Zininzi iindlela zokujoyina isinyithi, kwaye i-welding yindlela efunekayo yokudibanisa iindawo ezininzi zetsimbi. Ukuba umtsha kwishishini lokuwelda, usenokungaqondi ukuba zingaphi iinkqubo zokuwelda ezikhoyo zokudibanisa isinyithi. Eli nqaku liza kuchaza iinkqubo ezingundoqo ze-welding ezi-8, zikunika ukuqonda okunzulu kwishishini le-welding.

Arc Welding

Ukuwelda kweArcisebenzisa i-arc yombane ukwenza ubushushu, ukunyibilika kunye nokudibanisa iintsimbi kunye. Le yeyona nkqubo ixhaphakileyo yokuwelda kwaye ibandakanya ubuchule obufana ne-arc welding manual kunye ne-gas-shielded welding.

I-arc welding ye-manual ifanelekile kwintsimbi yesakhiwo.

I-welding ekhuselwe ngegesi isebenza kakuhle kwizinto ezifana nentsimbi engatyiwayo kunye ne-aluminiyam.

Iingcebiso: Khusela indawo ye-weld kwi-oxidation kunye neentlantsi, kwaye ulawule imimiselo yangoku kunye ne-voltage ukufezekisa iziphumo ezilungileyo.

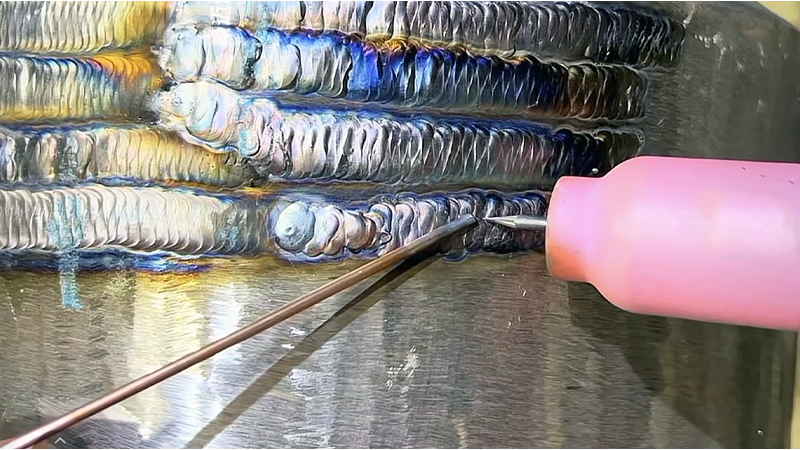

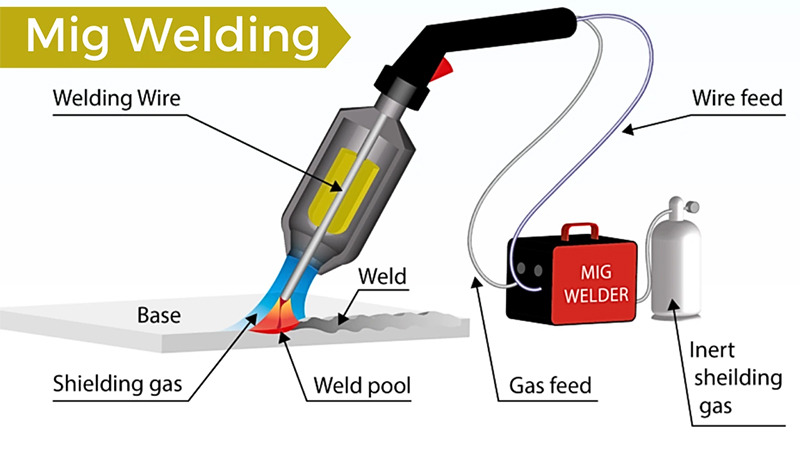

I-MIG/MAG Welding

Ukuwelda kwe-MIG/MAG kubandakanya ukondla i-electrode yocingo eqhubekayo ngetotshi ye-welding ngelixa i-arc inyibilikisa ucingo kunye nomphezulu wesinyithi ukwenza i-weld. Irhasi yokukhusela ihamba ngetotshi ukukhusela intsimbi ekungcolisekeni.

Ukuwelda kwe-MIGidumile kumashishini afana nokwakhiwa kweenqanawa, ukwakhiwa kwemibhobho, kunye nezakhiwo zentsimbi.

Inkulu kwii-workpieces ezinkulu, ezingashukumiyo kunye neeprojekthi zokulungisa.

