ADB-260 MFDC indawo umatshini welding

Intshayelelo yeMveliso

Intshayelelo yeMveliso

-

I-01 inokucinezela ngokufanelekileyo i-welding spatter kwaye ifumane iziphumo ezizinzileyo kunye neziphezulu ze-welding

Ukunikezelwa kobushushu obuqhubekayo obuveliswa yi-flat output current ye-intermediate frequency welding machine yenza ubushushu be-nugget buphakame ngokuqhubekayo. Ngexesha elifanayo, ulawulo oluchanekileyo lwe-slope yangoku ekhulayo kunye nexesha aliyi kubangela i-spatter ngenxa yokutsiba kobushushu kunye nexesha elingalawulekiyo lokunyuka kwangoku. Velisa.

-

02 Amandla amafutshane-ngexesha, ukusebenza kakuhle kwe-thermal, imilo entle ye-welding

I-intermediate frequency inverter spot welder ine-flat output welding current, eqinisekisa ukusebenza kakuhle kunye nokubonelela ngokuqhubekayo kobushushu be-welding. Kwaye ixesha-ngexesha lifutshane, lifikelela kwinqanaba le-ms, elenza ukuba indawo ye-welding ichaphazele ukushisa encinci, kwaye i-solder joints yenziwe kakuhle.

-

03 Ulawulo oluchanekileyo oluchanekileyo

Ngenxa yokusebenza rhoqo (ngokuqhelekileyo i-1-4KHz) yomatshini we-welding we-intermediate frequency spot, ukuchaneka kokulawulwa kwengxelo ngama-20-80 amaxesha omatshini wokuwelda we-AC jikelele kunye nomatshini wokuwelda wendawo yesibini, kunye nolawulo lwemveliso oluhambelanayo. ukuchaneka nako kuphezulu kakhulu.

-

04 Ukonga amandla

ukonga amandla. Ngenxa yokusebenza kakuhle kwe-thermal, i-welding encinci ye-welding kunye nelahleko encinci yentsimbi, umatshini we-inverter welding unokugcina amandla angaphezu kwama-30% kunomatshini we-AC we-welding kunye nomatshini wokuwelda indawo yesibini xa udibanisa umsebenzi ofanayo.

-

05 Inverter indawo welding umatshini ilungele igridi unikezelo lwamandla balance, ngaphandle izixhobo imbuyekezo amandla

Isetyenziselwa ukuwelda indawo kunye ne-nut projection welding yentsimbi ephezulu-yomelele kunye nentsimbi eshushu eyenziweyo kwishishini lokwenziwa kweemoto, ukuwelda kwendawo kunye ne-multi-point projection welding yepleyiti yentsimbi ephantsi yekhabhoni, ipleyiti yensimbi engenasici, ipleyiti enezinki, ipleyiti yealuminiyam, ukumelana nokugawula kunye nokuwelda indawo yocingo lobhedu kushishino lombane oluphezulu noluphantsi, ukuwelda indawo yesilivere, ukujongisa ipleyiti yobhedu, ukuwelda indawo yesilivere ehlanganisiweyo, njl.

