ADB-360 MFDC indawo umatshini welding

Intshayelelo yeMveliso

Intshayelelo yeMveliso

-

Ukucinezela ngokufanelekileyo i-welding spatter kwaye ufezekise iziphumo ezizinzileyo kunye neziphezulu ze-welding

unikezelo oluqhubekayo lobushushu oluveliswa yimveliso yeflethi yangoku yomatshini we-welding frequency frequency yenza ubushushu be-nugget buphakame ngokuqhubekayo. Ngexesha elifanayo, ulawulo oluchanekileyo lwe-slope yangoku ekhulayo kunye nexesha aliyi kubangela i-spatter ngenxa yokutsiba kobushushu kunye nexesha elingalawulekiyo lokunyuka kwangoku.

-

Ixesha elifutshane lamandla-kwixesha le-welding, ukusebenza kakuhle kwe-thermal, kunye nokumila okuhle kwe-welding

UKUBA i-inverter spot welder ine-flat output welding current, eqinisekisa ukusebenza kakuhle kunye nokubonelela ngokuqhubekayo kobushushu be-welding. Kwaye ixesha-ngexesha lifutshane, lifikelela kwinqanaba le-ms, elenza ukuba indawo ye-welding ichaphazele ukushisa encinci, kwaye i-solder joints yenziwe kakuhle.

-

Ulawulo oluchanekileyo oluchanekileyo

ukusebenza frequency eliphezulu (ngokuqhelekileyo 1-4KHz) of the intermediate frequency spot welding machine, ukuchaneka kokulawulwa kwengxelo ngama-20-80 amaxesha omatshini wokuwelda we-AC jikelele kunye nomatshini wokuwelda wendawo yesibini, kunye nokuchaneka kokulawula imveliso kwakhona. phezulu kakhulu.

-

Ukonga amandla

ukonga amandla. Ngenxa yokusebenza kakuhle kwe-thermal, i-welding encinci ye-welding kunye nelahleko encinci yentsimbi, umatshini we-inverter welding unokugcina amandla angaphezu kwama-30% kunomatshini we-AC we-welding kunye nomatshini wokuwelda indawo yesibini xa udibanisa umsebenzi ofanayo.

-

Inverter indawo umatshini welding ilungele igridi unikezelo lwamandla balance, ngaphandle izixhobo imbuyekezo amandla

Isetyenziselwa ukuwelda indawo kunye ne-nut projection welding yentsimbi ephezulu-yomelele kunye nentsimbi eshushu eyenziweyo kwishishini lokwenziwa kweemoto, ukuwelda indawo kunye ne-multi-point projektha ye-welding yepleyiti yentsimbi ephantsi kwekhabhoni, ipleyiti yensimbi engenasici, ipleyiti enezinki, ipleyiti yealuminiyam kunye ucingo, ukunqanda ukunyathela kunye nokuwelda indawo yocingo lobhedu kushishino lombane oluphezulu noluphantsi, ukuwelda indawo yesilivere, ukujongiswa kwepleyiti yobhedu, ukuwelda indawo yesilivere ehlanganisiweyo, njl.