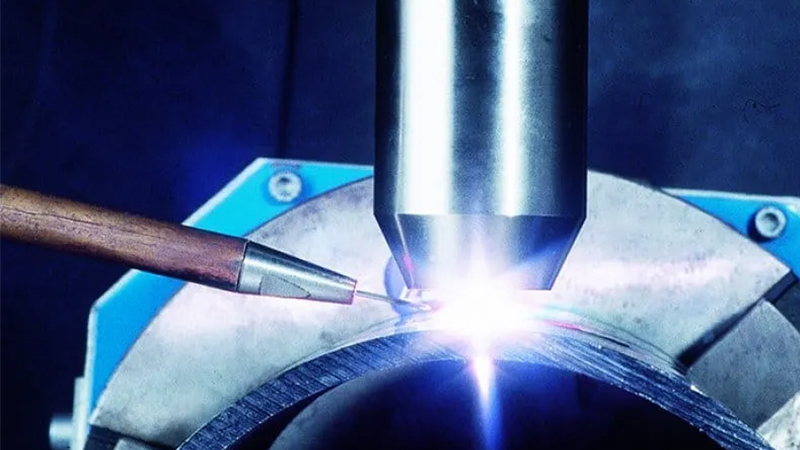

TIG Welding

TIG ukuwelda, okanye i-Tungsten Inert ye-Gas welding, isebenzisa i-electrode ye-tungsten engasetyenziswayo ukwenza i-welds echanekileyo. Igesi ekhuselayo, njenge-argon, ikhusela indawo ye-weld ekungcoleni.

Ukuchaneka okuphezulu kuyenza ilungele izixhobo ezibuthathaka njenge-aluminiyam kunye nentsimbi engatyiwayo.

Ngokuqhelekileyo isetyenziswa kwimizi-mveliso yeemoto, i-aerospace, kunye nemveliso echanekileyo.

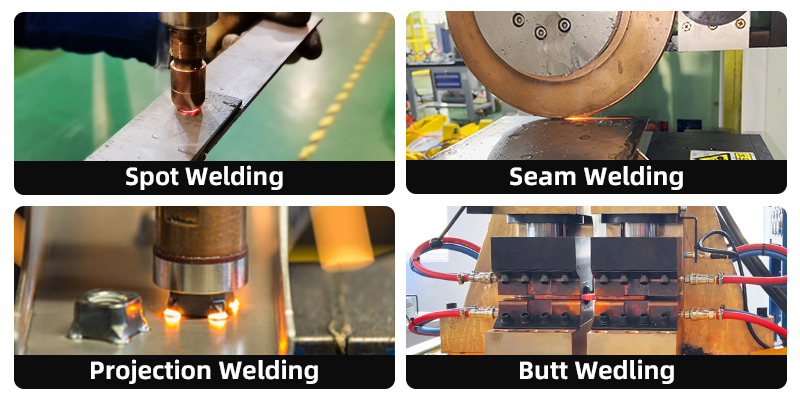

I-Resistance Welding

In ukumelana welding, iziqwenga ezibini zetsimbi zicinezelwe phakathi kwe-electrode, kwaye umsinga wombane udala ukushisa ukuze udibanise nabo. Iindidi eziphambili zibandakanya indawo, ingqikelelo, i-butt, kunye ne-seam welding.

I-Resistance welding iyakhawuleza, ayifuni izinto zokuzalisa, kwaye kulula ukuzenzela.

Isetyenziswa kakhulu kwiindawo zemoto, i-elektroniki, kunye nezixhobo zasekhaya. Umzekelo, ilungele ukuwelda amantongomane emoto.

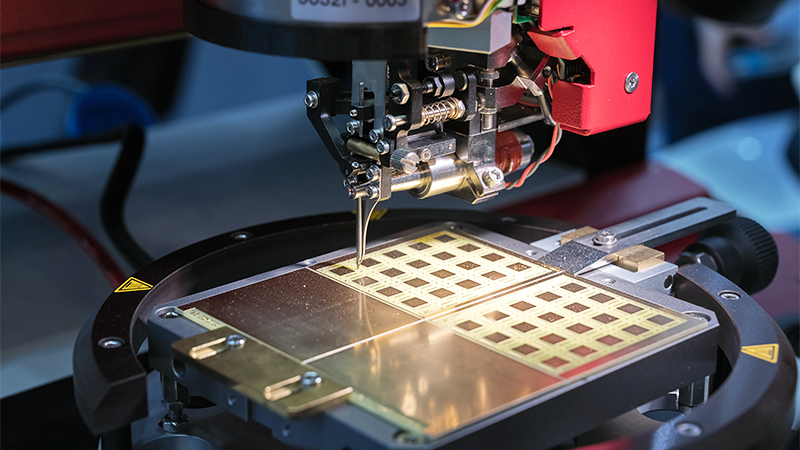

Laser Welding

Ukuwelda kweLaseryindlela esebenzisa i-laser beam njengomthombo wamandla ukutshisa ngokuchanekileyo kunye nokudibanisa isinyithi okanye iiplastiki. Xa kuthelekiswa ne-arc welding yendabuko, i-laser welding iyakhawuleza kwaye isebenza ngakumbi. Inokudibaniswa lula kunyeirobhothi welderkwaye bubuchule obuphambili ekuqhubeni imathiriyeli yelaser. I-laser welding ayifuni i-electrode kwaye ayifuni ukuqhagamshelana nezinto zokusebenza. Xa udibanisa izinto ezibhityileyo okanye iingcingo ezicolekileyo, ayibangeli umva ukunyibilika njenge-arc welding.

