhedu lesiseko se-capacitor

ucingo lwephini

I-Motor rotor pin

Thermostat steel stainless

Nickel yobhedu ene-tin-plated

Umgca wamanqaku amane

Umatshini wokuthunga umsonto hook

Amandla amatsha IGBT pin wire

itheminali yocingo ene-enameled

iteyiphu ephothiweyo ezenzekelayo

Iqokobhe lentsimbi diode ikepusi

I-Motor terminal yoqhagamshelwano ngocingo

Diode bump

Icwecwe lenikelo ucingo lobhedu

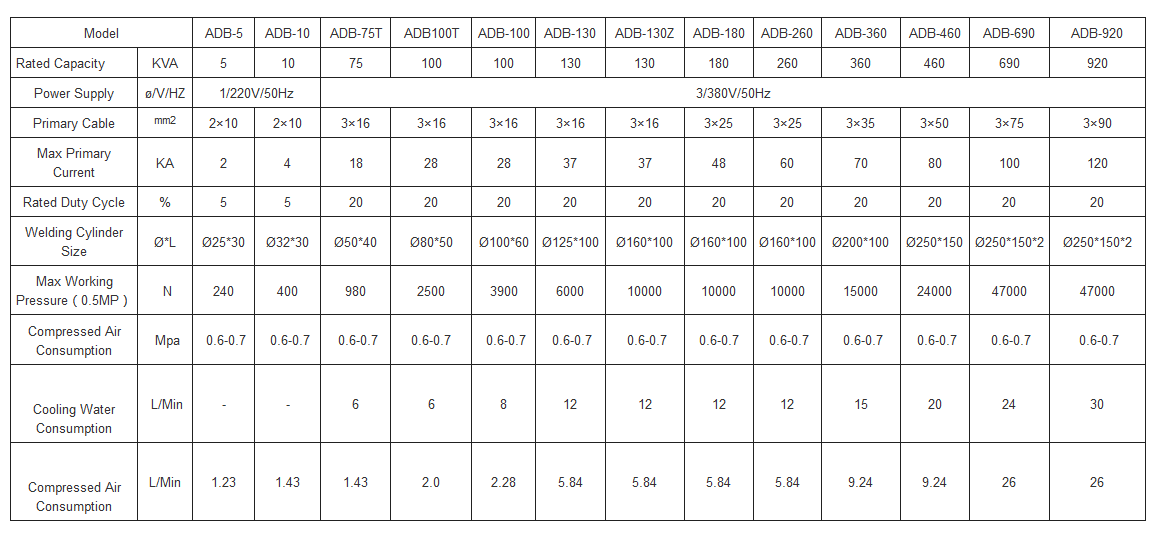

Welder Iinkcukacha

Welder Iinkcukacha

Inkqubo yesiko

Inkqubo yesiko

I-Welder FAQ

I-Welder FAQ

- Umbuzo: Yintoni i-spot welder?

A: Isixhobo sokuwelda sisixhobo sesinyithi esisetyenziselwa ukuwelda iinxalenye ezimbini zentsimbi kunye.

- Q: Uthini umgaqo wokusebenza kumatshini wokuwelda?

A: Izixhobo zokuwelda zisebenzisa ubushushu obuphezulu kunye noxinzelelo ukuwelda iindawo ezimbini zentsimbi kunye ukwenza uqhagamshelo olomeleleyo.

- Umbuzo: I-spot welders isebenzisa ubushushu obuphezulu kunye noxinzelelo ukuwelda iindawo ezimbini zetsimbi kunye ukwenza uqhagamshelwano oluqinileyo.

A: Indawo yokudibanisa ifanelekile kwizinto ezininzi zetsimbi, kuquka intsimbi, ubhedu, i-aluminiyam, intsimbi, njl.

- Umbuzo: Zeziphi iingenelo eziphambili ze-spot welder?

A: Eyona nto iluncedo kumatshini wokuwelda isantya esikhawulezayo, ukusebenza kakuhle, ixabiso eliphantsi, kunye namandla aphezulu okuwelda.

- Umbuzo: Zeziphi izinto ezingalunganga eziphambili ze-spot welders?

A: Eyona nto ingalunganga ye-welder yendawo kukuba ilungele kuphela ukuwelda kweepleyiti zetsimbi ezibhityileyo, kwaye ayinakusetyenziselwa ubungakanani obukhulu okanye iindawo ezishinyeneyo.

- Q: Buthini ubomi benkonzo yespot welder?

A: Ubomi benkonzo ye-spot welder buxhomekeke kubuninzi bokusetyenziswa, umgangatho kunye nokugcinwa. Ngokuqhelekileyo, i-welder efanelekileyo iya kuhlala iminyaka emininzi.

Thumela i-imeyile kuthi

Thumela i-imeyile kuthi