Iisampulu zeWelding

Iisampulu zeWelding

Ipleyiti yeAluminiyam

iphepha lobhedu legumbi lomphunga

Hex nut yesiFrentshi

ipleyiti yokuvavanya isihlalo esiphezulu sentsimbi

ukomeleza ubambo

nut engqukuva

isilungisi sesihlalo

uqhagamshelwano lwesilivere

ipleyiti enesilivere

yenziwe ngentsimbi eshayinayo

ucingo lwesiphelo

thermoformed steel square nut

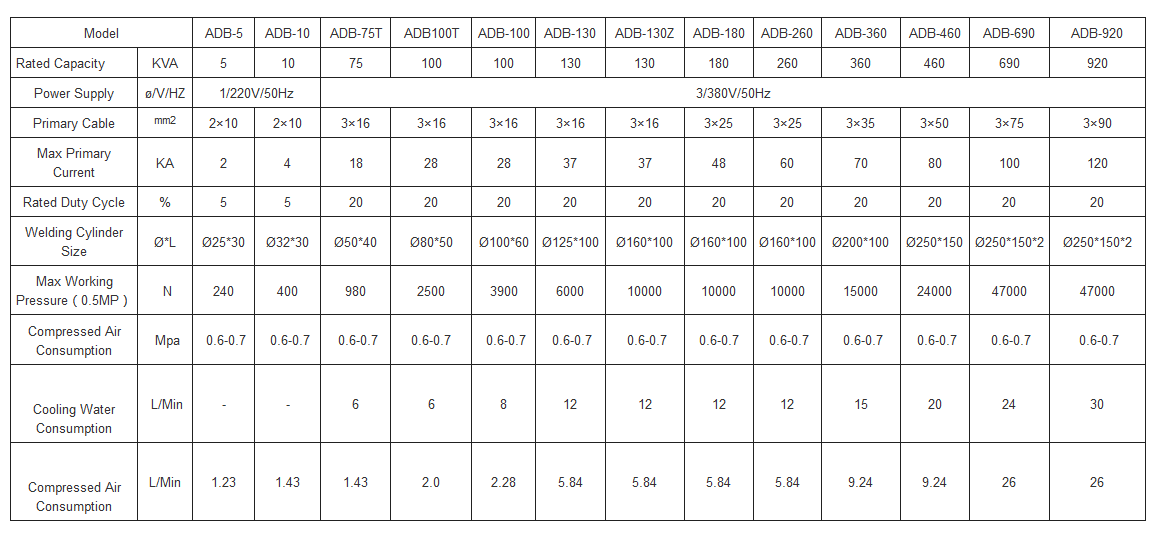

Welder Iinkcukacha

Welder Iinkcukacha

Inkqubo yesiko

Inkqubo yesiko

I-Welder FAQ

I-Welder FAQ

- Q: Ukuqinisekisa njani ukhuseleko lomatshini wokuwelda?

A: Iinkqubo zokusebenza ezikhuselekileyo kufuneka zilandelwe xa usebenzisa i-spot welder, kubandakanywa ukunxiba izixhobo zokhuseleko, ukuqinisekisa ukuba isixhobo sisebenza ngokufanelekileyo, kunye nokuphepha ukubamba iingcingo ezivulekileyo.

- Umbuzo: Ngaba i-Spot Welders ifuna ukuLondolozwa rhoqo?

A: Ewe, ukugcinwa rhoqo kuya kugcina indawo yakho yokuwelda isebenza ngeyona ndlela ingcono kwaye yandise ubomi besixhobo sakho.

- Umbuzo: Kubandakanya ntoni ukugcinwa komatshini wokuwelda?

A: Ukugcinwa kwe-spot welder kubandakanya ukucoca izixhobo, ukutshintshwa kwezinto ezigugileyo, ukujonga iintambo zombane kunye nombane, kunye nokujonga imeko yokusebenza kwesixhobo.

- Umbuzo: Yeyiphi i-electrode endiyifunayo kwisixhobo sokuwelda?

A: Ukukhethwa kwee-electrode kufuneka kumiselwe ngokohlobo kunye nezinto eziphathekayo zeprojekthi ye-welding.

- Umbuzo: Indlela yokujongana nokunxiba kwe-electrode ngexesha lokusetyenziswa komatshini we-welding?

A: Xa i-electrode igugile, kufuneka itshintshwe ngexesha ukuze kuqinisekiswe ukusebenza kakuhle kwezixhobo.

- Umbuzo: Unokukhetha njani uxinzelelo olufanelekileyo lomatshini wokuwelda?

A: Uxinzelelo olufanelekileyo kufuneka lugqitywe ngokohlobo kunye nezinto eziphathekayo zeprojekthi ye-welding ukuqinisekisa iziphumo ezilungileyo ze-welding.

Thumela i-imeyile kuthi

Thumela i-imeyile kuthi