Ukuwelda ngePlasma

Ukuwelda kwePlasma kuvelisa iplasma nge-arc ene-eneji ephezulu, enyibilikisa i-workpiece. Izinto zokuzalisa zongezwa ukudibanisa iintsimbi kunye.

Isebenza ngesinyithi, iplastiki, kunye neekeramics.

Ihlala isetyenziswa kwi-aerospace, iimoto, kunye nokuveliswa kwe-elektroniki.

Ultrasonic Welding

I-Ultrasonic welding isebenzisa ii-vibrations eziphezulu-frequency kwiindawo ezimbini eziphantsi koxinzelelo, ezibangela ukuba zidibanise ngaphandle kokunyibilika. Obu buchule busebenza kwiintsimbi, iiplastiki, kunye nezinto ezingafaniyo.

Ivelisa amajoyina achanekileyo, acocekileyo kwaye kulula ukuzenzekelayo.

Ixhaphakile kumashishini afuna ukuwelda okulungileyo, okuqinileyo.

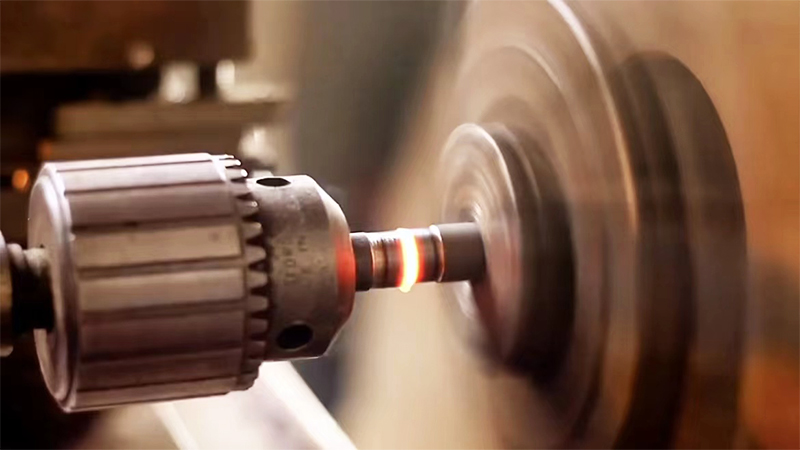

I-Friction Welding

I-Friction welding ivelisa ubushushu ngokuhlikihla okukhawulezileyo kwemiphezulu emibini, ithomalalisa ukwenza iqhina elomeleleyo. Le nkqubo ye-slid-state iphelisa imfuno yomthombo wobushushu wangaphandle.

Ikhusela iziphene ezifana ne-deformation kunye neentanda.

Isetyenziswa kakhulu kwimveliso yemizi-mveliso, enjengamavili eenqwelomoya kunye neeasi zikaloliwe.

Indlela yokukhetha iNkqubo yeWelding eLungileyo

Xa ukhetha inkqubo ye-welding, qwalasela:

Uhlobo lwezinto eziphathekayo (umzekelo, ialuminiyam, intsimbi engatyiwayo)

Ubungakanani bomsebenzi kunye nobukhulu

Iimfuno ezichanekileyo

Ingaba i-automation iyafuneka

Ukuvavanya iindlela ezininzi kunokukunceda ufumane esona sisombululo silungileyo kwiprojekthi yakho ethile.

Ngokuqonda ezi nkqubo ze-8 eziphambili ze-welding, unokukhetha indlela efanelekileyo yeprojekthi yakho kwaye uhlolisise amathuba amatsha kwishishini le-welding.

Imibuzo ebuzwa qho

1. Yiyiphi inkqubo ye-welding efanelekileyo kumacandelo emoto?

I-Resistance welding lolona khetho luphezulu kumacandelo eemoto ngenxa yesantya esikhawulezayo, ukugqiba kobuhle, kunye ne-automation elula.

2. Zeziphi izinto ezinokudityaniswa?

Unako ukuwelda iintlobo ngeentlobo zesinyithi, kuquka intsimbi engatyiwa, ubhedu, ialuminiyam, kunye nentsimbi.

3. Ngaba zonke iinkqubo ze-welding zisebenzisa ii-filler rods?

Hayi. Umzekelo, ukumelana ne-welding ayifuni iintonga zokugcwalisa.

4. Ndingazifunda phi ezinye izakhono zokuwelda?

Ungaya kwizikolo ezikhethekileyo zokufundela umsebenzi okanye ufumane amava okusebenza kwizixhobo zokuvelisa.

Ixesha lokuposa: Oct-21-2024