Iisampulu zeWelding

Iisampulu zeWelding

Ipleyiti yeAluminiyam

iphepha lobhedu legumbi lomphunga

Hex nut yesiFrentshi

ipleyiti yokuvavanya isihlalo esiphezulu sentsimbi

ukomeleza ubambo

nut engqukuva

isilungisi sesihlalo

uqhagamshelwano lwesilivere

ipleyiti enesilivere

yenziwe ngentsimbi eshayinayo

ucingo lwesiphelo

thermoformed steel square nut

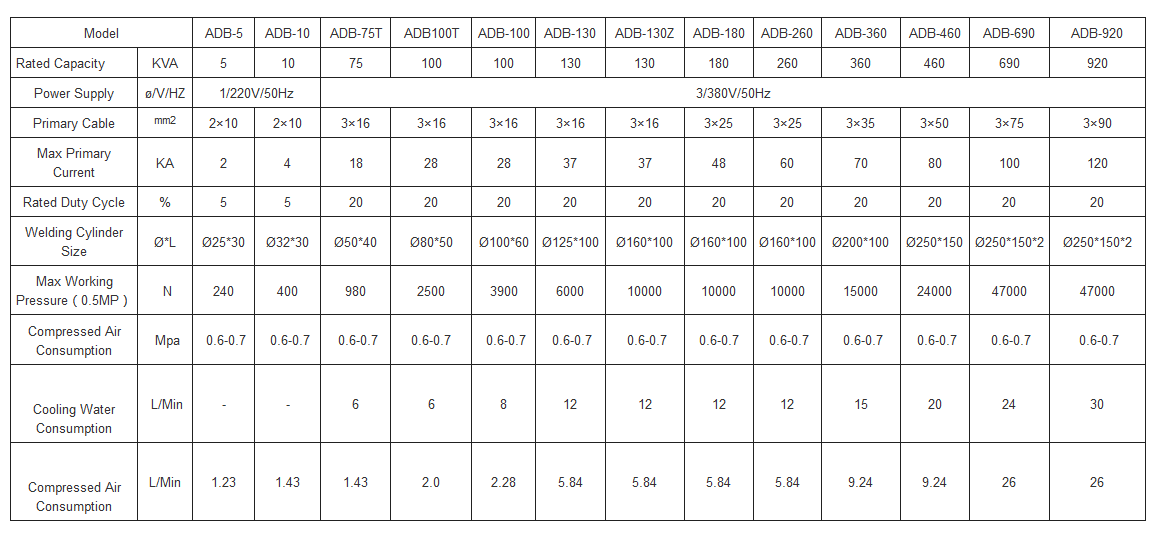

Welder Iinkcukacha

Welder Iinkcukacha

Inkqubo yesiko

Inkqubo yesiko

I-Welder FAQ

I-Welder FAQ

- Umbuzo: Kukangaphi ukugcinwa kwe-spot welder kusenzeka?

A: Ubuninzi bokugcinwa kufuneka bugqitywe ngokusetyenziswa kwe-spot welder kunye nokusingqongileyo kwemveliso, kwaye ngokuqhelekileyo kuyacetyiswa ukuba kwenziwe ulondolozo kanye ngenyanga.

- Q: Unokukhetha njani unikezelo lwamandla olufanelekileyo kumatshini wokuwelda?

A: Ukukhethwa konikezelo lwamandla kumatshini we-welding kufuneka kumiselwe ngokwamandla esixhobo kunye nendawo yokusetyenziswa ukuze kuqinisekiswe ukuba izixhobo zinokusebenza ngokuqhelekileyo.

- Umbuzo: Loluphi uhlobo lwamanyathelo okhuseleko ekufuneka asetyenziswe ngabashicileli?

A: Abashicileli be-spot bafuna ukusetyenziswa kweeglasi zokukhusela, iiglavu, kunye nezinye izixhobo zokukhusela ukugcina abaqhubi bekhuselekile.

- Umbuzo: Kufuneka kuqhagamshelwe njani unikezelo lwamandla kumatshini wokuwelda?

A: Umbane kufuneka udityaniswe ngokweemfuno zombane kunye nemigangatho yokhuseleko lwesixhobo.

- Umbuzo: Bude kangakanani ubomi benkonzo ye-spot welder?

A: Ubomi benkonzo yomatshini wokuwelda buxhomekeke kwizinto ezifana nomgangatho wezixhobo, ukugcinwa kunye nokusetyenziswa kwendawo, ngokuqhelekileyo phakathi kweminyaka emi-5-10.

- Q: Yintoni isantya sokuwelda sendawo yokuwelda?

A: Isantya se-Welding sixhomekeke kubukhulu kunye nobunzima beprojekthi ye-welding kwaye ngokuqhelekileyo ngamaxesha amaninzi ngomzuzwana.

Thumela i-imeyile kuthi

Thumela i-imeyile kuthi